Low-internal-stress steel for bridge structure and production method of low-internal-stress steel

A technology of bridge structure and production method, applied in the field of steel manufacturing for bridge structure, can solve the problems of high chemical composition alloy content, affecting users' use, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Specific embodiments of the present invention are described in detail below, which, as a part of the description, illustrate the principle of the present invention through examples, and other aspects, features and advantages of the present invention will become clear through the detailed description.

[0052] Each embodiment of the present invention is produced according to the following steps:

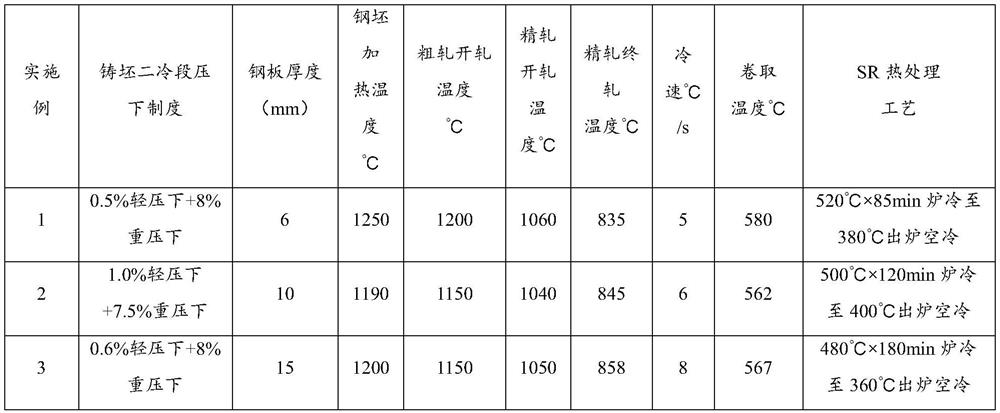

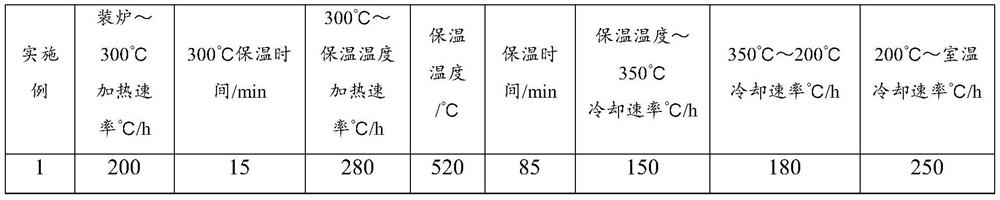

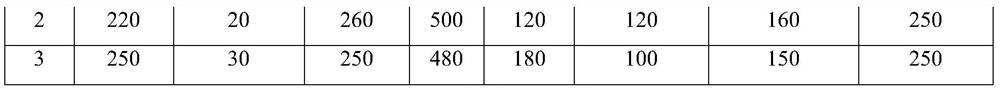

[0053] 1) Converter smelting realizes deep desulfurization of ladle furnace (S≤0.0013%), vacuum removes gas inclusions and controls the dynamic light reduction of the slab in the secondary cooling water zone of continuous casting to 0.5-2.5%, and then adopts the cumulative heavy reduction parameter control The continuous casting slab has a reduction ≥ 7%. After the slab is continuously cast, the ferrite grain size range of the continuous casting slab is controlled between 100 and 250 μm. To heat the slab, control the heating temperature to 1150-1280°C, and control the heating r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com