Steel plate with very low yield point and manufacturing method thereof

A yield point and steel plate technology, applied in the field of extremely low yield point steel plate and its manufacturing, can solve the problems of low cycle fatigue resistance, low yield point, low yield point of welded joints and room temperature deformation ability of carbon structural steel, etc. Achieve the effect of low low cycle fatigue resistance, low yield strength and excellent room temperature plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

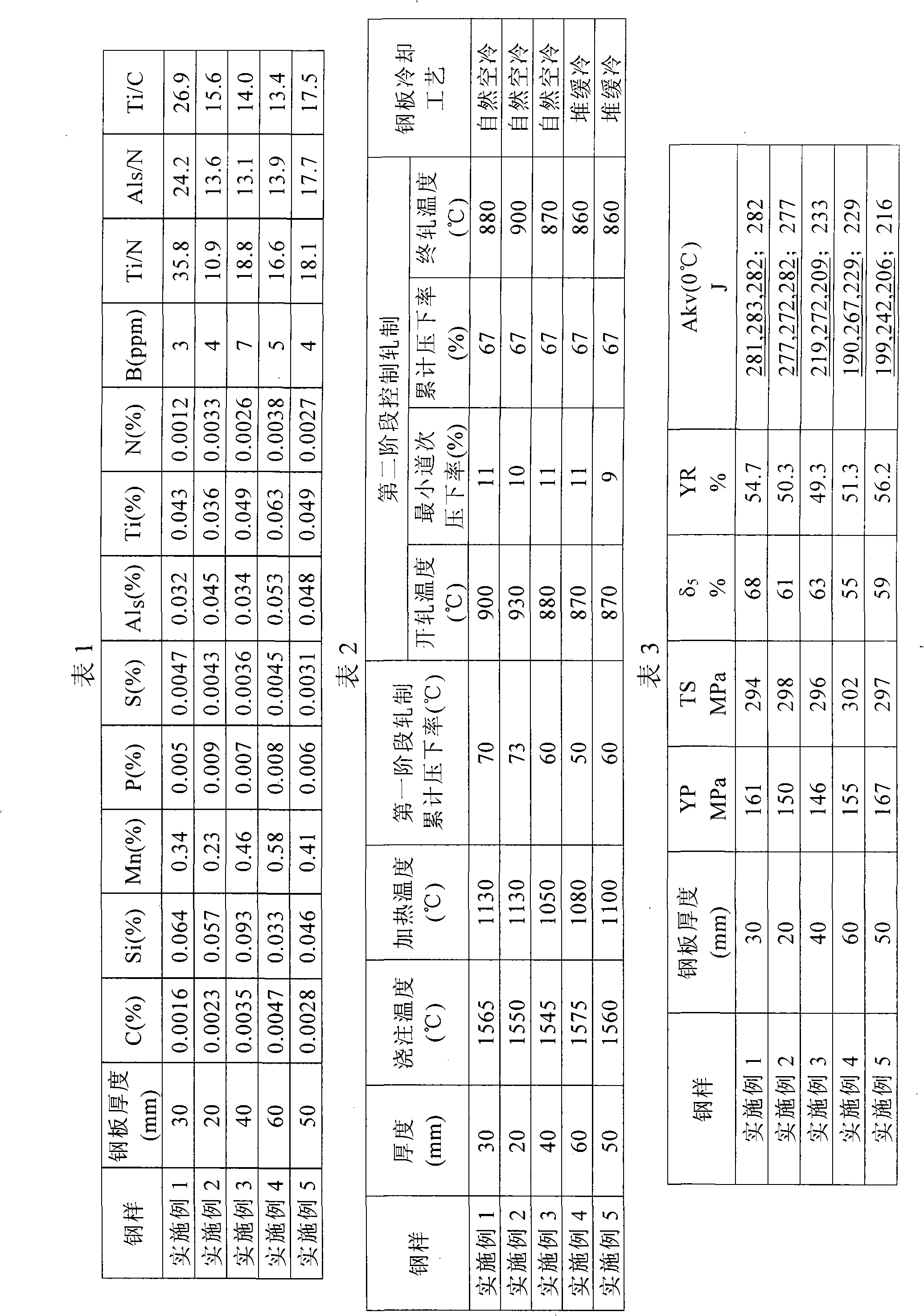

Examples

Embodiment 1

[0048] Manufacturing process: TDS molten iron deep desulfurization→converter smelting→RH (vacuum refining)→continuous casting→slab off-line finishing→slab cutting to length→heating→controlled rolling (CR)→steel stack slow cooling→AUT / MUT (automatic / manual flaw detection)→Steel edge trimming, head and tail trimming→sampling and performance testing→steel cutting to length→surface quality and appearance size, marking and testing→delivery.

[0049]

[0050] In the present invention, through the combination design of simple alloy elements and special controlled rolling process, the steel plate can obtain excellent comprehensive mechanical properties. The key core technology of steel plate manufacturing has laid the foundation for the development of lower yield point steel plates (such as YP≤135MPa); its successful development will definitely contribute to the improvement of the safety and earthquake resistance of my country's steel structures, and drive the design concept of Chin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com