Hot-dip galvanized steel sheet with yield strength of 550MPa and production method thereof

A hot-dip galvanized steel sheet, yield strength technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of galvanized steel sheet strength fluctuation, unstable product output, and inability to adapt to high strength and high toughness Use requirements and other issues to achieve the effect of good strength and toughness, high strength, good yield strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

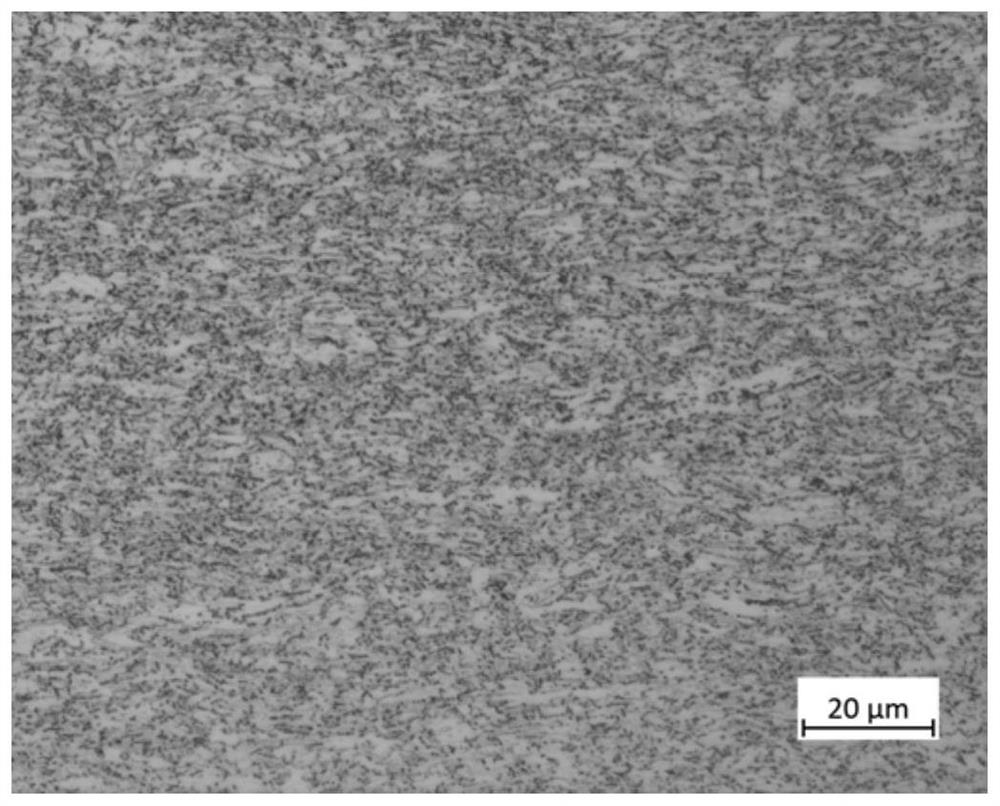

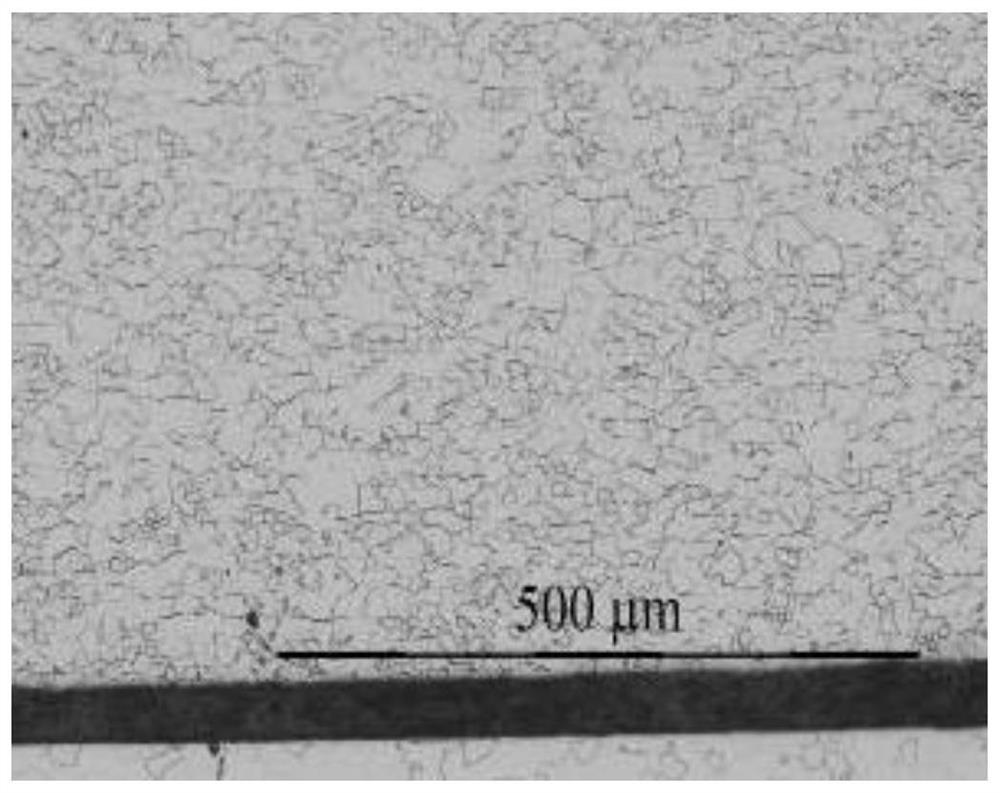

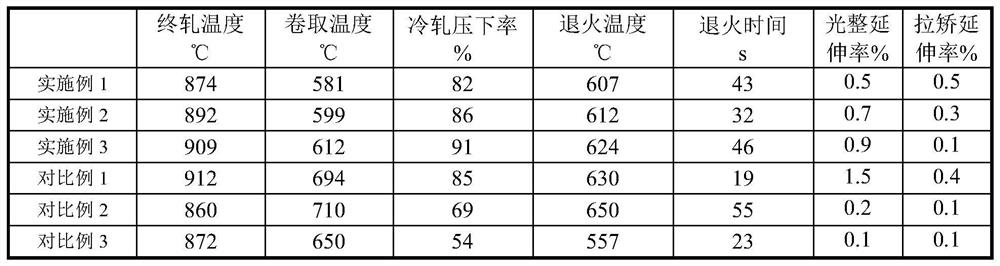

[0063] The chemical composition of the steel plate in this example is: C 0.008%, Si≤0.009%, Mn 0.19%, P0.012%, S 0.016%, Als 0.022%, Ti 0.032%, Nb 0.043%, N 0.0028%, O 0.0019 %, Cu0.030%, Cr 0.010%, and the rest are iron and other impurities. The finishing temperature of hot rolling is 874°C, the coiling temperature is 581°C; the reduction rate of cold rolling is 82%; when galvanizing, the annealing temperature T of the RTF section is 607°C, the annealing time t is 43s, and the skin elongation is 0.5% , Tensile straightening elongation 0.5%.

Embodiment 2

[0065] The chemical composition of the steel plate in this example is: C 0.010%, Si≤0.006%, Mn 0.10%, P0.008%, S 0.010%, Als 0.005%, Ti 0.001%, Nb 0.060%, N 0.0026%, O 0.0016 %, Cu0.045%, Cr 0.022%, and the rest are iron and other impurities. The finishing temperature of hot rolling is 892°C, the coiling temperature is 599°C; the reduction rate of cold rolling is 86%; when galvanizing, the annealing temperature T of the RTF section is 612°C, the annealing time t is 32s, and the skin elongation is 0.7% , Tensile straightening elongation 0.3%.

Embodiment 3

[0067] The chemical composition of the steel plate in this example is: C 0.006%, Si≤0.008%, Mn 0.30%, P0.009%, S 0.005%, Als 0.070%, Ti 0.080%, Nb 0.001%, N 0.0015%, O 0.0017 %, Cu0.060%, Cr 0.040%, and the rest are iron and other impurities. The finishing temperature of hot rolling is 909°C, the coiling temperature is 612°C; the reduction rate of cold rolling is 91%; when galvanizing, the annealing temperature T of the RTF section is 624°C, the annealing time t is 46s, and the skin elongation is 0.9% , Tensile straightening elongation 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com