YP100MPa steel plate and manufacture method thereof

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve the problems of discontinuous yielding and low cycle fatigue resistance of carbon structural steel, and improve safety and shock resistance, The effect of reducing the grade of steel used and simplifying the design of steel structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with embodiment.

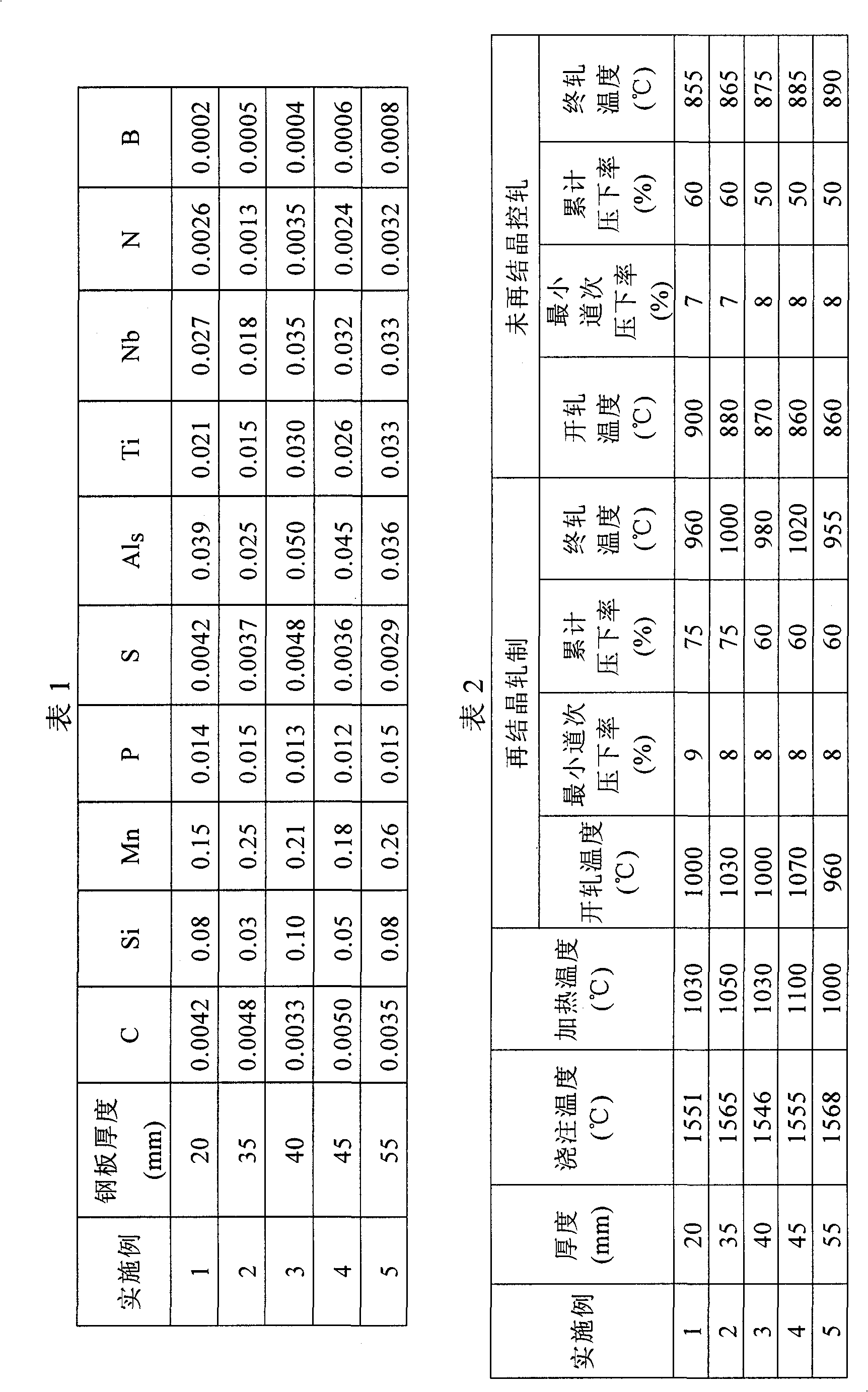

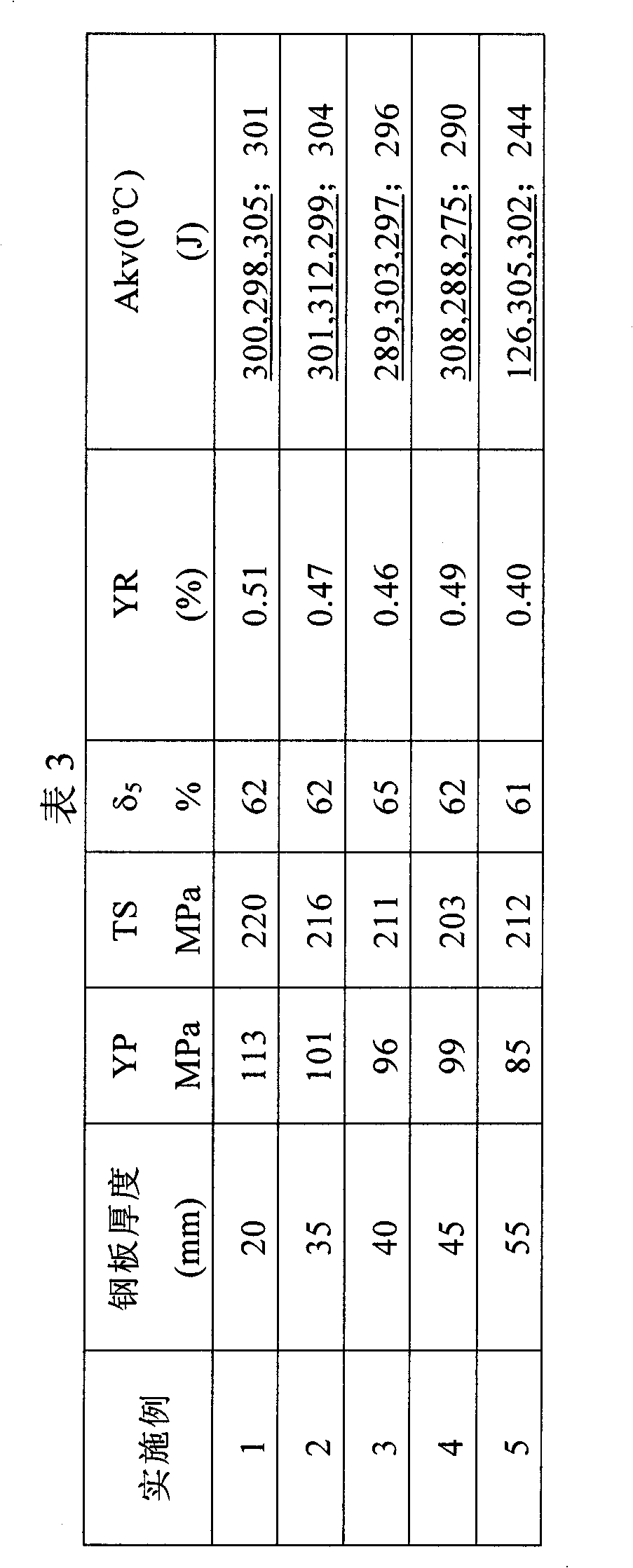

[0046] Examples of the present invention refer to Table 1, Table 2 shows the manufacturing process, and Table 3 shows the performance of the steel in the examples of the present invention.

[0047] It can be seen from Table 3 that the steel plate has an extremely low yield point to yield strength ratio, excellent room temperature deformation capacity (high elongation) and excellent low temperature impact toughness, which can meet the requirements of seismic dampers for large steel structures.

[0048] In summary, the technical characteristics of the steel plate of the present invention, the steel plate can obtain excellent comprehensive mechanical properties through the combination of simple alloy element design and special rolling; the ultra-low yield point steel plate not only improves bridge structure, super high-rise The seismic performance of large steel structures such as build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com