Hot-rolled high-carbon steel sheets and process for production of the same

A hot-rolled steel sheet, high-carbon technology, applied in the field of high-carbon hot-rolled steel sheet and its manufacturing, can solve the problems of poor productivity, stabilization, temperature rise, etc., and achieve high yield, stable stamping formability, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

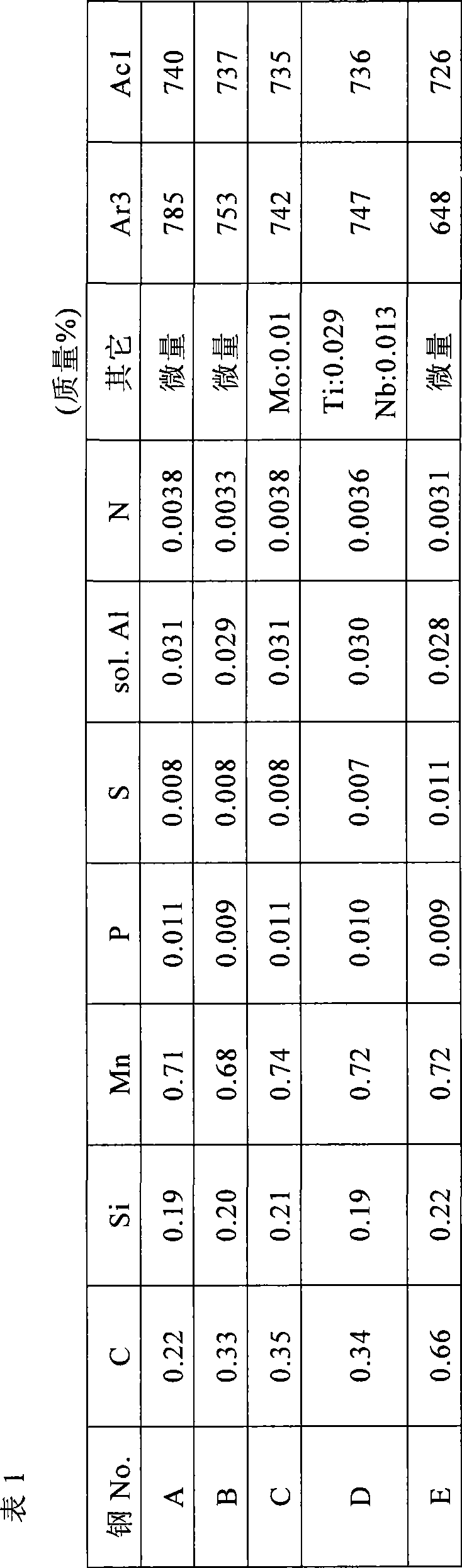

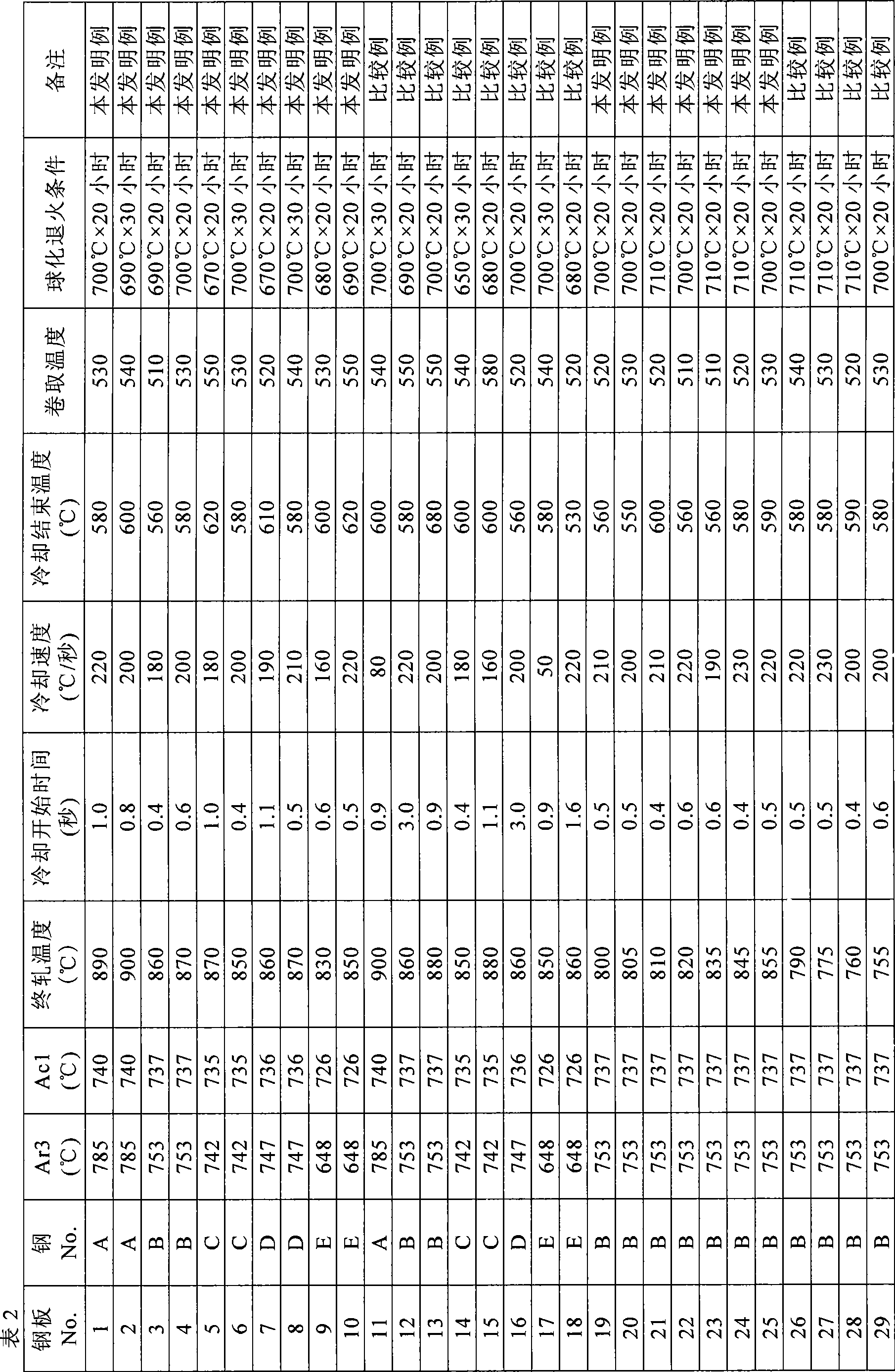

[0080] The steel with the chemical composition shown in Table 1 was continuously cast, and the obtained slab was heated to 1250°C, hot-rolled under the conditions shown in Table 2, pickled, and then used under the conditions shown in Table 2. Spheroidizing annealing was performed by the box annealing method to produce a hot-rolled steel sheet with a thickness of 4.0 mm.

[0081]

[0082]

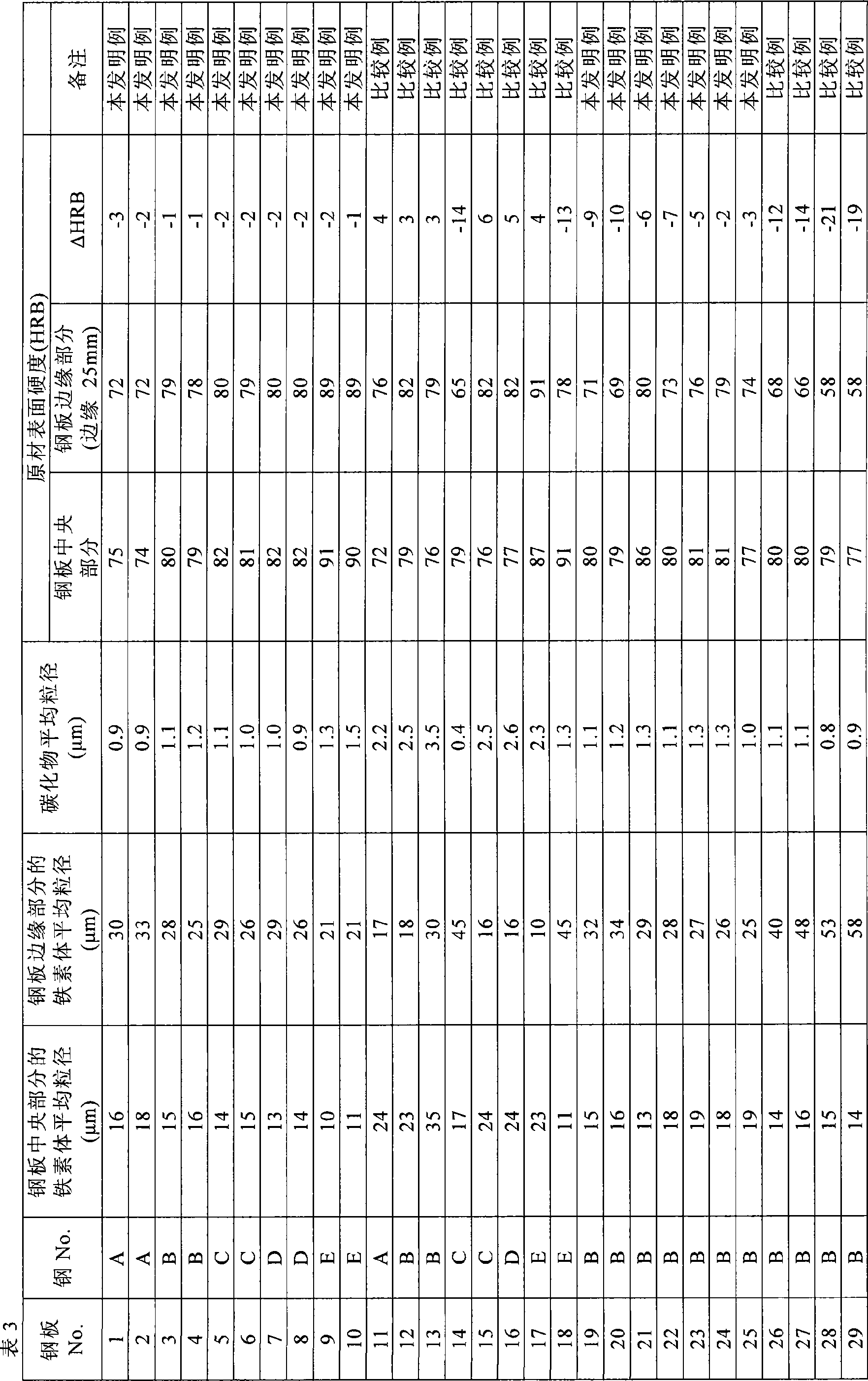

[0083] Then, samples were taken from the hot-rolled steel sheet obtained by the above operations, and the average particle size of ferrite at the edge of the steel sheet, the average particle size of ferrite at the center of the steel sheet, and the average particle size of carbide were measured, and the factors reflecting these structures were measured. material hardness. Each measurement method and conditions are as follows.

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com