Submarine tunnel composite lining interlaminar water seepage longitudinal cross flow-proof construction method

A technology for composite lining and underwater tunnels, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of free drainage composite lining channeling, etc., and achieve the problem of water seepage longitudinal channeling, with obvious effect and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

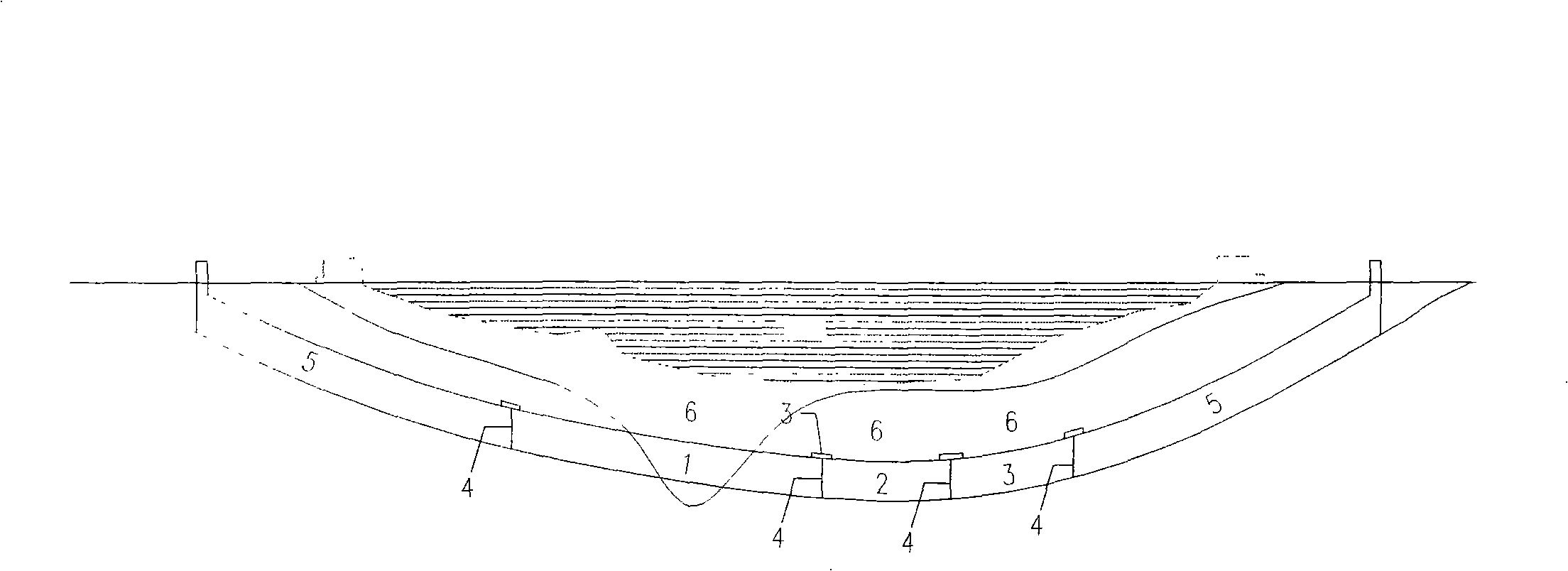

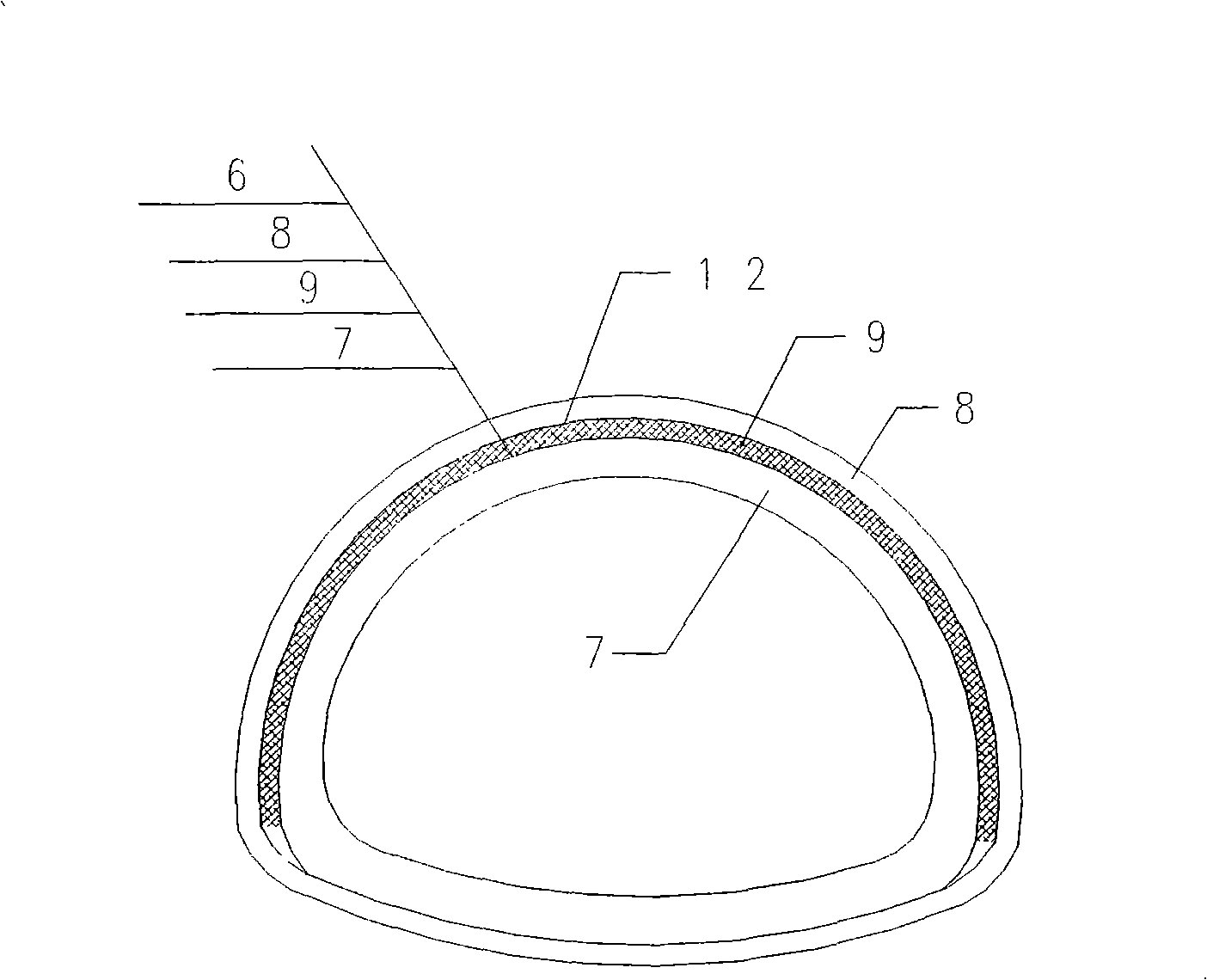

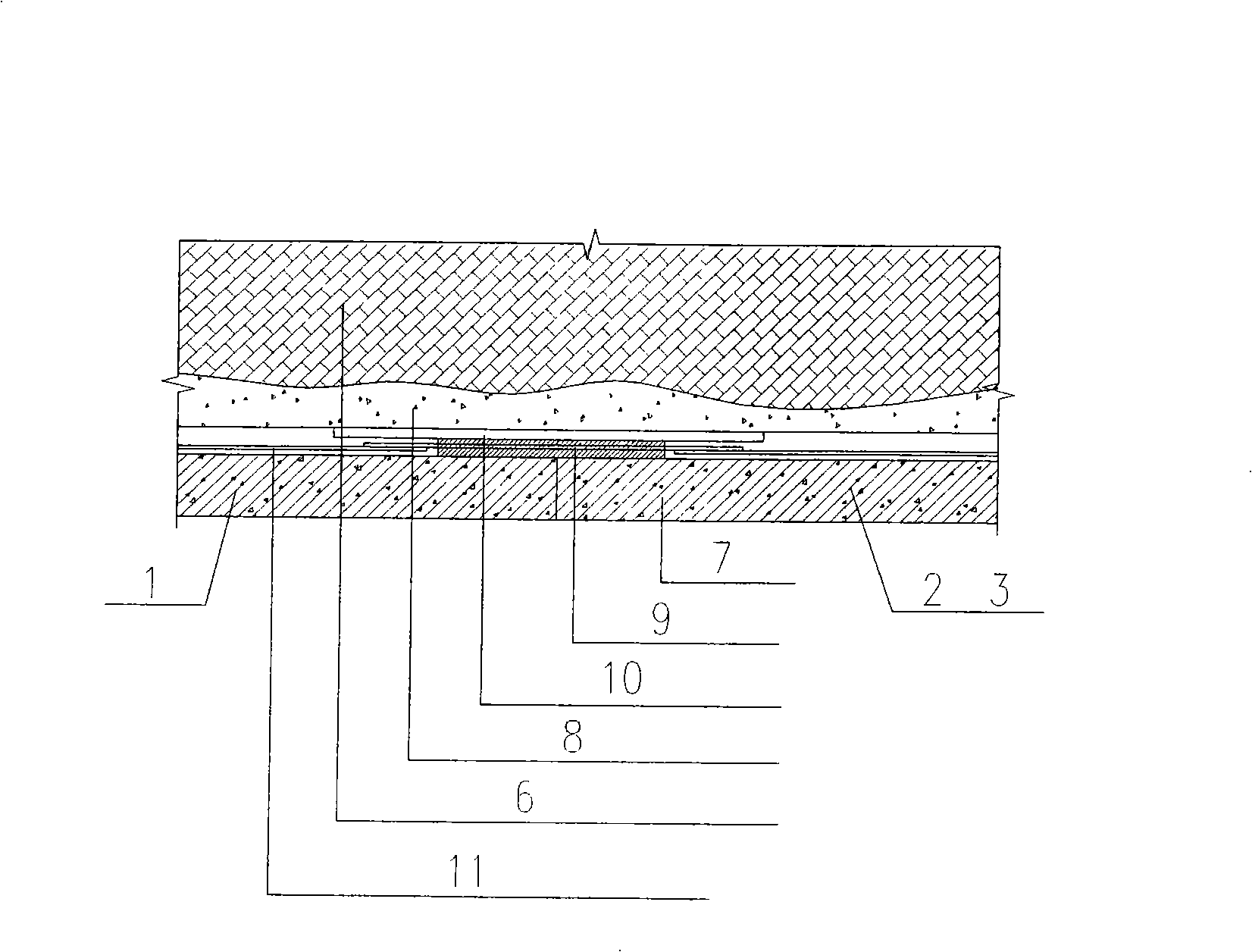

[0019] according to figure 1 , figure 2 , image 3 It can be seen that a construction method for longitudinal channeling prevention of water seepage between composite lining layers of underwater tunnels is suitable for the transitional sections of tunnels 5 and 6 linings with different surrounding rocks, such as between the fully enclosed lining 1 and the free-discharging lining 3 and between the restricted-discharging lining 2 and the free lining. Drain between linings 3. The longitudinal anti-channeling structure 4 is composed of a waterproof cement slurry 10 and a double-sided self-adhesive waterproof 9 with BAC, and the steps are as follows:

[0020] A. Remove the dust and sundries on the surface of initial support 8.

[0021] B. Sprinkle water on the surface of the dry initial support 8 and wet it thoroughly.

[0022] C. Mechanically stir the cement and water evenly, that is, the cement slurry is 10, and the water-cement ratio is 1:1.

[0023] D. Pop up the coil pav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com