Quake-proof construction steel with lamellar tearing resistance and excellent performance and production method thereof

A technology for anti-lamellar tearing and construction steel, applied in the field of earthquake-resistant construction steel and its production, can solve the problems of increased production cost, high content of precious alloy elements Cr and Ni, low strength level, etc., to improve welding efficiency , the effect of excellent welding performance and excellent seismic performance

Inactive Publication Date: 2011-03-30

武钢集团有限公司

View PDF8 Cites 39 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its shortcomings: more precious alloy elements Cu and Cr are added, which increases the production cost

Its shortcomings: the high content of precious alloy elements Cr and Ni increases the production cost

The chemical composition and production process of the steel of the invention are different from those of the steel of the invention, and only Q345 grade products with a thickness of less than 90 mm can be produced, and the strength level is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0046] The present invention is further described below:

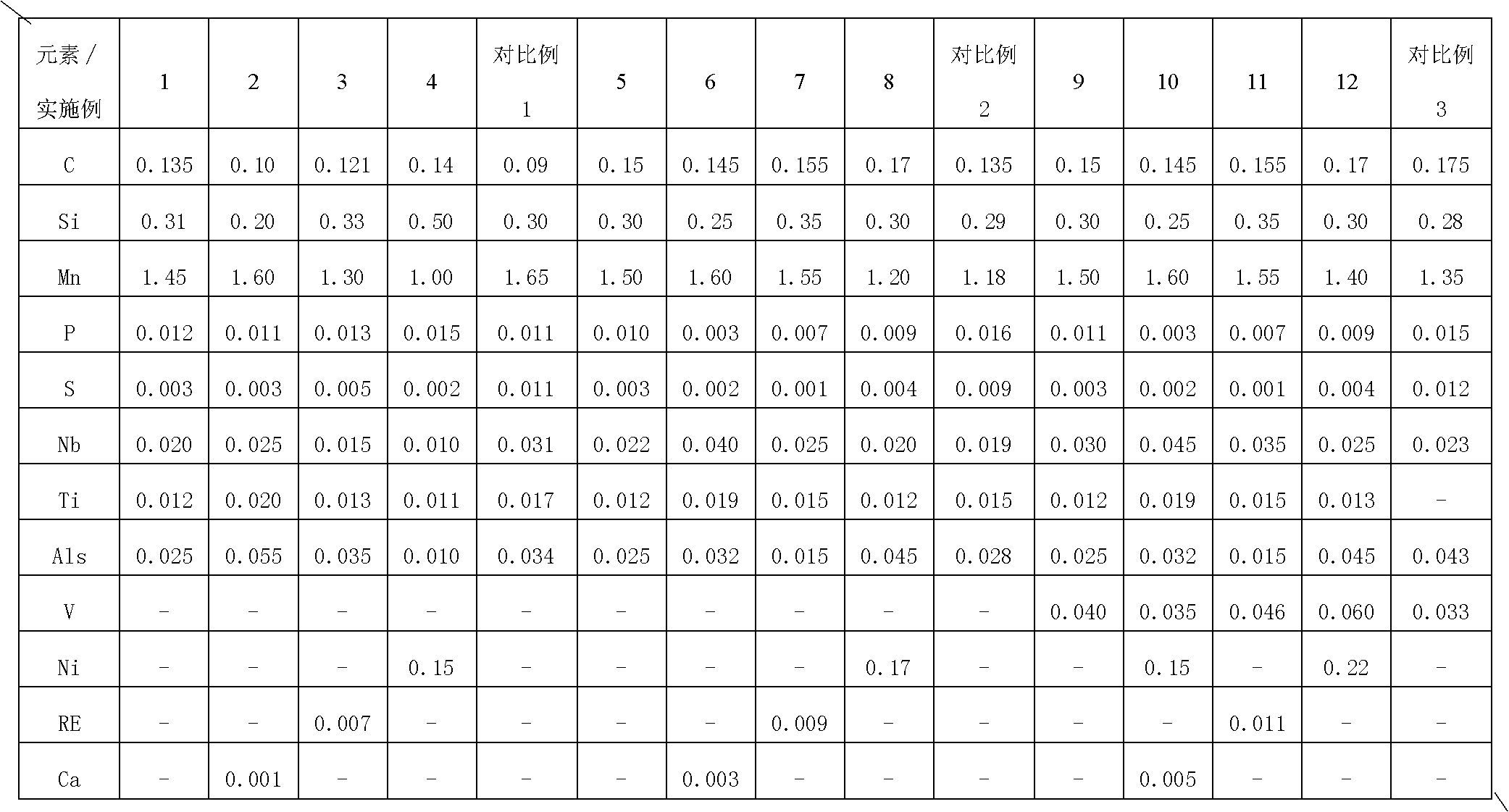

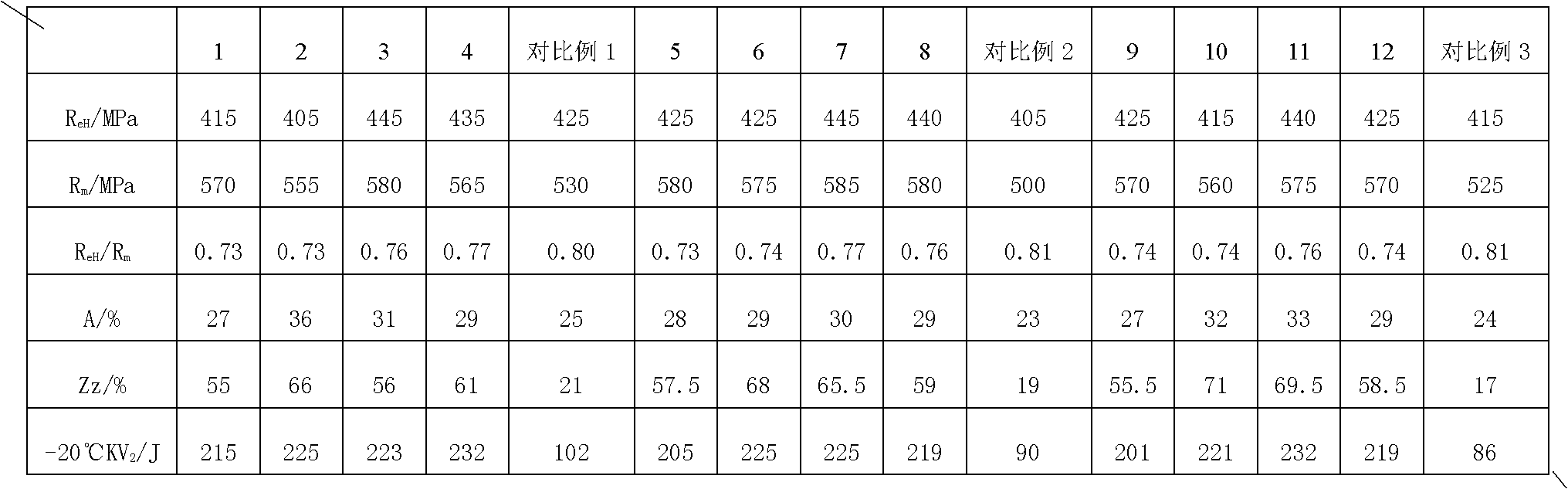

[0047] Table 1 is the value list of each chemical element of the embodiment of the present invention and comparative example;

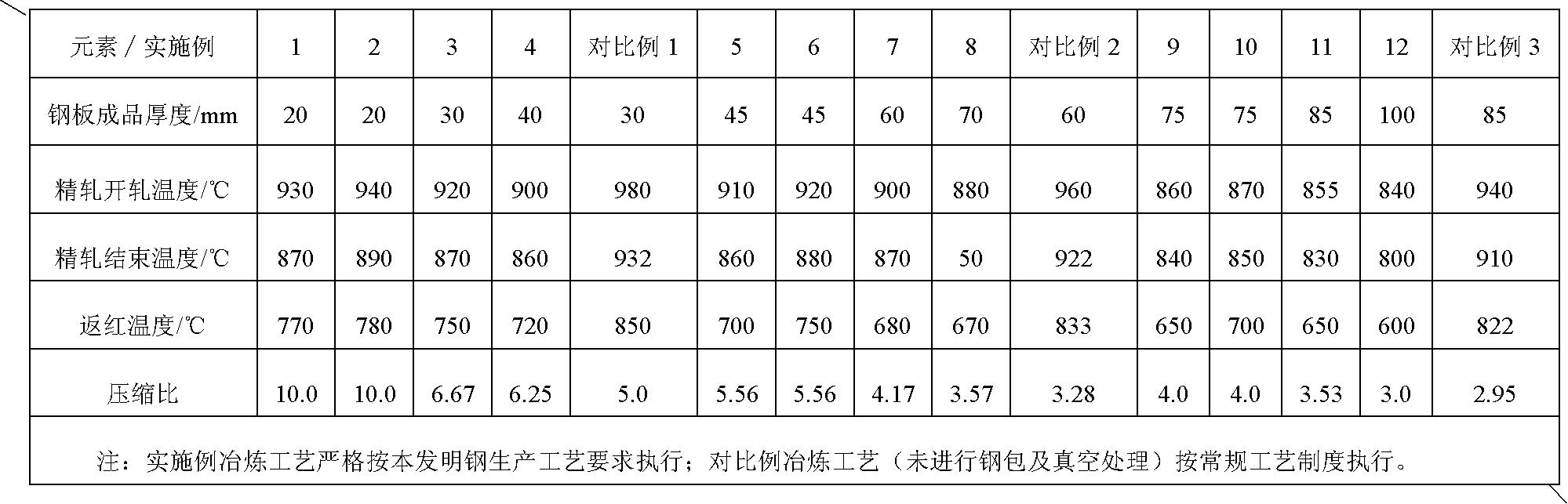

[0048] Table 2 is the value list of the embodiment of the present invention and comparative example process parameter;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to quake-proof construction steel with lamellar tearing resistance and excellent performance and a production method thereof. The steel is suitable for steel plates of which the thicknesses are between 20 and 100 millimeters and comprises the following chemical components: less than or equal to 0.015 percent of C, less than or equal to 0.015 percent of Si, less than or equal to 0.015 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.02 to 0.04 percent of Nb, 0.005 to 0.020 percent of Ti, 0.010 to 0.060 percent of Als and the balance of Fe. The method comprises the following steps of: performing the pretreatment of molten iron; performing desulfuration treatment; controlling target components of a smelting terminal point, wherein the target components comprise 0.05 to 0.07 percent of [C] and less than or equal to 0.015 percent of [P]; refining through a ladle furnace, and feeding aluminum wires and blasting argon; performing relative humidity (RH) vacuum treatment, and introducing the argon before the treatment; adding SiCa wires; casting continuously and performing the pouring of full-process protection; heating casting blanks; performing rough rolling; performing precision rolling; and cooling. The steel of the invention has the excellent quake-proof performance (ReH / Rm is less than or equal to 0.77); and the contractibility rate of a cross section in the full-thickness direction is between 40 and 70 percent, so the steel meets the requirements of key stressed points of major constructions such as steel structure work and the like fully.

Description

technical field [0001] The invention relates to steel for construction and a production method thereof, in particular to anti-seismic construction steel with excellent lamellar tear resistance and a production method thereof. Background technique [0002] The Wenchuan earthquake triggered the industry's thinking on the seismic performance of construction steel. From a practical point of view, the construction of high-rise buildings in China is increasing. In order to ensure the safety of buildings, China should improve the series of domestic construction steel and increase the production of high-strength steel. proportion. In addition to ensuring the seismic performance of the steel plate, the thickness direction performance of the steel plate for construction is also the main inspection item for this type of steel. Excellent lamellar tear resistance, that is, the reduction of area in the direction of the full thickness of the steel plate must meet the high requirements of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/14C22C33/04C21D8/02

Inventor 童明伟郭斌卜勇王世森张开广张俊峰梅荣利董汉雄习天辉董中波

Owner 武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com