Entire terminal cover explosion proof construction for capacitor

An explosion-proof structure and capacitor technology, which is applied in the direction of capacitors and electrical components, can solve the problems of large manpower, material resources, financial resources, unqualified electrical properties of products, and splashing of solder particles, so as to save solder wire, save manufacturing costs, and improve electrical conductivity. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

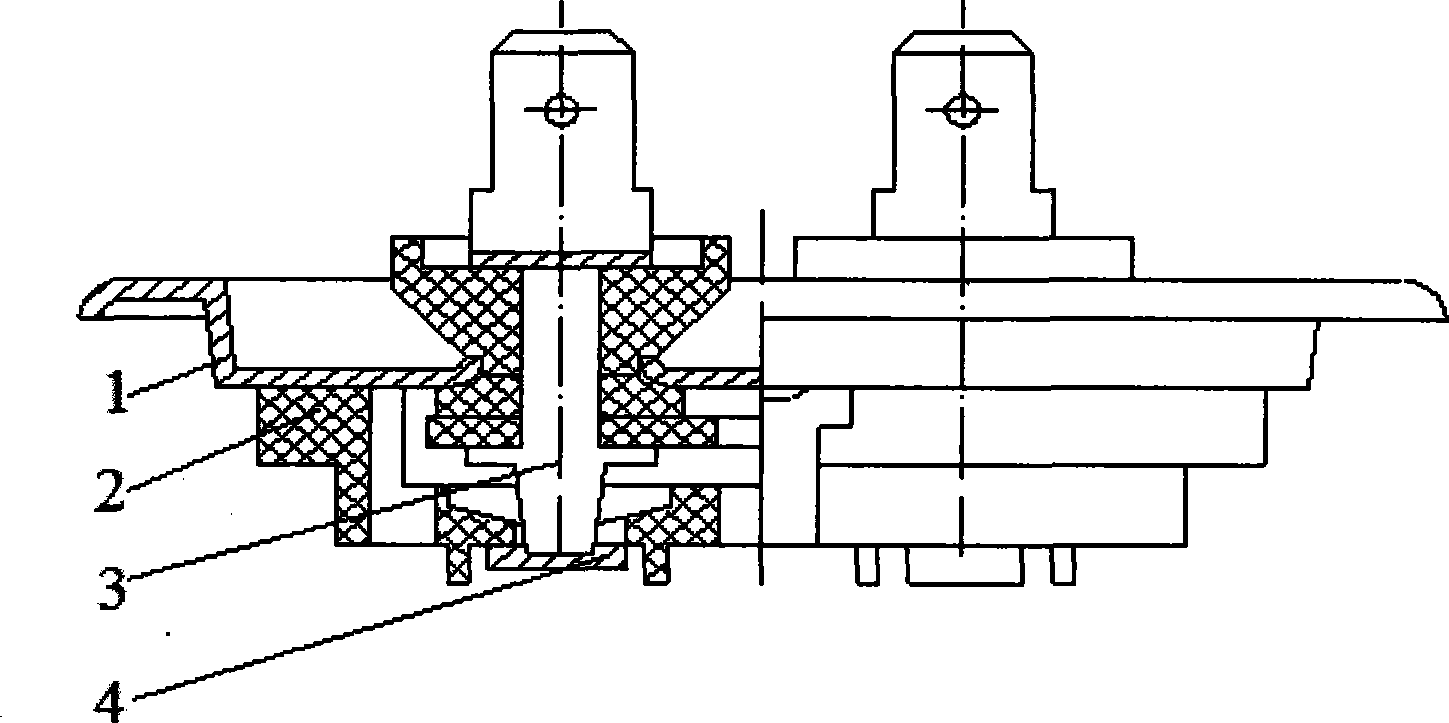

[0023] The connection structure between the end of the rivet 3 and the explosion-proof copper foil 4 of the present invention is a spot welding structure.

[0024] Such as figure 1 As shown, the rivet 3 and the explosion-proof copper foil 4 are spot welded together by spot welding. The end cap 1 of the integral explosion-proof structure does not need to be assembled and can be used directly, which saves time and at the same time saves the manufacturing cost of the product. The entire assembly line used to make the end cap is removed. Moreover, the integral end cover does not need to be welded, which saves solder wire and saves material cost.

[0025] The improvement of the end cover structure brings about the improvement of the explosion-proof mechanism of the product. However, the thickness of the explosion-proof copper foil 4 and the contact area for electric welding are required. The explosion-proof copper foil 4 must have a certain thickness, and the contact area for electric ...

Embodiment 2

[0027] The surface layer of the explosion-proof copper foil 4 of the present invention is provided with a tin-plated layer.

[0028] In view of the poor welding characteristics of copper foil, the present invention adopts tin plating on the surface of the explosion-proof copper foil 4, which makes it easy to weld during production and saves welding time. The electrical conductivity of the explosion-proof copper foil 4 and the rivet 3 is excellent, and the contact area of the spot weld is large enough to ensure that it will not be damaged by overcurrent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com