Aluminum alloy fusion welding device

A fusion welding and aluminum alloy technology, applied in the field of aluminum alloy welding, can solve the problems of many bubbles in the weld, affecting the welding quality, low strength of the welded joint, etc., and achieve the effect of improving strength, fatigue strength and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

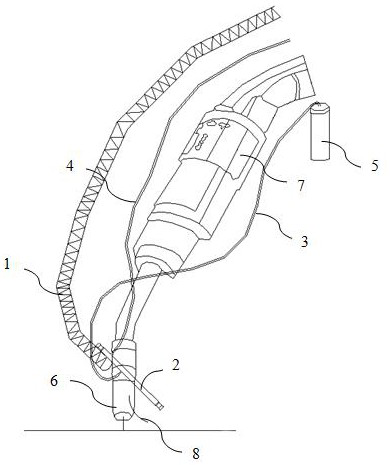

[0036] like figure 1 As shown, an aluminum alloy fusion welding device includes: a fixing device 1, a welding device 7, and a cooling device. The front end of the welding equipment 7 is provided with a welding torch 6; The upper end of the fixing device 1 is fixedly connected with the welding equipment 7 ; the lower end of the fixing device 1 is fixedly connected with the spray gun 2 .

[0037] The fixing device 1 has a structure with multiple adapters, which can precisely adjust the angle between the spray gun 2 and the welding torch 6 as well as the height and flow rate of the spray gun 2 itself. In this embodiment 1, the included angle between the spray gun 2 and the welding torch 6 is 45°. The direction of the spray gun 2 is opposite to the advancing direction of the welding torch 6 . The nozzle of the welding torch 6 is 20mm away from the welding seam; the cold source is 45mm away from the molten pool.

[0038] The water guide pipe 3 is used to guide the cooling liqui...

Embodiment 2

[0044] In this embodiment, compared with Embodiment 1, the difference is that: the angle between the spray gun 2 and the welding torch 6 is 40°; the nozzle of the welding torch 6 is 15mm away from the welding seam; the cooling source is 35mm away from the molten pool.

Embodiment 3

[0046] In this embodiment, compared with Embodiment 1, the difference is that: the angle between the spray gun 2 and the welding torch 6 is 50°; the nozzle of the welding torch 6 is 25mm away from the welding seam; the cooling source is 55mm away from the molten pool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com