Cladding power stripper adopting graphite and white graphite materials and micro-channel water cooling

A technology of microchannel and white graphite, which is applied to lasers, phonon exciters, laser components, etc., can solve problems such as difficult processing and threats to laser system stability, reduce temperature peaks, increase stripping power, and thermal conductivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

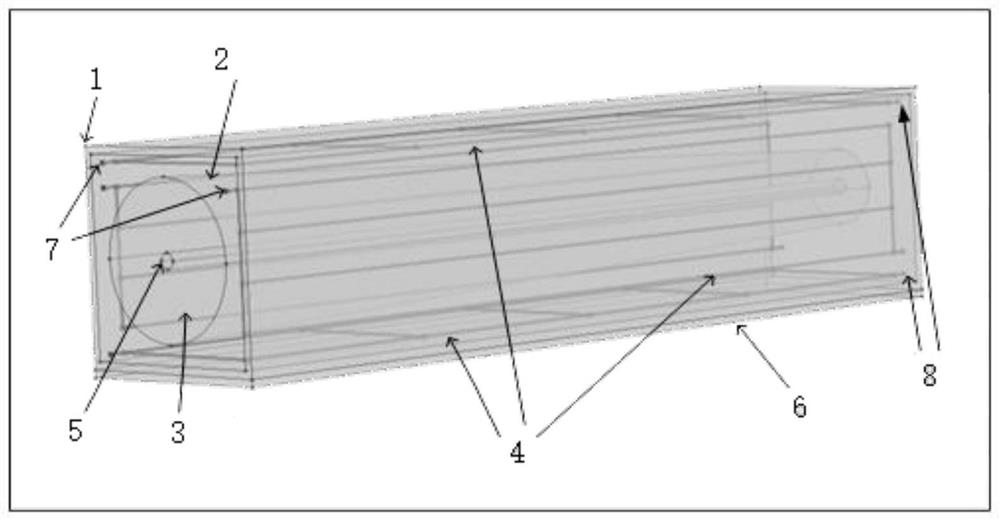

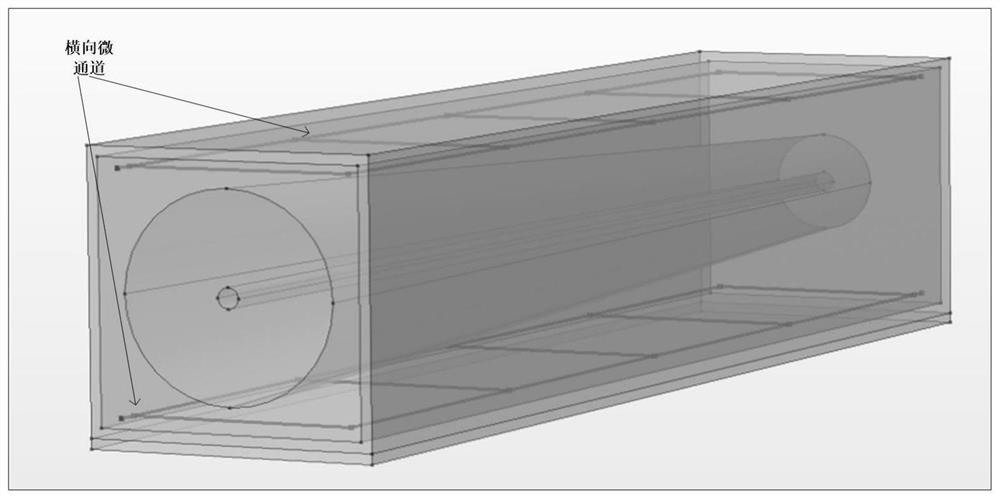

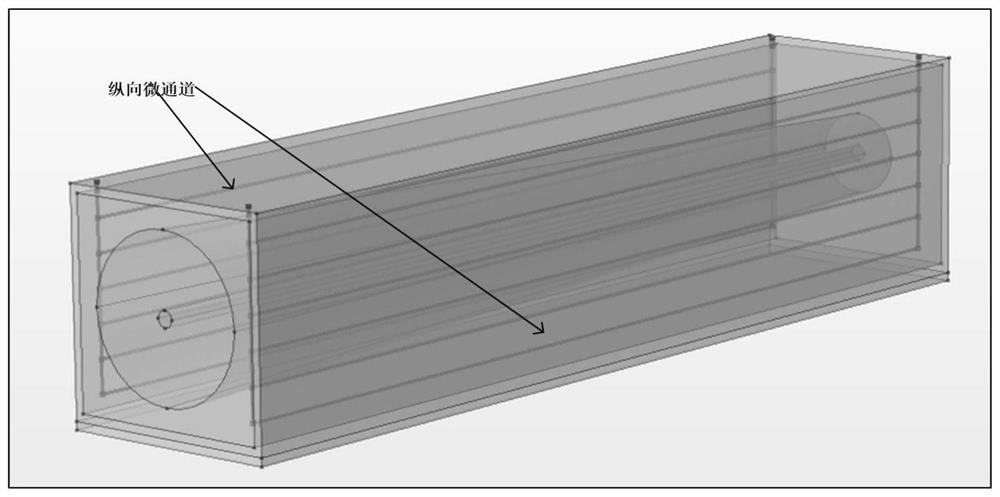

[0022] Specific embodiments of the present invention such as figure 1 As shown, a cladding power stripper using graphite, white graphite material and microchannel water cooling technology according to the present invention includes a heat sink protection shell 1, a heat sink 2, a high-fold plastic cavity 3, a microchannel 4, an optical fiber 5. Heat sink 6, the optical fiber 5 is arranged at the inner center of the high-folding plastic cavity 3, and the outside of the high-folding plastic cavity 3 is a heat sink 2, which is close to the high-folding plastic cavity 3 in the heat sink 2 Microchannels 4 are arranged on the surface, and the outside of the heat sink 2 is a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com