Thermochromic pavement coating with automatic temperature regulation function and preparation method thereof

A temperature-induced discoloration and coating technology, applied in coatings, radiation-absorbing coatings, heat-sensitive coatings, etc., can solve problems such as rutting, shifting, wrapping, poor hiding power, and threats to driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the organic reversible thermochromic pavement coating in embodiment 1 to embodiment 4 comprises the following steps:

[0043] 1) Add the water-based silicone-acrylic emulsion and rutile titanium dioxide to the mixer in proportion, and stir evenly for 10-15 minutes at a rotational speed of 100-150 rpm;

[0044] 2) Evenly mix the leveling agent, dispersant and defoamer in equal proportions;

[0045] 3) The thermochromic powder, the mixed three additives and water are added to the mixer in proportion to uniformly stir for 15-25 minutes, and the rotating speed is 150-250 rpm;

[0046] 4) Finally, the film-forming aid is added, the rotational speed is adjusted to 100-150 rpm, and the stirring is performed for 15-25 minutes.

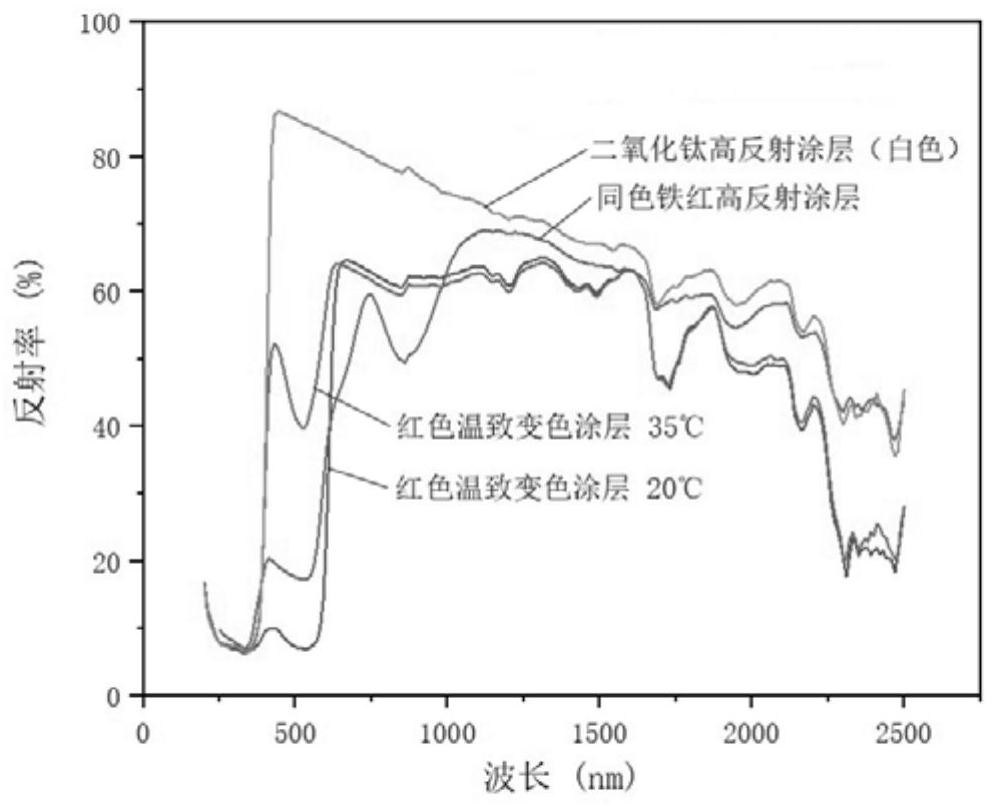

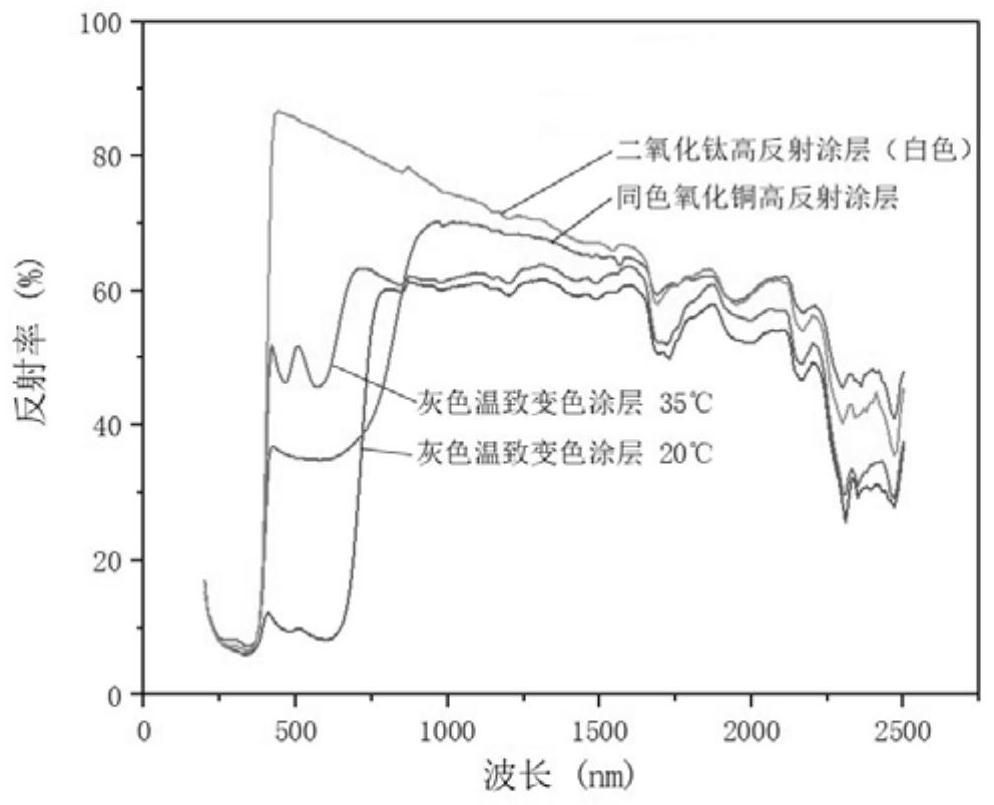

[0047] Reflectivity testing was performed on representative Examples 1 and 2. After the coating is prepared, it is coated on an aluminum plate of 6cm×6cm, dried and cured at a room temperature of about 25°C for at least 24 ho...

Embodiment 1

[0050] Examples 1 and 2 are low brightness (brightness value is 0-40) before discoloration, medium brightness (brightness value is 40-80) after discoloration, and the high-reflection coating with the same color and fixed color is medium brightness Or high brightness (brightness value is 80-100), compared with that, the reversible thermochromic coating only improves the reflectivity in the near-infrared band while the visible band is still low, which can alleviate the light-colored coating with too high visible reflectivity The negative impact on the visual environment of the road (glare, light pollution), and at the same time achieve the purpose of effective temperature regulation.

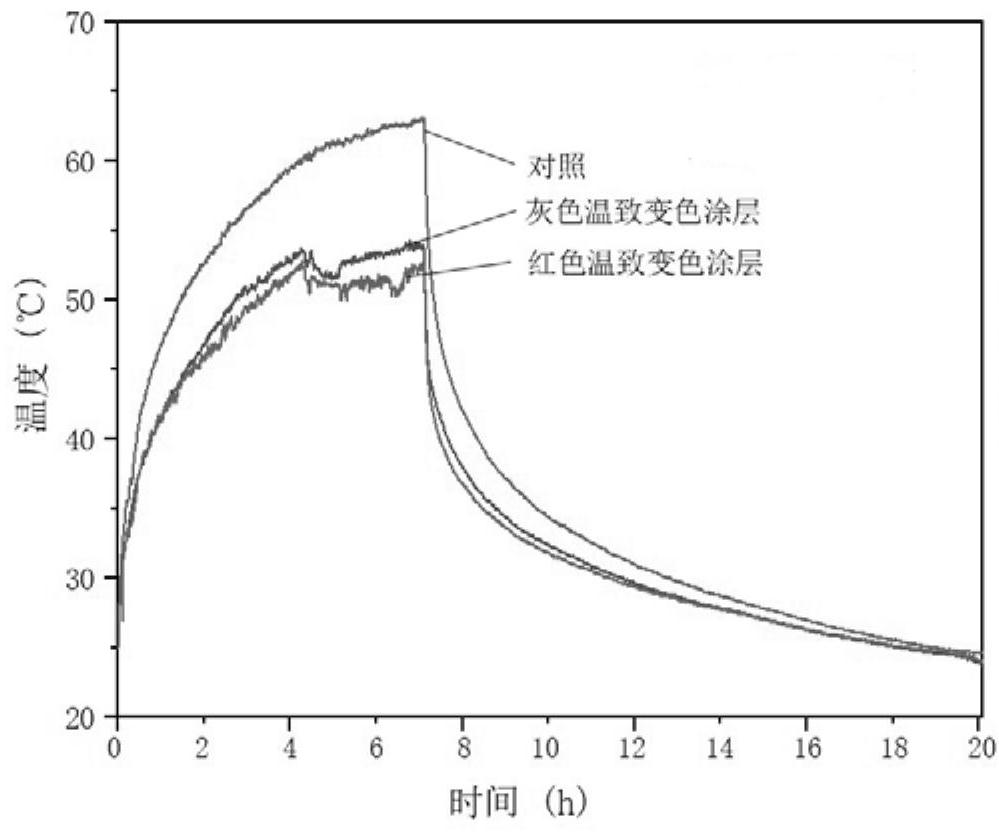

[0051] The indoor cooling effect test was carried out on representative examples 1 and 2. The two thermochromic coatings of Example 1 and Example 2 and the high-reflection coating of the same color system and fixed color were respectively coated on the surface of the rotary compaction test piece, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com