Low-load combustor capable of combusting stably

A burner, low-load technology, applied in burners, burners burning powder fuel, combustion types, etc., can solve the problems of weak concentration capacity and narrow load adjustment range, reduce NOx generation, and adapt to coal types. The effect of strengthening and enlarging the fire area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

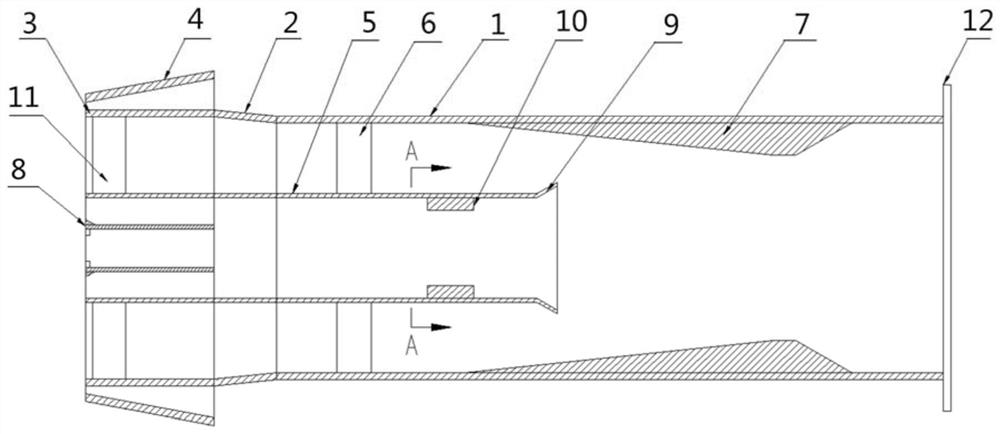

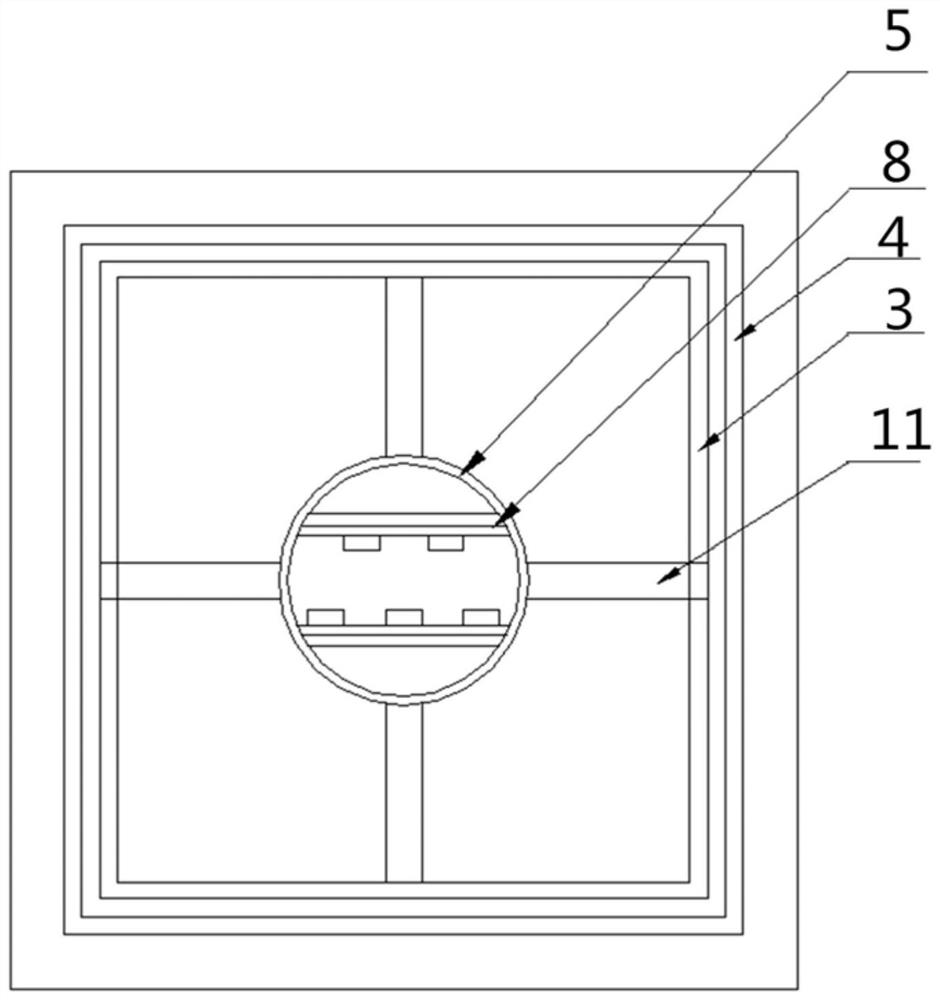

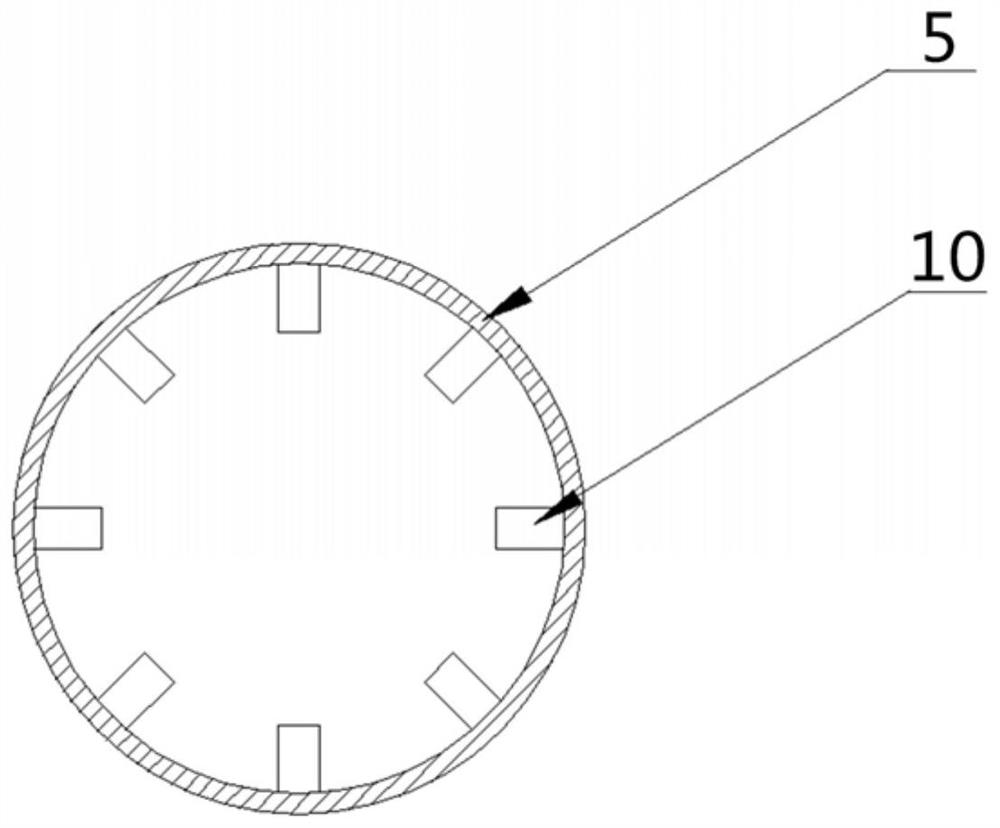

[0031] DETAILED DESCRIPTION - A low-load stable combustion burner 13, such as figure 1 and figure 2 As shown, it includes pulverized coal nozzle body 1, square and round transition head 2, light phase pulverized coal nozzle 3, peripheral air nozzle 4, dense phase pulverized coal pipeline 5, support plate 6, Venturi concentrator 7, flame stabilizer 8, dense phase A phase homogenizer 10 and a light-phase spoiler 11, the pulverized coal nozzle body 1 is cylindrical, the pulverized coal nozzle 3 of the light phase is a square cylinder, and the pulverized coal nozzle body 1 passes through the square-circle transition head 2 and The light-phase pulverized coal nozzle 3 is connected, and the peripheral wind nozzle 4 is a hollow quadrangular truss shape. The peripheral wind nozzle 4 is arranged on the outer layer of the light-phase pulverized coal nozzle 3, and the dense-phase pulverized coal pipeline 5 is arranged on the pulverized coal nozzle body 1, In the overall structure forme...

specific Embodiment approach 2

[0035]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 2 A low-load stable combustion burner 13, including a pulverized coal nozzle body 1, a radius transition head 2, a light-phase pulverized coal nozzle 3, a peripheral air nozzle 4, a dense-phase pulverized coal pipeline 5, a support plate 6, and a Venturi Concentrator 7, flame stabilizer 8, dense phase powder homogenizer 10 and light phase spoiler 11, the pulverized coal nozzle body 1 is cylindrical, and the pulverized coal nozzle 3 of the light phase is square cylindrical. The pulverized coal nozzle body 1 is connected to the light-phase pulverized coal nozzle 3 through the square-circle transition head 2. The peripheral wind nozzle 4 is a hollow quadrangular truss shape, and the peripheral wind nozzle 4 is arranged on the outer layer of the light-phase pulverized coal nozzle 3. The dense-phase coal The pulverized coal pipeline 5 is arranged in the overall structure formed by the pulverized coal nozzle body 1, the radius tr...

specific Embodiment approach 3

[0038] A low-load stable combustion burner 13, including a pulverized coal nozzle body 1, a square-circle transition head 2, a light-phase pulverized coal nozzle 3, a peripheral air nozzle 4, a dense-phase pulverized coal pipeline 5, a support plate 6, a Venturi concentrator 7, Flame stabilizer 8 and light-phase spoiler 11, the pulverized coal nozzle body 1 is cylindrical, the pulverized coal nozzle 3 is square cylindrical, and the pulverized coal nozzle body 1 passes through the square-circle transition head 2 Connected with the light-phase pulverized coal nozzle 3, the peripheral wind nozzle 4 is a hollow quadrangular truss, the peripheral wind nozzle 4 is arranged on the outer layer of the light-phase pulverized coal nozzle 3, and the dense-phase pulverized coal pipeline 5 is arranged on the pulverized coal nozzle body 1 1. In the overall structure formed by the square-circle transition joint 2 and the light-phase pulverized coal nozzle 3, the dense-phase pulverized coal pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com