Method for manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased thermal budget, sensitivity of wafer fluctuation devices, and unstable temperature peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The inventors of the present invention have found that in the existing rapid thermal annealing process for suppressing the diffusion and migration of dopant ions, the effect of the peak annealing process on inhibiting the diffusion and migration of dopant ions is more obvious than that of the uniform temperature annealing process , but the spike annealing process will cause quality problems such as wafer fluctuations and device sensitivity degradation due to factors such as excessively high temperature peaks and excessively fast heating or cooling speeds.

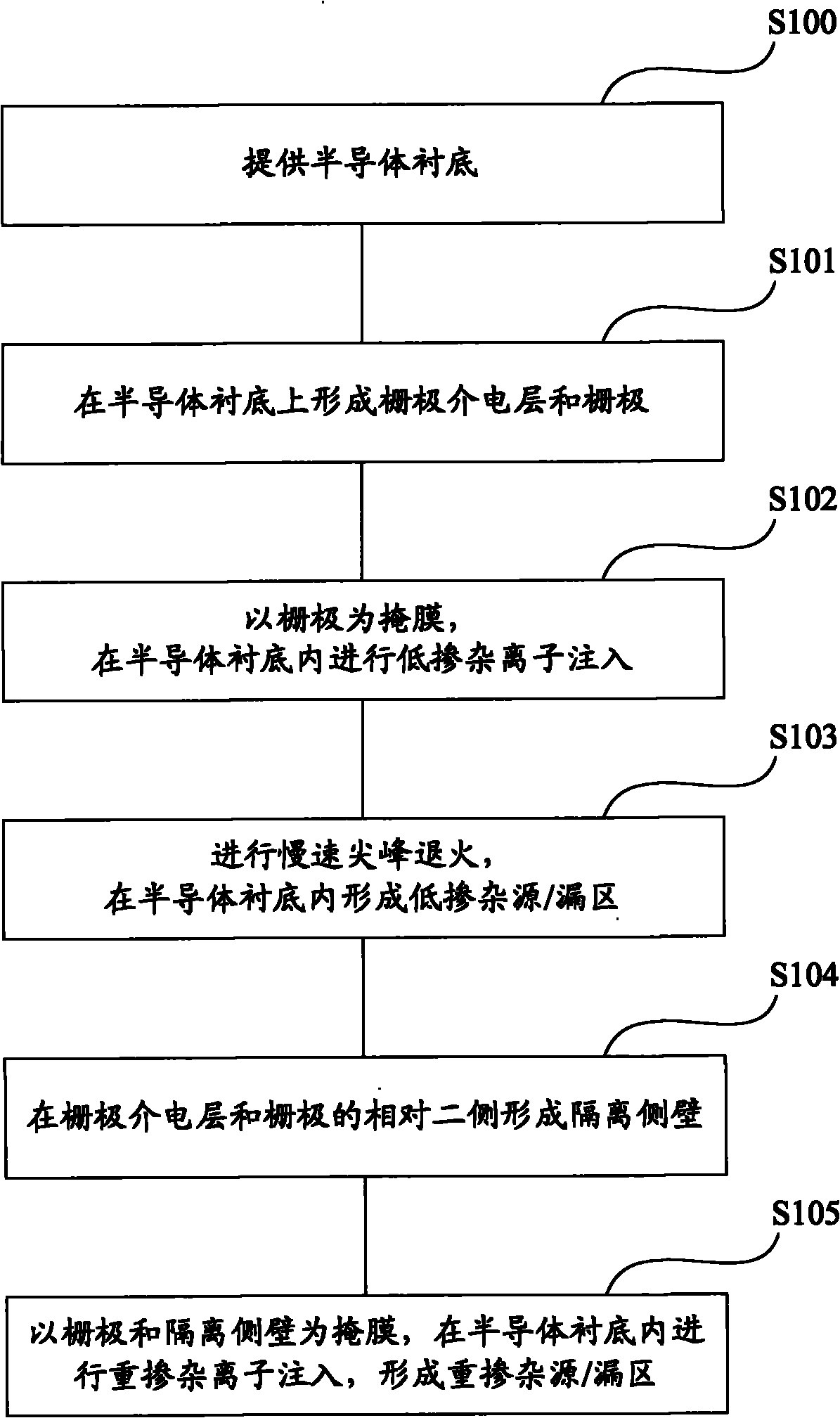

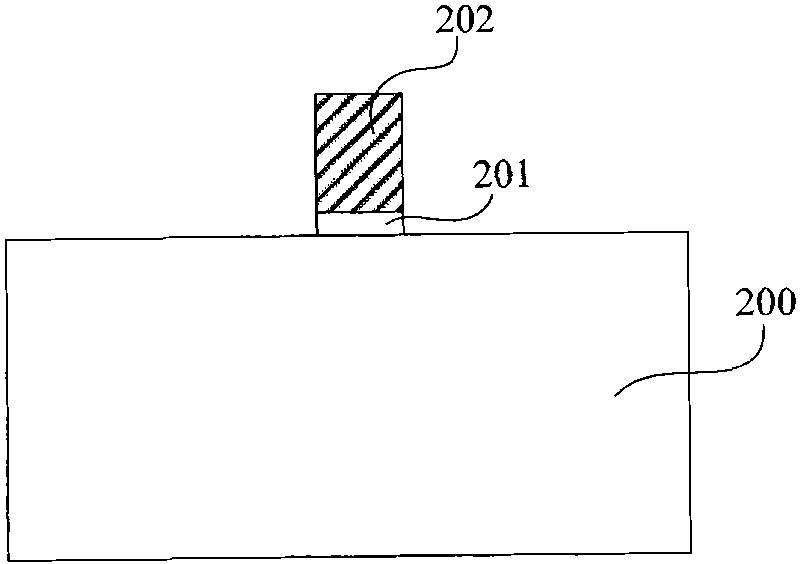

[0019] Therefore, in the manufacture of semiconductor devices, in order to prevent the occurrence of the above-mentioned defects. The present invention firstly provides a semiconductor substrate, on which a gate dielectric layer and a gate located on the gate dielectric layer are formed; using the gate as a mask, lightly doped with ions in the semiconductor substrate Implantation; performing slow spike annealing to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com