Lithium ion battery, modified lithium ion battery anode material and preparation method of anode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrode manufacturing, positive electrodes, etc., can solve problems such as unfavorable lithium ion and electron rapid transmission, unfavorable ternary material structure stability, and material rate performance decline, etc., to achieve Good industrial application prospects, improved cycle stability, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

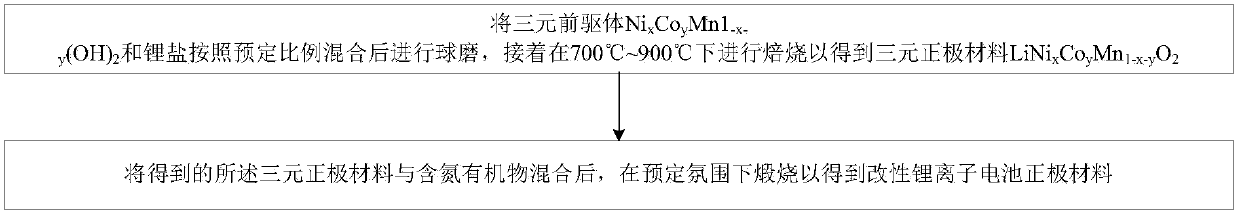

[0025] The preparation method of described modified lithium-ion battery cathode material mainly comprises the following steps:

[0026] Step 1, the ternary precursor Ni x co y Mn1 -x-y (OH) 2 (0≤x≤1, 0≤y≤1) and lithium salt are mixed according to a predetermined ratio and then ball-milled, followed by calcination in air or oxygen atmosphere at a temperature of 700°C to 900°C to obtain the ternary cathode material LiNi x co y mn 1-x-y o 2 (0≤x≤1, 0≤y≤1).

[0027] Specifically, the predetermined ratio is nNi:nLi=1:(1-1.2); the ternary precursor and lithium salt are mixed according to a predetermined ratio and then added to a ball mill, and a ball milling medium is added to the ball mill, and ball milled for 1 hour A homogeneous mixture is obtained after ~4 hours, and the obtained mixture is calcined in air or oxygen atmosphere at a temperature of 700° C. to 900° C. for 5 to 12 hours to obtain the ternary positive electrode material. The lithium salt is one or more of lit...

Embodiment 1

[0033] The preparation method of the modified lithium-ion battery cathode material provided by the first embodiment of the present invention mainly includes the following steps:

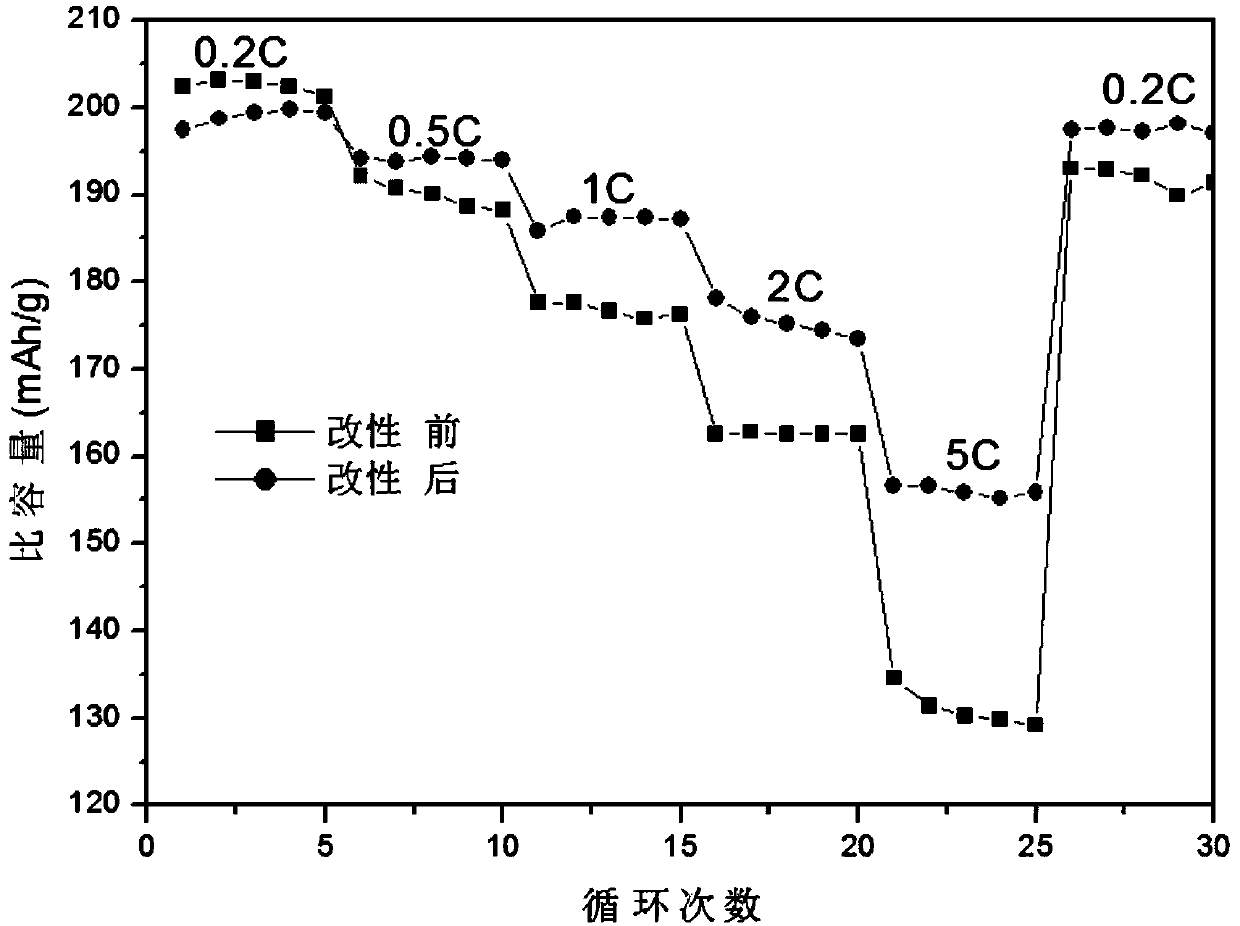

[0034] 1.1 Add 10g Ni 0.6 co 0.2 mn 0.2 (OH) 2 and 4.3g Li 2 CO 3 After mixing, put it into an agate ball mill jar with a volume of 80ml, the ball-to-material ratio is 2:1, and run at a speed of 300r / min for 1 hour; Raise the temperature to 450°C, and then raise the temperature to 850°C at 2°C / min for 12 hours to obtain a ternary material.

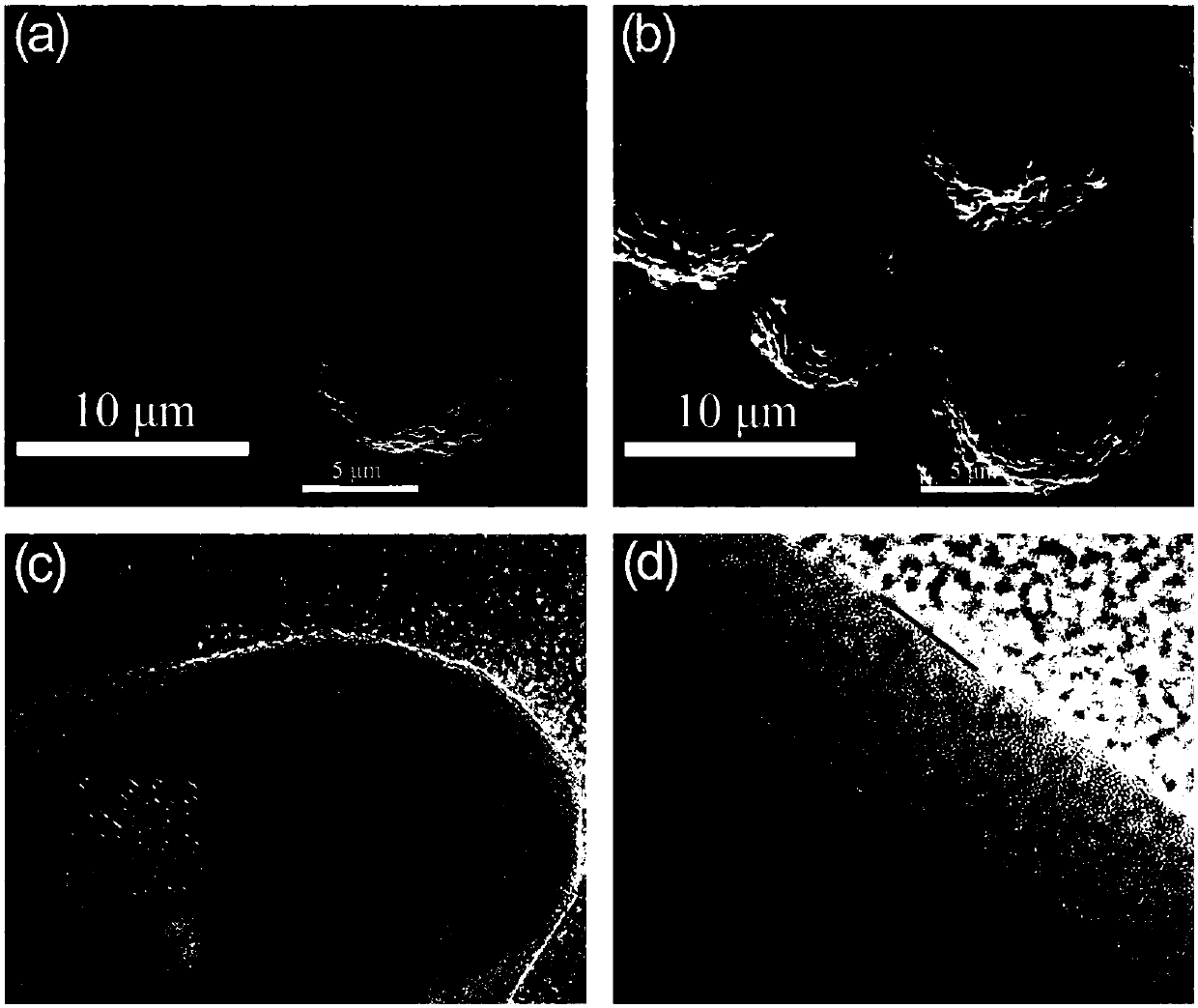

[0035] 1.2 Mix 1g of the obtained ternary material and 0.05g of melamine manually in an agate mortar for half an hour, then transfer to an agate ball mill jar with a volume of 80ml, the ratio of ball to material is 2:1, and run at a speed of 300r / min for 1 hour; then put the obtained mixed powder into a muffler furnace and heat up to 650°C at 5°C / min and then keep it warm for 1 hour to obtain the modified lithium-ion battery positive electrode material.

...

Embodiment 2

[0038] The preparation method of the modified lithium-ion battery cathode material provided by the second embodiment of the present invention mainly includes the following steps:

[0039] 2.1 Add 10g Ni 0.5 co 0.2 mn 0.3 Oh) 2 and 4.3g Li 2 CO 3 After mixing, put it into an agate ball mill tank with a volume of 80ml, the ratio of ball to material is 2:1, and run at a speed of 300r / min for 1 hour; The temperature was raised to 450°C in one minute, and then raised to 850°C at a rate of 2°C / min and held for 12 hours to obtain a ternary material.

[0040] 2.2 Mix 1g of the obtained ternary material and 0.1g of chitosan manually in an agate mortar for half an hour, then transfer to an agate ball mill jar with a volume of 80ml, the ratio of ball to material is 2:1, and run at a speed of 300r / min for 1 Hours; then put the uniformly mixed powder into a muffler furnace to raise the temperature to 650°C at 5°C / min and keep it warm for 1 hour to obtain the modified lithium-ion batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com