Curve screen based on nanometer touch-control membrane technique and manufacturing method thereof

A nano-touch film, curved screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. problem, to achieve the effect of light weight, good ductility and flexibility, and improved surface conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

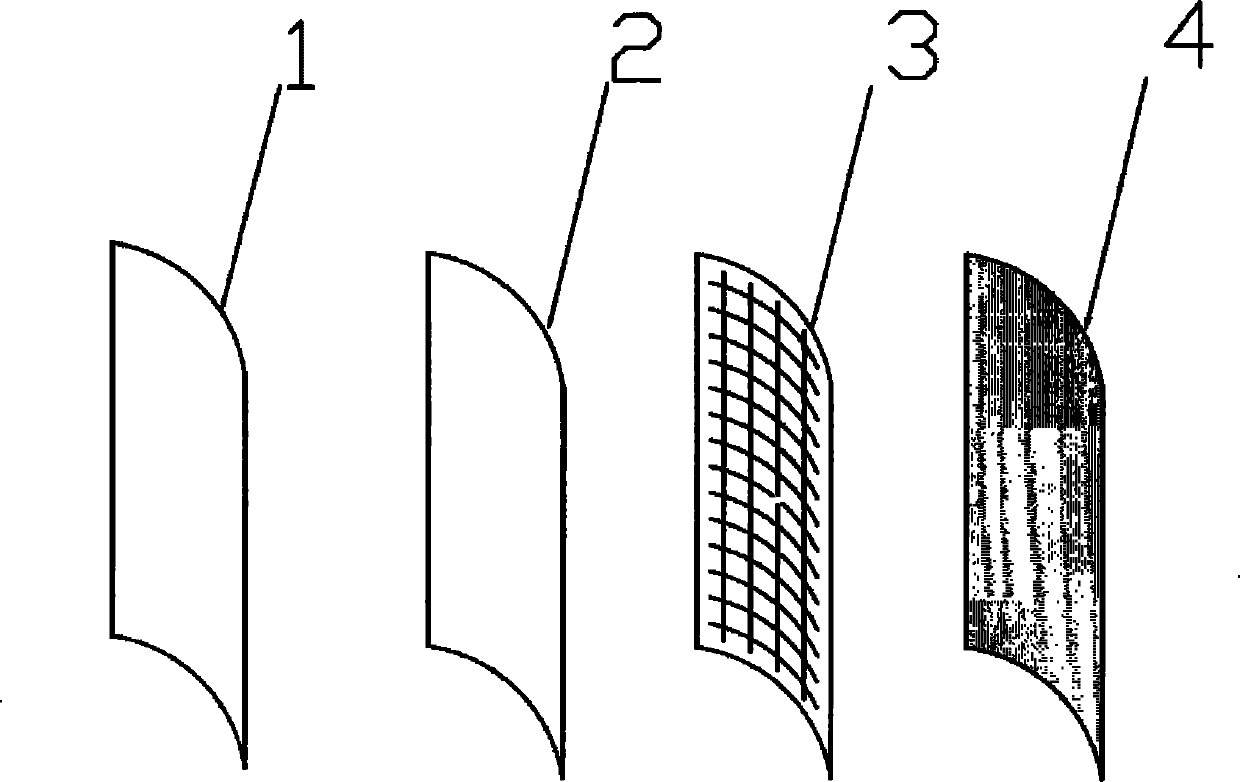

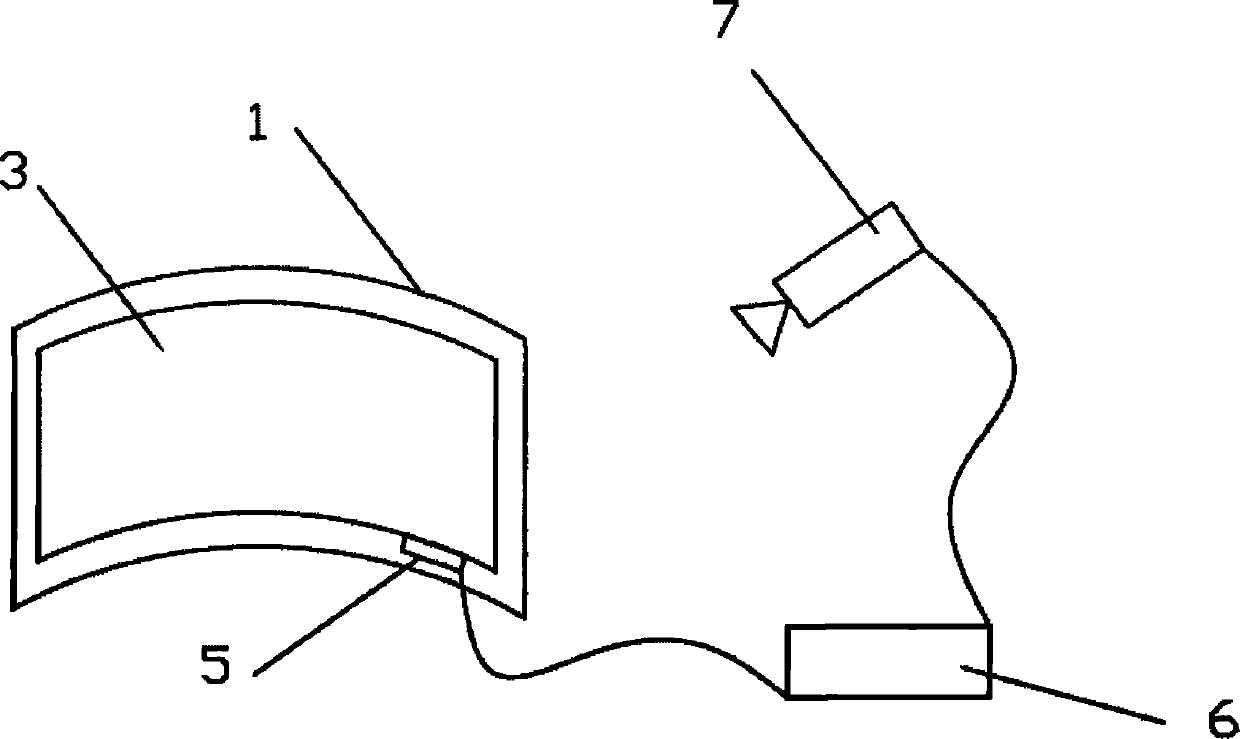

[0043] A curved screen based on nano touch film technology in this embodiment, such as figure 2 and image 3 As shown, it includes a curved substrate 1. The curved substrate 1 is a non-metallic transparent medium, which can be glass, acrylic plate or film, etc. The curvature of the curved substrate 1 is 0-180 degrees, and the bonding surface of the curved substrate 1 is The convex curved surface is sequentially attached with an adhesive film 2, a nano-touch film 3 and an imaging flexible film 4. The imaging flexible film 4 can be a holographic film or a gray film. The sensing signal of the nano-touch film 3 is collected and controlled by an integrated circuit 5 through a USB interface. Or the RS-232 interface is connected to the calculation control unit 6, and the calculation control unit 6 is connected to the projection imaging unit 7 through wired communication.

[0044] The preparation method of the curved screen of this embodiment includes the following steps:

[0045] ...

Embodiment 2

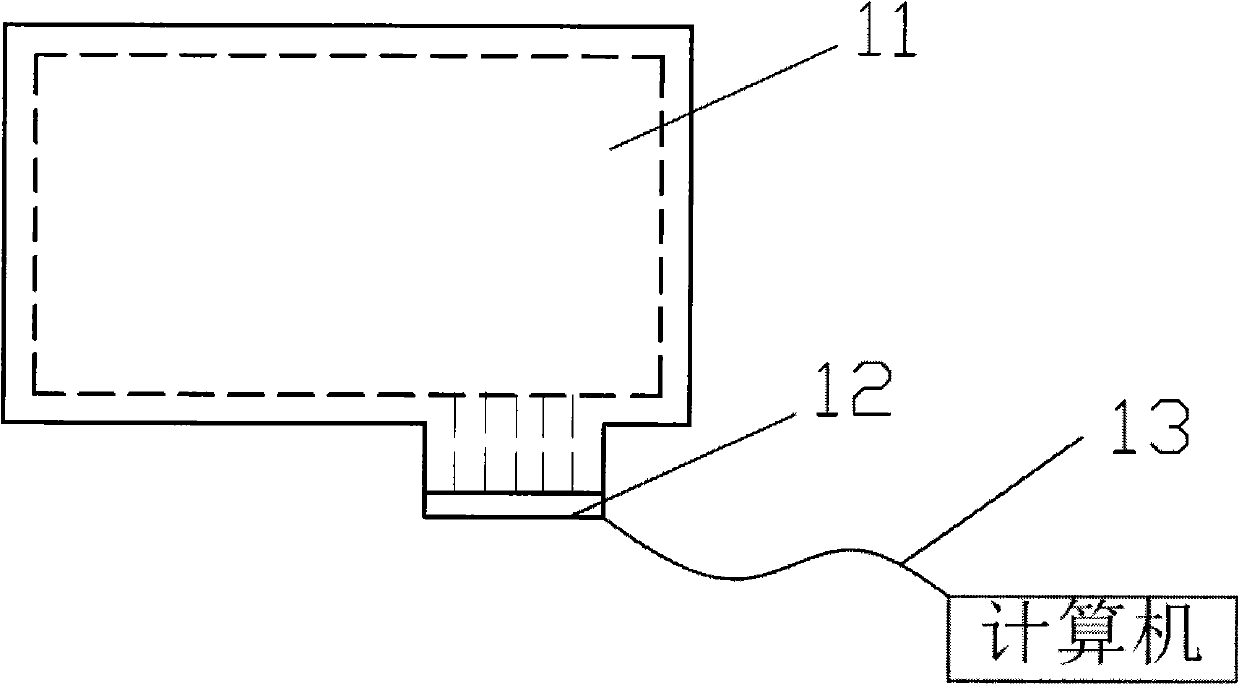

[0061] A curved screen based on nano touch film technology in this embodiment, such as Figure 4 and Figure 5 As shown, the flexible imaging device 8 is used as a curved substrate, including LCD display screens, LED display screens, OLED display screens, CNT carbon nanotube display screens, display paper or graphene display units, etc., and the curvature of the flexible imaging device 8 is 0 ~180 degrees, the adhesive surface of the flexible imaging device 8 is a concave surface, and the nano-touch film 3 is attached, and the sensing signal acquisition control integrated circuit 5 of the nano-touch film 3 passes through the cellular interface, WiFi or BlueTooth interface and the computing control unit 6 Connection, the computing control unit 6 is connected with the flexible imaging device 8 through wireless communication.

[0062] The preparation method of the curved screen of this embodiment includes the following steps:

[0063] Step 1: In an environment shielded from ele...

Embodiment 3

[0074] A curved screen based on nano-touch film technology in this embodiment is similar in structure and preparation method to Embodiments 1 and 2, except that the curved substrate or flexible imaging device is a wave-like multi-dimensional curved surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com