Metal bipolar plate and preparation method thereof

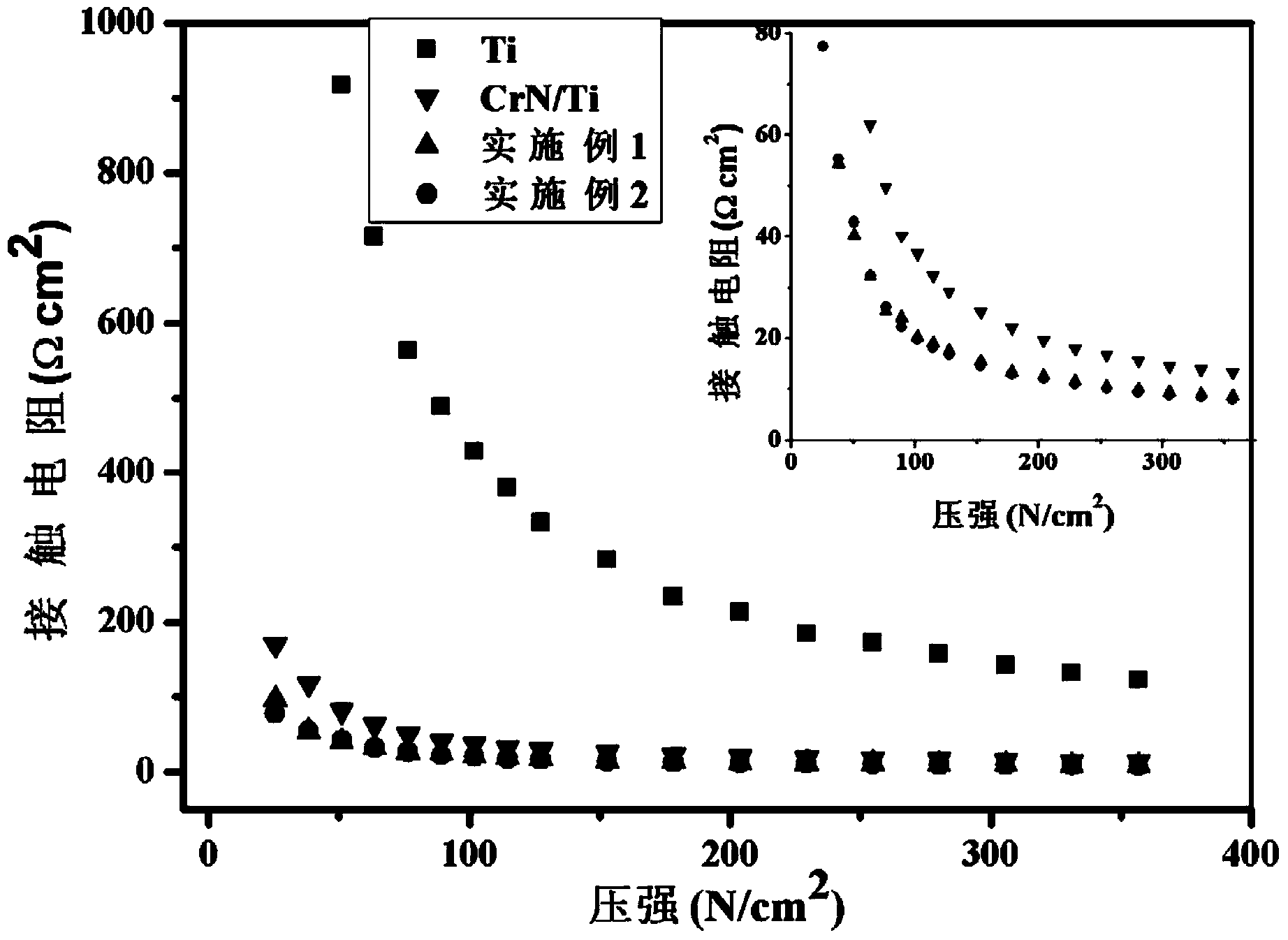

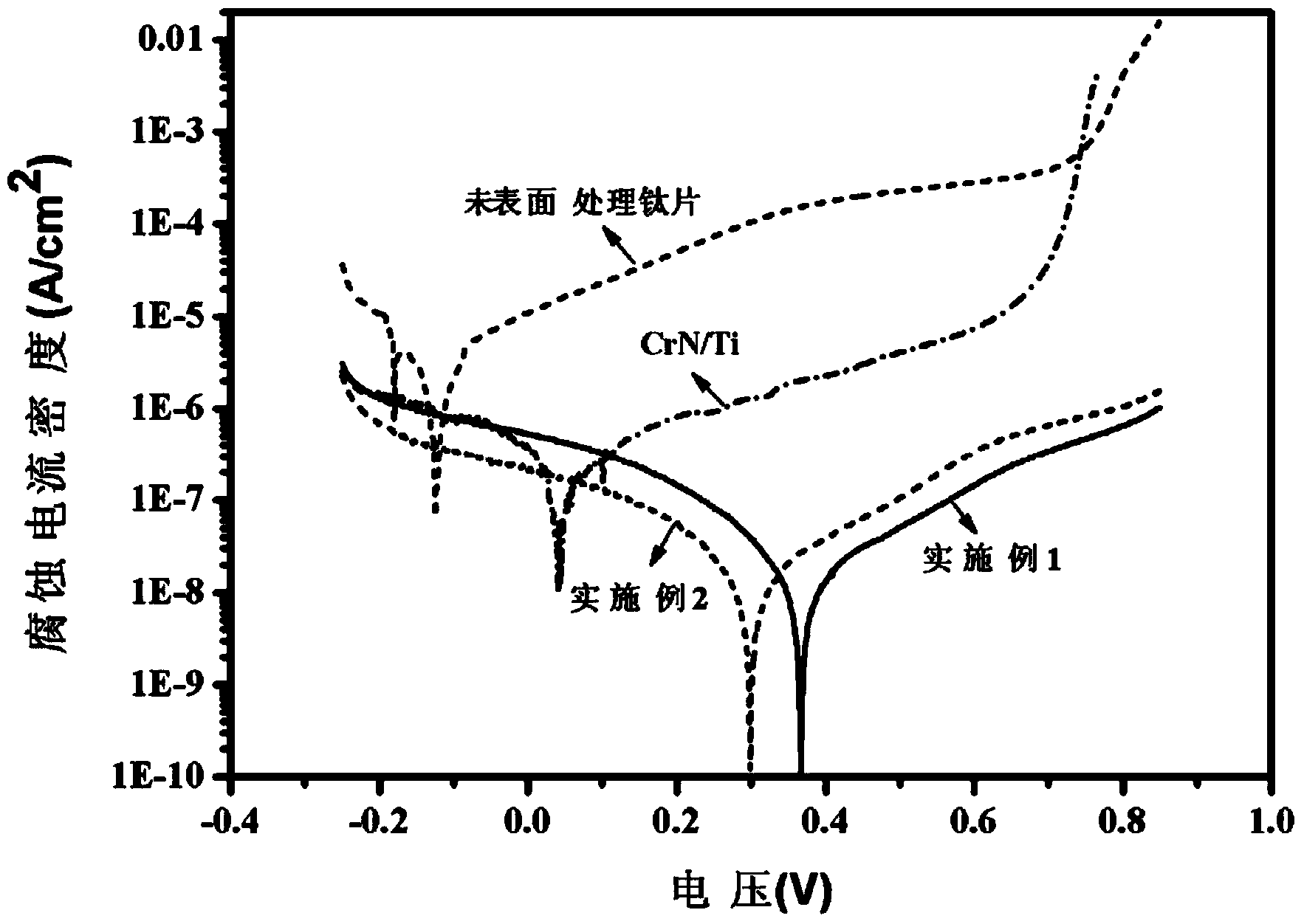

A metal bipolar plate and modified layer technology, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of large volume, low mechanical strength, limited application of graphite bipolar plates, etc., to improve long-term operation, overcome the Weak binding force, the effect of improving power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Pretreatment: L400 multi-arc ion plating equipment is used for film deposition. Firstly, the 0.1mm thick titanium substrate is treated with surface degreasing and depassivation layer in a mixture of hydrofluoric acid and hydrochloric acid, the treated titanium substrate is cleaned with deionized water, and then the titanium substrate is placed on on the substrate. There are four target positions in the coating chamber, Ti targets are installed on the two opposite cathode arc sources, and Cr targets are installed on the other pair of target positions. Wherein, the volume ratio of deionized water, concentrated hydrochloric acid and hydrofluoric acid in the mixed solution may be 10:4:1.

[0051] Sputtering cleaning: vacuumize the cavity until the vacuum degree is less than 10 -4 After Pa, Ar gas of 1.5 Pa was passed into the vacuum cavity, and the temperature of the titanium substrate was kept at 320°C. Before thin film deposition, the titanium substrate was cleaned by ...

Embodiment 2

[0062] The steps of pretreatment and sputtering cleaning are the same as in Example 1.

[0063] Deposition of titanium modified layer:

[0064] 1) Deposition of TiCN: Open the shielding plate of the Ti target, apply a bias voltage of -60V on the target, and keep the air pressure at 1.5Pa; 2 Gas, C 2 h 2 and Ar gas, N 2 and C 2 h 2 The flow ratio is 1:1.3, C 2 h 2 and N 2 The sum of the gas volume accounts for 70% of the total gas volume, and the reaction time is controlled to obtain a TiCN layer thickness of 0.8 μm;

[0065] 2) Deposition of TiC: Open the shielding plate of the Ti target, apply a bias voltage of -60V on the target, and keep the air pressure at 1.5Pa; 2 h 2 and Ar gas, so that the Ar gas carries a volume fraction of 70% of C 2 h 2 , control the reaction time, the obtained TiC layer thickness is 1.6 μm.

[0066] Deposition of chrome modified layer:

[0067] 1) Deposition of CrN: Open the shielding plate of the Cr target, apply a bias voltage of -60...

Embodiment 3

[0072] Pretreatment: L400 multi-arc ion plating equipment is used for film deposition. Firstly, the 0.1mm thick titanium substrate is treated with surface degreasing and depassivation layer in a mixture of hydrofluoric acid and hydrochloric acid, the treated titanium substrate is cleaned with deionized water, and then the titanium substrate is placed on on the substrate. There are four target positions in the coating chamber, Ti targets are installed on the two opposite cathode arc sources, and Cr targets are installed on the other pair of target positions. Wherein, the volume ratio of deionized water, concentrated hydrochloric acid and hydrofluoric acid in the mixed solution may be 9:5:1.

[0073] Sputtering cleaning: vacuumize the cavity until the vacuum degree is less than 10 -4 After Pa, Ar gas of 2.0 Pa was passed into the vacuum chamber, and the temperature of the titanium substrate was kept at 280°C. Before the thin film deposition, the titanium substrate was cleaned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com