Fabric and clothes using the same

a technology of fabric and clothes, applied in the field of fabric, can solve the problems of increasing the cost accompanied by this, the efficiency of diffusing static electricity generated inside the clothes into the outside of the clothes becomes poor, and the surface electric resistance in the outer surface of clothes is high, and achieves a high surface electroconductive property in clothes overall, excellent surface conductive performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

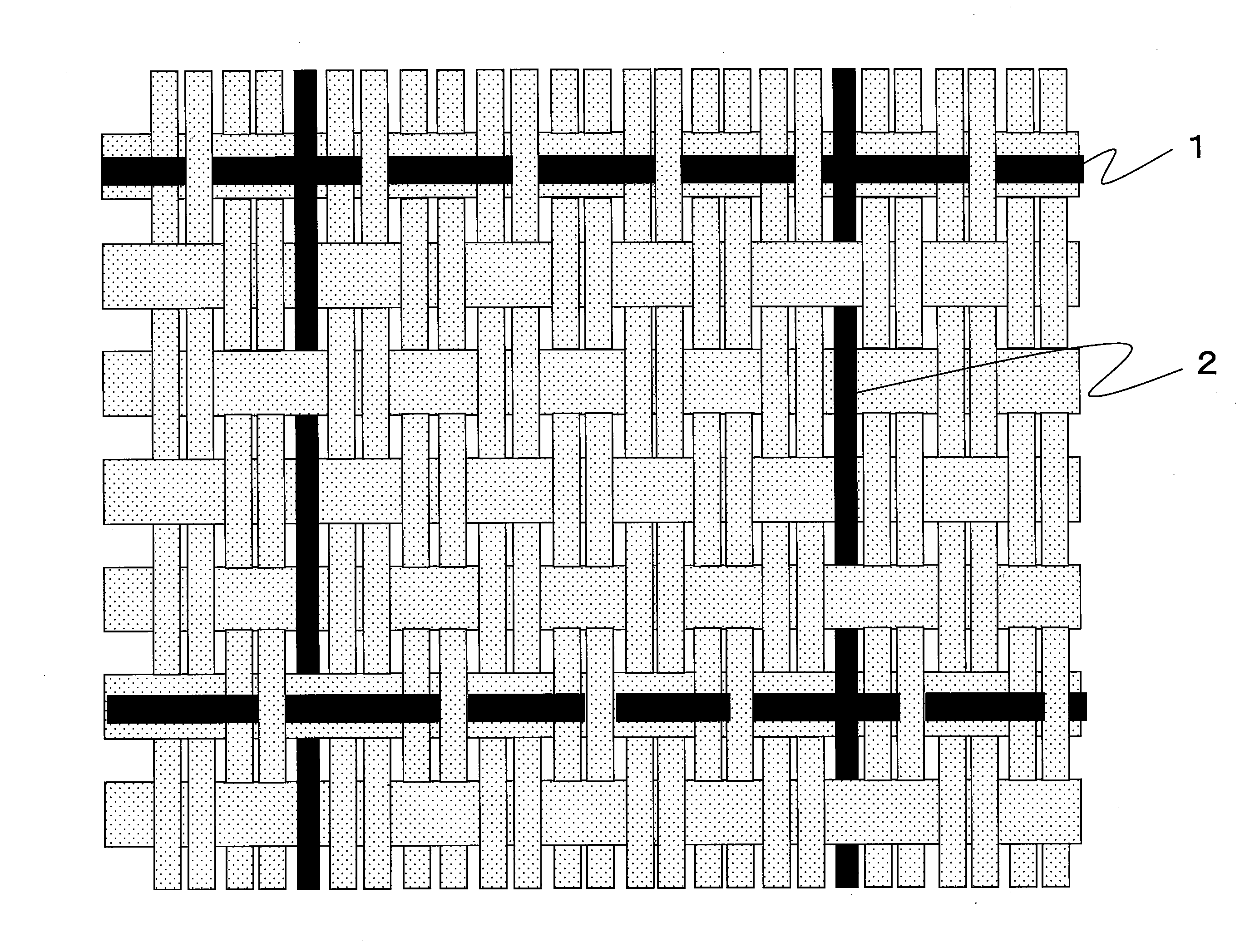

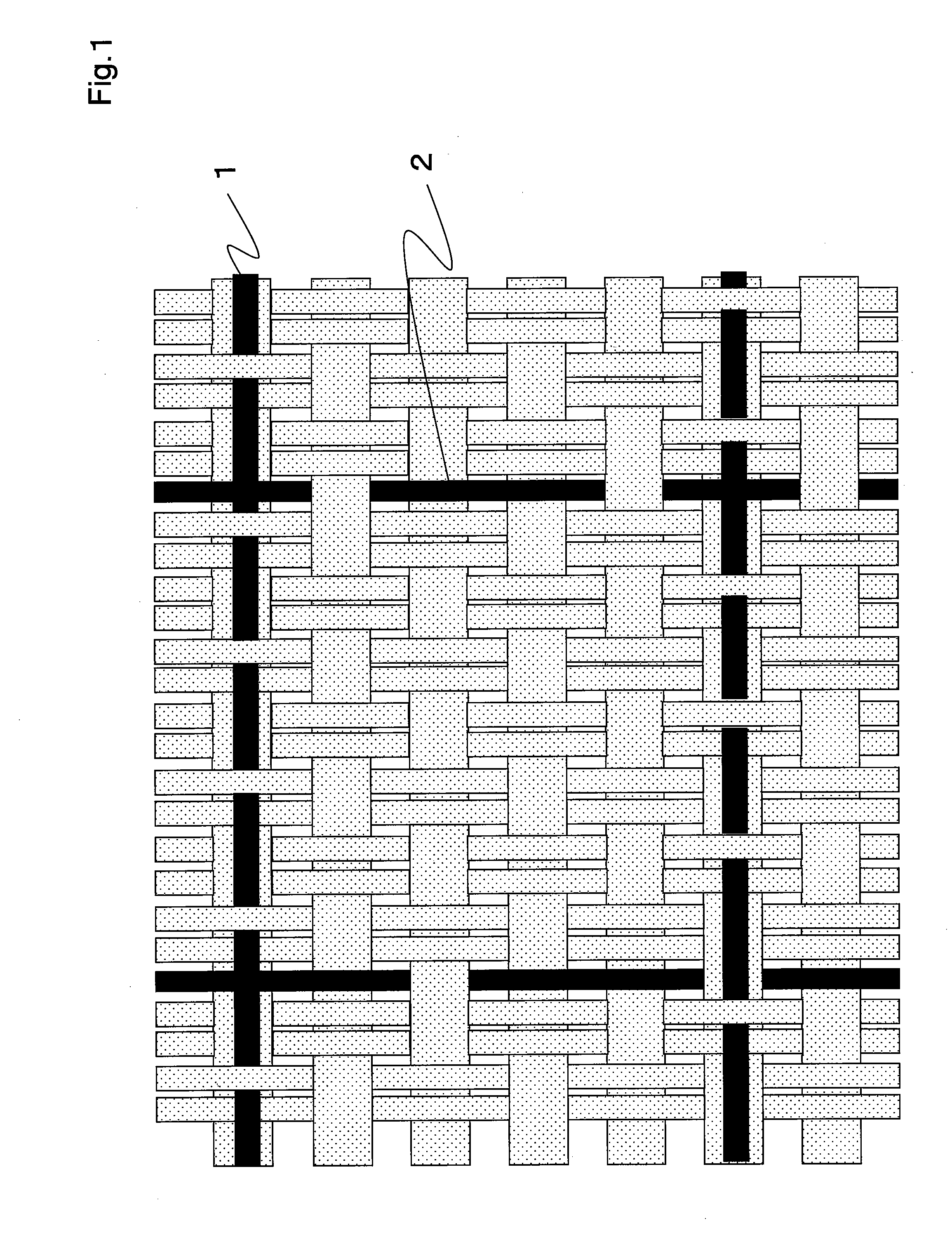

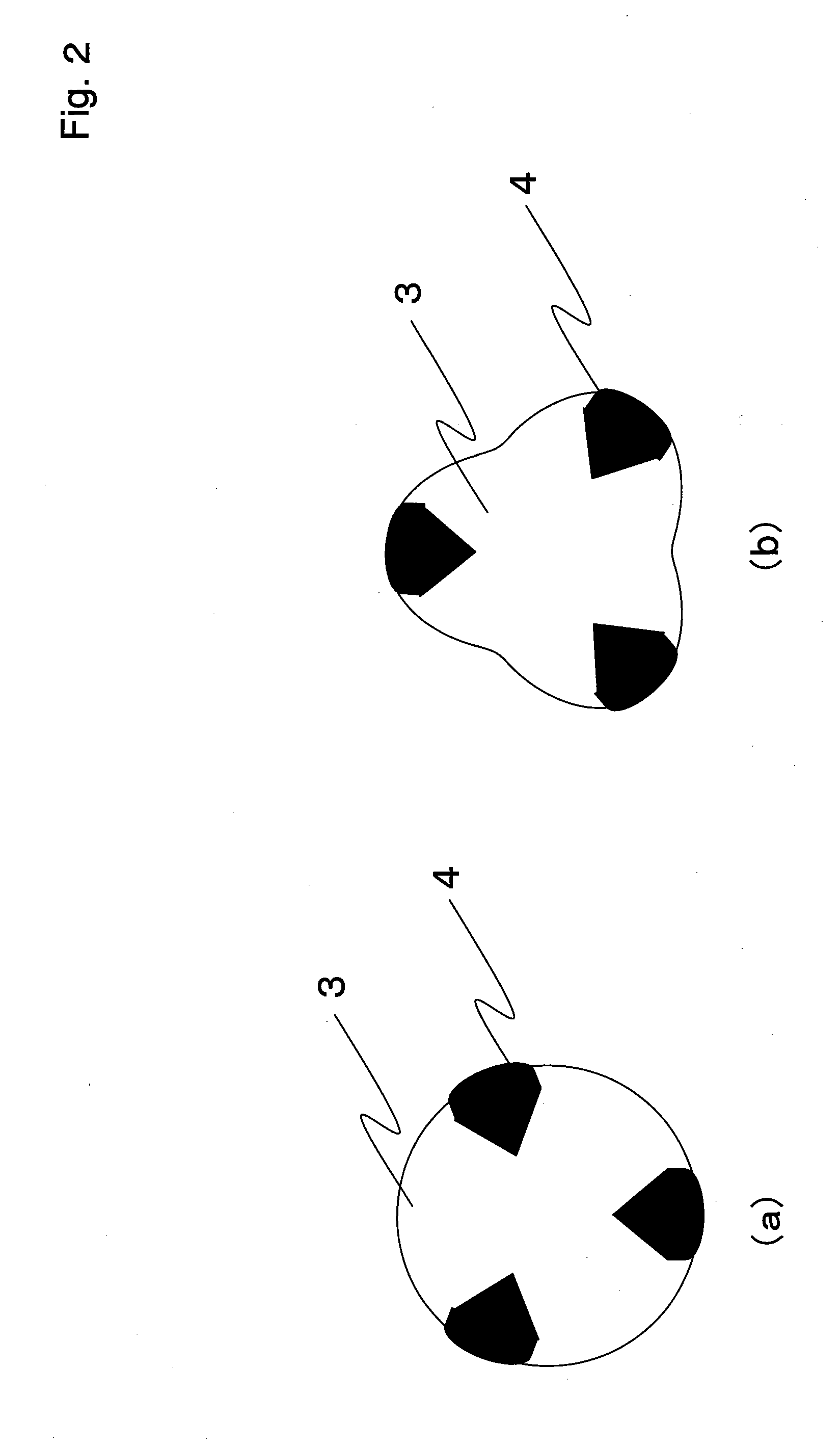

[0059]Using two-ply yarn of polyester melt adhesive fiber (84 decitex, 36 filaments) as a warp forming base weave and polyester false twist yarn (334 decitex, 96 filament) as a weft, and as a warp conductive yarn and a weft conductive yarn, a conductive yarn (84 decitex, 9 filaments) composed of surface exposing type yarn shown in FIG. 2 was used. The weave was made as shown in FIG. 1 in such manner that base weave was plain fabric (one-sided mat), and the warp conductive yarns were disposed by dobby weave in a ratio of every 24 yarns of base warps (pitch 5 mm) in skipping over 2 yarns in the obverse side, and one yarn in the reverse side. The weave was made as shown in FIG. 1 in such manner that the weft conductive yarns were inserted in a ratio of every 11 yarns of base wefts in weft double weave (pitch 5 mm), and disposed on the base weft (namely being float yarn) in skipping over 3 yarns in the obverse side, and one yarn in the reverse side. In this way, a gray fabric of 141 yar...

example 2

[0060]It was carried out in the same conditions as Example 1 except that only conductive yarn was changed. Namely, as the conductive yarn, there was used a double twisted yarn (89 decitex, 18 filaments) of polyester false twist yarn (33 decitex, 12 filaments) with surface exposing type conductive yarn (56 decitex, 6 filaments). The fabric obtained was sewn by a sewing machine, and the surface electric resistance of sewn part was measured. Various data are shown in Table 1.

example 3

[0061]Using two-ply yarn of polyester false twist yarn (84 decitex, 36 filaments) as a warp forming base weave and polyester false twist yarn (334 decitex, 96 filaments) as a weft, and as a warp conductive yarn and a weft conductive yarn, a surface exposing type conductive yarn (84 decitex, 9 filaments) was used. The weave was made in such manner that base weave was plain fabric (one-sided mat), and the warp conductive yarns were disposed by dobby weave in a ratio of every 32 yarns of base warps (pitch 5 mm) in skipping over 3 yarns in the obverse side, and one yarn in the reverse side. The weave was made in such manner that the weft conductive yarns were inserted in a ratio of every 15 yarns of base wefts in weft double weave (pitch 5 mm), and disposed on the base weft in skipping over 6 yarns in the obverse side, and 2 yarns in the reverse side. In this way, a gray fabric of 202 yarns / 2.54 cm in warp density and 74 yarns / 2.54 cm in weft density was produced. This gray fabric was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| surface electric resistance | aaaaa | aaaaa |

| surface electroconductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com