Device and method for producing high-purity ultrafine spherical silicon micro-powder by means of gas heating

A technology of spherical silicon micropowder and gas heating, which is applied to chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve problems such as easy agglomeration, large shrinkage, and product quality pollution, and achieve improved spheroidization speed and distribution Narrow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

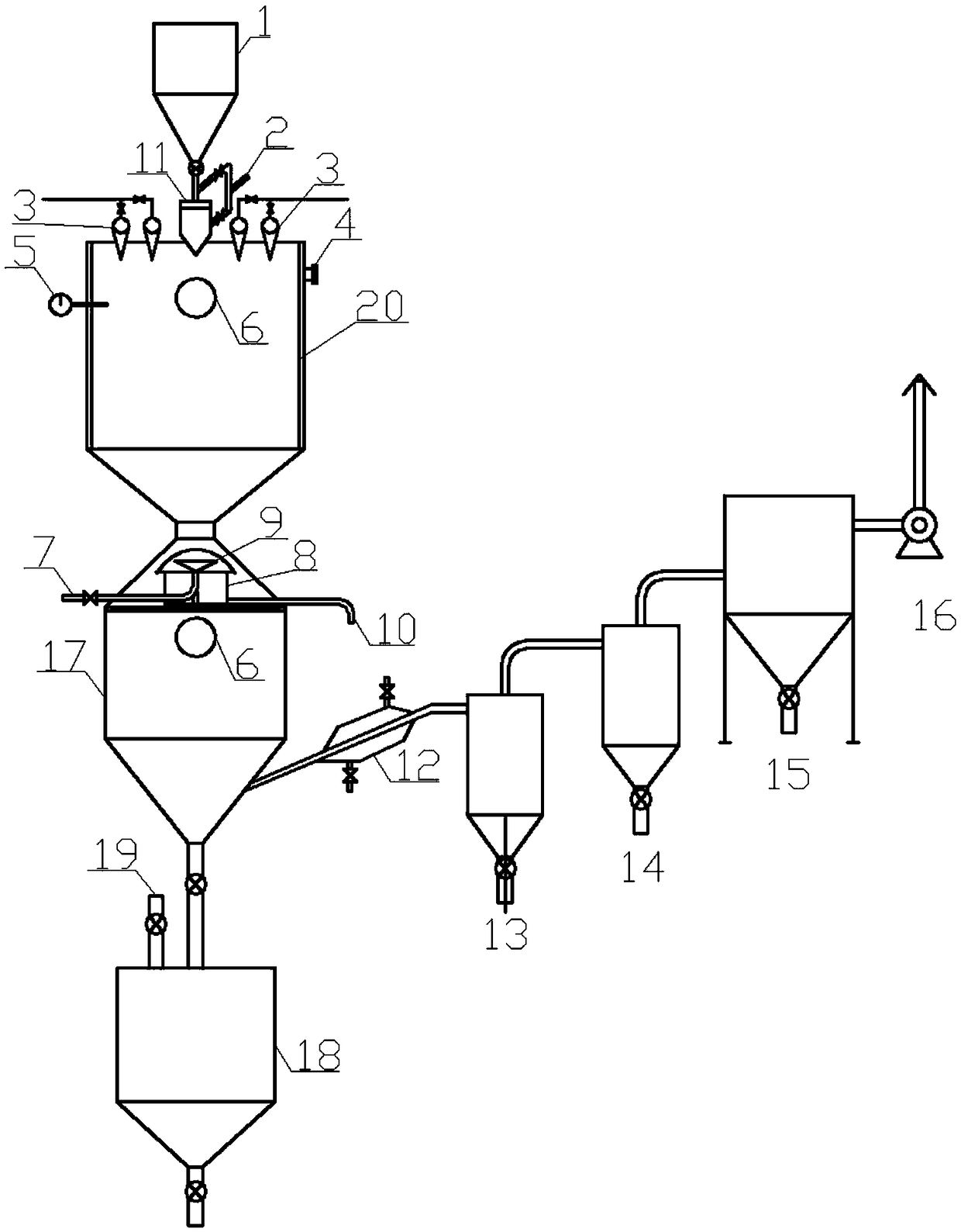

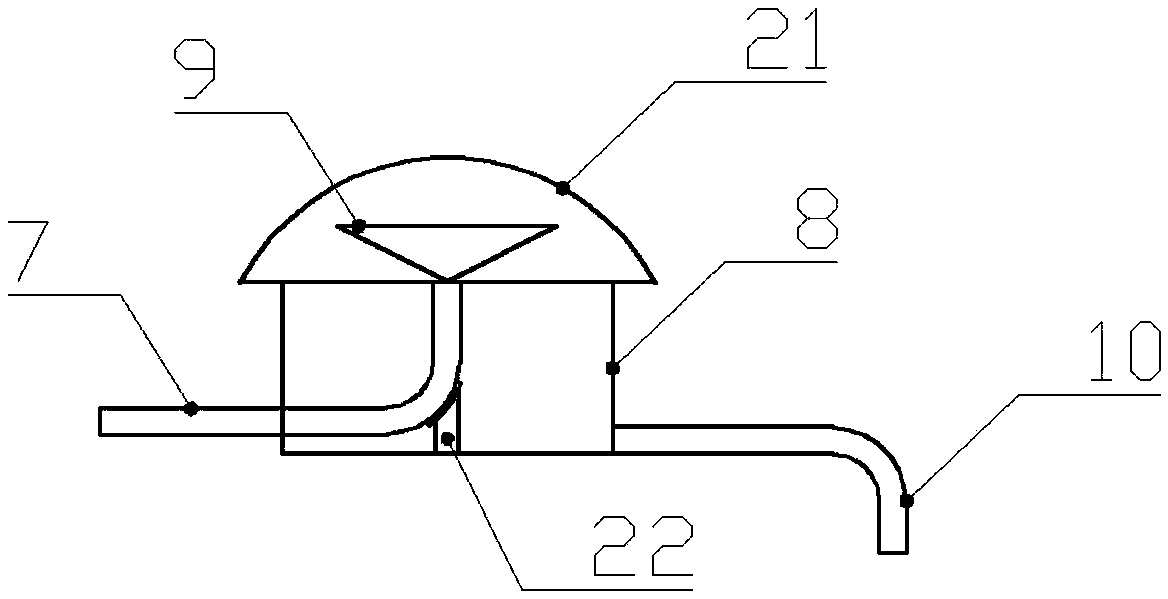

[0062] figure 1 Shows the structure diagram of the device provided by the present invention.

[0063] An electric heating device for producing high-purity ultrafine spherical silicon powder includes a powder silo 1, an atomization device, a high-temperature melting furnace 20, a cooling silo 17, a finished product warehouse 18 and a dust removal system.

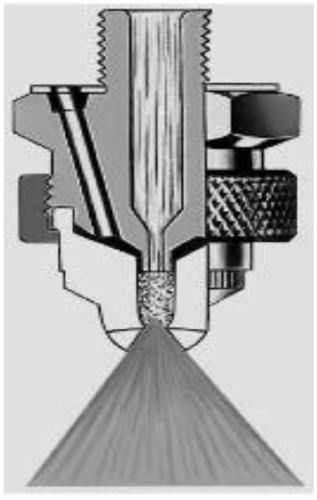

[0064] The atomization device includes an atomizer 11 and a compressed air channel 2; the discharge port of the fine powder silo 1 is connected to the atomizer 11 through a tube, which is connected to the compressed air channel 2; a valve is provided at the lower part of the fine powder silo 1.

[0065] The atomizer 11 is a compressed gas atomizer, which is the prior art, and its structure is as figure 2 Shown. The atomizer is wrapped with a cooling pipe, which is used to cool the atomizer and make it work in a lower temperature range.

[0066] The upper part of the high temperature melting furnace 20 is a cylindrical shape with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com