High temperature resistant dust collector

A high temperature resistant, dust collector technology, applied in chemical instruments and methods, dispersed particle filtration, filtration and separation, etc., can solve the problems of inability to handle high temperature gas, reduce the use range of dust removal devices, etc., to achieve high dust removal efficiency, system safety and stability The effect of operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred embodiment of the present invention will be specifically introduced below in conjunction with the accompanying drawings.

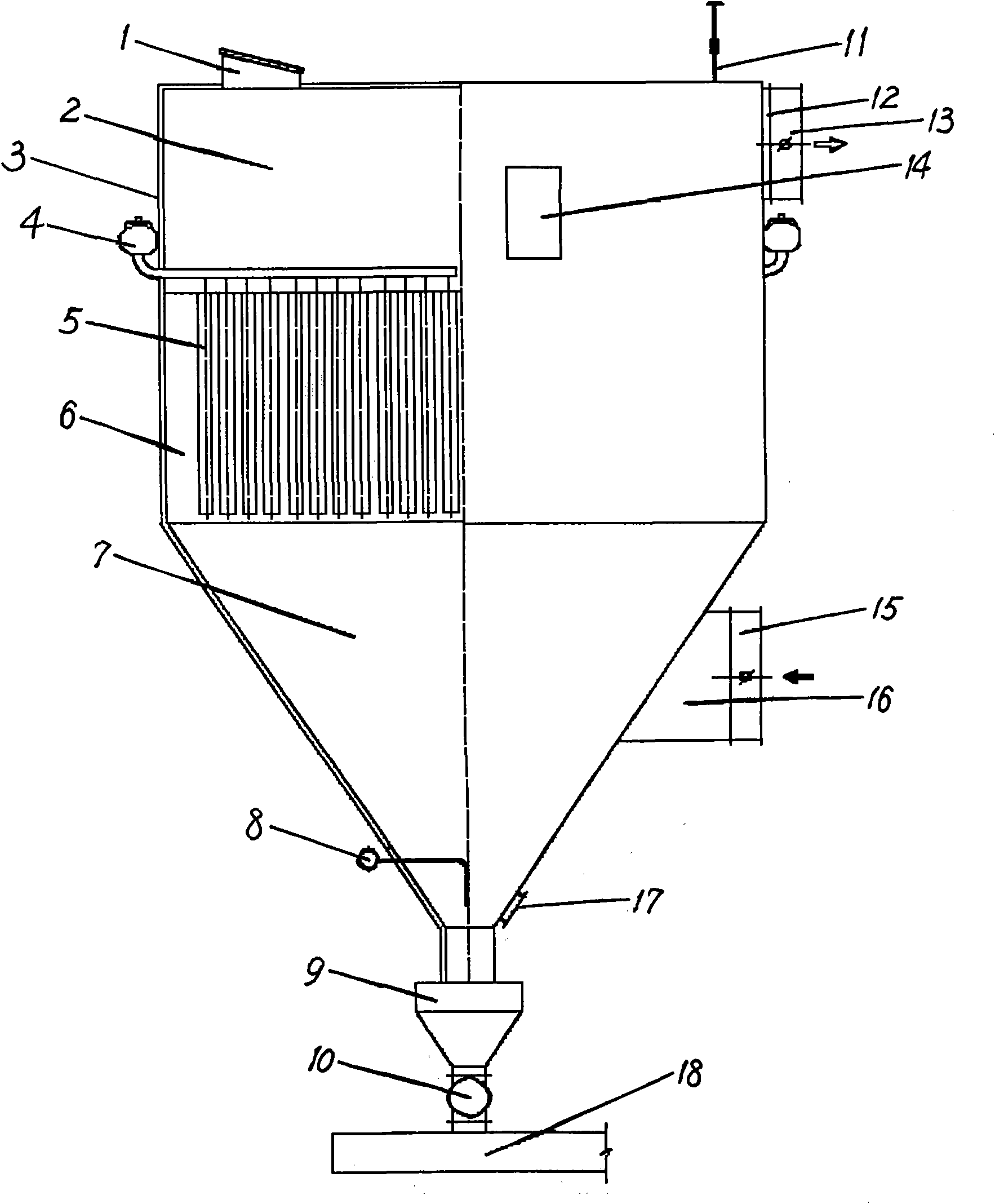

[0030] Referring to the accompanying drawings, a high temperature resistant dust collector of the present invention consists of an explosion relief valve 1, a clean room 2, an insulation shell 3, a pulse injection device 4, a metal filter cartridge 5, a filter chamber 6, an ash hopper 7, and an air cannon 8 , cooling small bucket 9, ash discharge device 10, diffuser 11, purification gas outlet 12, outlet valve 13, maintenance door 14, inlet valve 15, dusty gas inlet 16, gas replacement device 17 and ash delivery device 18.

[0031] According to the flue gas volume of different scales, the dust collector can be combined in units or modules, and each unit is equipped with an air outlet valve and an air inlet valve; multiple dust collector units or modules can share a set of compressed air pipelines and storage Gas tank, and set a set of as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com