Dust collector for textile machine

A technology of textile machines and dust collectors, which is applied in the direction of removing smoke and dust, cleaning methods and utensils, and cleaning hollow objects. It can solve the problems of untimely removal of dust particles and affect the dust removal effect. The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

[0021] The reference signs in the drawings of the description include:

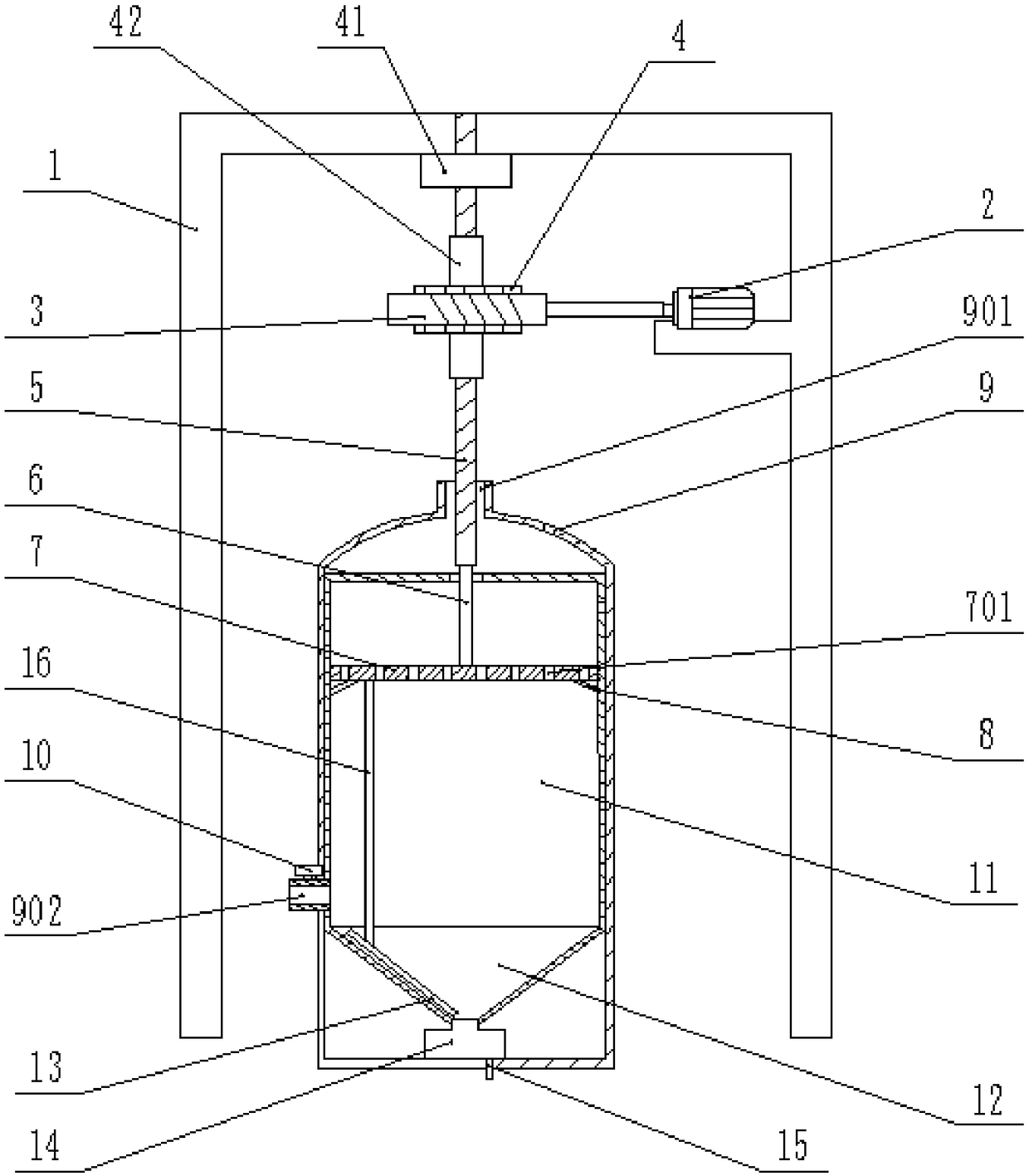

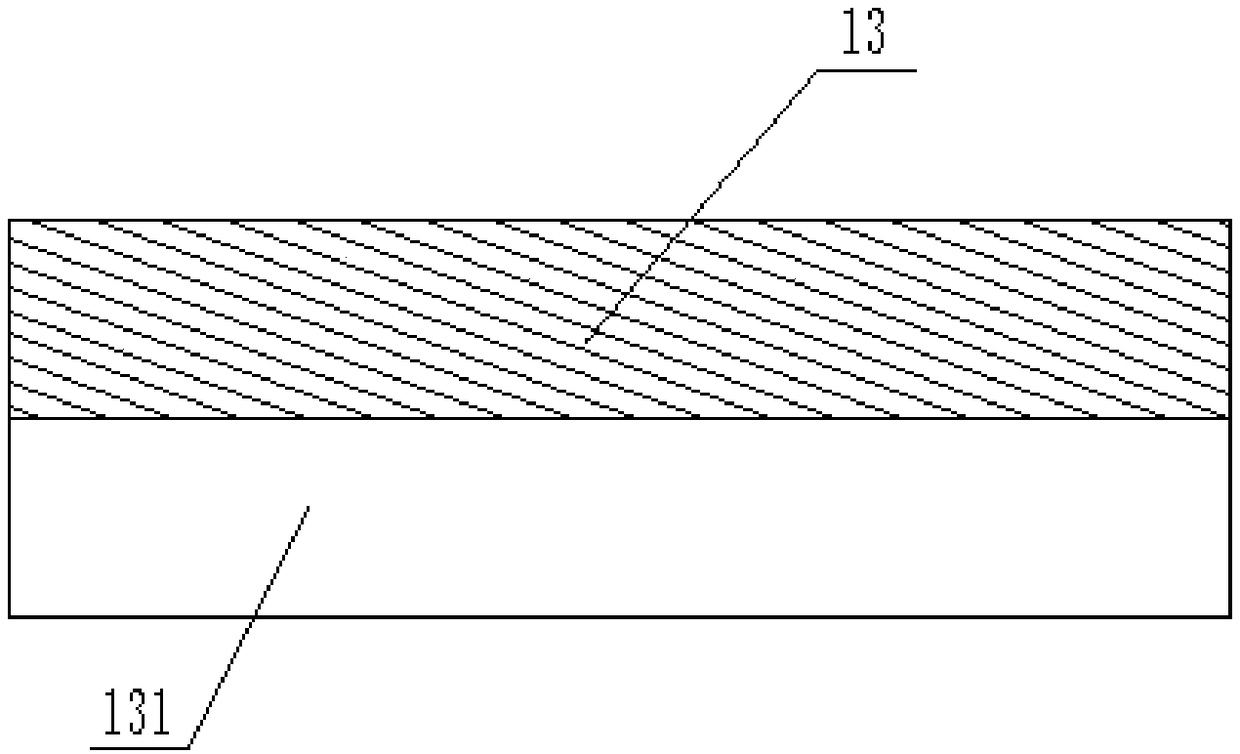

[0022] Frame 1, motor 2, worm 3, worm wheel 4, nut 41, spline sleeve 42, screw rod 5, push rod 6, pressure plate 7, air outlet 701, scraper 8, dust removal housing 9, air outlet 901, air inlet Air pipe 902, one-way valve 10, settling bucket 11, dust bucket 12, dust scraper 13, drainage groove 131, dust box 14, dust pipe 15, telescopic shaft 16.

[0023] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0024] The dust collector for textile machines includes a frame 1, a power mechanism and a dust removal housing 9, the power mechanism includes a motor 2, a worm 3, a worm wheel 4, a nut 41 and a screw 5, and the motor 2 and the nut 41 are fixed on the frame 1 , the output shaft of the motor 2 is fixed to the worm 3, the worm 3 meshes with the worm wheel 4, a spline sleeve 42 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com