Non-woven fabric automatic slitting and winding machine

A non-woven, winding machine technology, applied in the direction of winding strips, textiles and papermaking, textile material cutting, etc., can solve problems affecting product quality, punching or embossing deformation, etc., to achieve high-quality winding , to solve the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

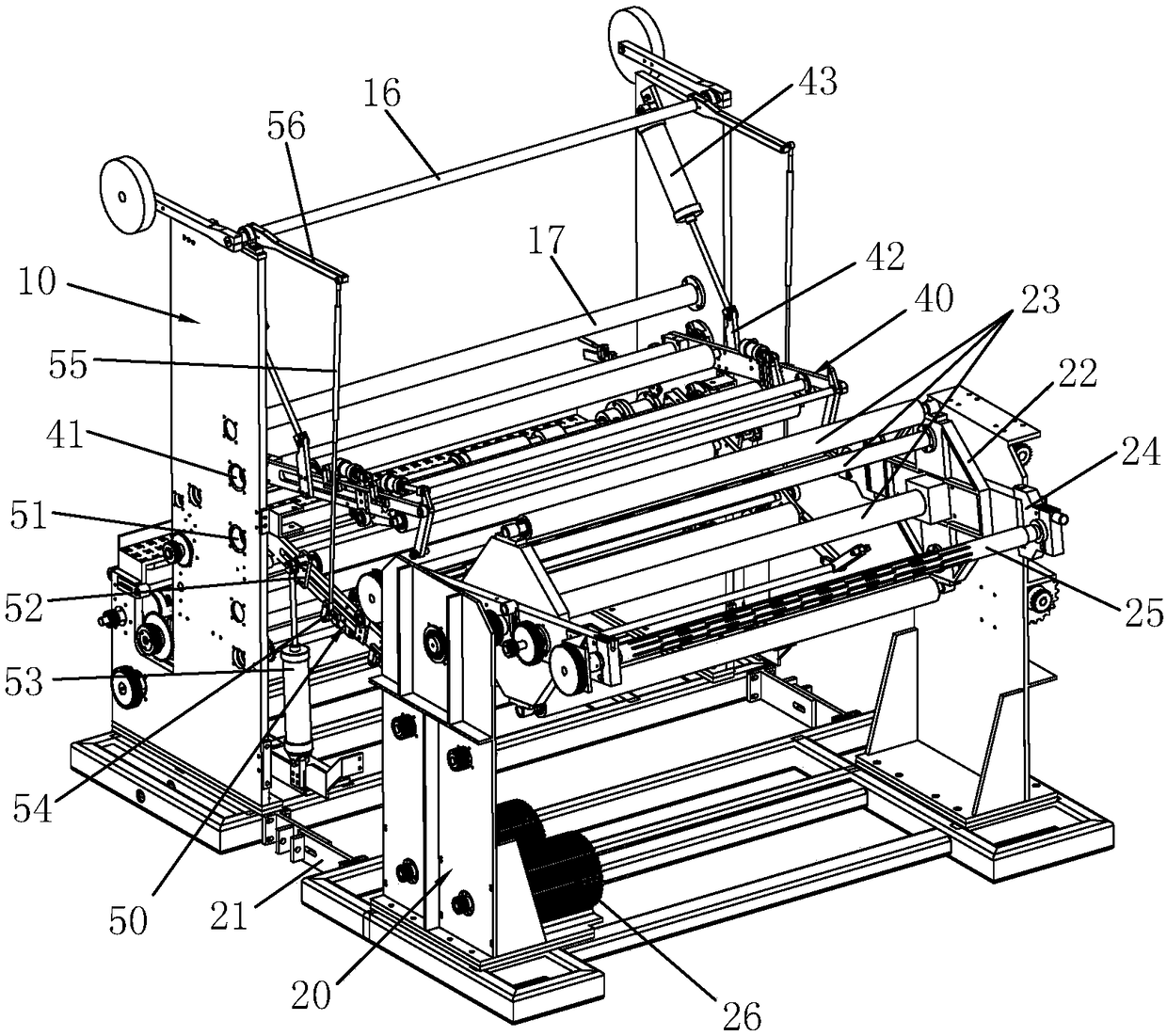

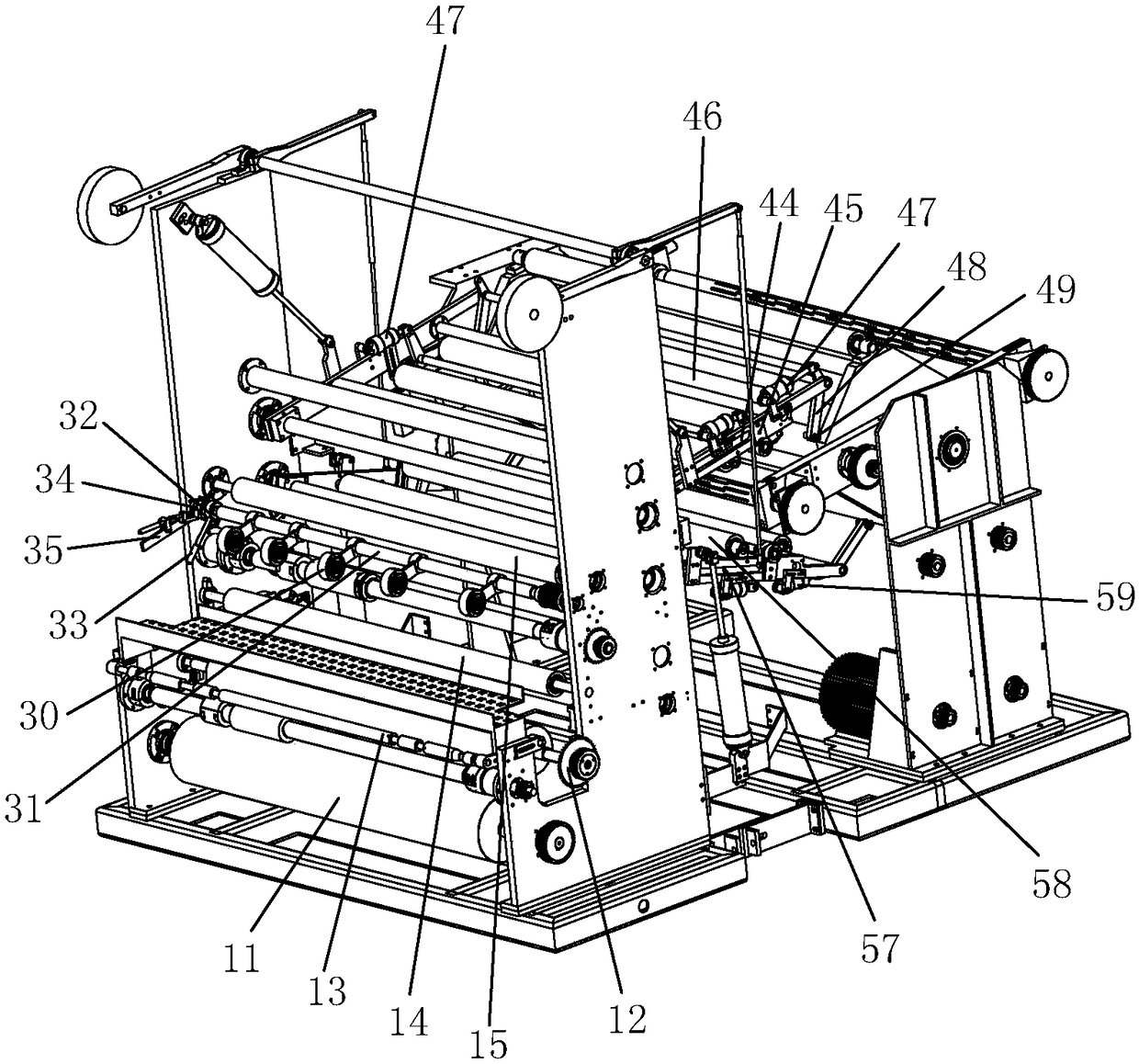

[0011] Such as figure 1 with figure 2 As shown, the non-woven fabric automatic slitting and winding machine of the present invention includes a front support 10 and a rear support 20, and a connecting block 21 is used to connect the front support 10 and the rear support 20. A cloth roll 11 is arranged at the lower front of the front support 10, and the cloth roll 11 is used for rolling non-woven fabrics, and a guide roller 12 is arranged at the upper end of the cloth roll 11, and the guide roll 12 is used for guiding non-woven fabrics. A cloth pressing bar 13 is arranged between the cloth rolling cylinder 11 and the guide roller 12, and the cloth pressing bar 13 is used to ensure smooth movement of the nonwoven fabric.

[0012] Such as figure 1 with figure 2 As shown, guide roller 14 and guide roller 15 are respectively provided with guide roller 12 upper ends, and between guide roller 14 and guide roller 15, slitting cutter 30 is arranged, and slitting cutter 30 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com