Warping machine

A warping machine and warp beam technology, applied in the field of warping machines, can solve the problems of yarn falling off and winding beside the original yarn roll, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

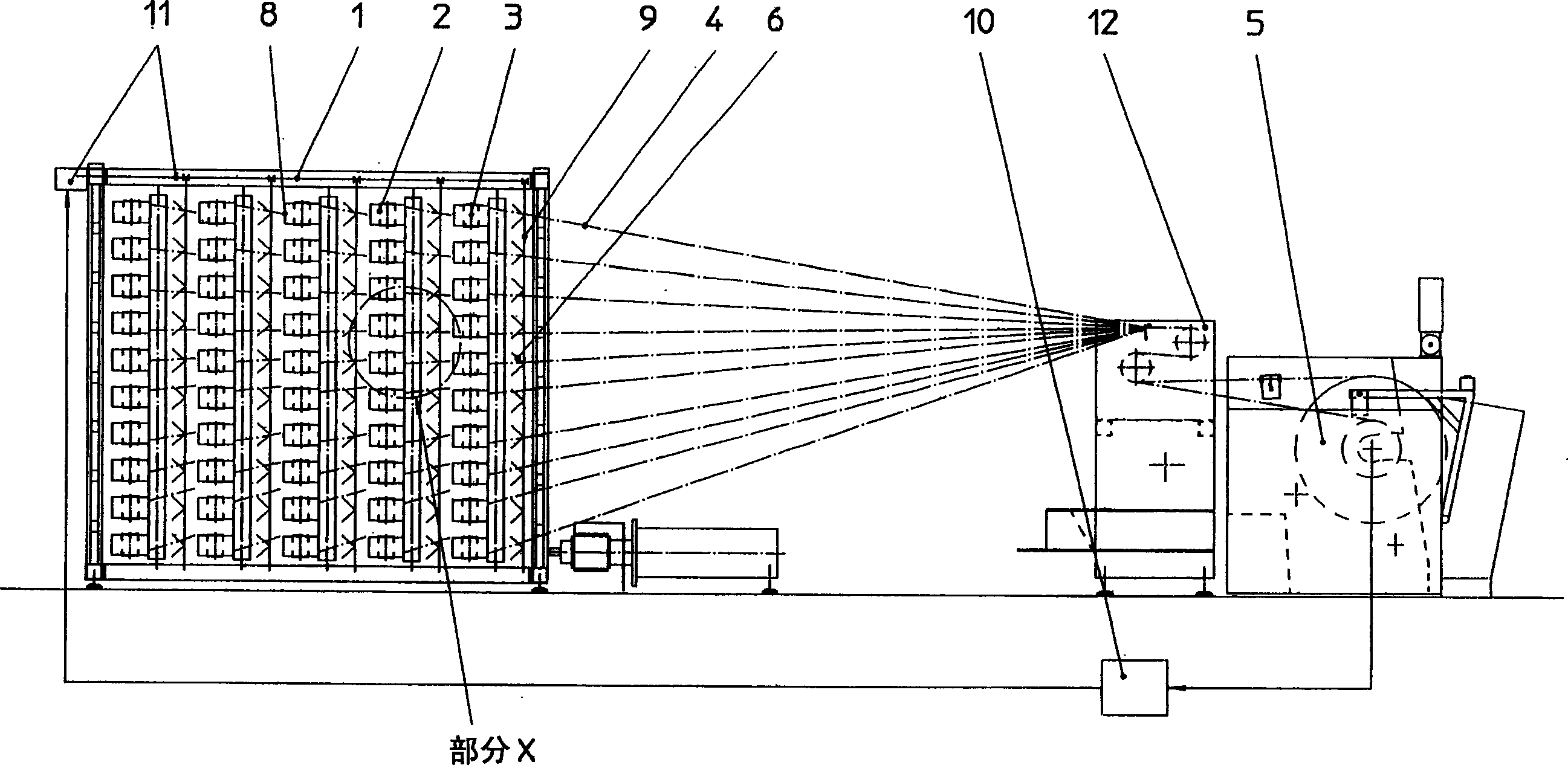

[0023] figure 1 The entire configuration of the warping machine of the present invention is shown in . The warping machine has a bobbin holder 1 , a pre-drawing device 12 and a winding device with a warp beam 5 . The bobbin holder 1 has a plurality of bobbin holders 2 whose axes 3 are oriented vertically and which are fastened to a substantially horizontally arranged bobbin holder. The yarn 4 is drawn from the bobbin 2 and delivered to the warp beam 4 by means of a pre-drawing device 12, said warp beam being pivoted in a device by means of which the warp beam is rotated to achieve the yarn 4 Winding (forward run).

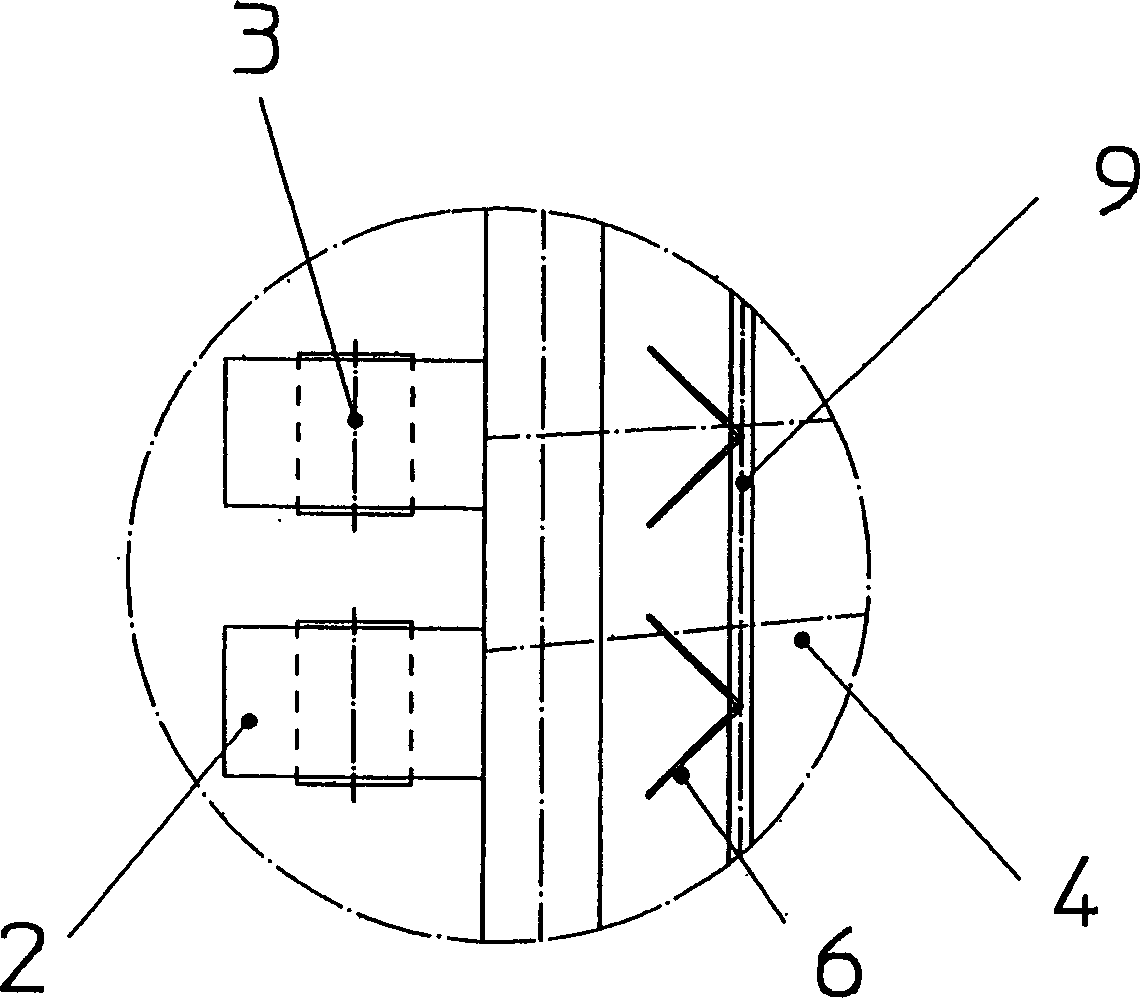

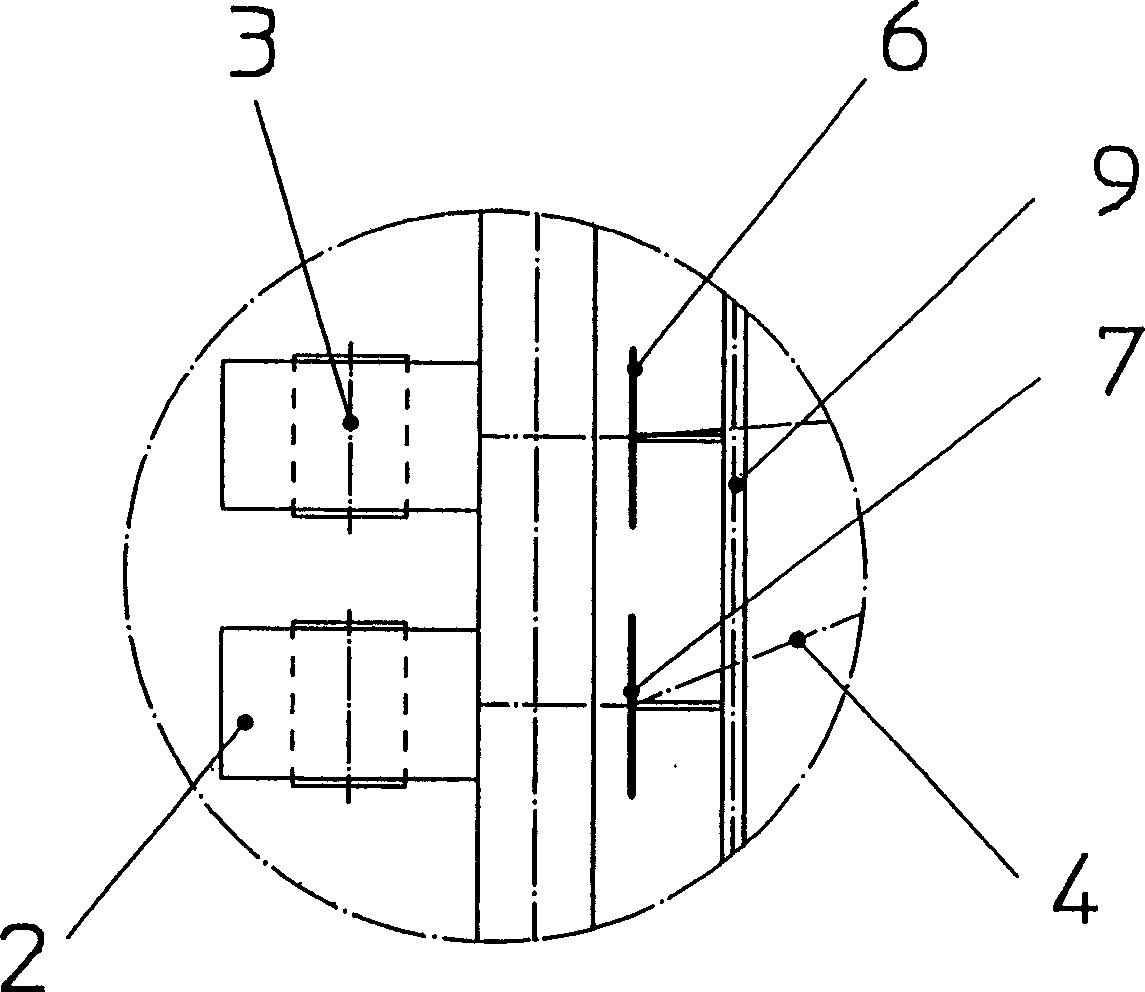

[0024] In addition, the bobbin holder also has a plurality of thread guides 6, the number of which is equal to the number of bobbins provided. The yarn guides 6 are arranged on rods 9 or rails or beams and are respectively located within the area of each bobbin 2 of the bobbin holder 1 . Wherein the yarn guide 6 is fixedly connected with the rod member 9 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com