Knife rest for multi-wire cutting machine and multi-wire cutting machine with same

A multi-wire cutting machine and tool holder technology, which is applied to fine working devices, working accessories, stone processing equipment, etc. Wire spindle steel wire, reducing the cutting accuracy of thicker materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

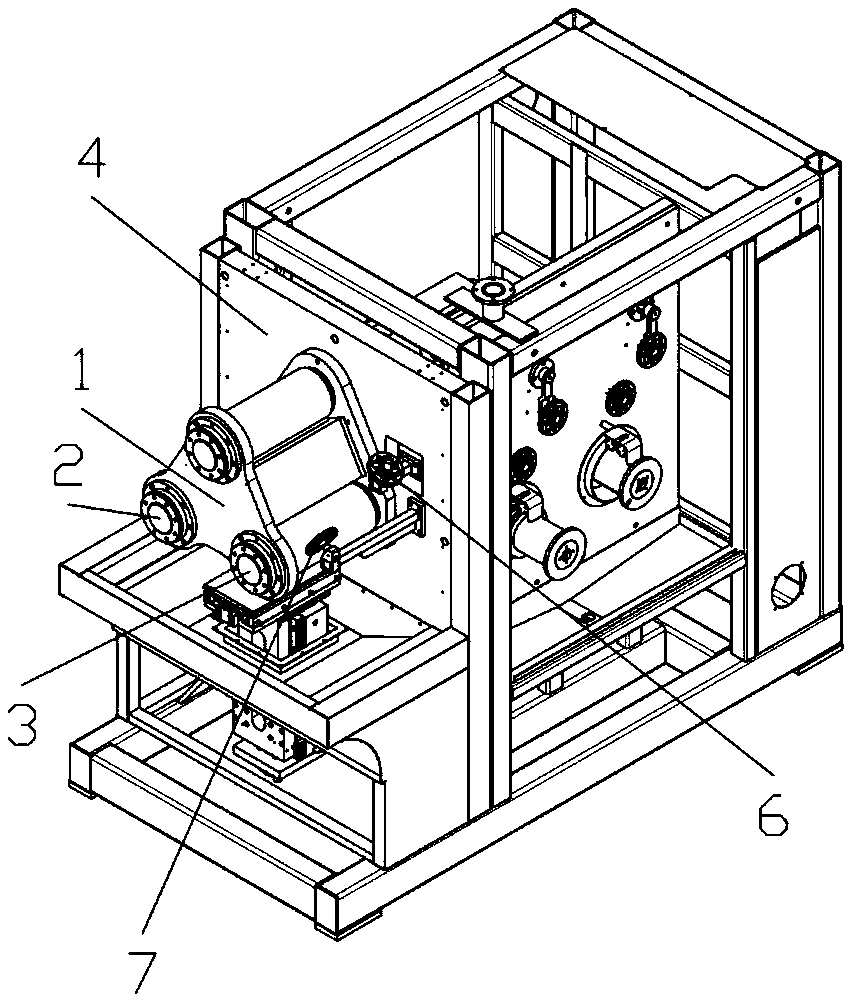

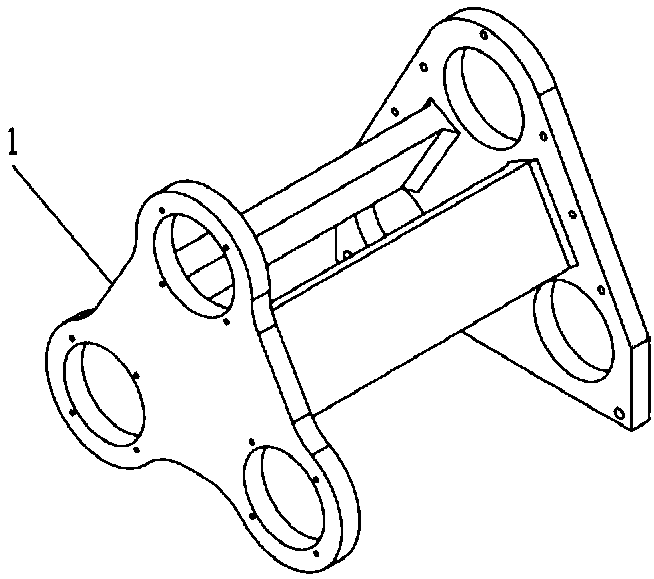

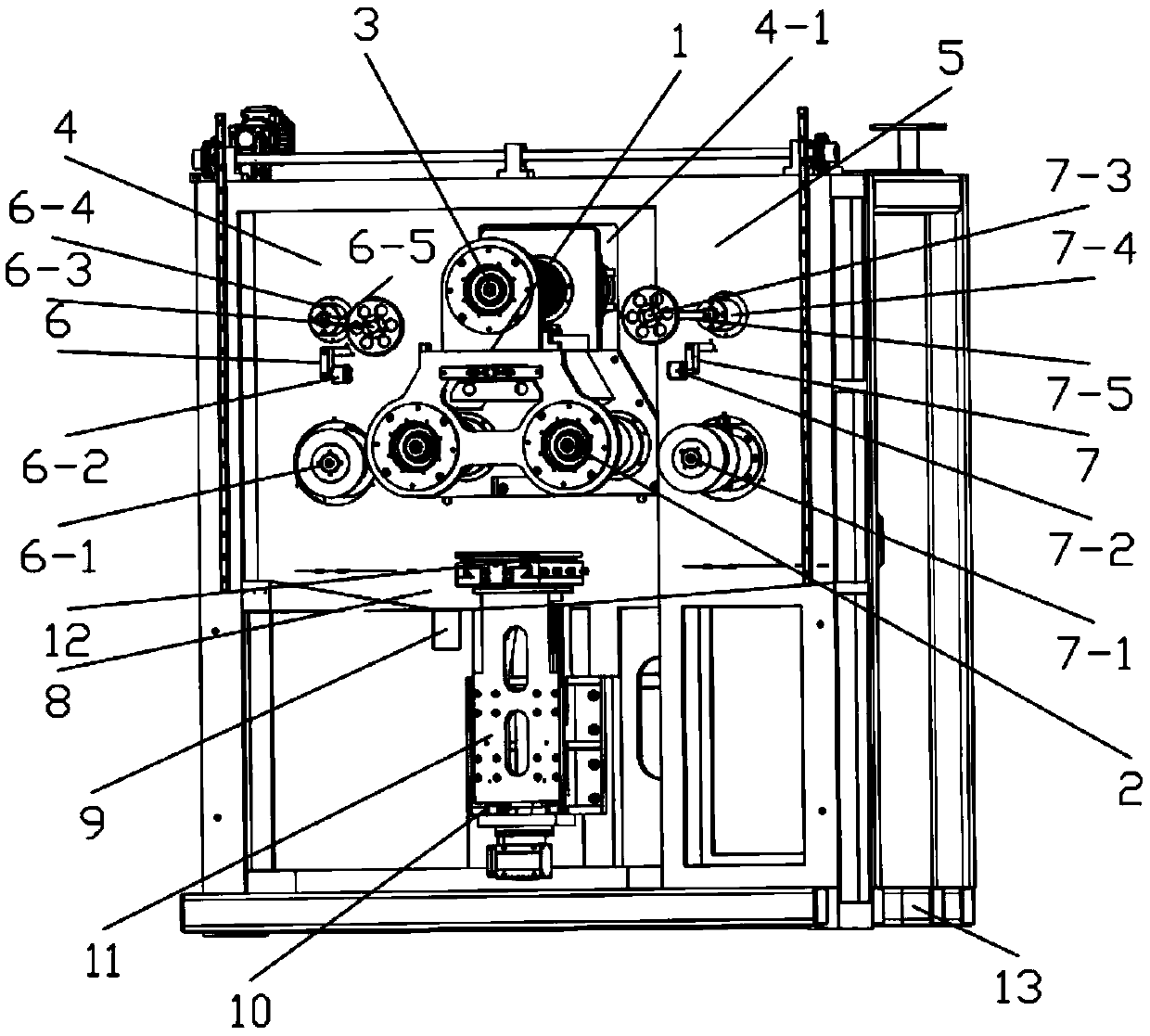

[0431] Such as Figure 5 to Figure 7 As shown, this embodiment provides a knife rest for multi-wire cutting machine, the knife rest 1 is divided into a knife rest lower body 1-1 and a knife rest upper body 1-2, the knife rest lower body 1-1 and the The tool holder upper body 1-2 is connected in rotation through the shaft body assembly 1-3.

[0432] This embodiment adopts the technical means that the tool rest is divided into a lower body and an upper body of the tool rest, and the lower body of the knife rest and the upper body of the knife rest are connected by a shaft assembly through a technical means, so it can be aimed at For different thickness slicing requirements, especially large thickness slicing requirements, adjust the spacing of steel wires, and at the same time, if Figure 30 As shown, the upper body of the tool holder can be rotated and adjusted according to the direction of the upper steel wire, so that the direction of the groove of the upper winding spindle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com