Automatic winding machine for producing magnetic core

An automatic winding machine and magnetic core technology, applied in the direction of coil manufacturing, can solve the problems of low production efficiency, scattered coils, low precision, etc., and achieve the effects of high work efficiency, simple equipment and reliable winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

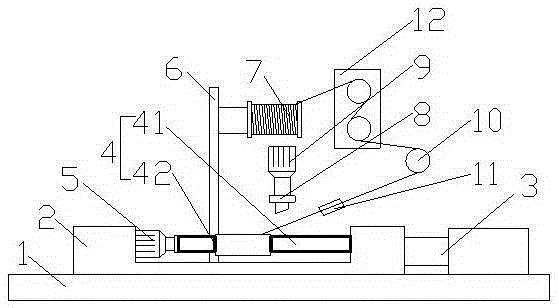

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an automatic winding machine for producing magnetic cores proposed by the present invention.

[0013] refer to figure 1 , the present invention proposes an automatic winding machine for producing magnetic cores, comprising: a support body 1, a winding frame 2, a first driving device 3, a winding device 4, a second driving device 5, a pay-off stand 6, a Wire wheel 7, wire breaking device 8 and the third driving device 9; support body 1 is provided with a chute penetratingly along its length direction, and winding skeleton 2 is arranged on the support body 1, and extends downwards to form and described chute Cooperating with the slide rail, the first driving device 3 can drive the winding frame 2 to slide in the chute; the winding device 4 is arranged on the winding frame 2, and the winding device 4 includes a first winding body 41 and a second winding body 41. Two winding bodies 42, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com