Material belt subpackaging machine, material belt subpackaging machine system and material belt subpackaging method

A packing machine and tape technology, which is applied in thin material processing, transportation and packaging, electrical components, etc., can solve the problems of tray packing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

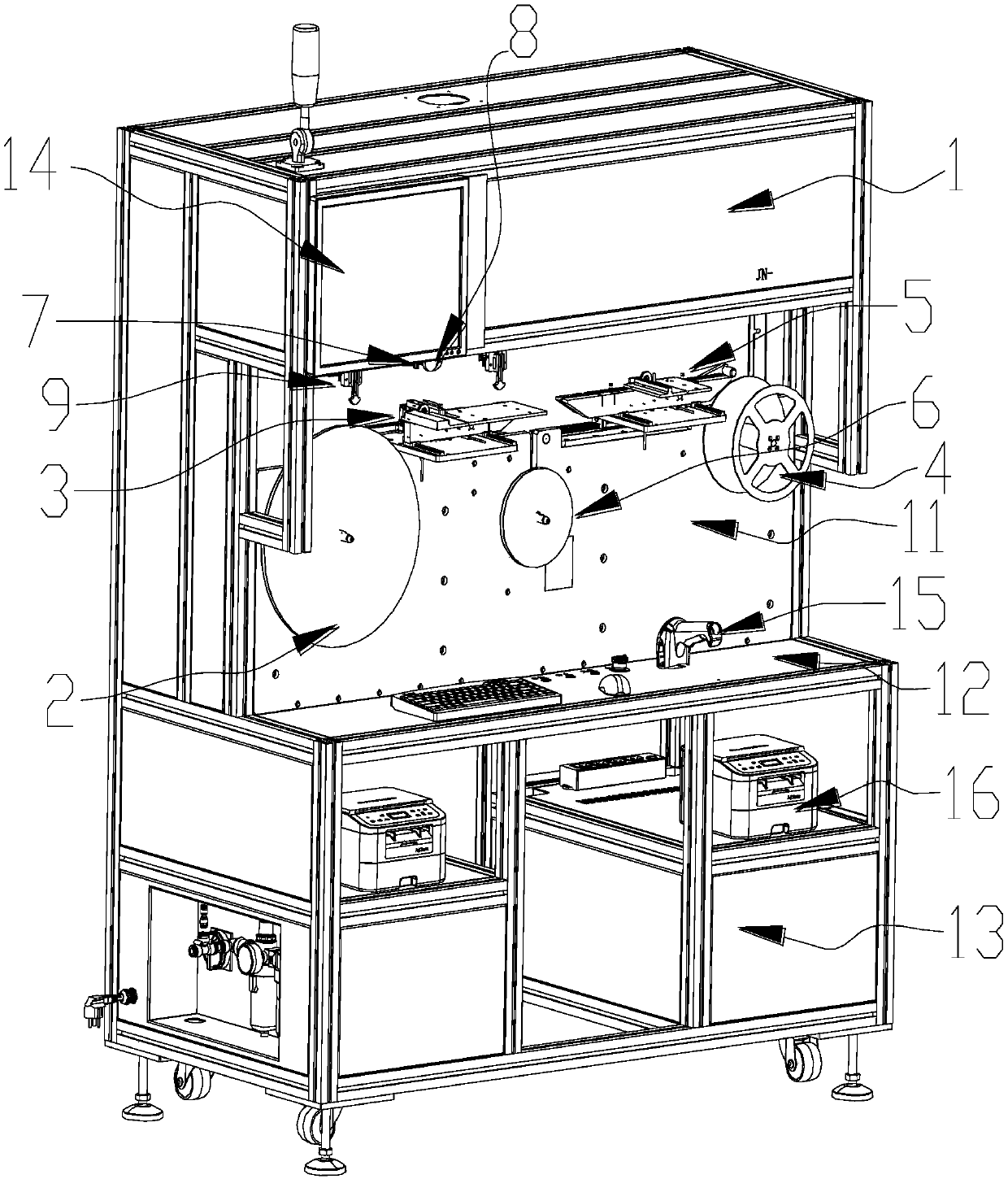

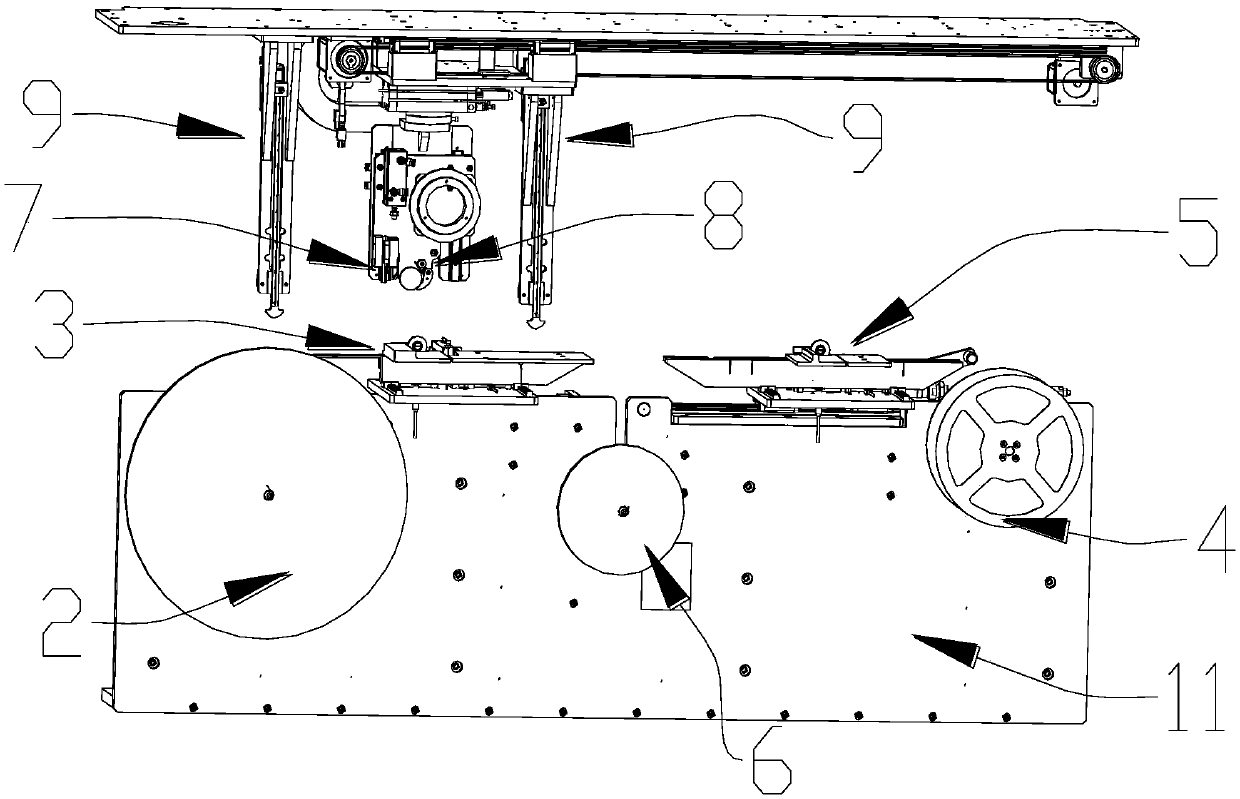

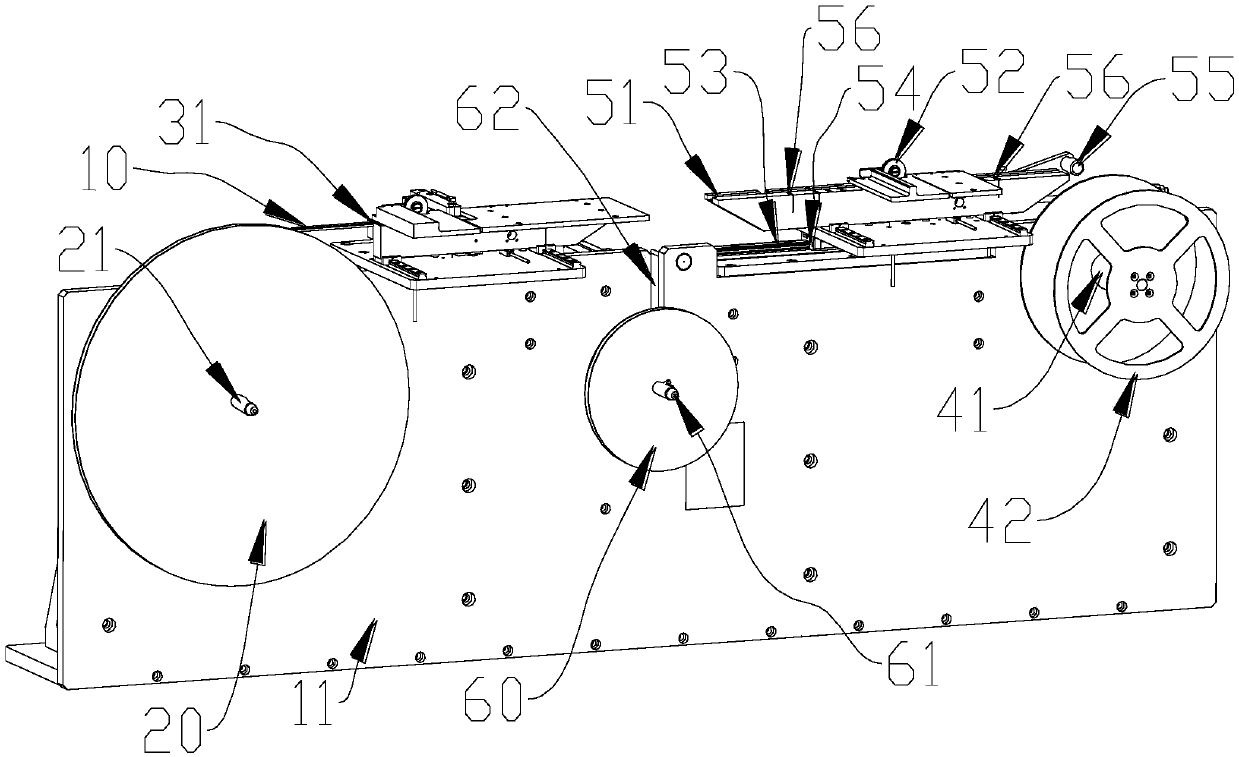

[0060] An embodiment of the present invention provides a tape packing machine system, which combines Figure 1 to Figure 7 As shown, the material tape distribution machine system includes: material tape distribution machine, barcode reader and barcode printer. The material tape distribution machine has a control module, and the control module is connected to the producer's server through the network communication module to obtain material data. The reader scans the barcode data on the tray to be loaded, and then uploads the barcode data to the central server (MES system) of the producer, and the server can send the tape information (that is, the distribution information) according to the barcode data, such as: The number of reels, the number of tapes per reel, the model of the material, the work order information, and if there is any surplus, there will be return information, etc. According to the tape information, it is possible to determine the actual amount of tape that nee...

Embodiment 2

[0100] This embodiment is based on the hardware foundation of the tape packing machine system in the above-mentioned embodiment 1, and provides a kind of tape packing method, refer to Figure 8 As shown, the specific method steps are as follows.

[0101] Step 1001: Obtain the barcode data of the tray to be divided into which is read by the barcode reader, upload the barcode data to the server, and receive the tape information fed back by the server according to the barcode data.

[0102] In this step, use the barcode reader to scan the barcode data on the tray to be divided into, and then upload the barcode data to the producer's central material information), such as: the number of reels, the number of tapes per reel, the model of the material, work order information, and if there is any surplus, there will be return information, etc. According to the tape information, it is possible to determine the actual amount of tape that needs to be packaged, and through the unified ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com