Automatic delivery method for cone yarn dyeing powdery dye and special equipment therefor

A technology of powdery dye and special device, which is applied in the direction of processing textile material equipment configuration, textile material processing, textile processing machine accessories, etc., can solve the accuracy of feeding, the error of weighing instrument and judgment is difficult to guarantee, and the technical data cannot be completed online. Calling and checking, inability to realize computerized information management of technical files, etc., to achieve the effect of one-time accurate production, real-time production, reduction of pollution and damage to operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

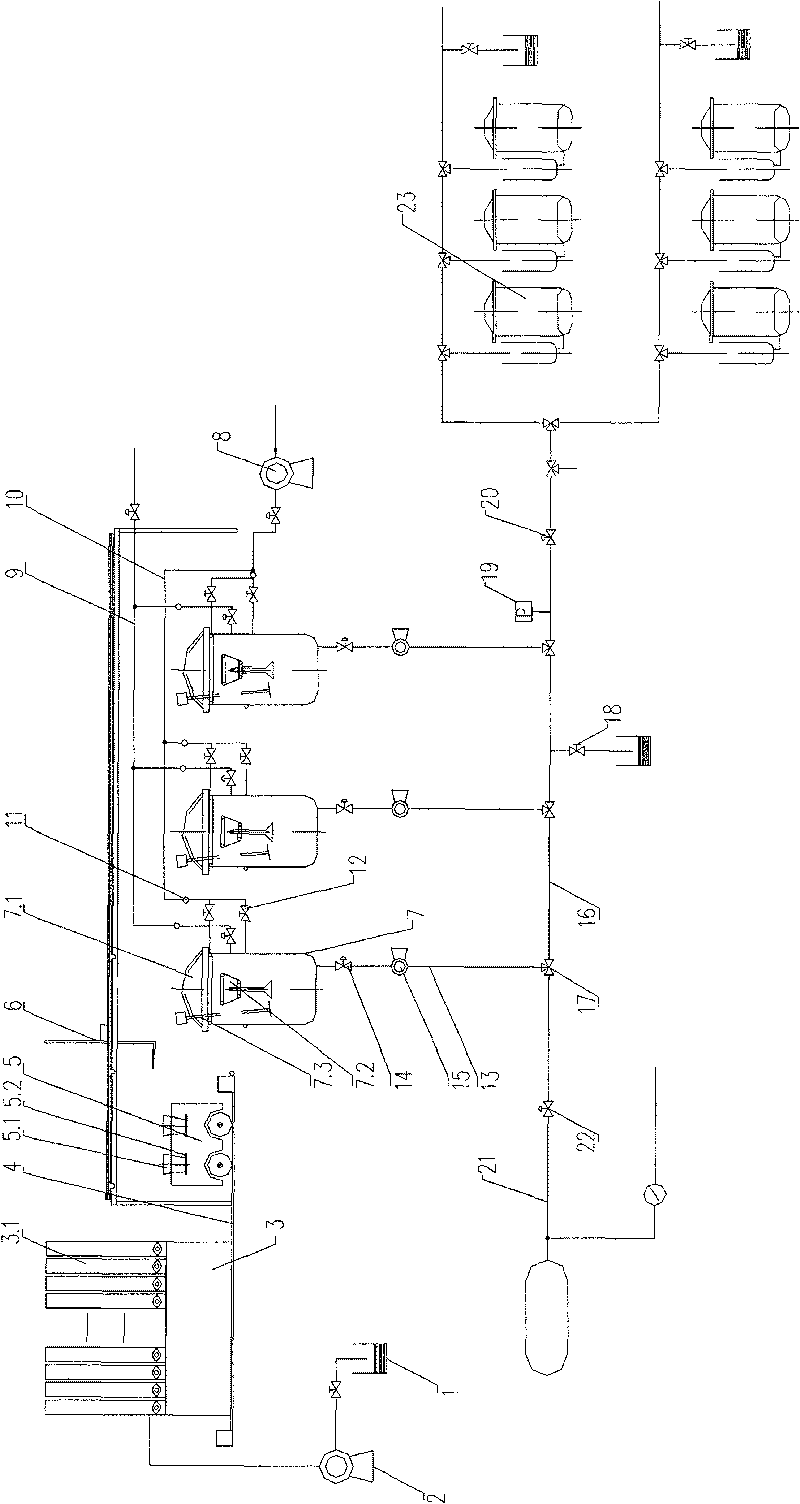

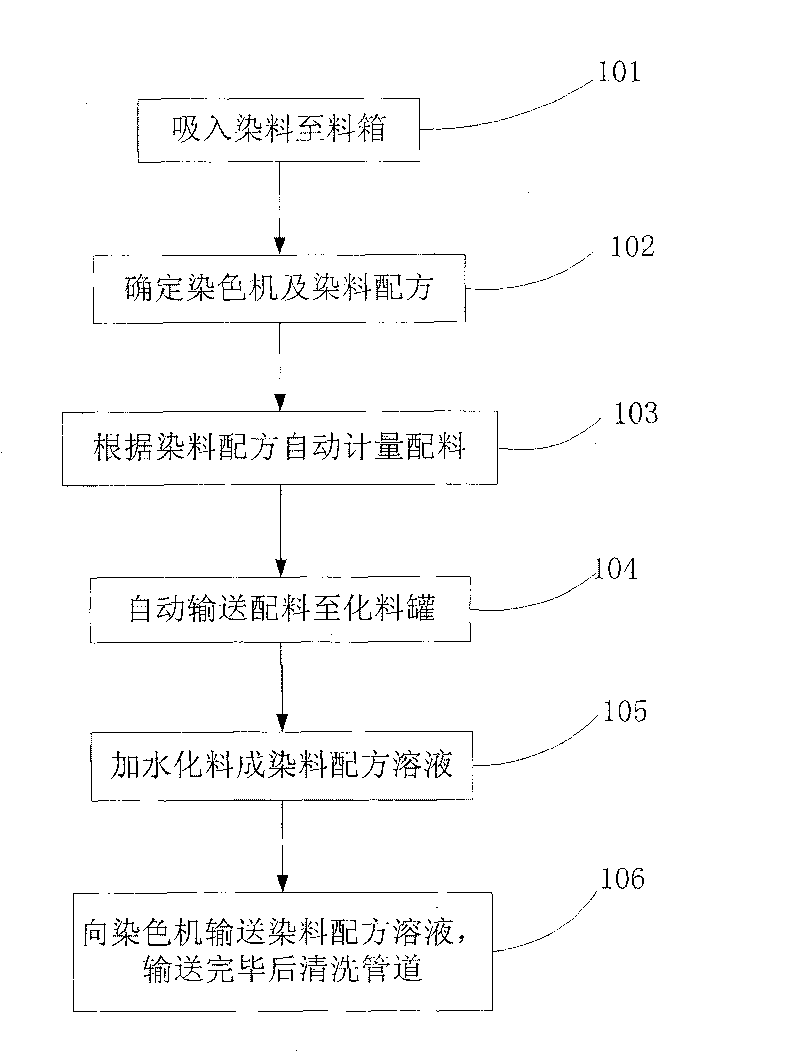

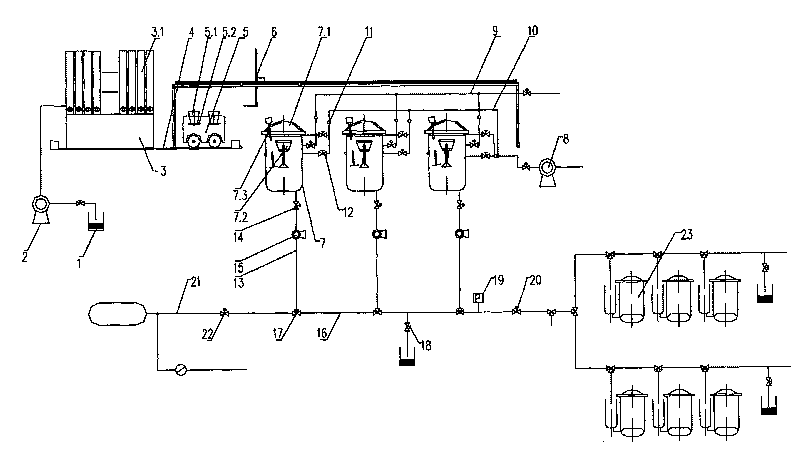

[0036] Such as figure 1 Shown is a special device for the automatic distribution method of cheese dyeing dyes, including a raw material barrel 1 and a chemical tank 7, an automatic batching machine 3, a weighing trolley 5 and a robot 6.

[0037] The automatic batching machine 3 includes a support, a feed box, a feeding mechanism, a double-screw feeding mechanism and an opening and closing cover mechanism (not shown in the figure). In order to prevent the dye agglomeration in the material box, there is an oscillating mechanism in the material box.

[0038] The weighing trolley 5 includes a car body, an electronic balance 5.2 and a transmission mechanism (not shown in the figure) disposed therein, and a material basin 5.1 disposed above the electronic balance 5.2.

[0039] The chemical material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com