Intelligent grain threshing integrated device

A kind of grain and intelligent technology, which is applied in threshing equipment, drying gas arrangement, and preservation of seeds through drying, etc., can solve the problems of low degree of integration, labor and time costs, adverse effects of grain moisture-proof work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

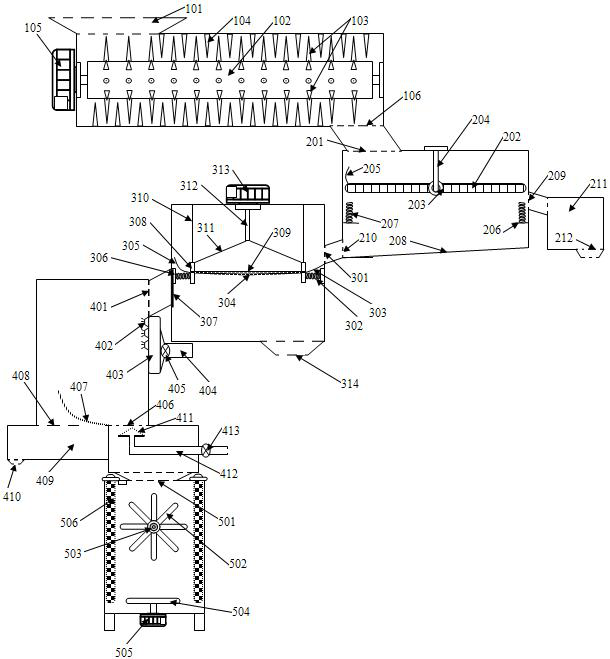

[0035] Further explanation in conjunction with accompanying drawings: Figure 1-Figure 5 The integrated smart grain threshing device of this embodiment includes a straw crushing chamber, a screening unit, a net mill room, a grain raising unit, a barn and a bran grinding room.

[0036] Such as figure 1 As shown, the straw crushing chamber includes a crushing chamber casing, a grain input port 101, a straw crushing shaft 102, an inner crushing cone 103, an outer crushing cone 104, a crushing motor 105, and a crushing chamber discharge port 106; It is a horizontal hollow cylinder structure, the grain material input port is set on the top wall of the crushing chamber shell, the straw crushing shaft is placed horizontally in the crushing chamber shell, and 12 rows of inner crushing cones (8 per row) are arranged on the straw crushing shaft 12 rows of outer crushing cones (10 per row) are arranged on the inner wall of the crushing chamber shell at a position spaced from each row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com