Patents

Literature

41results about How to "Avoid miscasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic delivery method for cone yarn dyeing powdery dye and special equipment therefor

ActiveCN101476222AAvoid miscastingAvoid overshootingControlling ratio of multiple fluid flowsTextile treatment machine arrangementsWater pipeDyeing

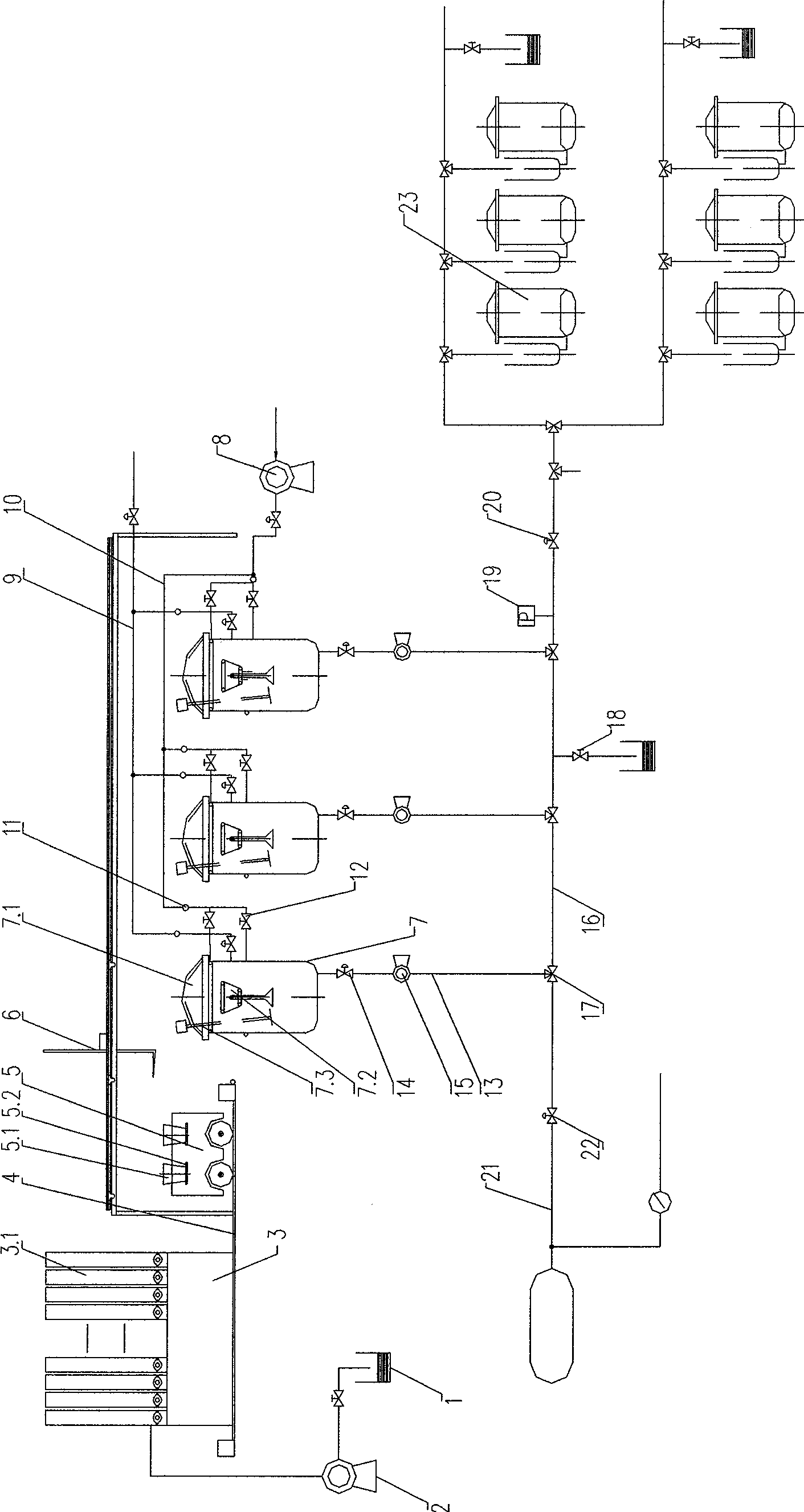

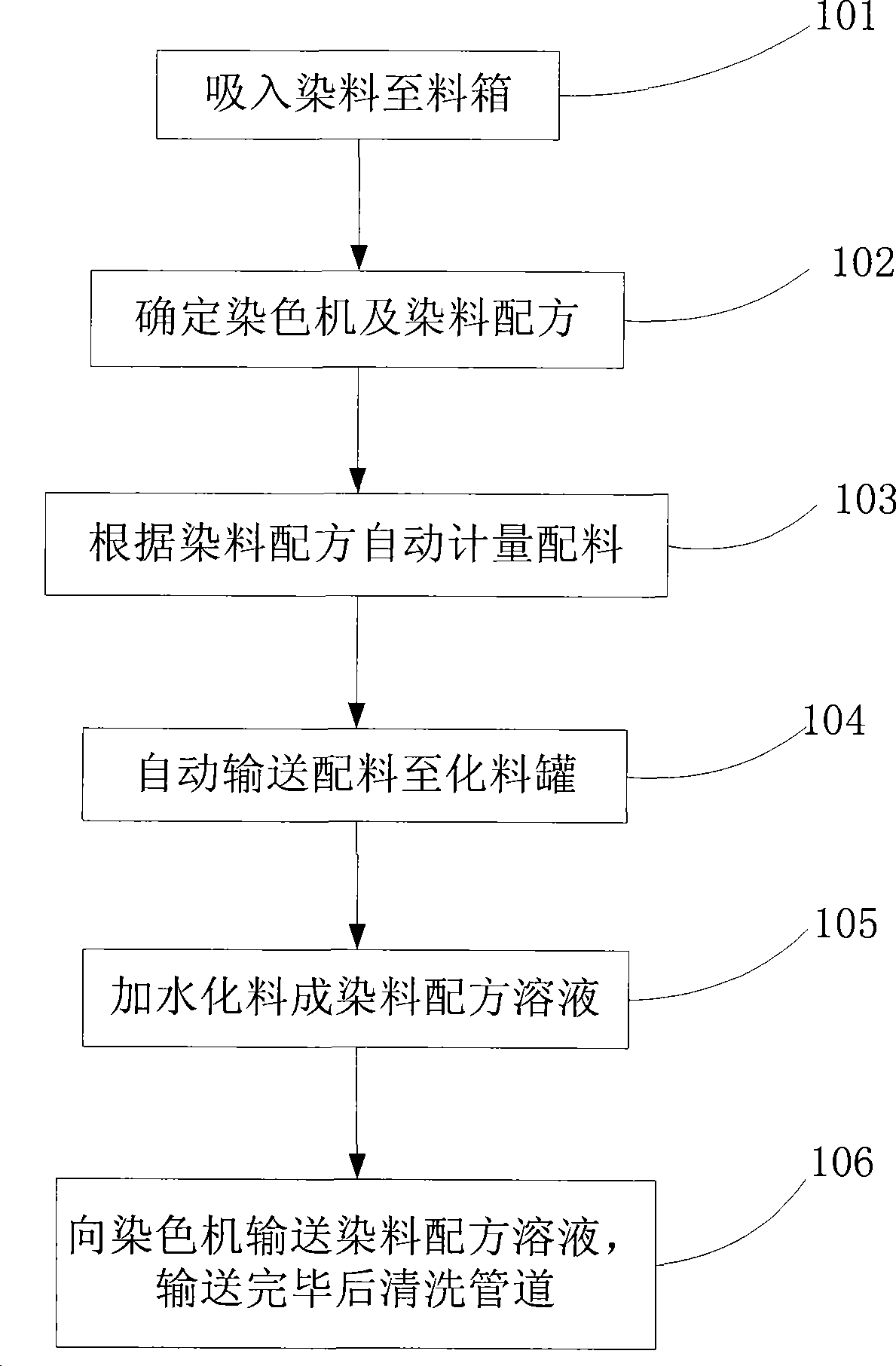

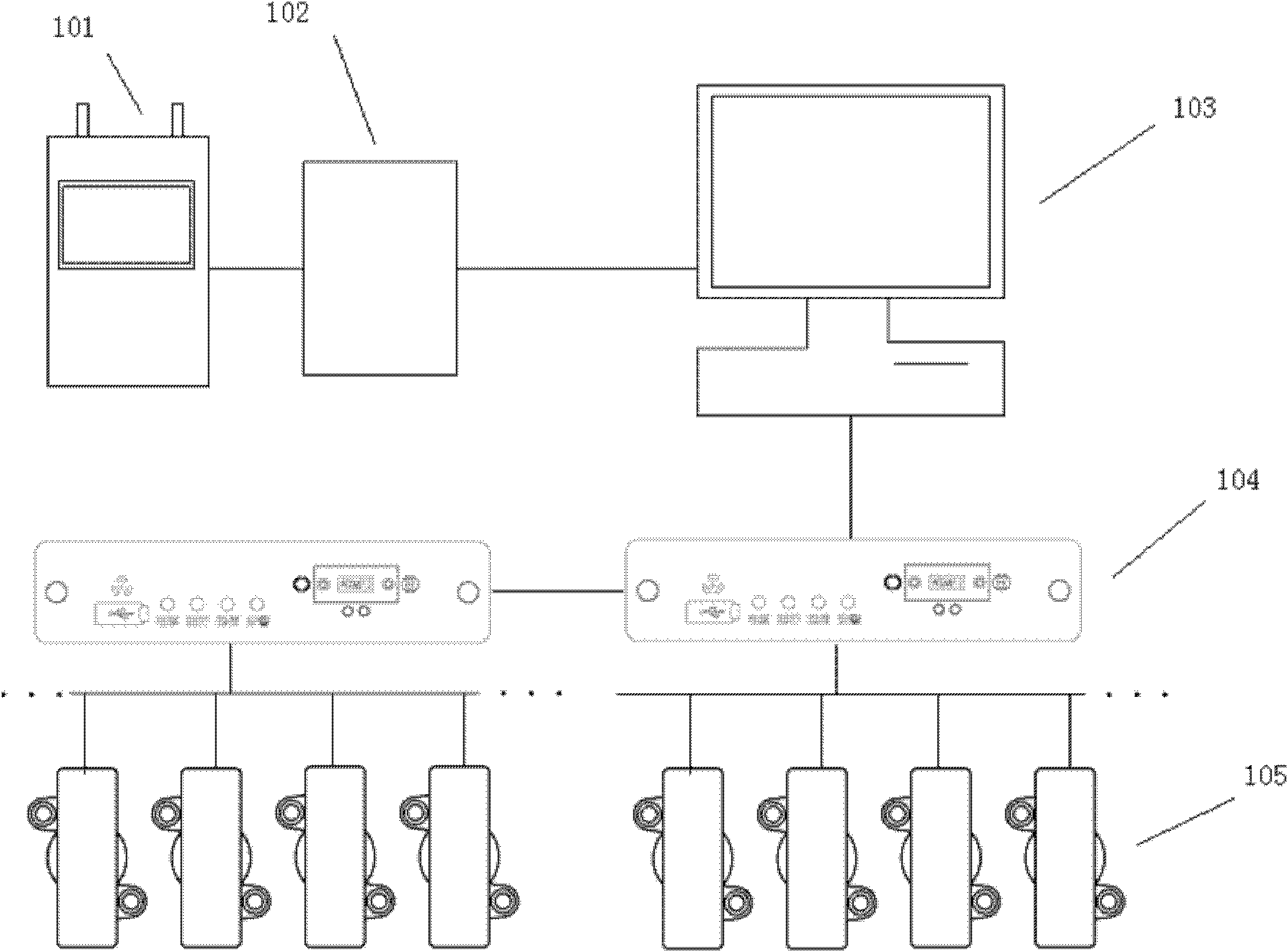

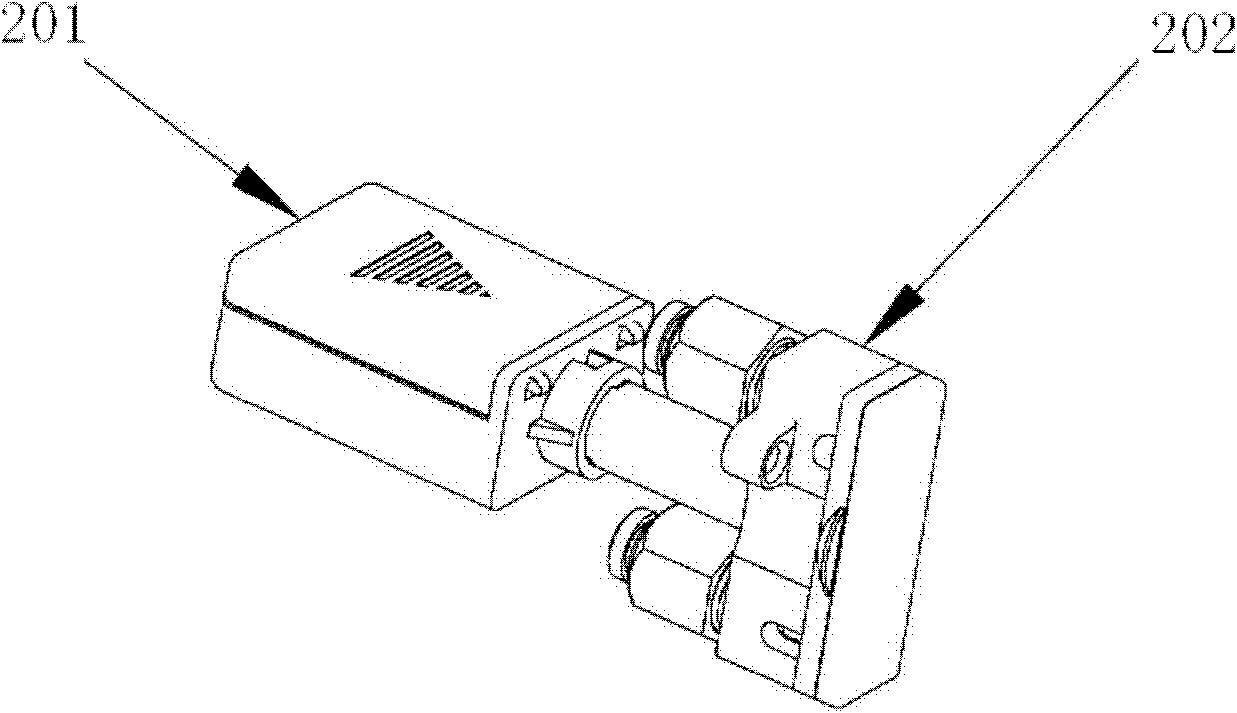

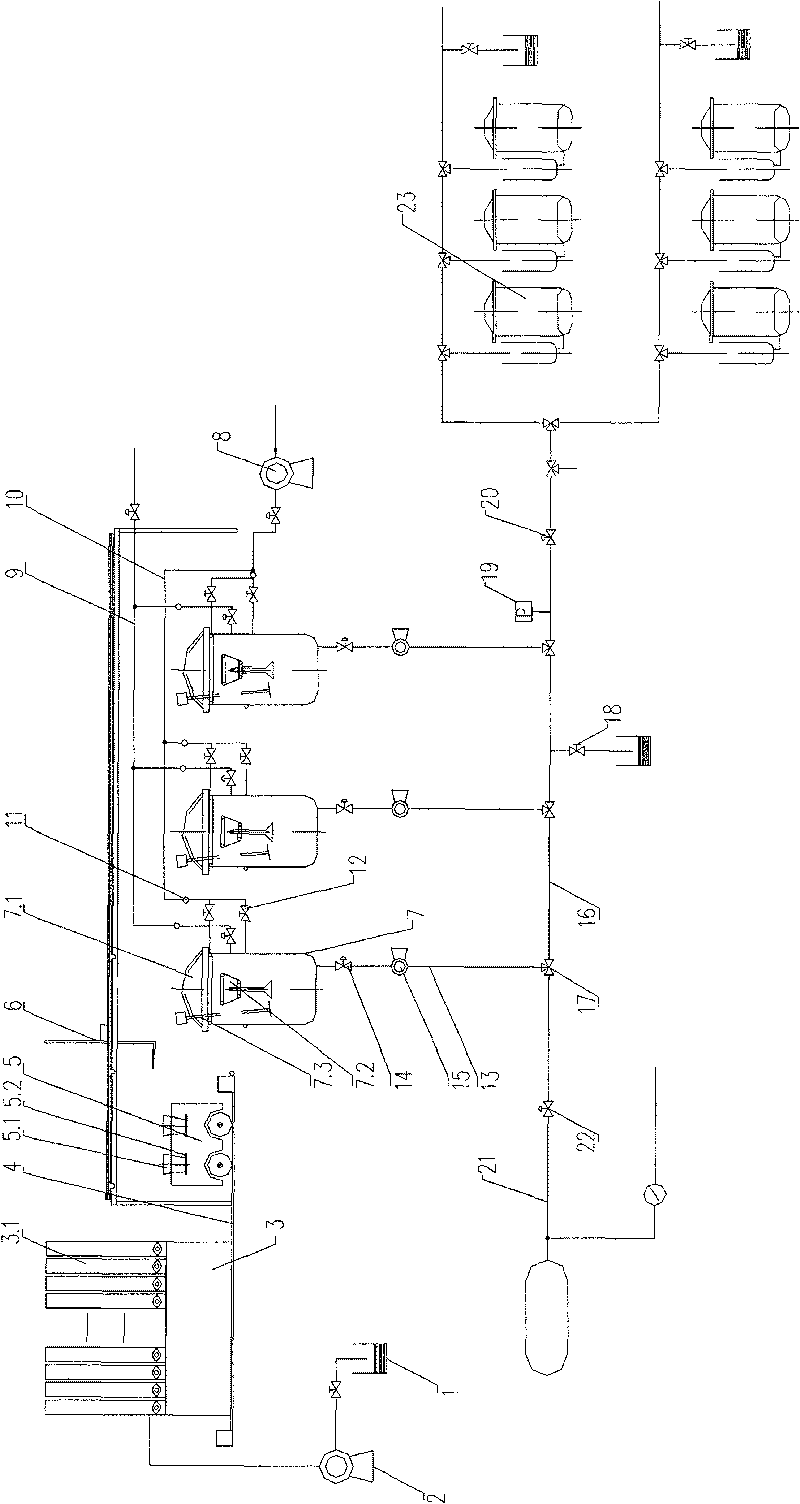

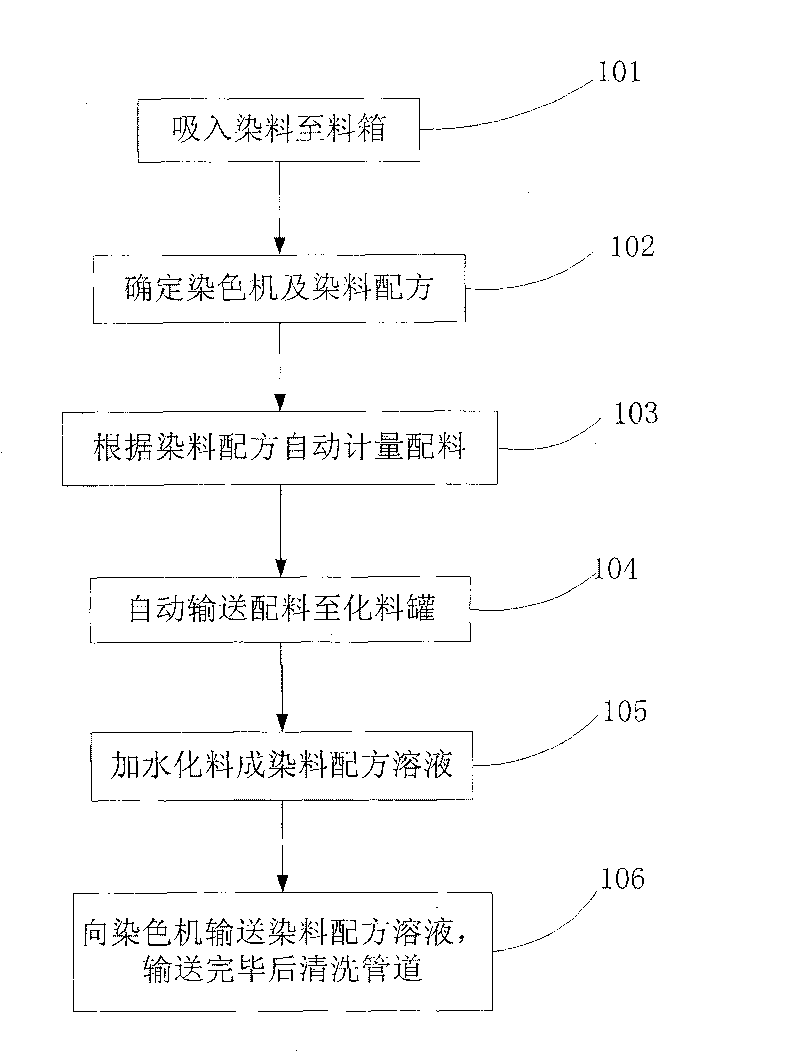

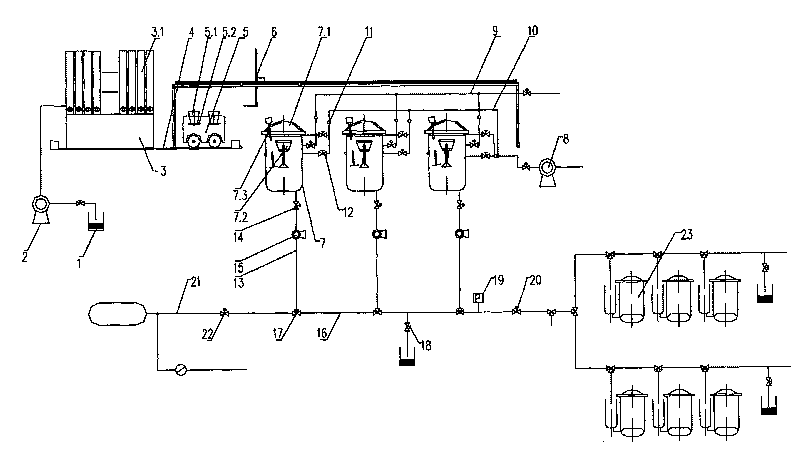

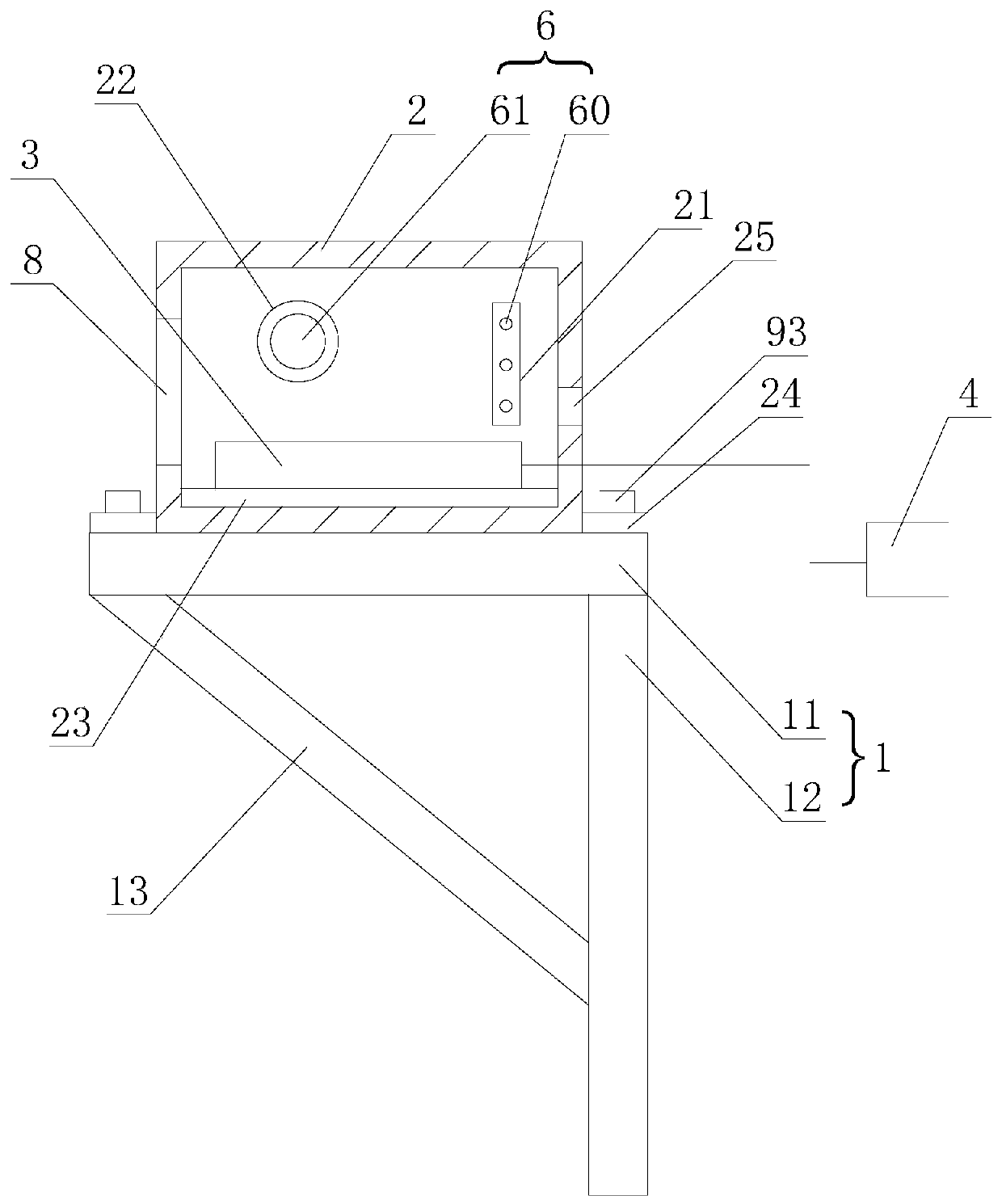

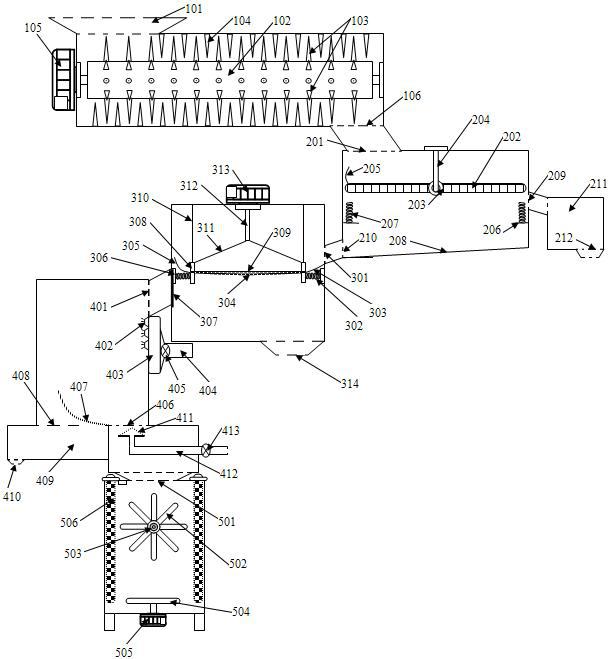

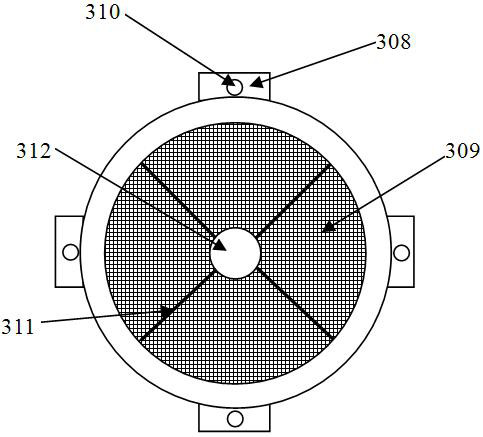

The invention discloses a powder form dye automatic distribution and delivery method used in cheese dyeing and special-purpose equipment thereof. The method comprises the following steps: absorbing dye to dye tank; determining dyeing machine and dye formula; metering dyes automatically according to the dye formula; conveying the dyes to dye dissolving tank; adding water to dissolving the dyes into formula solution; and conveying dyes formula solution to dyeing machine. In the equipment of the invention, the raw material barrel is connected with dye tank; an proportioning track is disposed between the automatic dyes proportioning machine and the dye dissolving tank, and a metering dolly runs thereon; a robot runs between the proportioning track and the dye dissolving tank; the dye dissolving tank is connected to a water pump through a cold water pipe and a warm water pipe respectively; the dye dissolving tank is connected with the main pipe through a branch pipe; and one end of the main pipe is connected with compressed air pumping station, the other end is connected with the dyeing machine. The invention increases one time sample conforming rate, reduces the direct / indirect energy and manpower cost, realizes in time production and one time accurate production, and achieves the safe reliable clean production with less pollution.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

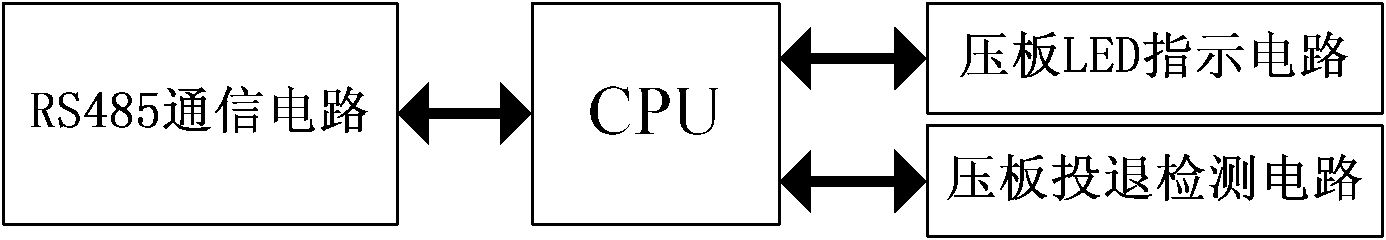

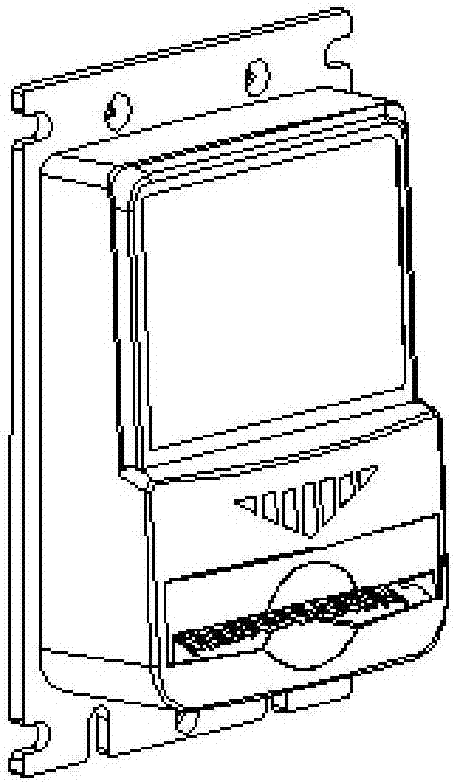

Plate error prevention device and working method thereof

The invention provides a plate error prevention device and a working method thereof used for commissioning and ceasing state detection of a relay protection plate and an error prevention operation of the relay protection plate, and problems of error commission, error cease, missed commission, missed cease and the like of the plate are solved. The plate error prevention device comprises an intelligent plate, a plate controller, a transmission adapter, a computer key and a computer management system. A plate intelligent part detects commissioning and ceasing states of a plate commissioning and ceasing function part and transmits commissioning and ceasing state information to the plate controller through a communication circuit, and the plate controller uploads collected commissioning and ceasing state information of the plate to the computer management system. When the plate is needed to be operated, the computer management system forms an operation order and sends the operation order to the computer key through the transmission adapter. The computer is inserted into the corresponding plate controller. The plate controller transmits operation information to the the plate needing to be operated. An indicator light of the plate needing to be operated is on and operating the plate is prompted. After the operation of the operation order is completed, the computer key is transmitted to the computer management system back.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

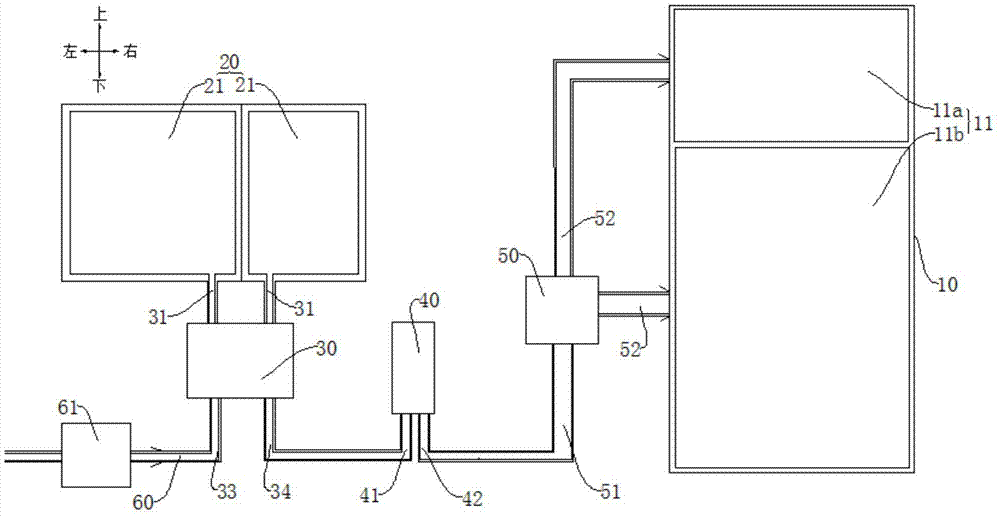

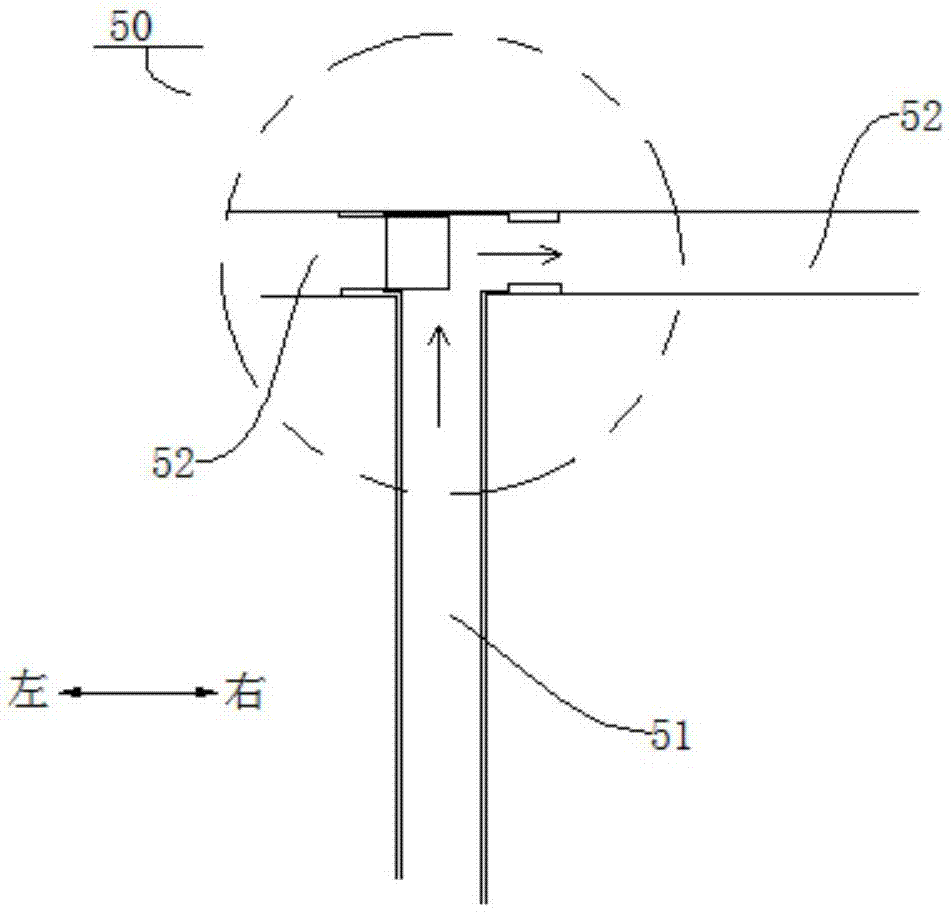

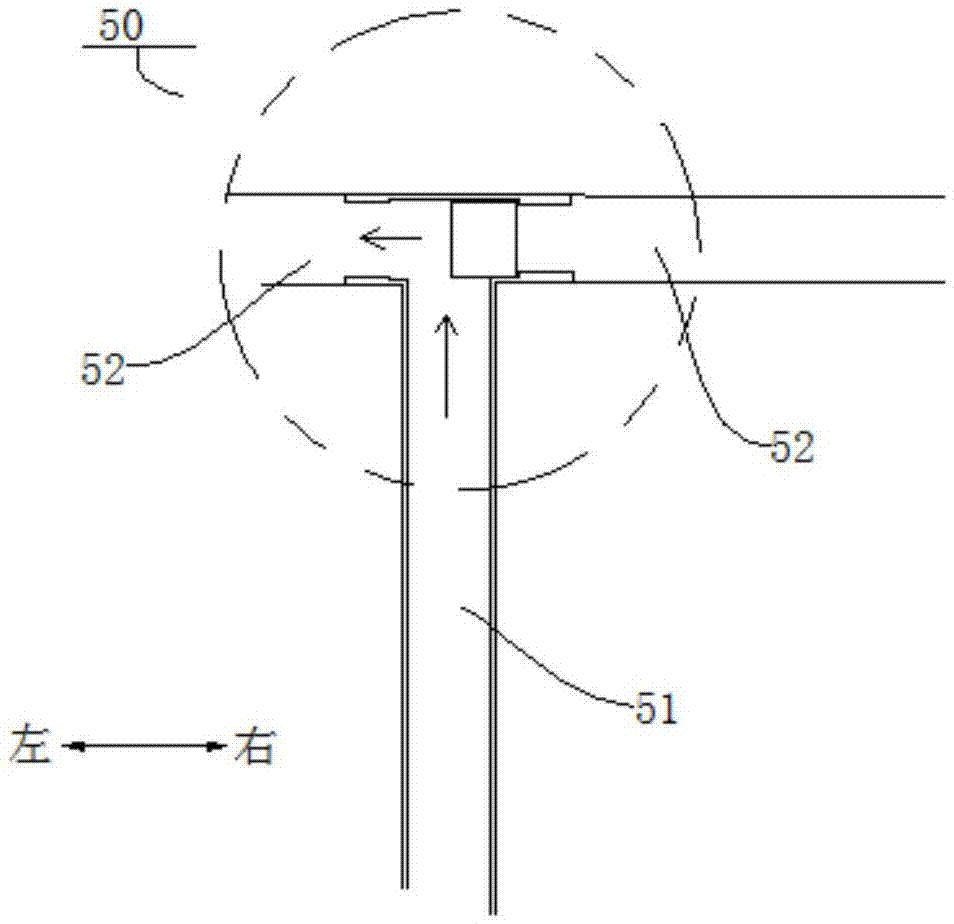

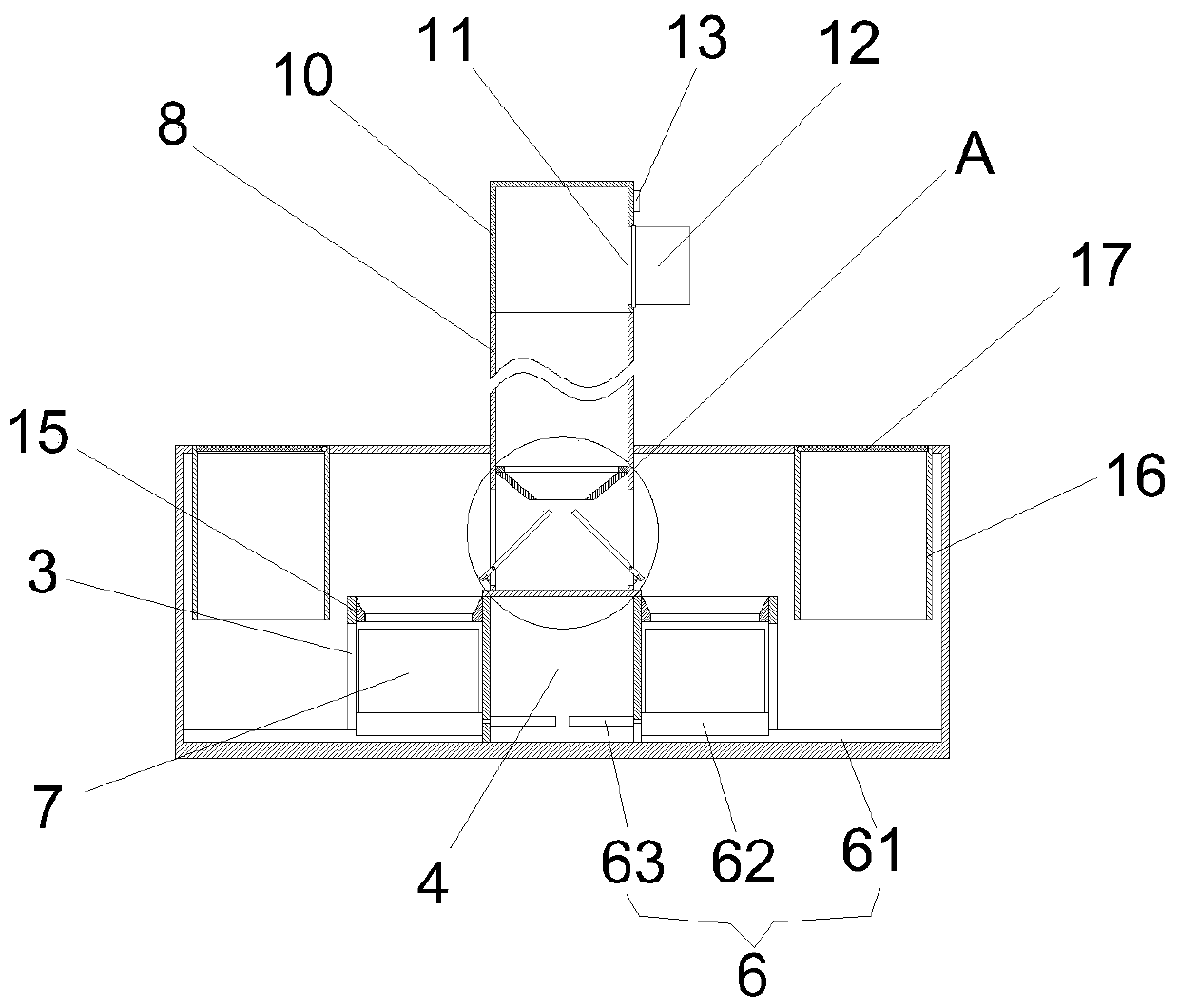

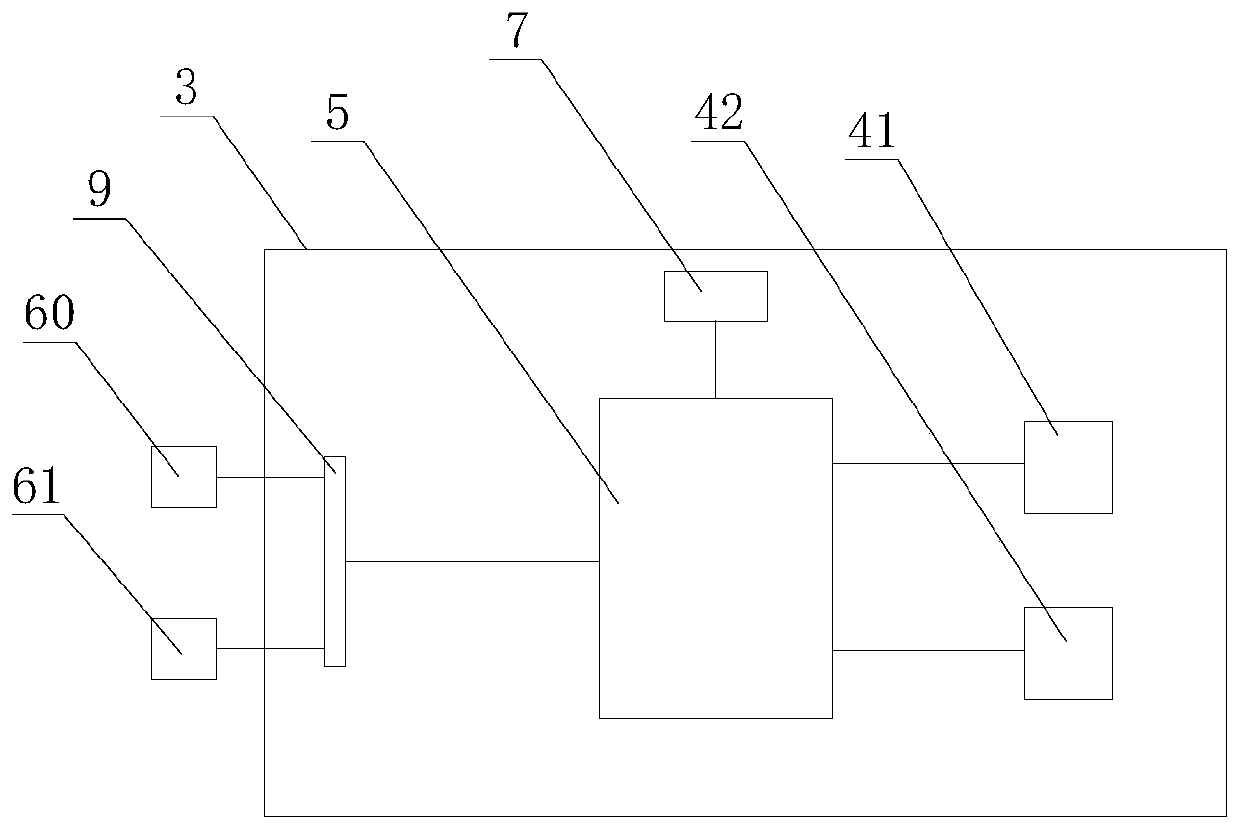

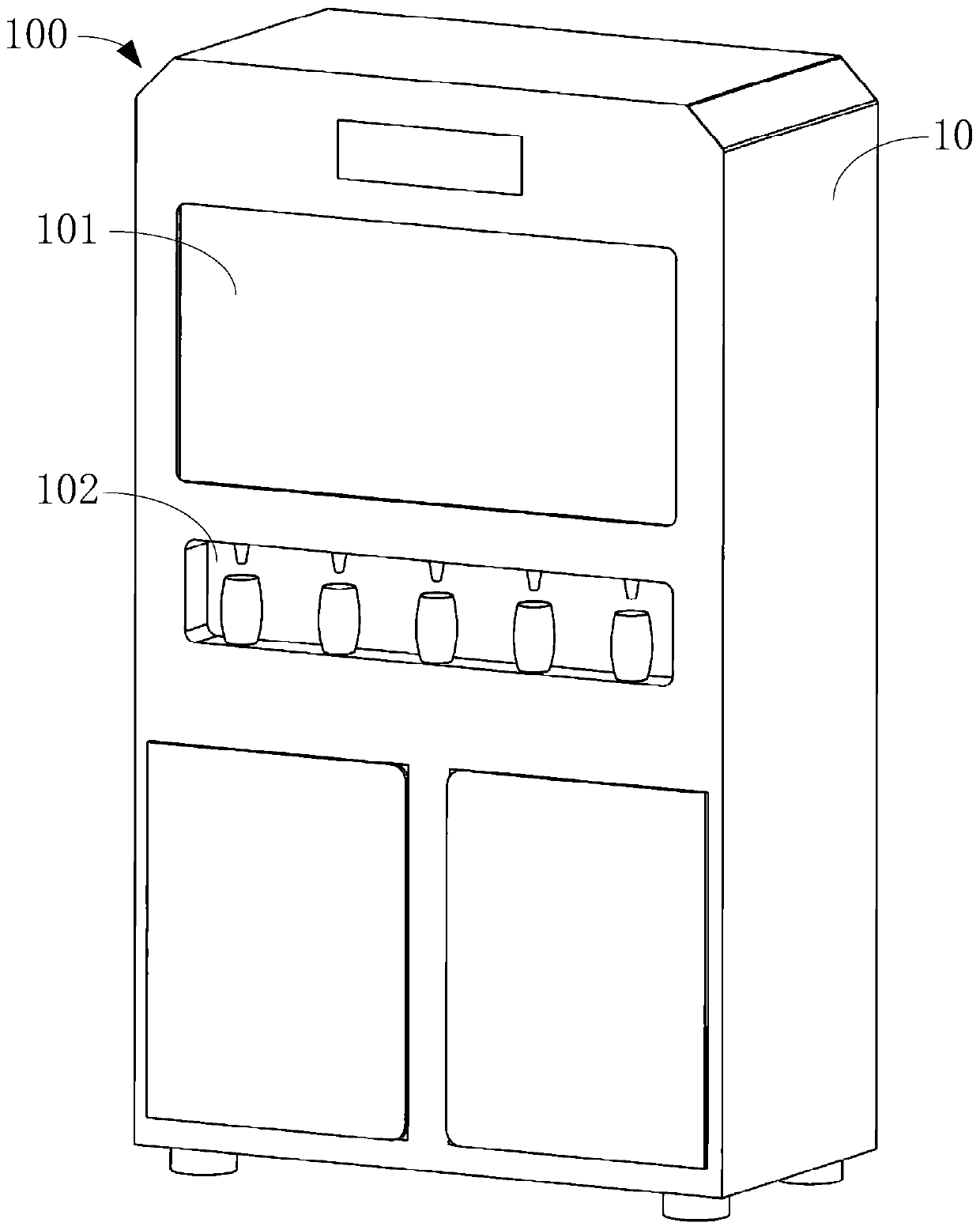

Automatic detergent-placing system and composite washing machine thereof

InactiveCN106906614AEasy to useAutomatic delivery is easy to implementOther washing machinesTextiles and paperInlet valveEngineering

The invention discloses an automatic detergent-placing system and a composite washing machine thereof. The automatic detergent-placing system comprises a detergent storage box, a reversing valve, a detergent-placing pump and a valve body assembly. A plurality of detergent storage chambers are arranged in the detergent storage box, the detergent storage box and the reversing valve are communicated, the reversing valve comprises a liquid outlet and a plurality of liquid inlets, the liquid inlets correspond to the detergent storage chambers one to one, the inlet of the detergent-placing pump is connected with the liquid outlet, the liquid outlet is communicated with one of the liquid inlets and disconnected with the other liquid inlets, the valve body assembly comprises a water inlet valve port and a plurality of water outlet valve ports, the water outlet valve ports correspond to washing buckets one to one and are communicated with the washing buckets, and the water inlet valve port is communicated with one of the water outlet valve ports and disconnected with the other water outlet valve ports. According to the automatic detergent-placing system for the composite washing machine, automatic detergent placing of the composite washing machine is easily achieved, the operation of manually adding a detergent is replaced, and the usage performance of the composite washing machine is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

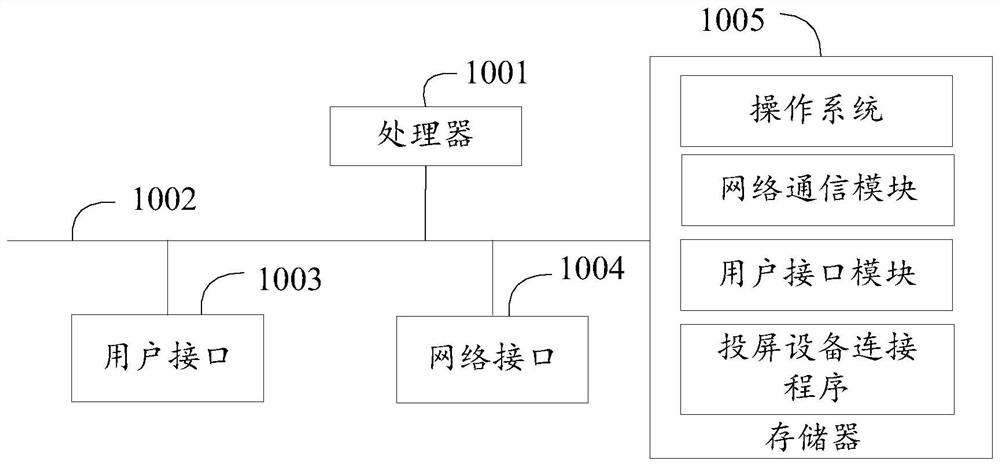

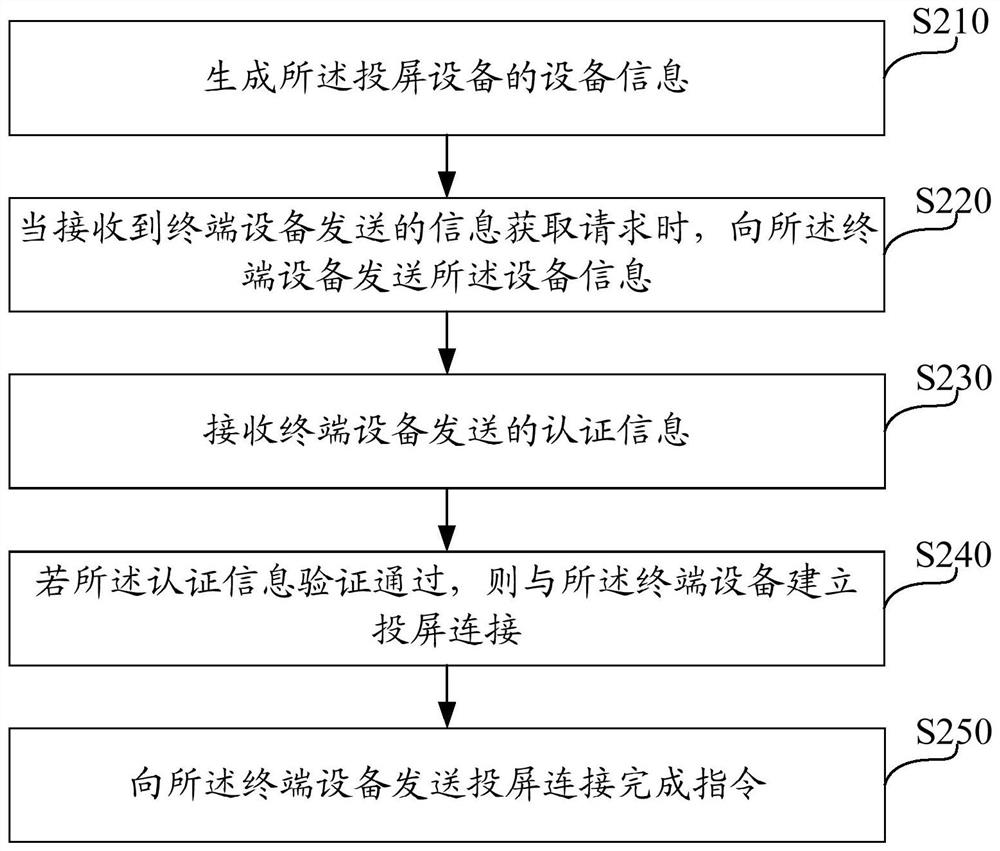

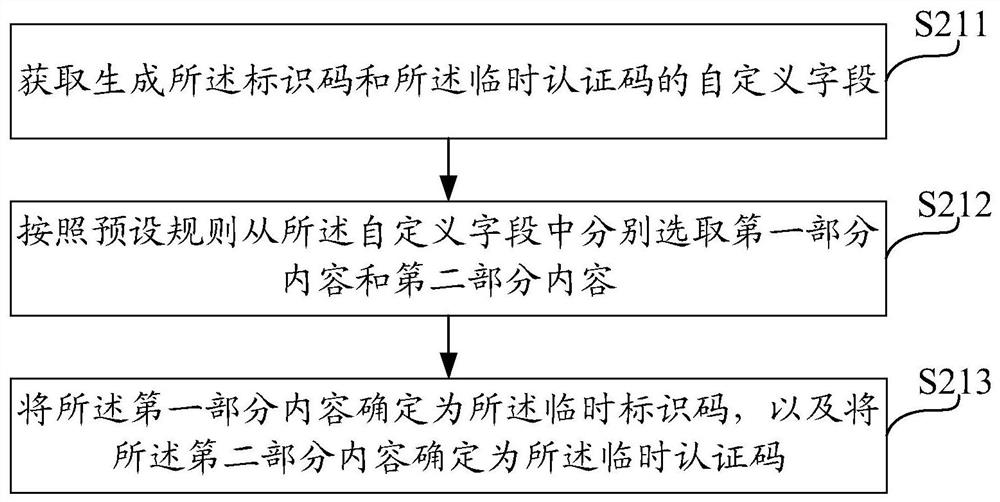

Screen projection equipment connection method, system and equipment and storage medium

ActiveCN112637842AImprove securityImprove experienceConnection managementSecurity arrangementComputer hardwareTerminal equipment

The invention discloses a screen projection device connection method, system and device and a storage medium. The method comprises the steps: generating device information of a screen projection device; when an information acquisition request sent by the terminal equipment is received, sending equipment information to the terminal equipment; receiving authentication information sent by the terminal equipment; if the authentication information passes the verification, establishing a screen projection connection with the terminal device; and sending a screen projection connection completion instruction to the terminal equipment. The problems that existing screen projection equipment is low in safety, and mistaken screen projection by other terminal equipment occurs easily are solved, the safety of the screen projection equipment is improved, the phenomenon that mistaken screen projection by other terminal equipment occurs is avoided, the process of manually establishing the screen projection equipment and the terminal equipment by a user is omitted, convenience, quickness and high efficiency are realized, and the user experience is enhanced.

Owner:SHENZHEN SKYWORTH SOFTWARE

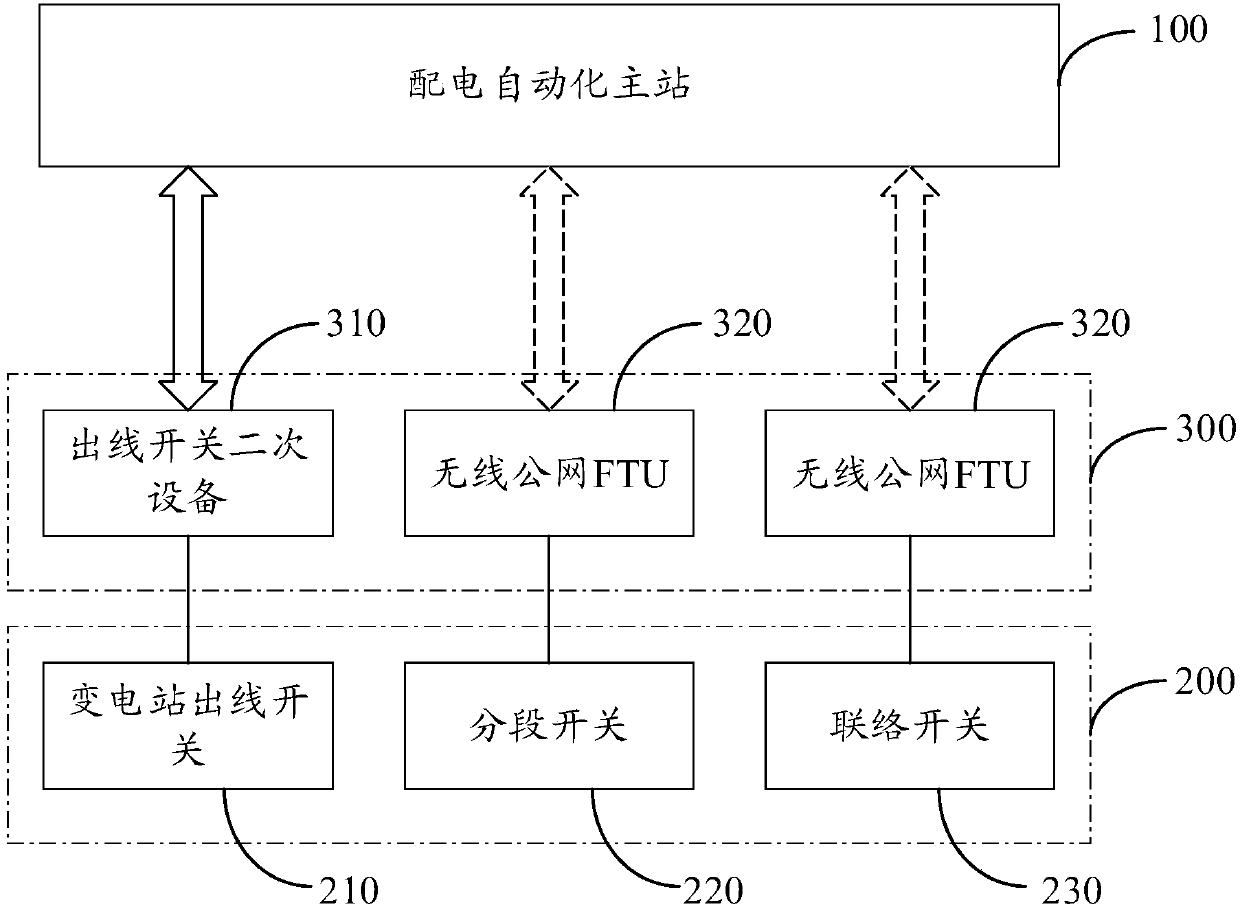

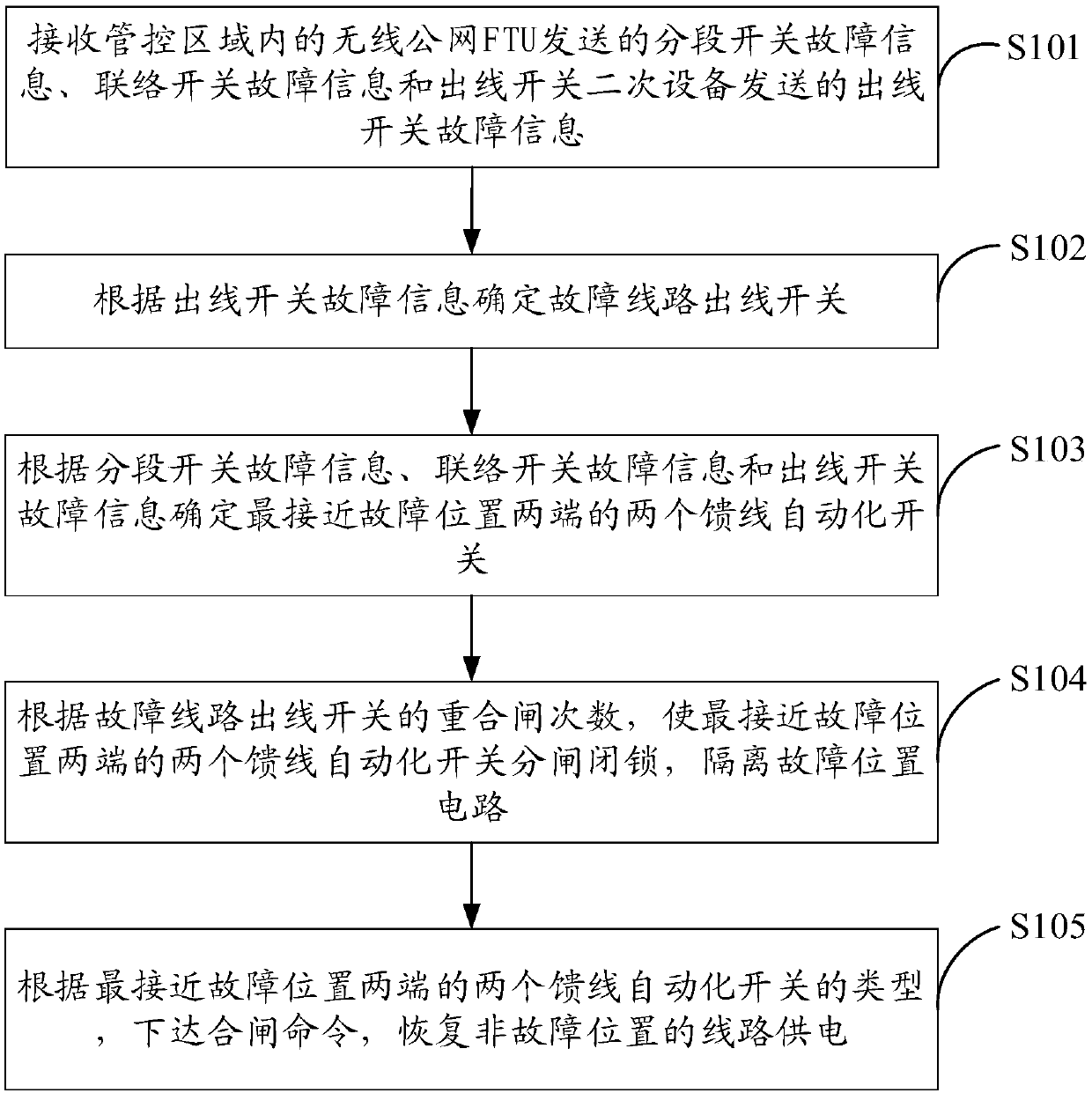

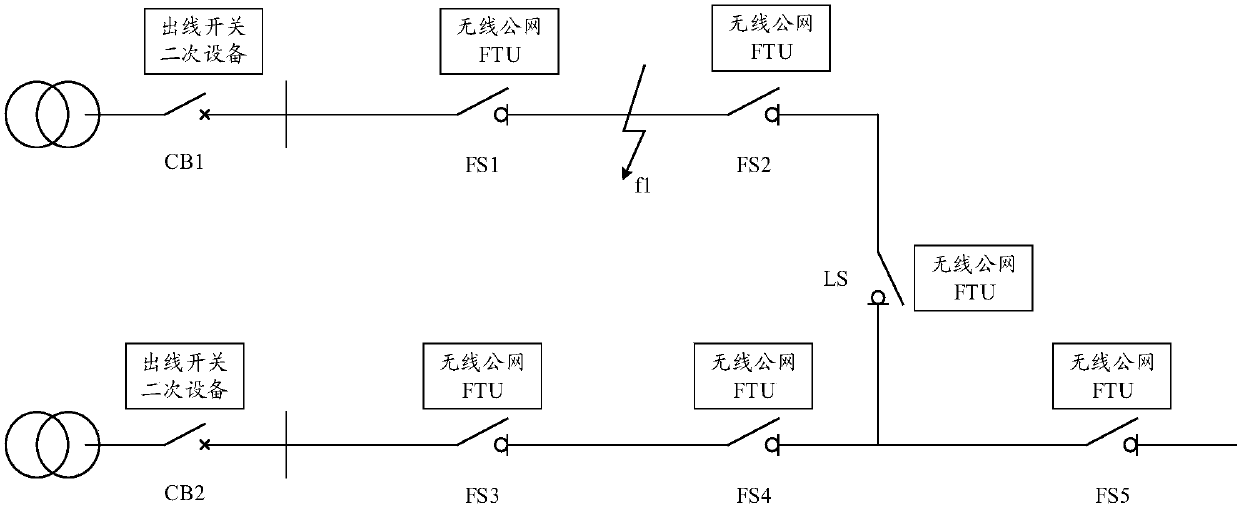

Distribution network overhead line fault self-recovery method and system

ActiveCN107612148AAvoid misidentificationReliable fault self-healingEmergency protective circuit arrangementsFault locationSelf recoveryFailure causes

The invention provides a distribution network overhead line fault self-recovery method and system. Section switch fault information, interconnection switch fault information and outlet switch fault information in a control area are received, fault line outlet switches and two feeder automation switches the most closest to two ends of a fault position are determined according to the fault information, the two feeder automation switches the most closest to the two ends of the fault position are opened and locked according to the re-closing frequency of the fault line outlet switches, closing commands are given to different switches according to the types of the two feeder automation switches the most closest to the two ends of the fault position, and line power supply of a non-fault positionis recovered. Therefore, different re-closing frequency of different outlet switches in a line can be adapted to, isolation of the fault position is ensured, different closing commands are given according to different types of the two feeder automation switches the most closest to the two ends of the fault position, power supply recovery of the line at the non-fault position is ensured, one morepower failure caused by mistaken switching of the switches is prevented, and fault self-recovery can be more reliably realized.

Owner:GUANGXI POWER GRID ELECTRIC POWER RES INST +2

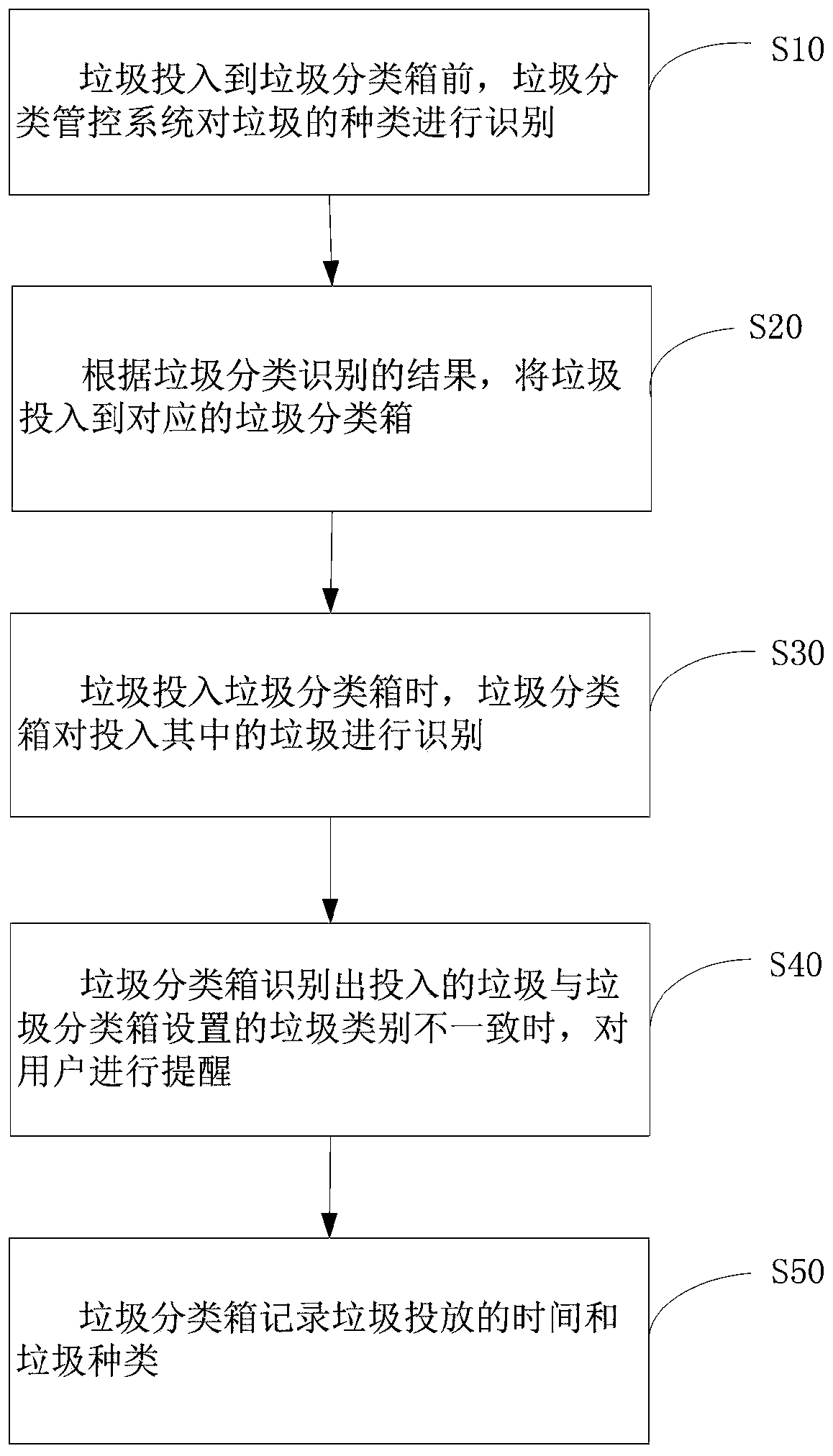

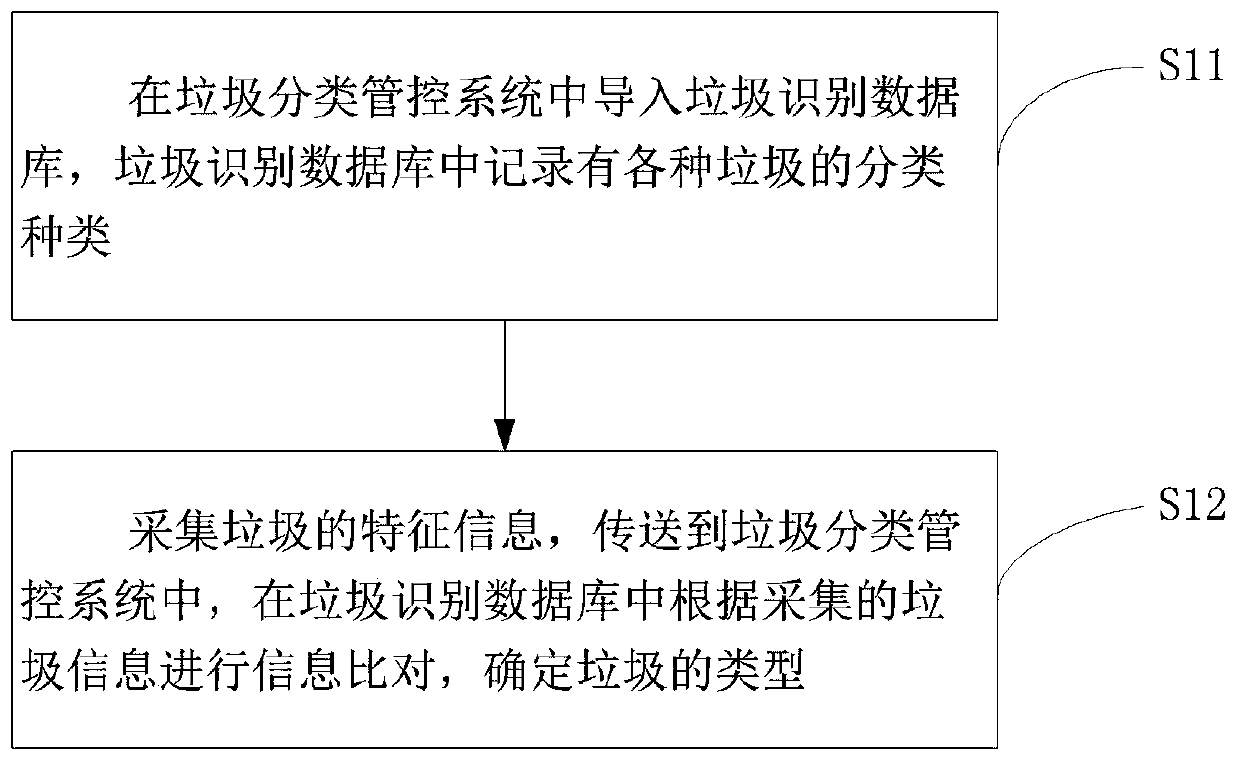

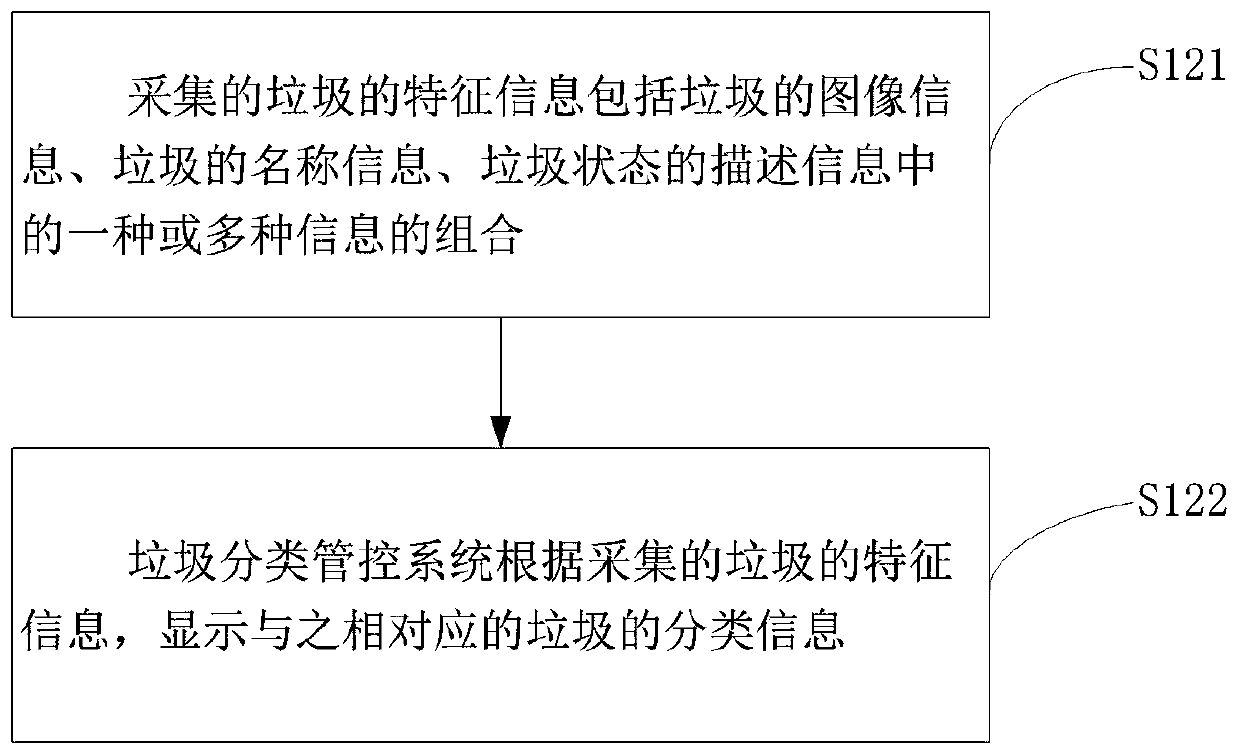

Garbage classification control method and system

InactiveCN110589297AAvoid miscastingData processing applicationsWaste collection and transferComputer science

The invention discloses a garbage classification control method and system. The system comprises a garbage classification control library, information of garbage can be collected and compared with information in the garbage classification control library, and the variety of the garbage is recognized. Garbage classification information relevant to the garbage is displayed according to the collectedgarbage information to be screed by a user. When the garbage is put into a garbage classifying box, the garbage is recognized again, and the phenomenon that the user puts in the garbage by mistake orputs in wrong garbage is avoided.

Owner:SHENZHEN AOXINBO ELECTRONICS TECH CO LTD

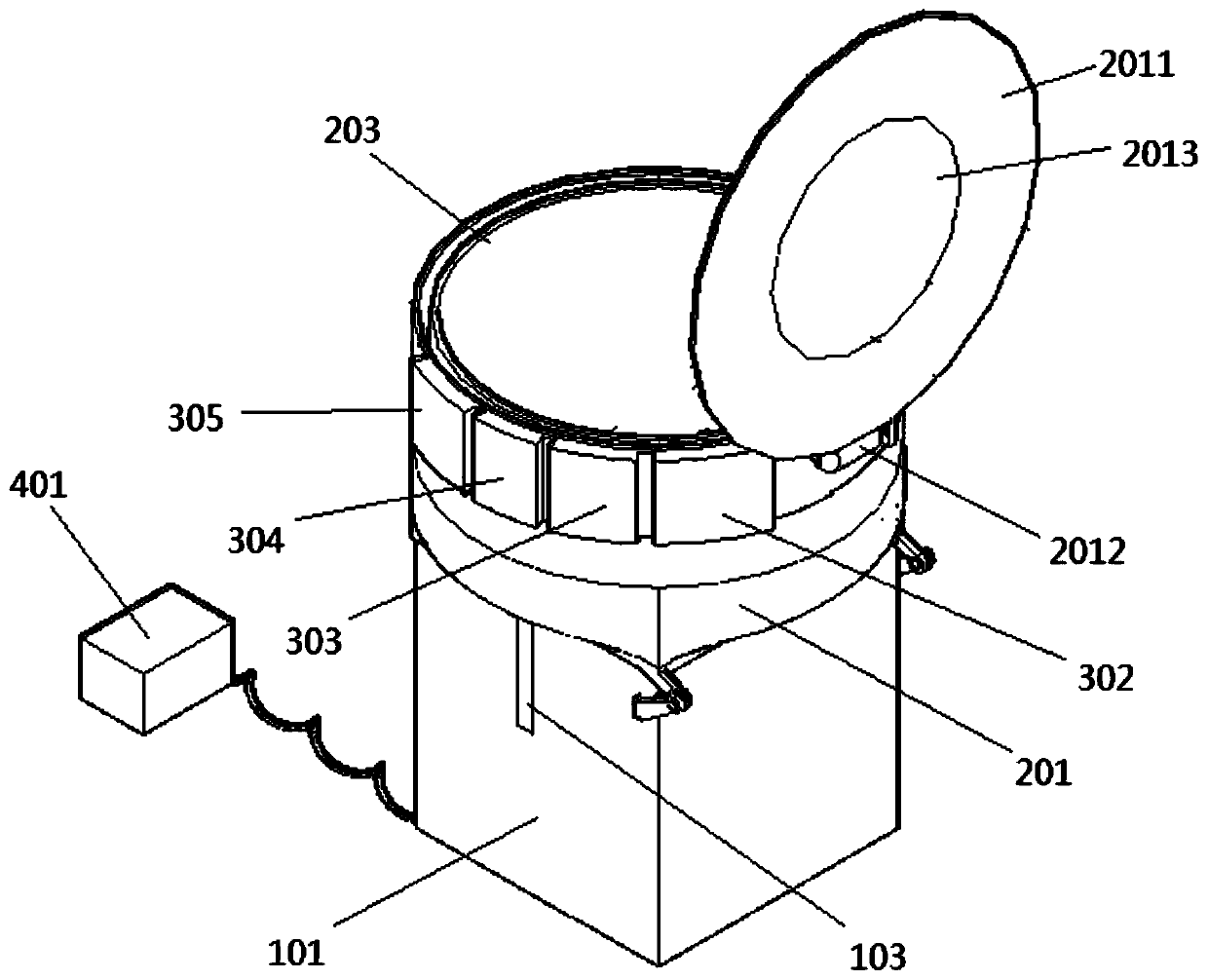

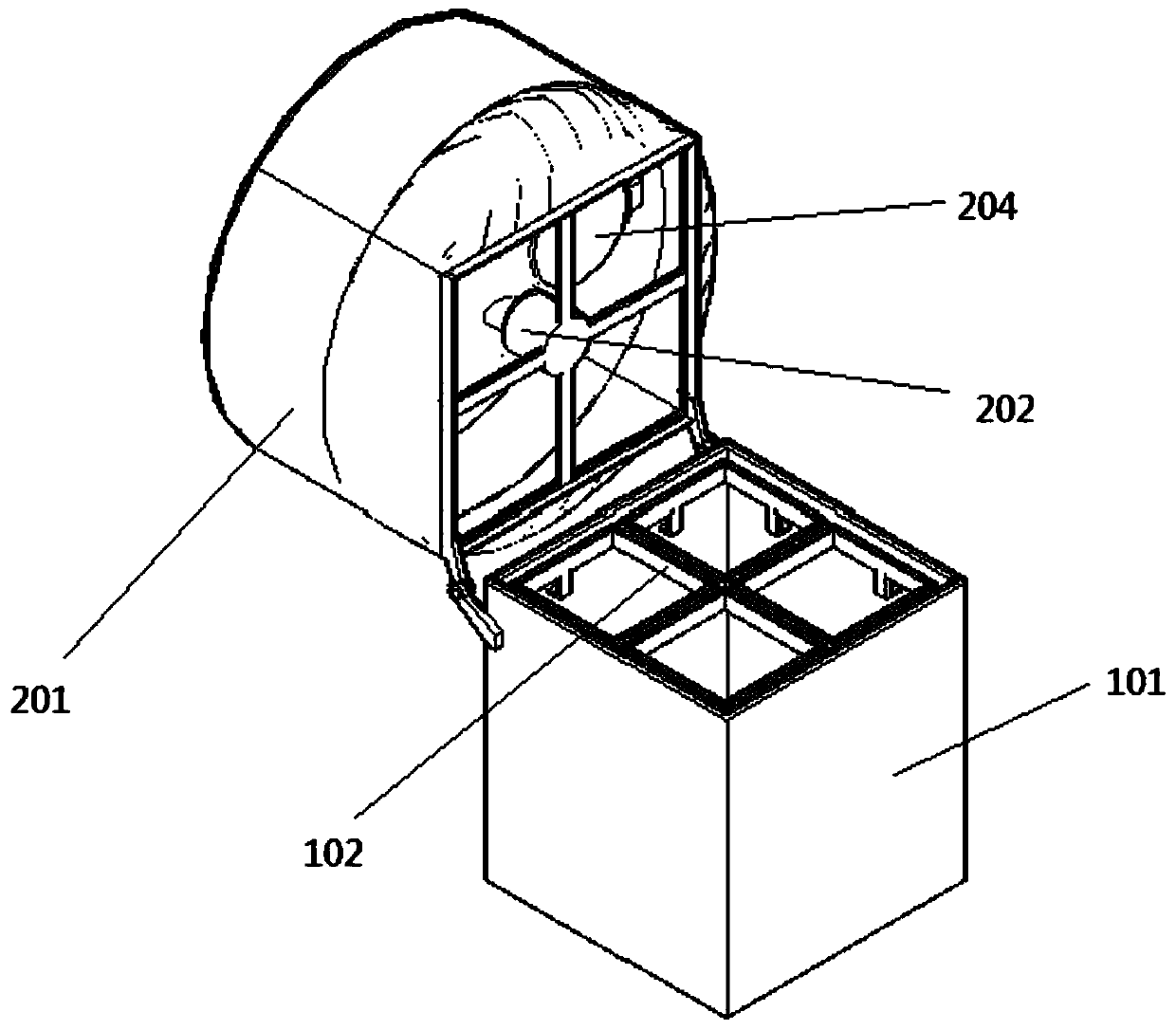

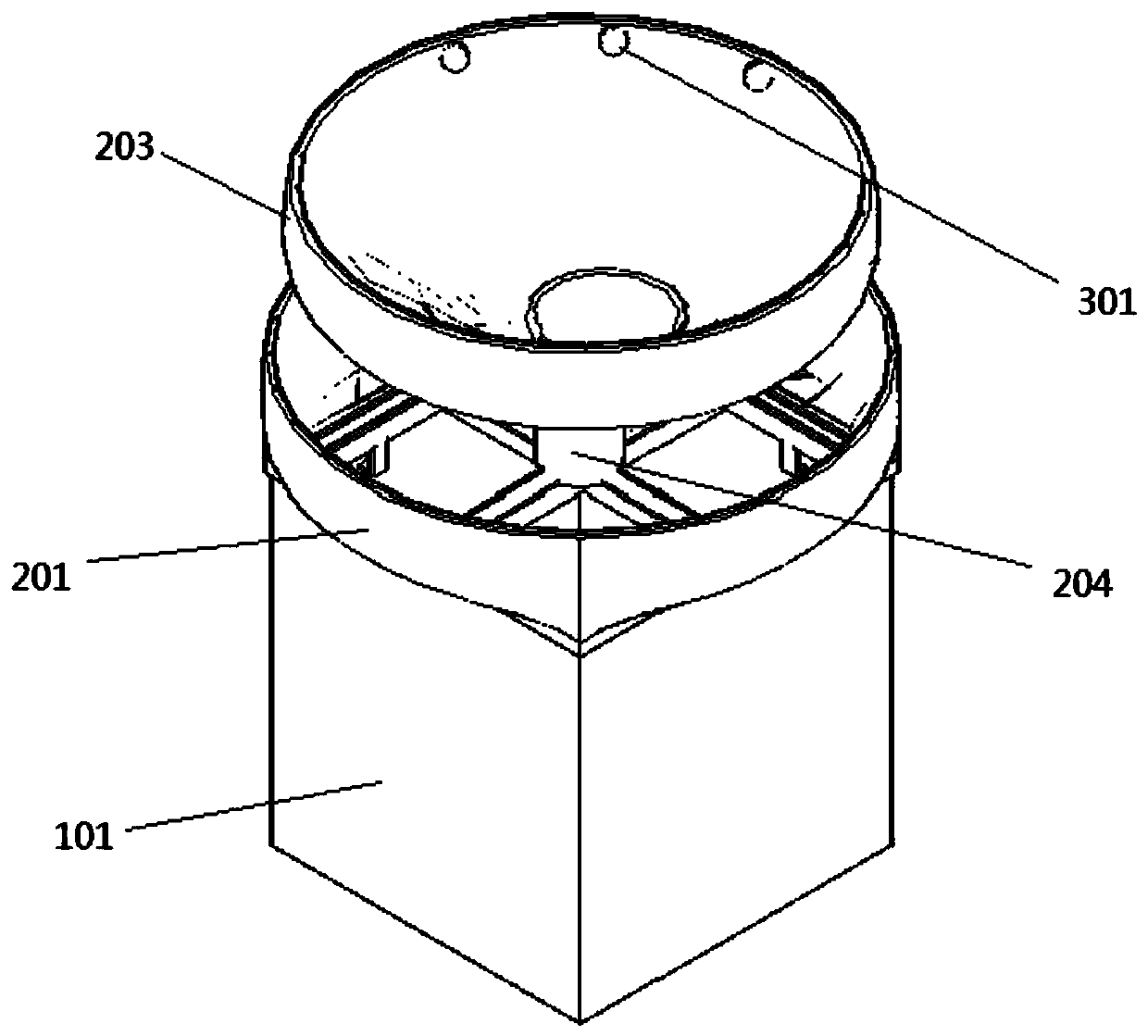

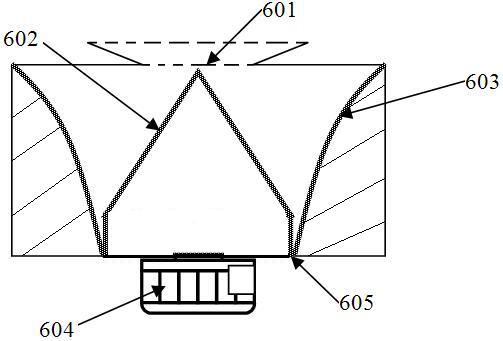

Garbage can for intelligently sorting medical waste and sorting method thereof

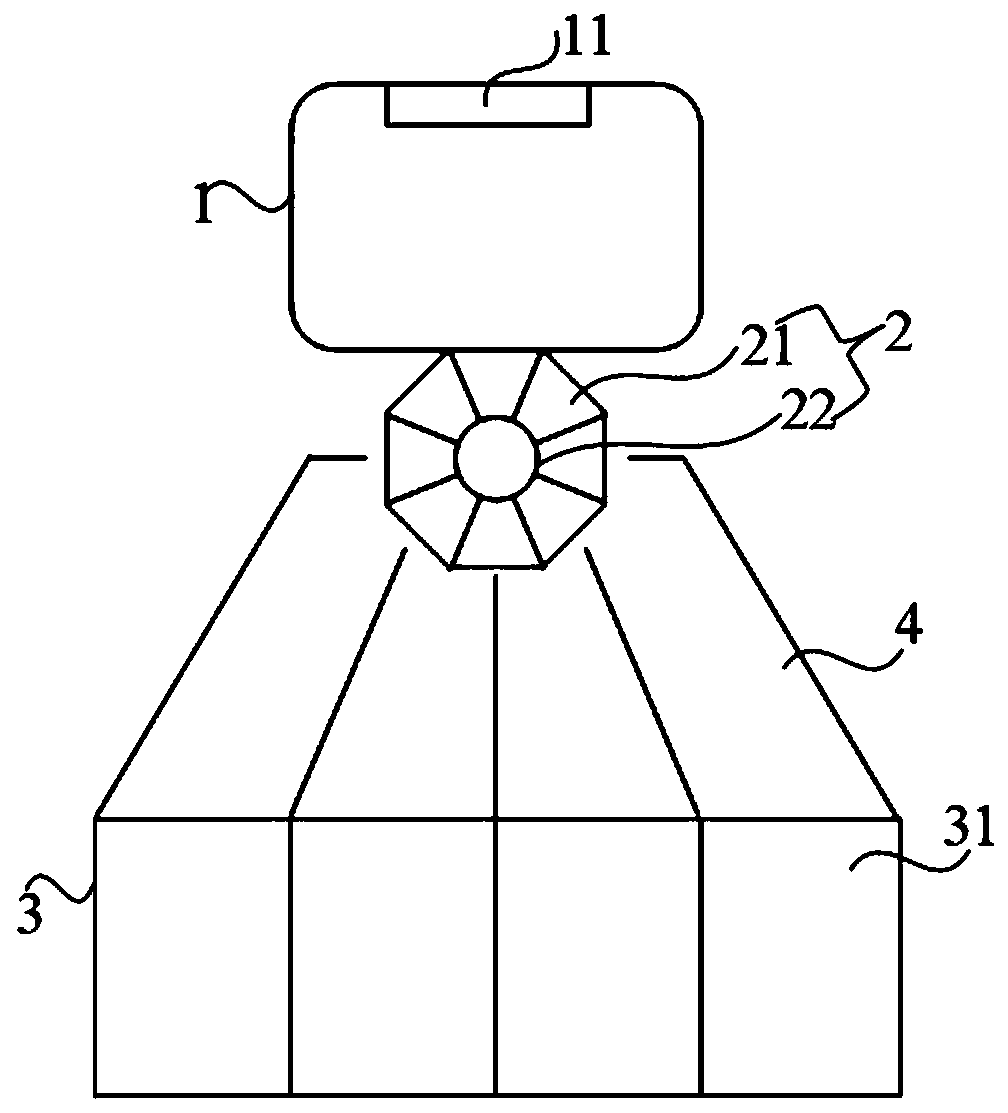

InactiveCN109928106AReduce sorting workImprove accuracyWaste collection and transferRefuse receptaclesClassification methodsMedical waste

The invention relates to a garbage can for intelligently sorting medical waste and a sorting method thereof, and belongs to the technical field of auxiliary sorting and recognition. The garbage can comprises a box body assembly, a box cover assembly, an image recognition system and a power supply module, wherein the box body assembly comprises a box body housing and a plurality of built-in garbagecans, the box cover assembly comprises a connecting cover, a central motor and an inner rotating bucket, the image recognition system comprises a camera, an information storage module, an informationprocessor and a human-computer interaction module, the box cover assembly is located above the box body housing, the connecting cover is used for fixing the inner rotating bucket, the central motor and the image recognition system, and the power supply module is connected with power supplies of all devices to which power needs to be supplied in the garbage can for intelligently sorting medical waste. The garbage can for intelligently sorting medical waste has the function of automatically identifying and sorting the medical waste by a machine, the use is convenient, and the sorting accuracy of the medical waste is increased; in addition, according to the garbage can for intelligently sorting medical waste, the number of garbage inlets is reduced, so that the condition of environmental pollution caused by the exposure of the medical waste is avoided, and the effects of cleanness and sanitation are achieved.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

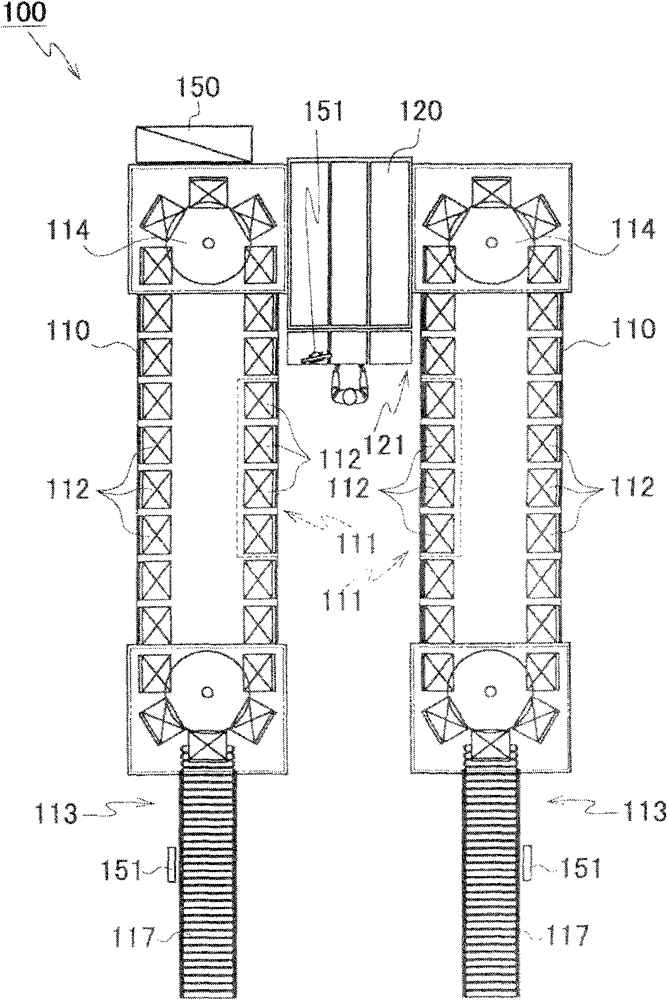

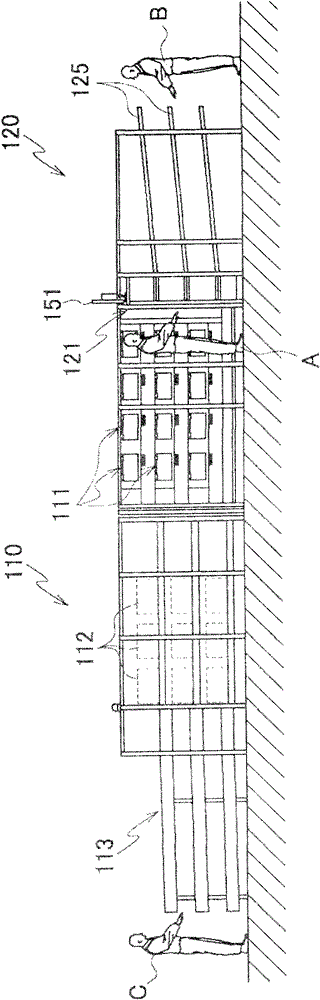

Item distribution system

InactiveCN102275709AReduce the frequency of movementImprove work efficiencyStacking articlesLogisticsEngineeringElectrical and Electronics engineering

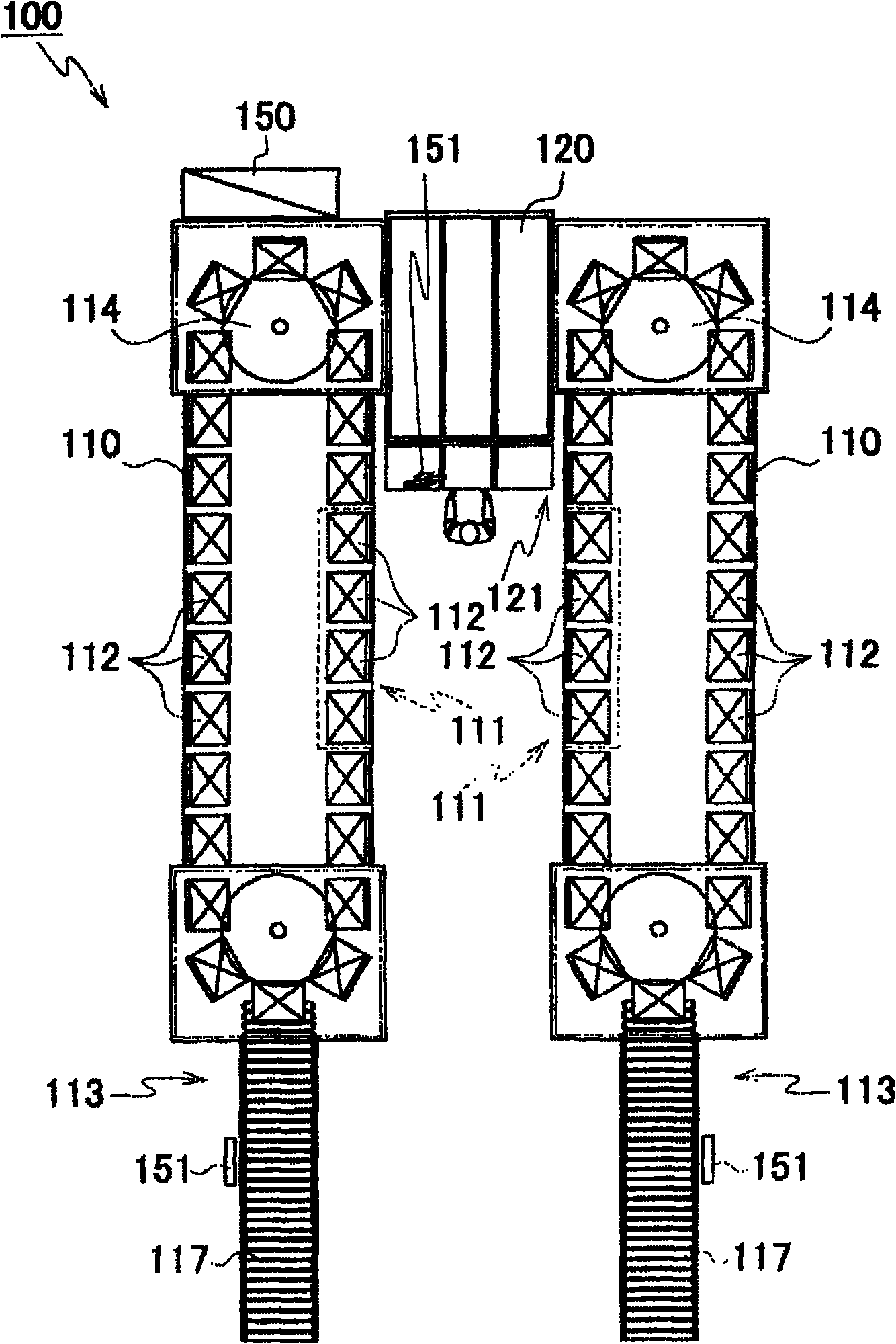

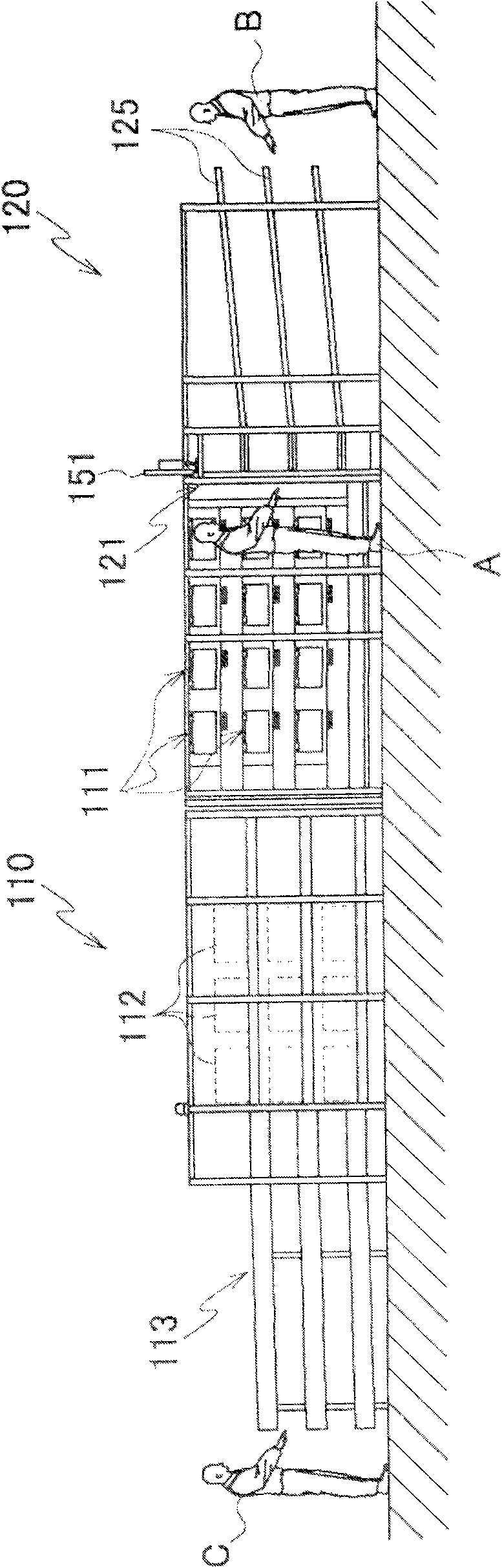

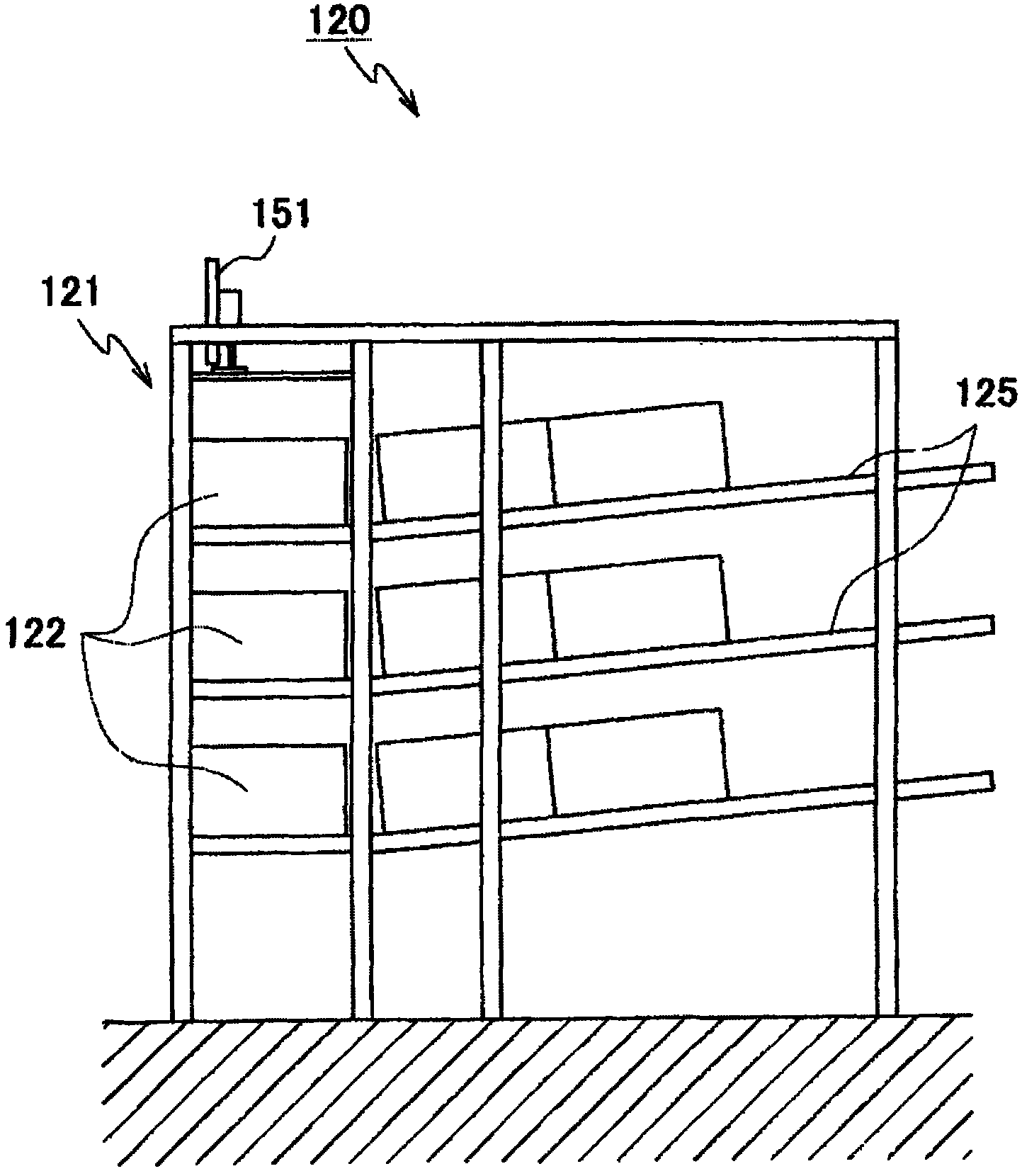

PROBLEM TO BE SOLVED: To provide an article sorting system capable of efficiently sorting articles in a short time and reducing a sorting mistake while placing only a light burden on a worker even in the case where article sorting destinations and the articles are diverse and where the number of articles is small. ŽSOLUTION: The article sorting system includes: a feed shelf 120 having a plurality of feed openings 121 enabling the article to be taken out of a feed box 122 for housing the article to be fed; a sorting shelf 111 having a plurality of sorting openings 111 enabling the charging of the article by placing a sorting box 112 into which the article to be sorted is charged; and a sorting control means 150 for controlling opening / closing of a feed opening shutter 123 on the basis of sorting information by giving the worker instructions about the article to be fed and the sorting destination to undergo the charging of the article. Ž

Owner:TSUBAKIMOTO CHAIN CO

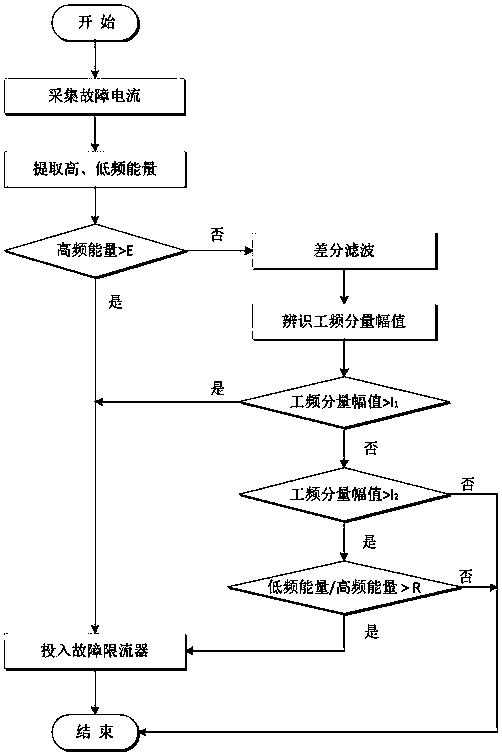

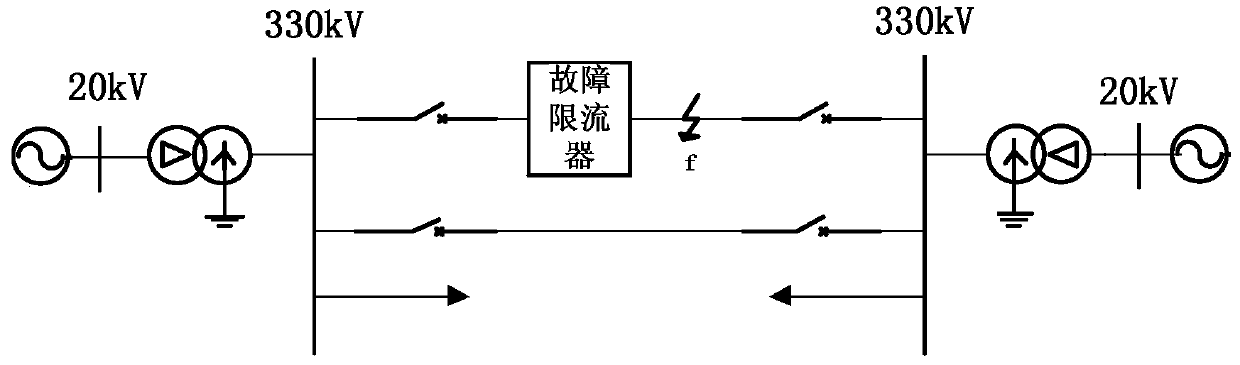

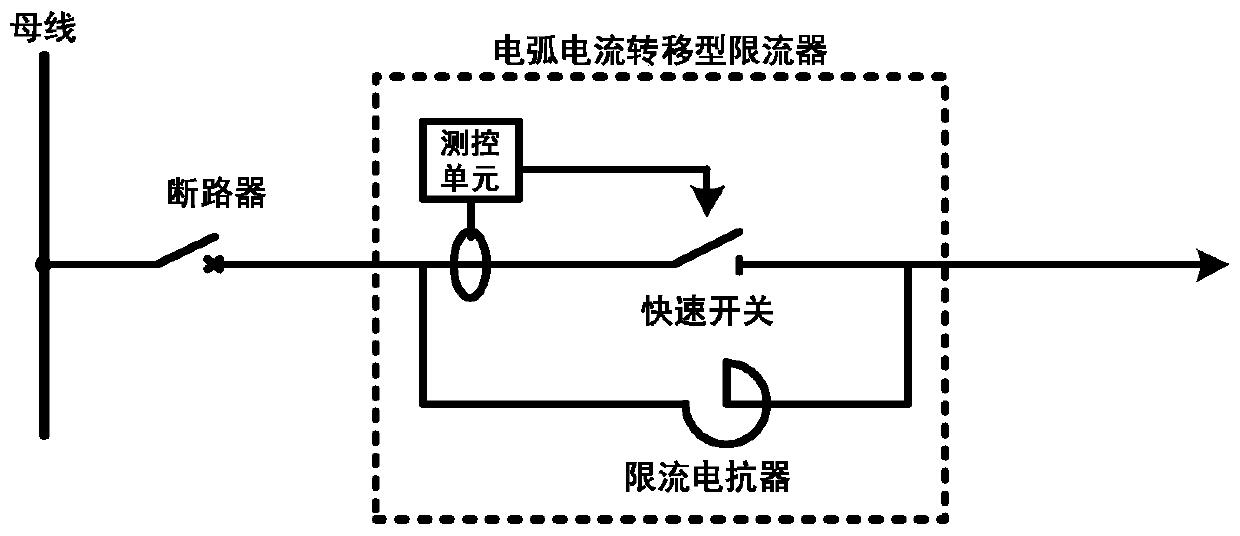

Fault current limiter input control method based on short-circuit current comprehensive information

ActiveCN110518557AAvoid "miscasting"Avoid threatsEmergency protective arrangements for limiting excess voltage/currentElectric power systemInput control

The invention discloses a fault current limiter input control method based on short-circuit current comprehensive information. The method comprises the steps of: extracting high-frequency and low-frequency energy of a collected fault current signal; if a high-frequency energy determination result meets the requirement, putting a fault current limiter immediately into use, otherwise, extracting a power frequency component, and determining whether the fault current limiter is put into use or not again according to the determination results of the low-frequency energy and the power frequency component; and finally, waiting for action of a relay protection device and fault isolation of a circuit breaker. According to the method, the fault current limiter can be rapidly and accurately put intouse, and the method has important practical significance for guaranteeing safe and stable operation of a power system.

Owner:XI AN JIAOTONG UNIV

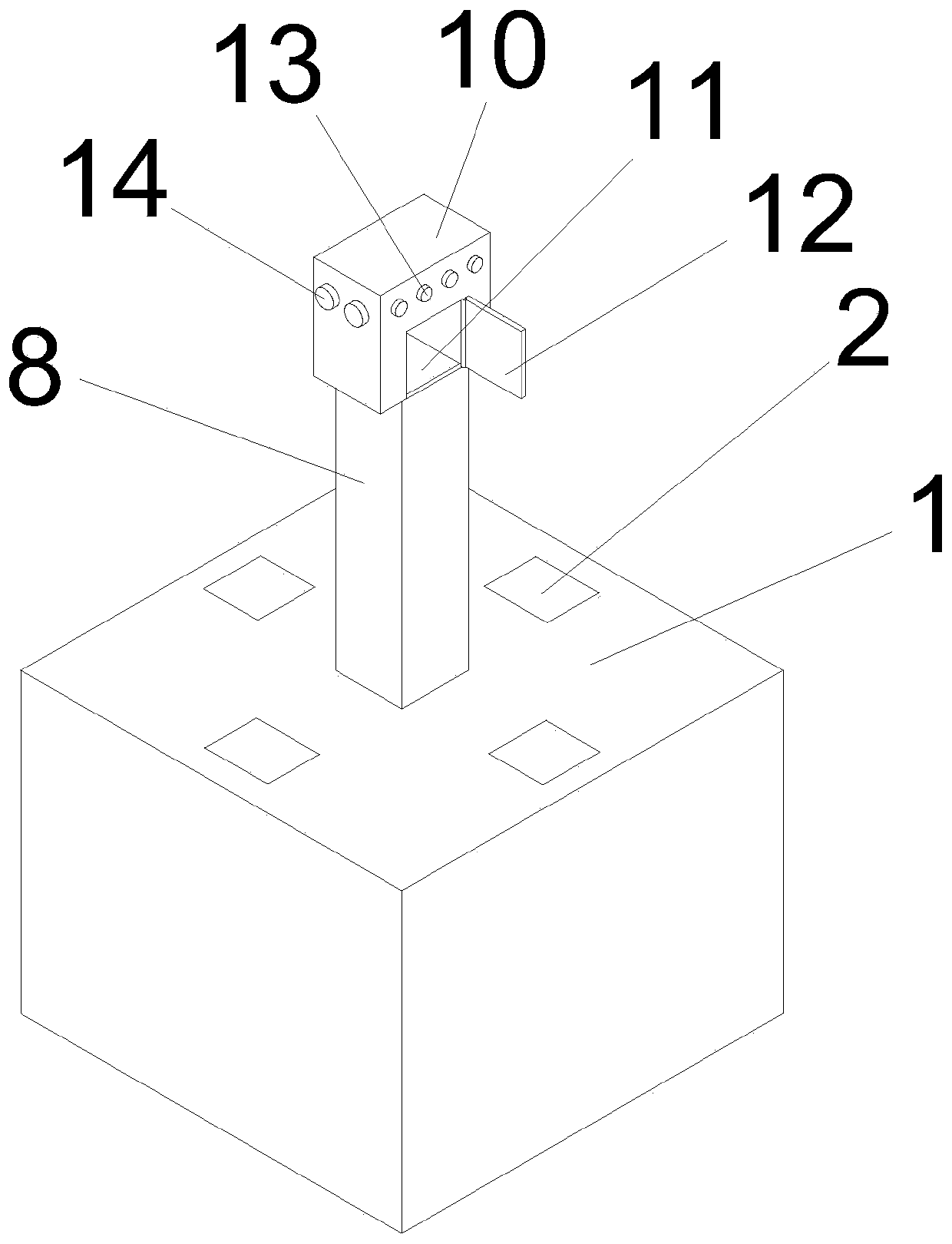

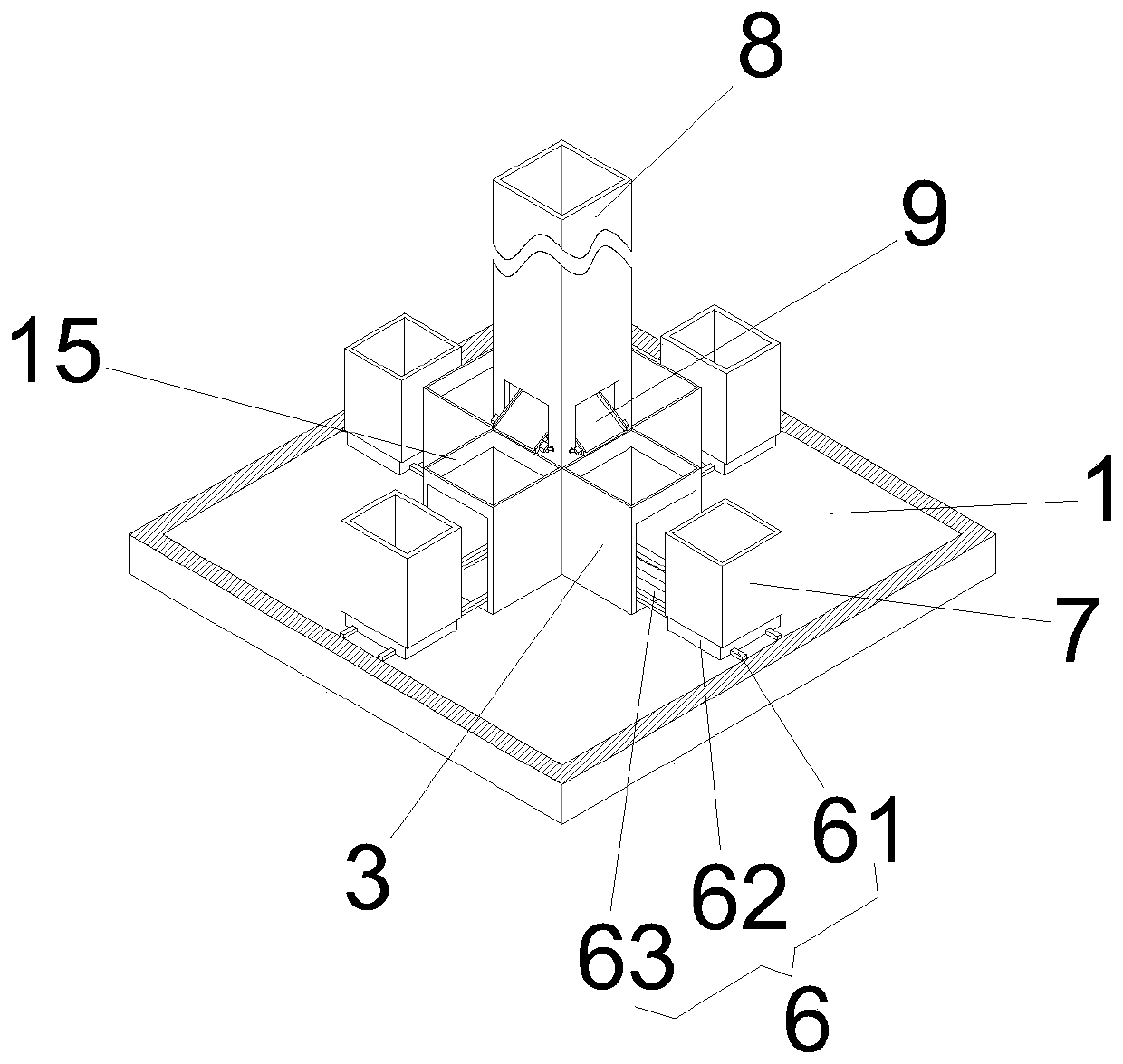

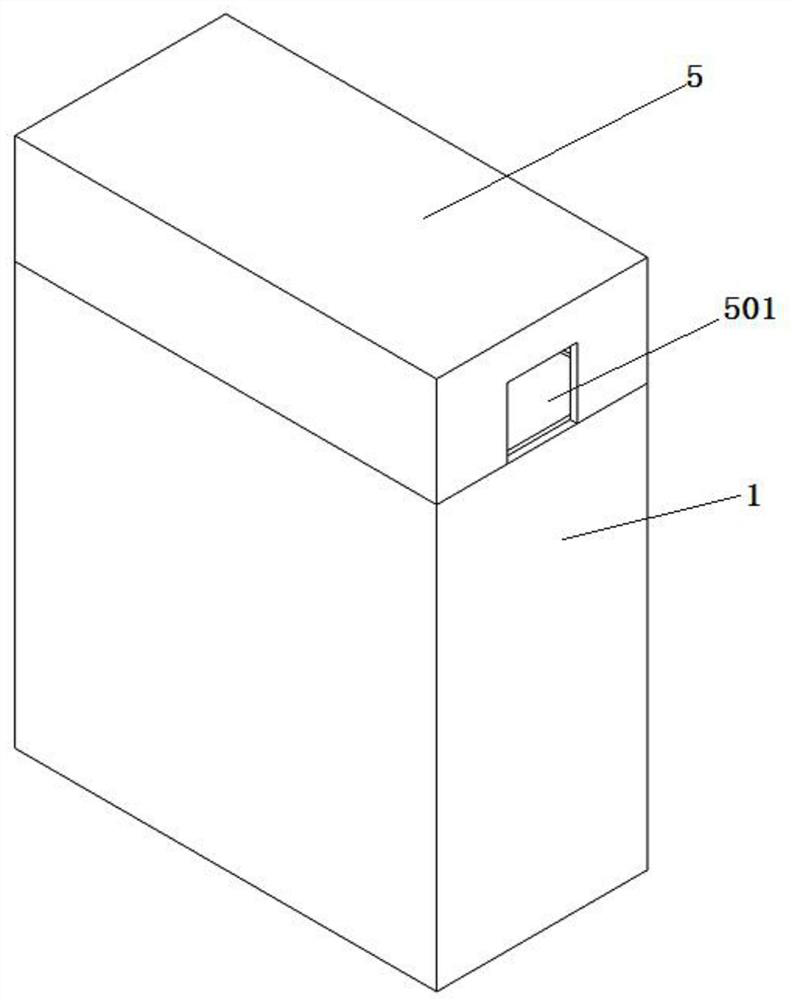

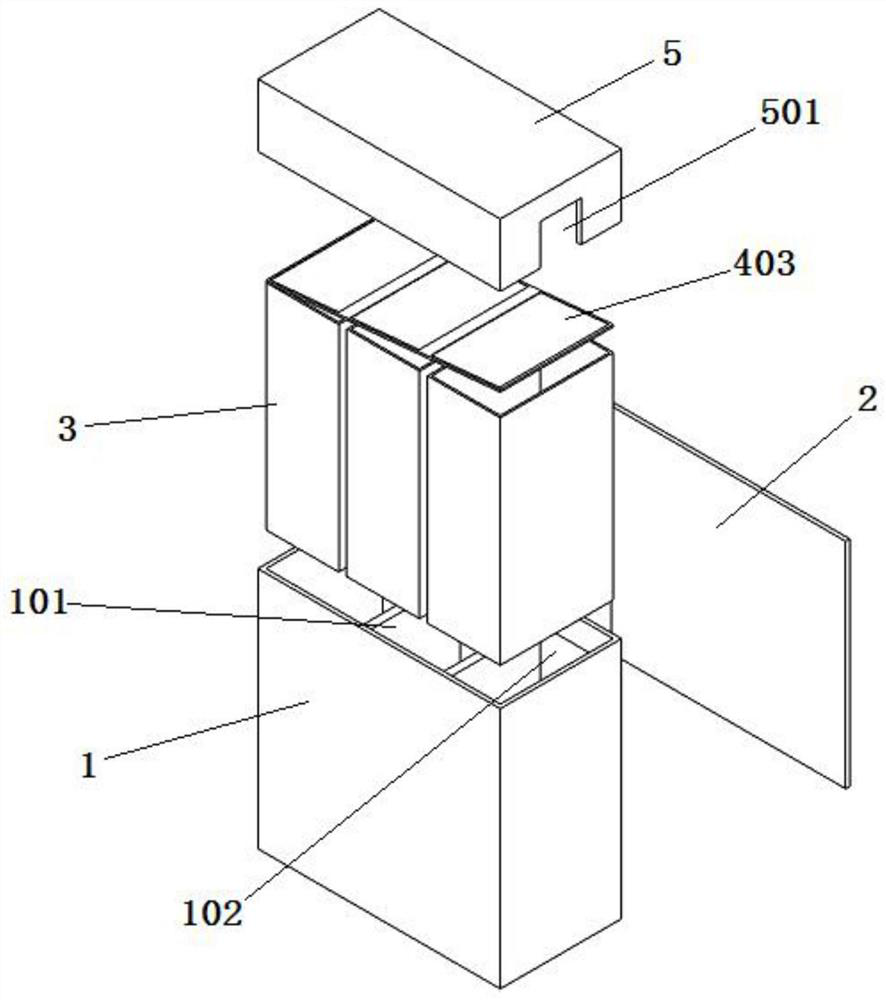

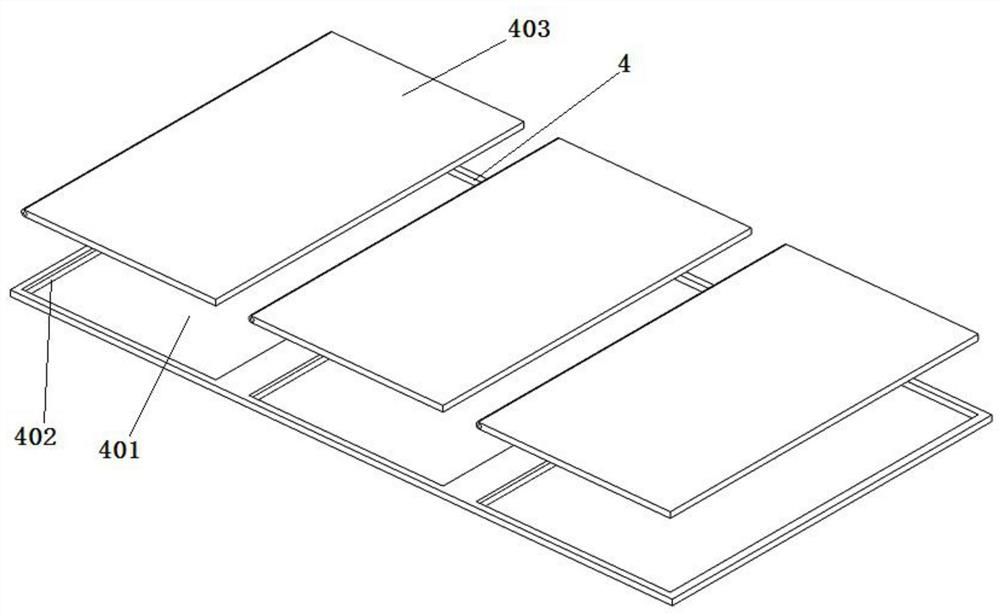

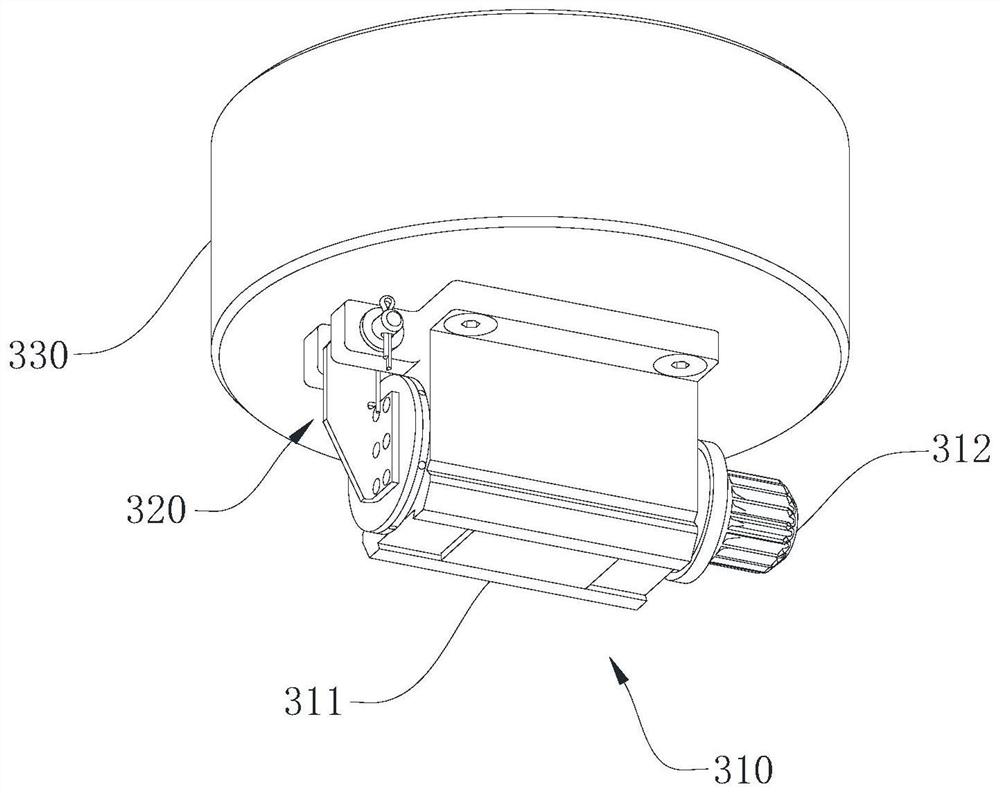

Buried combined dustbin

ActiveCN110980035AIsolate odorImprove environmental qualityRefuse receptaclesEnvironmental geologyMechanical engineering

The invention discloses a buried combined dustbin which comprises a buried box body, wherein the upper end surface of the buried box body is provided with a box body outlet; the bottom surface of theburied box body is connected with pairwise symmetrical box casings; two sides of each of the four box casings are connected to define an inner cavity; the upper end of the inner cavity is provided with a bottom support plate; the box casings and the bottom surface of the buried box body are connected with dustbin boxes through a sliding mechanism; the upper end surface of the bottom support plateis fixedly connected with a garbage inlet pipe; a classified receiving device is arranged at the side surface, near the lower end, of the garbage inlet pipe; the upper end of the garbage inlet pipe isconnected with a feeding box; and garbage classification buttons are arranged at positions, above a feeding opening, on the side surface of the feeding box. The buried combined dustbin has the advantages that the dustbin is buried under the ground, so that peculiar smells are isolated, the quality of the surrounding environment is improved, the ground occupied by the dustbin is reduced, and the overall attractiveness of a high-grade residential area and a high-grade office building is improved; and corresponding garbage feeding passages are opened through the garbage classification buttons, the garbage is accurately classified, and the garbage is prevented from being mistakenly classified and being thrown into the wrong dustbin boxes.

Owner:六安维奥智能科技有限公司

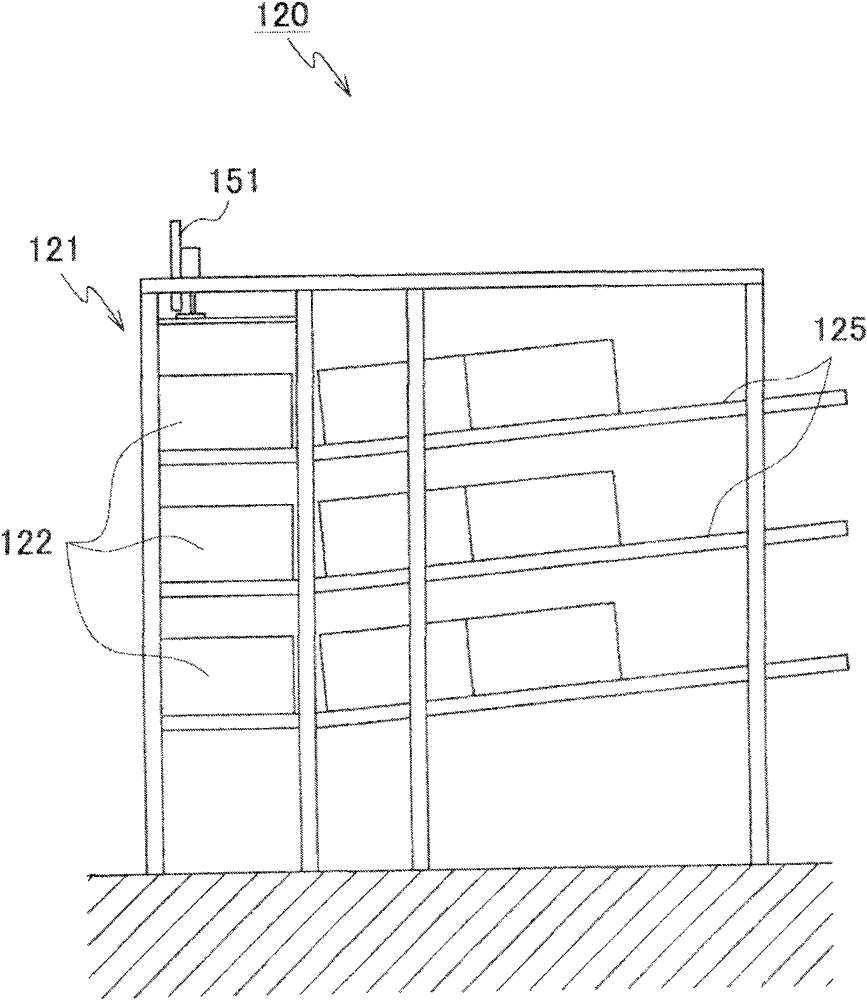

Item distribution system

InactiveCN102275709BReduce the frequency of movementImprove work efficiencyStacking articlesLogisticsDistribution controlDistribution system

The invention provides an article distribution system, comprising a supply rack (120) with a plurality of supply stalls (121) that can take out items from a supply box (122) containing items that need to be supplied, and a supply rack (120) that is loaded with The distribution box (112) of the article that should be distributed can be placed into the distribution shelf (110) of the multiple distribution stalls (111) of the article, and the items that need to be supplied and should be placed are displayed to the staff according to the distribution information. The item distribution system of the distribution control device (150) that controls the opening and closing of the distribution control device (150) of the distribution destination of the supply stall door (123). In this system, even when there are many distribution destinations and types of goods and the number of goods is small, it is possible to efficiently and quickly carry out distribution, reduce the burden on the staff, and reduce distribution errors .

Owner:TSUBAKIMOTO CHAIN CO

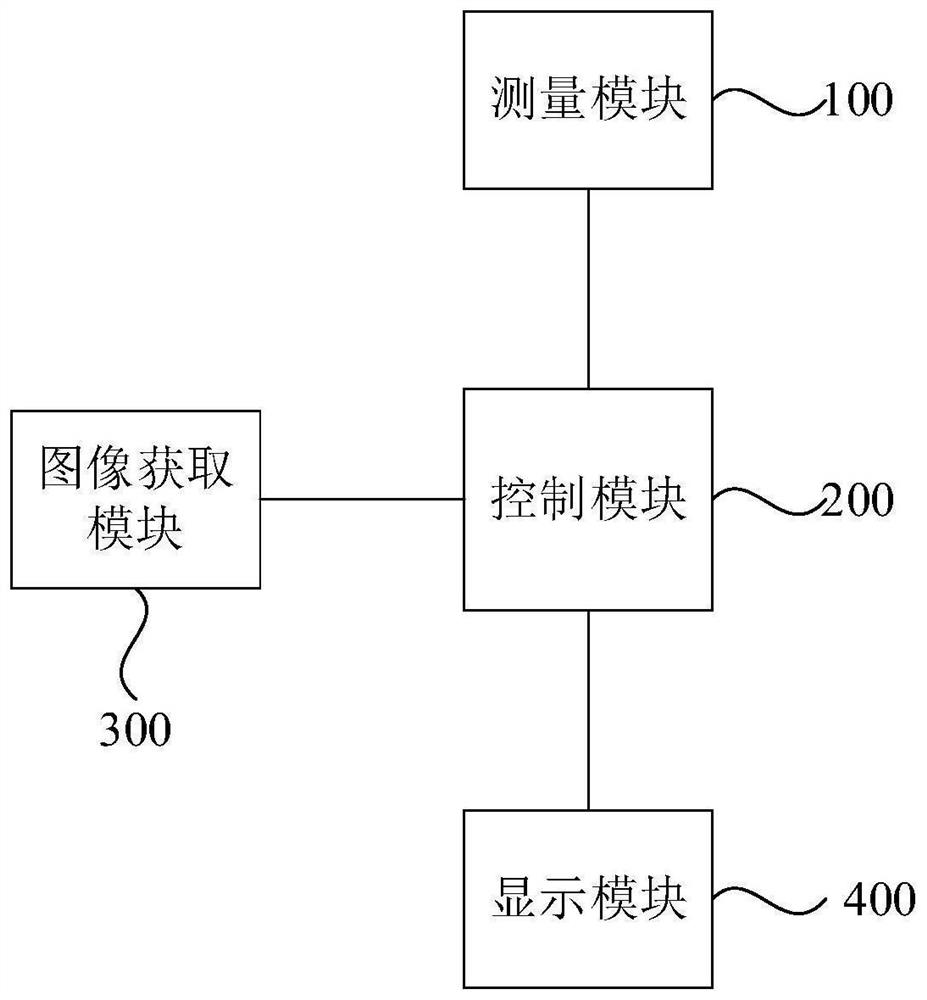

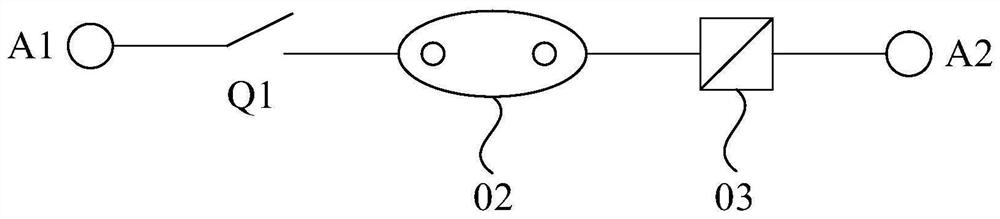

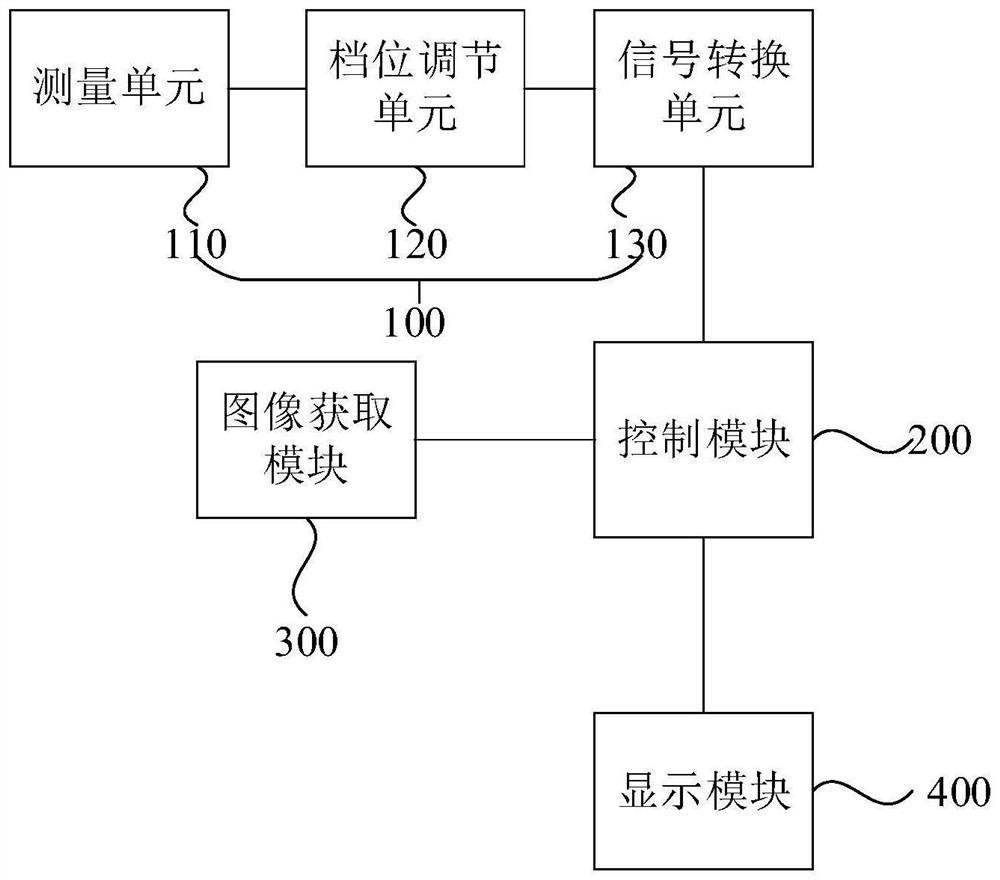

Measurement indicating device and method for relay pressure plate

PendingCN113933565AAvoid miscastingImprove accuracyVoltage/current isolationVoltage measurements onlyTransformerData information

The invention discloses a measurement indicating device and method for a relay pressure plate. The measurement indicating device for the relay pressure plate comprises a measurement module, a control module, an image acquisition module and a display module. The image acquisition module is electrically connected with the control module and is used for acquiring identification information of a to-be-tested relay pressure plate. The measuring module is electrically connected with the control module and is used for measuring the voltage of the first end and the voltage of the second end of a to-be-tested outlet pressure plate; and the control module is used for determining an input judgment result of the to-be-tested outlet pressure plate according to pre-stored data information of the to-be-tested outlet pressure plate, the voltage of the first end of the to-be-tested outlet pressure plate and the voltage of the second end of the to-be-tested outlet pressure plate. According to the measurement indicating method of the relay pressure plate provided by the embodiment of the invention, mistaken input of the to-be-detected outlet pressure plate caused by deviation of related knowledge memorized by an operator when the operator is used for judging whether the to-be-detected outlet pressure plate is switched on or not can be avoided, so that the input accuracy of the to-be-detected pressure plate is improved, and the safe operation of a transformer substation is ensured.

Owner:GUANGDONG POWER GRID CO LTD +1

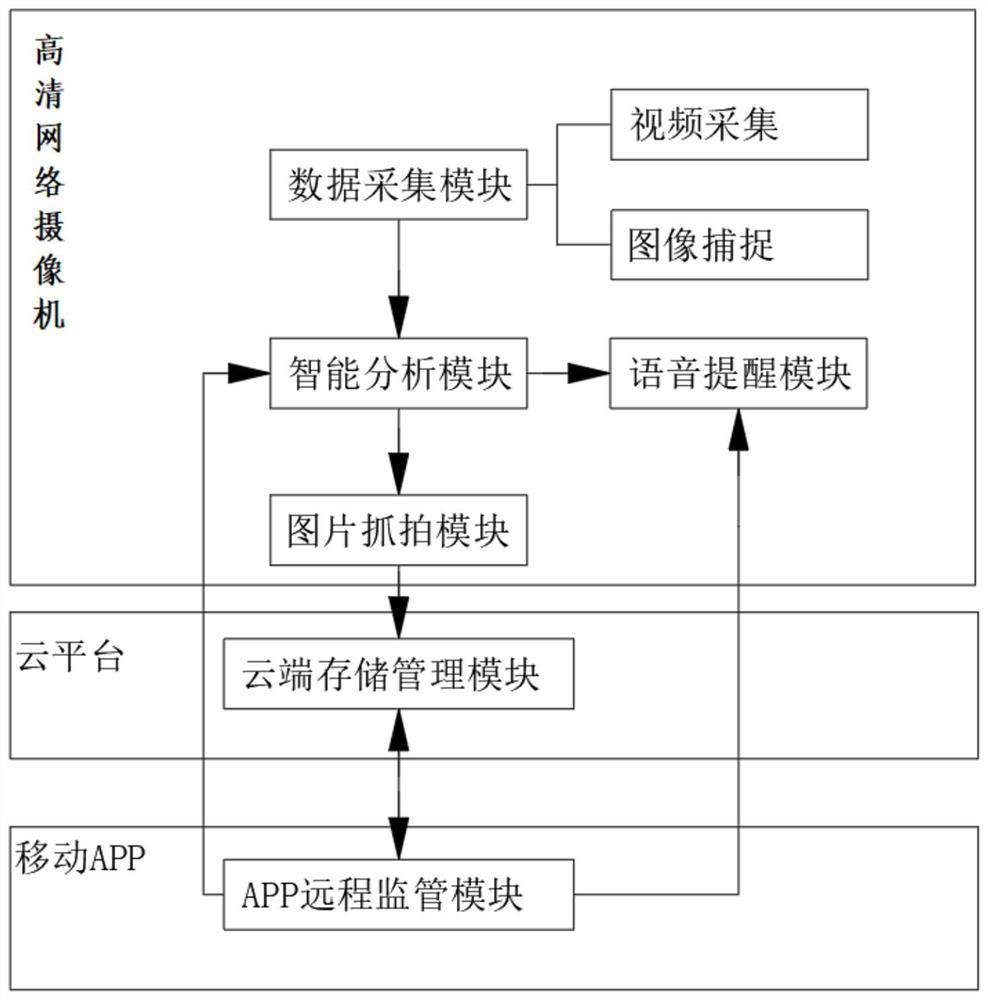

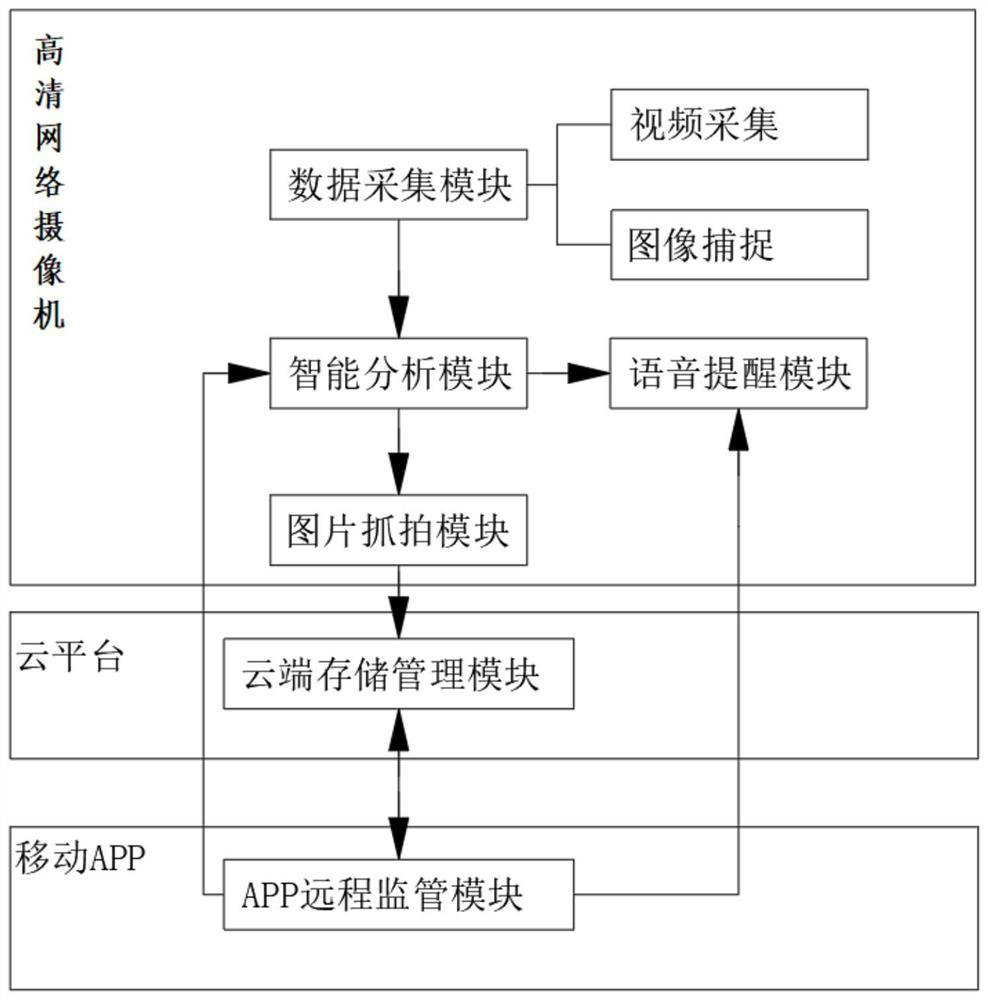

Voice prompt and video image supervision method for garbage classification delivery site

ActiveCN112597804AImprove classification efficiencyReduce processing costsClosed circuit television systemsBiometric pattern recognitionMobile appsVideo image

The invention discloses a voice prompt and video image supervision method for a garbage classification delivery site, and the invention consists of a high-definition network camera, a cloud platform and a mobile APP; the method monitors a person entering a garbage delivery place, and carries out the garbage type prompt of a deliverer when the person enters the garbage delivery range, and avoids wrong delivery by the people. When the person does not throw the garbage into the garbage can, the person is reminded quickly, and the person is warned to throw the garbage correctly and effectively; data statistics can be conducted on the garbage category of the garbage throwing position, the local main garbage category is obtained, then the garbage cans of the main garbage category can be added when the garbage can is placed next time, garbage cans of non-main garbage types are reduced, the garbage classification efficiency is improved, and the garbage treatment cost is reduced. The inventionhas the beneficial effects of improving the garbage classification efficiency, achieving remote monitoring, improving the classification effect of a garbage classification throwing site and the like.

Owner:上海阅目环境科技有限公司

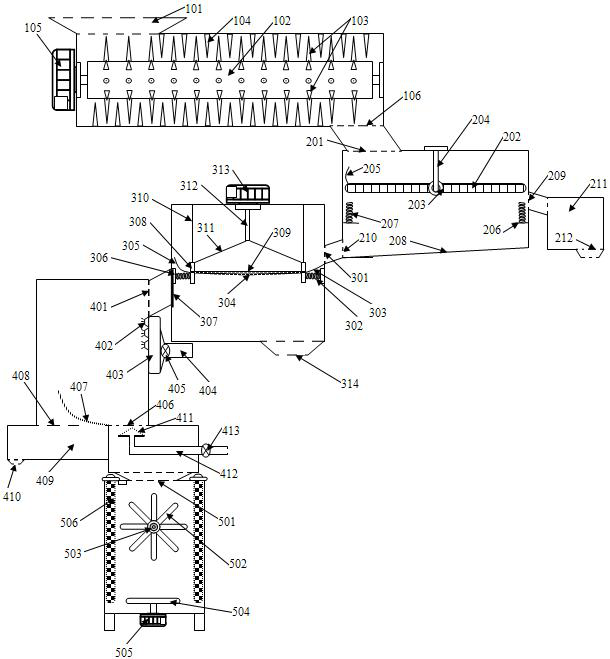

Automatic delivery method for cone yarn dyeing powdery dye and special equipment therefor

ActiveCN101476222BAvoid miscastingAvoid overshootingControlling ratio of multiple fluid flowsTextile treatment machine arrangementsYarnWarm water

The invention discloses a powder form dye automatic distribution and delivery method used in cheese dyeing and special-purpose equipment thereof. The method comprises the following steps: absorbing dye to dye tank; determining dyeing machine and dye formula; metering dyes automatically according to the dye formula; conveying the dyes to dye dissolving tank; adding water to dissolving the dyes intoformula solution; and conveying dyes formula solution to dyeing machine. In the equipment of the invention, the raw material barrel is connected with dye tank; an proportioning track is disposed between the automatic dyes proportioning machine and the dye dissolving tank, and a metering dolly runs thereon; a robot runs between the proportioning track and the dye dissolving tank; the dye dissolving tank is connected to a water pump through a cold water pipe and a warm water pipe respectively; the dye dissolving tank is connected with the main pipe through a branch pipe; and one end of the mainpipe is connected with compressed air pumping station, the other end is connected with the dyeing machine. The invention increases one time sample conforming rate, reduces the direct / indirect energyand manpower cost, realizes in time production and one time accurate production, and achieves the safe reliable clean production with less pollution.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Detection device for linkage of protection pressing plate of transformer substation

The invention relates to a detection device for linkage of protection pressing plates of a transformer substation. The device comprises a box body, a main control board and an upper computer. The maincontrol board is arranged in the box body. The main control board comprises a single-chip microcomputer and an alarm assembly. The single-chip microcomputer is connected with the upper computer. Thesingle-chip microcomputer receives the state of a protection pressing plate and transmits information to the upper computer for checking, and the single-chip microcomputer is in communication connection with the alarm assembly through a serial port. The device has the advantages that the state information of the protection pressing plate is received through the single-chip microcomputer and checked through the upper computer, and due to the fact that the single-chip microcomputer can receive the state information of the protection pressing plate in real time, misoperation of the pressing platecan be effectively prevented, and the safety level of a power grid is improved. Pressing plate misoperation is alarmed in real time, pressing plate mistaken switching and missing switching can be found in time, protection locking, misoperation or refusal is avoided, traffic safety risks are reduced, personal safety is guaranteed, and operation and maintenance personnel can be prevented from driving vehicles to run back and forth in all transformer substations through alarm signals sent by the alarm assembly.

Owner:STATE GRID ZHEJIANG CIXI POWER SUPPLY +1

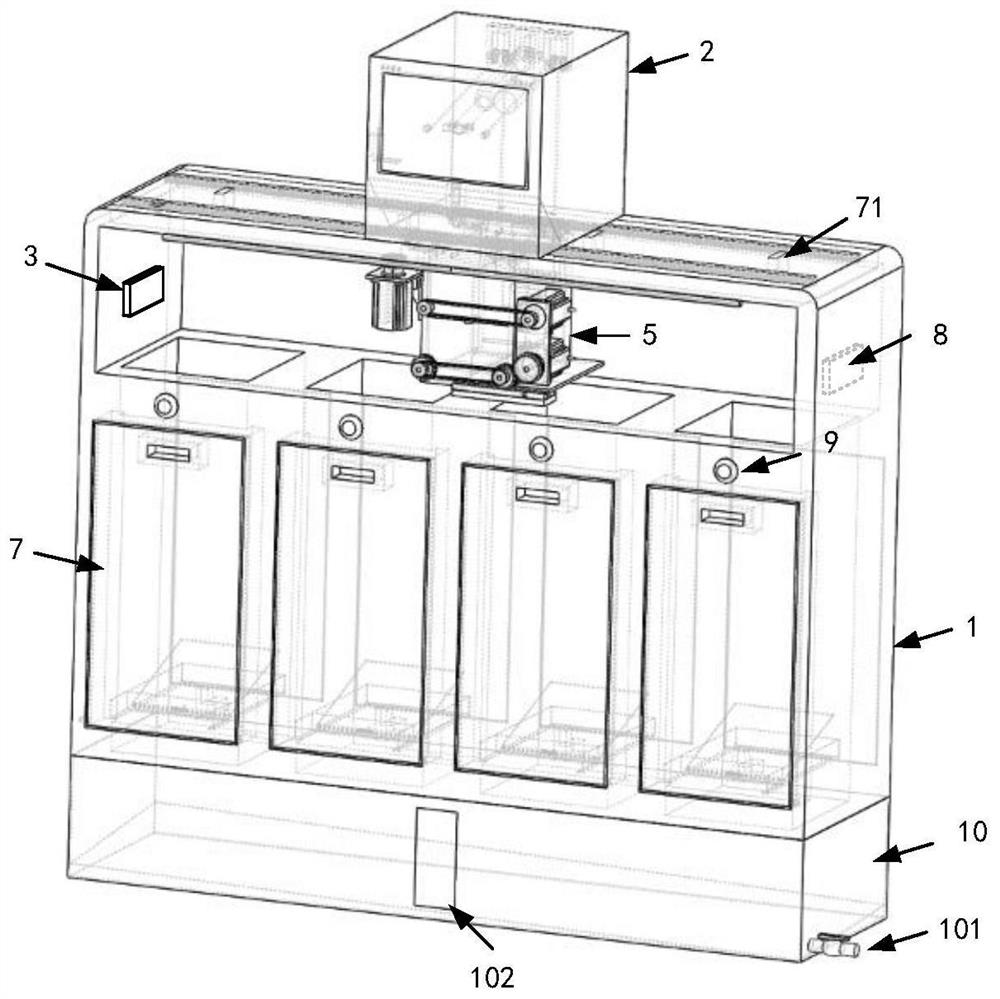

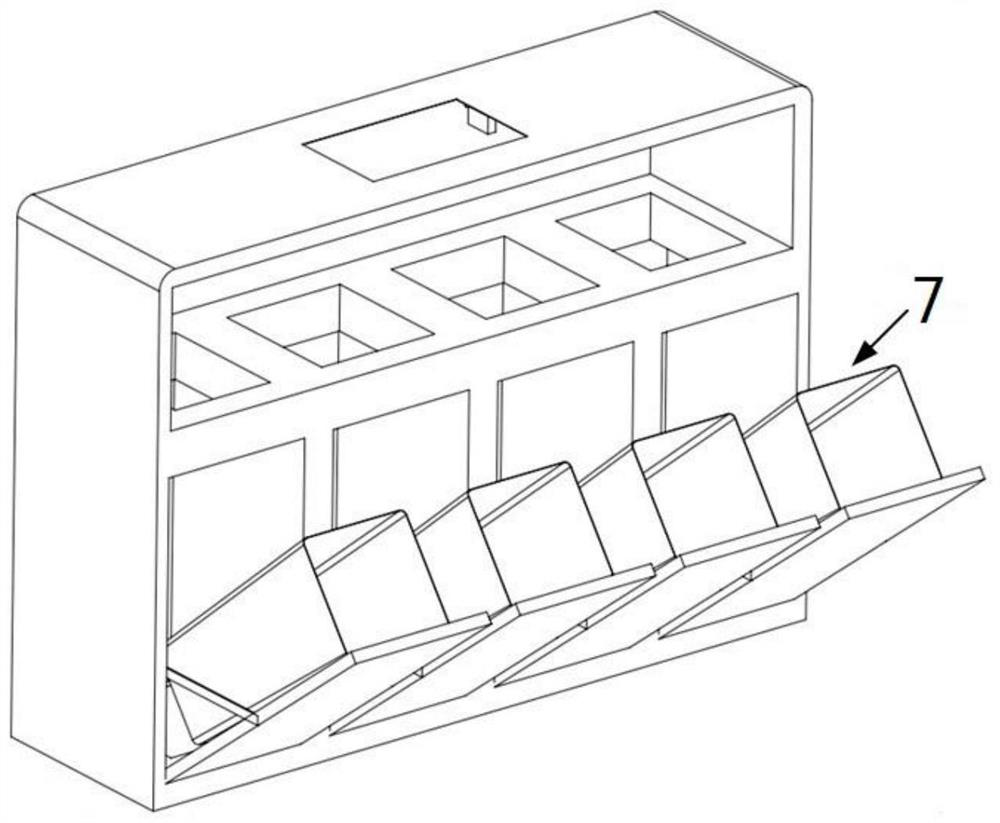

Small throughput intelligent garbage sorting device

ActiveCN111717561BAvoid miscastingAvoid recognition failureWaste collection and transferRefuse receptaclesSafe operationEmbedded system

The invention belongs to the technical field of garbage sorting, and in particular relates to a small-capacity intelligent garbage sorting device, aiming to solve the problem of insufficient usability of automatic garbage sorting devices in the prior art. The invention provides a small-capacity intelligent garbage sorting device, which includes a garbage sorting device body and a controller. The garbage sorting device body is provided with a garbage input port, a garbage transporting mobile box, and a plurality of sorting garbage containers; the surrounding side of the garbage transporting mobile box A garbage detection mechanism is provided, and the controller controls the garbage transport moving box to put the garbage into the designated sorting garbage container based on the detection result of the garbage detection mechanism. The intelligent garbage sorting device of the present invention can realize multiple functions such as garbage input detection, garbage category identification, non-rigid garbage compression, automatic garbage delivery, garbage filling state detection, solid-liquid separation, etc., and ensures safe operation of the device from the perspective of hardware design and workflow , to prevent mis-throwing of garbage, high space utilization rate, and has broad application prospects.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Medical garbage classification method and device

ActiveCN111115045AAvoid MisdeliveryAvoid Misdelivery PhenomenonRefuse receptaclesComputer hardwareControl cell

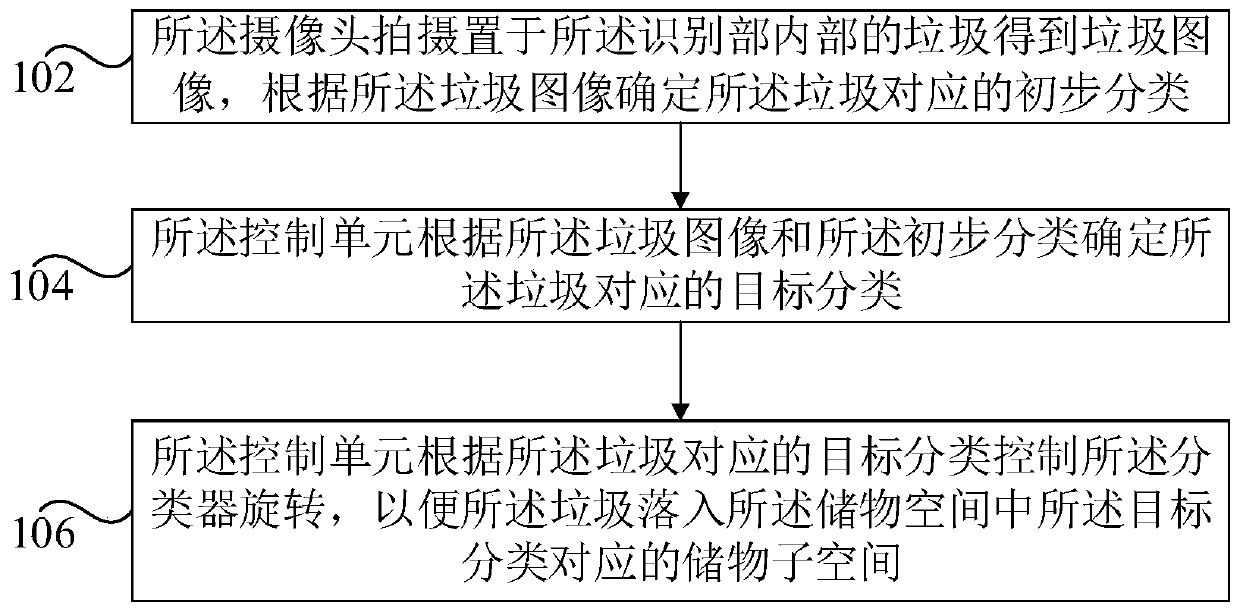

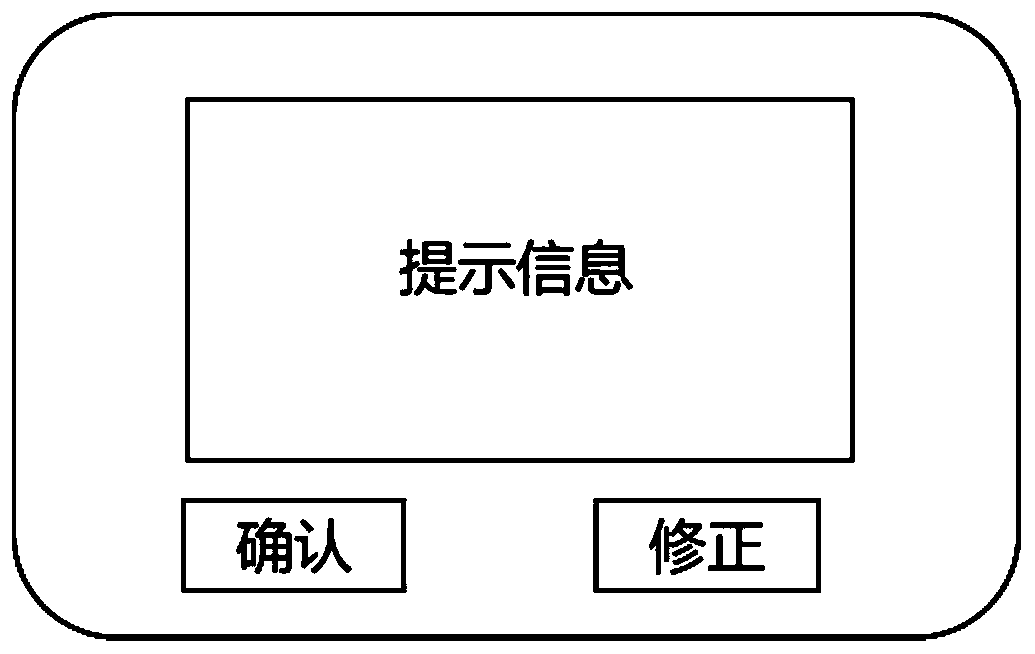

An embodiment of the invention discloses a medical garbage classification method and device. The medical garbage classification method is applied to the medical garbage classification device which comprises a recognition portion with a camera, a classifier, a storage space with multiple storage sub-spaces and a control unit. The medical garbage classification method comprises the steps that the camera shoots garbage which is placed inside the recognition portion, garbage images are obtained, the corresponding preliminary class of the garbage is determined according to the garbage images; the control unit determines the corresponding target class of the garbage according to the garbage images and the preliminary class; and the control unit controls the classifier to rotate according to thecorresponding target class of the garbage so that the garbage can drop into the storage sub-space, corresponding to the target class, of the storage space. By the adoption of the medical garbage classification method, the phenomenon that due to the fact than an operator is careless or is difficult to distinguish the garbage class, the medical garbage is wrongly thrown can be avoided, the medical garbage classification accuracy is improved, the garbage leakage is reduced, and the pollution to the environment is reduced.

Owner:GUANGZHOU KINGMED DIAGNOSTICS CENT

Intelligent cereal threshing integrated device

ActiveCN111656967ANot bad materialAchieves a gentle peeling effectMowersDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention relates to an intelligent cereal threshing integrated device. The intelligent cereal threshing integrated device comprises a straw crushing chamber, a screening component, a screen grinding chamber, a winnowing component, a granary and a bran grinding chamber. Through specifically arranging all the components, efficient integration of straw removing, threshing, separating, storing and bran treatment is achieved, and the labor cost and transportation cost are reduced greatly.

Owner:永州市冷水滩区五谷香农产品加工有限责任公司

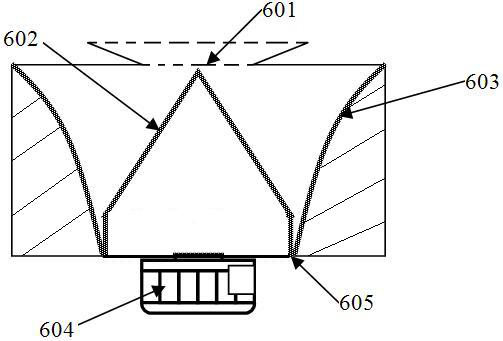

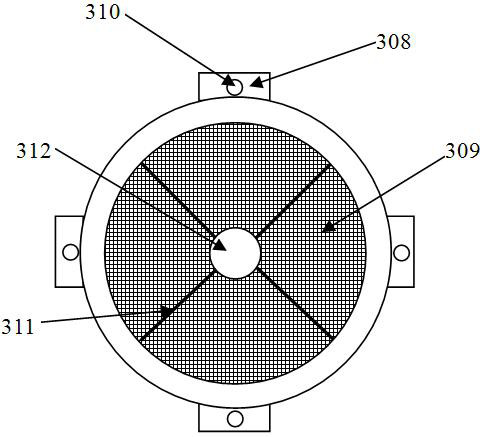

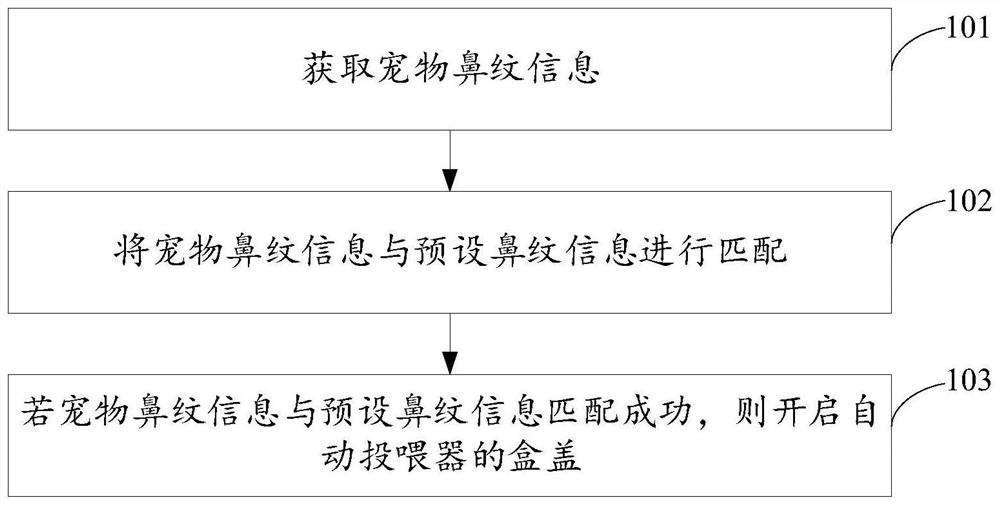

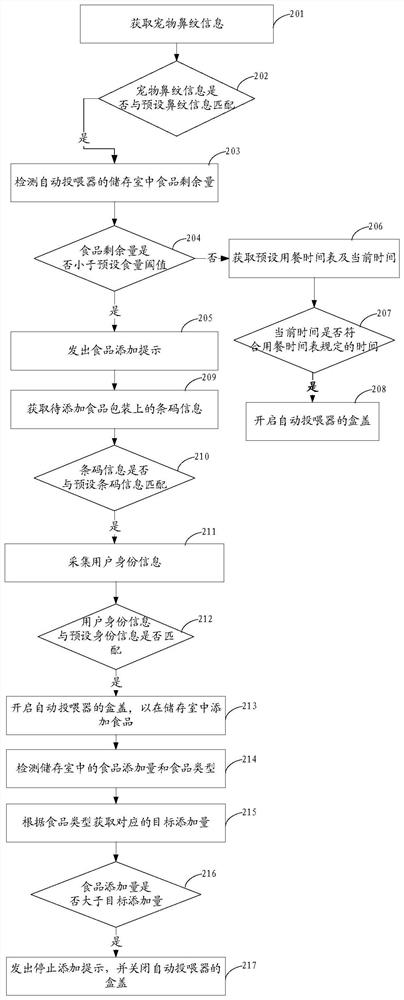

Pet feeding method, automatic feeder and storage medium

PendingCN114332937AImprove feeding accuracyGuarantee the quality of foster careAnimal feeding devicesBiometric pattern recognitionCompanion animalComputer science

The invention discloses a pet feeding method, an automatic feeder and a storage medium. The pet feeding method comprises the steps that pet nose print information is acquired; matching the pet nose print information with preset nose print information; and if the nose print information of the pet is successfully matched with the preset nose print information, opening a box cover of the automatic feeder. The pet nose pattern information is matched with the preset nose pattern information to control the box cover of the automatic feeder to be opened, the automatic feeder can be started according to the pet identity information, food is prevented from being fed by mistake, and the feeding accuracy is improved.

Owner:新瑞鹏宠物医疗集团有限公司

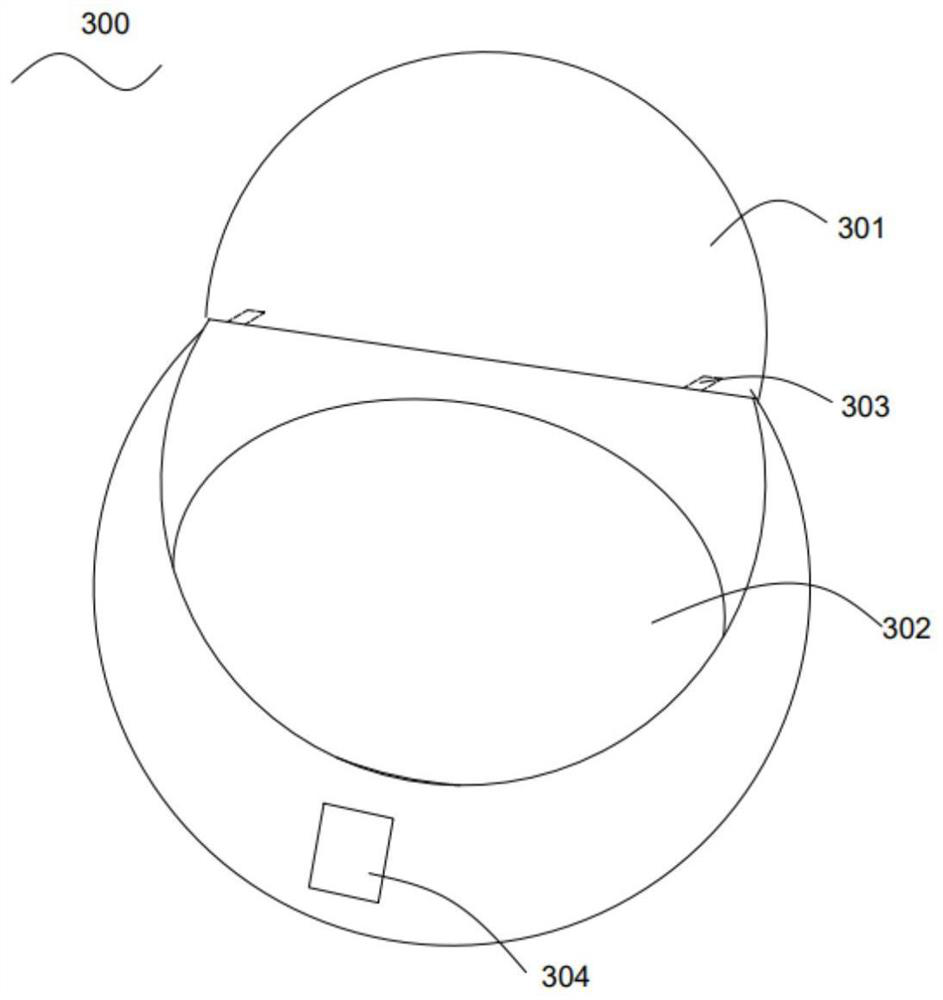

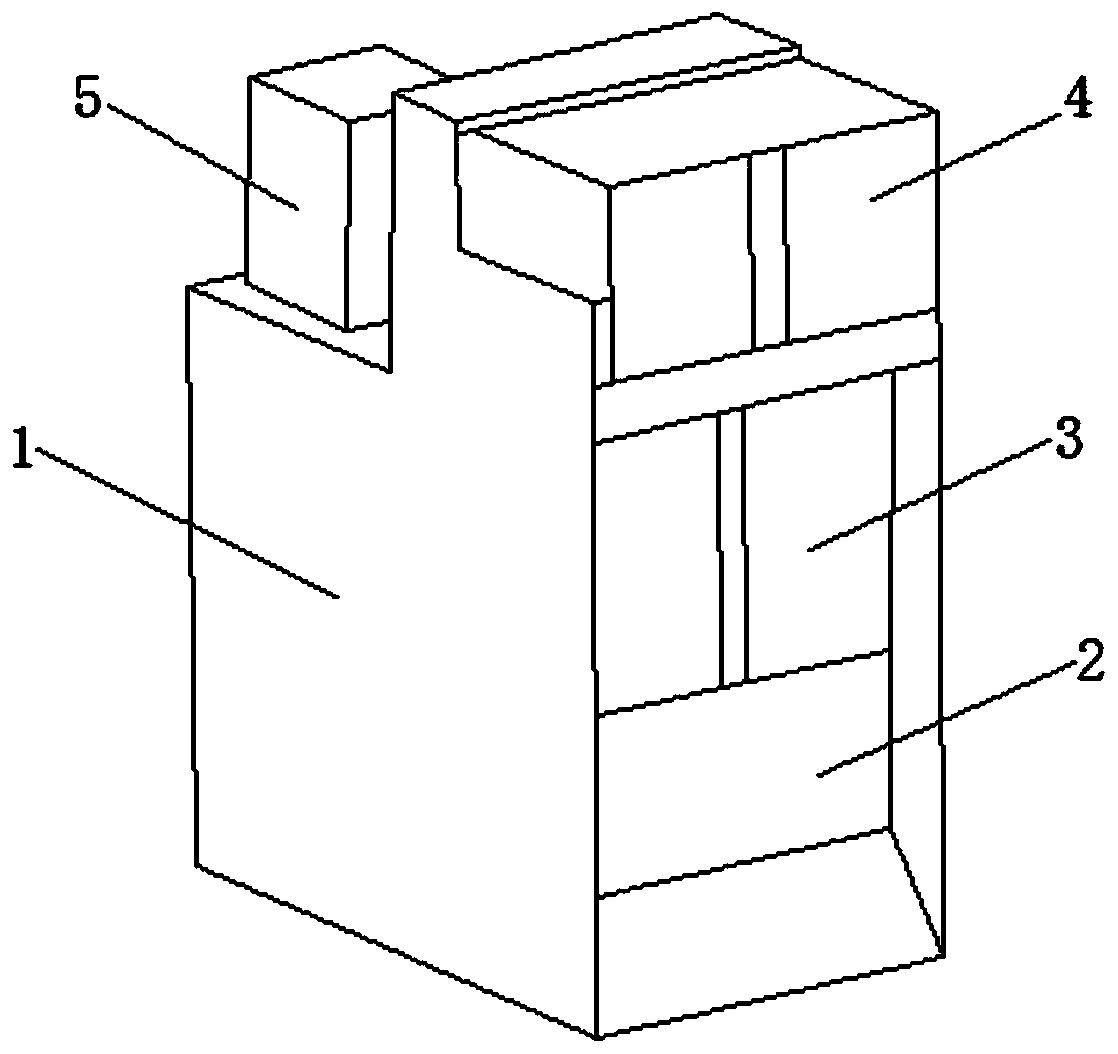

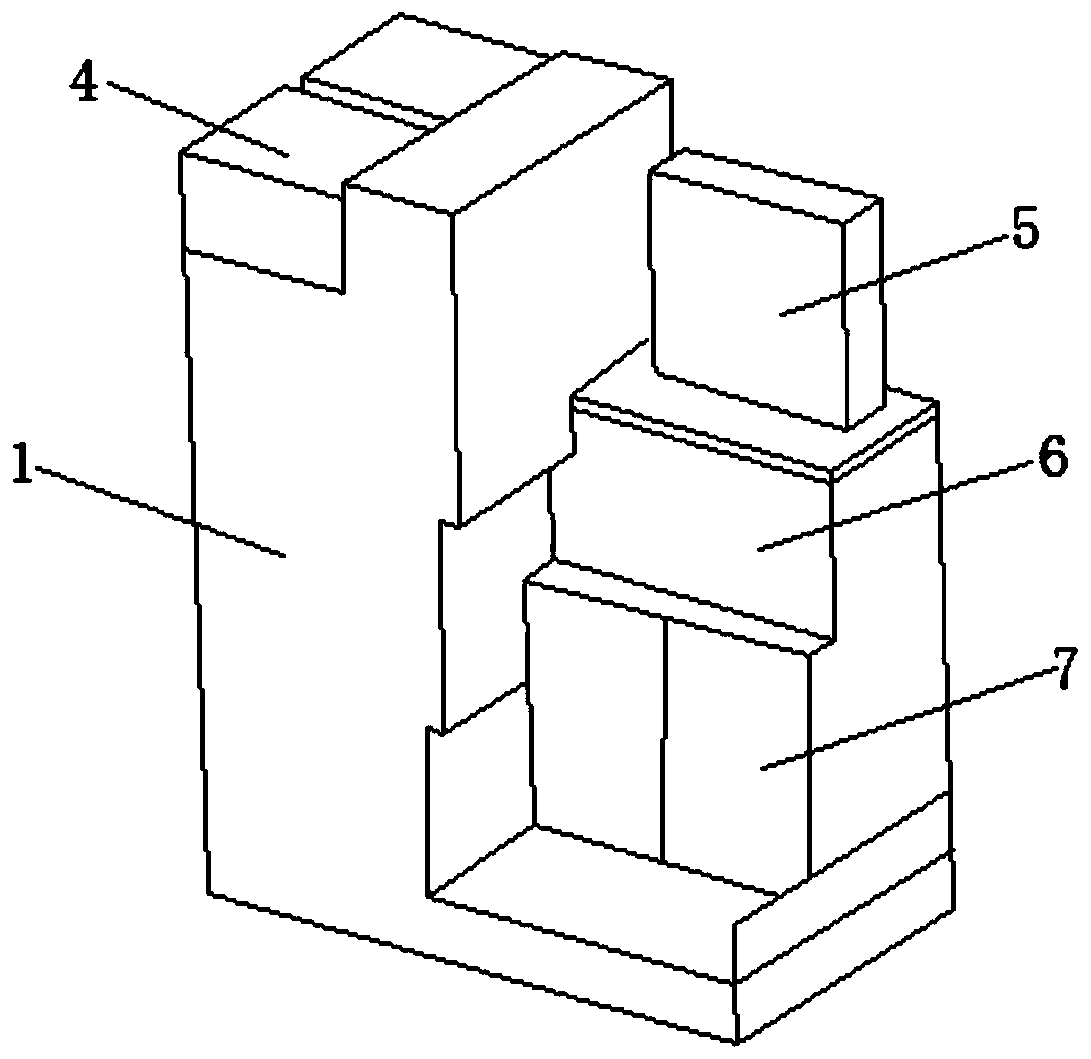

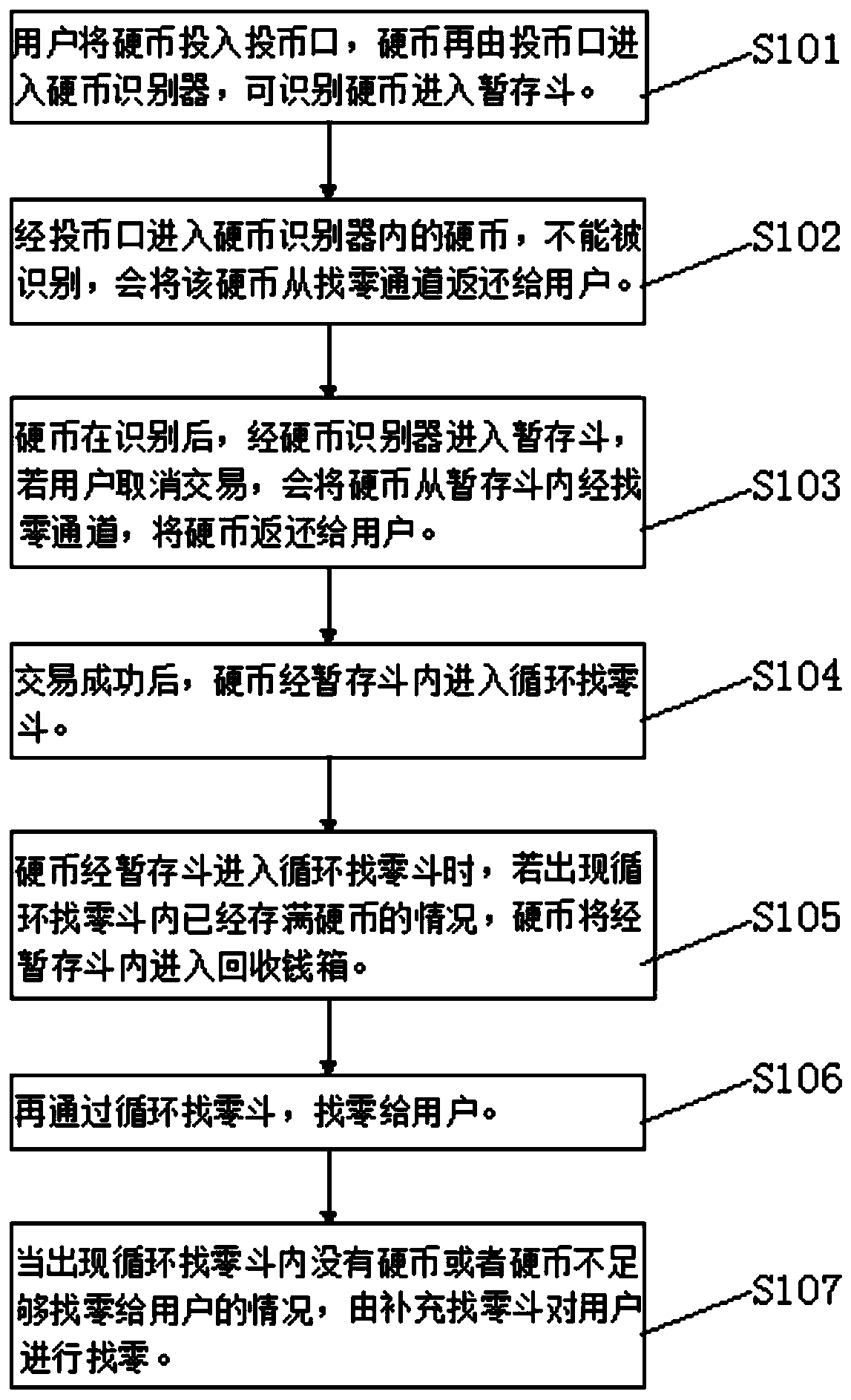

Adaptive mixed-change subway ticketing equipment and method

PendingCN110660151AIncrease profitReduce churnCoin testingCoin/currency accepting devicesCoinIndustrial engineering

The invention discloses adaptive mixed-change subway ticketing equipment and method. The adaptive mixed-change subway ticketing equipment comprises a frame, wherein a main control panel is arranged inthe frame; recycling cash boxes are arranged at the top end of the main control panel and inside the frame; supplementary change buckets are arranged at the upper parts of the recycling cash boxes and at the top end of the frame; and a coin identifier is arranged at one sides of the supplementary change buckets and at the top end of the frame. The adaptive mixed-change subway ticketing equipmentand method have the beneficial effects that on one hand, coins put into the equipment by users can be recycled inside the equipment, so that the situation that change can be carried out only by usingthe coins put by workers is avoided, thereby improving the utilization rate of the coins and also reducing a lot of manpower; and on the other hand, adaptive change to the users can be carried out according to the numbers and types of paper money and the coins in the equipment, thereby improving the recycling rate of the paper money and the coins and also reducing a lot of manpower.

Owner:北京智尚捷付科技股份有限公司

Intelligent garbage classification device based on Internet of Things and control system thereof

InactiveCN111942767AAvoid miscastingTimely exclusionWaste collection and transferRefuse receptaclesComputer hardwareControl system

The invention discloses an intelligent garbage classification device based on the Internet of Things and a control system thereof. The intelligent garbage classification device comprises a peripheralframe, two blocking plates are fixedly connected into the peripheral frame, a moving-out opening is formed in the rear end of the peripheral frame, and a rear cover plate is connected to the moving-out opening in a hinged manner; and the interior of the peripheral frame is divided into three containing cavities through the two blocking plates, garbage containing barrels are arranged in the containing cavities respectively, the height of the garbage containing barrels is smaller than that of the peripheral frame, and the height of the garbage containing barrels is equal to that of the blockingplates. According to the corresponding garbage classification device, when garbage is thrown, only one garbage throwing opening exists, the trouble of observing garbage cans is avoided, and the problem that mistaken throwing is caused due to the fact that corresponding characters on the garbage cans disappear is solved; corresponding garbage throwing openings can be intelligently opened through abutton, so that the garbage is thrown into the corresponding containing barrels; and meanwhile, through the disclosed corresponding structure and the related control system, whether faults exist in the garbage cans or not can be eliminated in time, and misoperation is prevented.

Owner:安盾智慧建设昆山有限公司

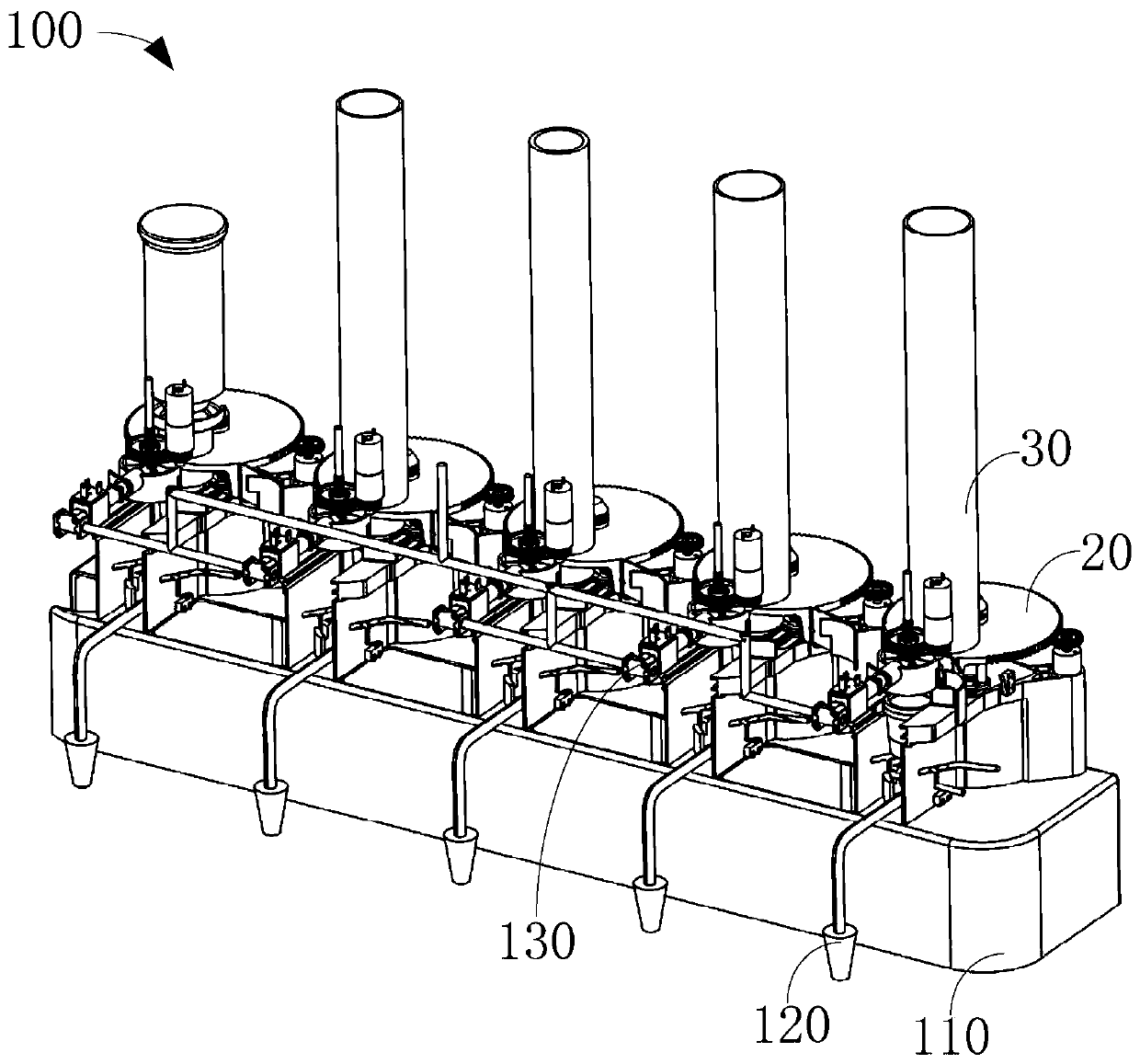

Rotating disc type medicine dispensing adjusting device and medicine dispensing adjusting method

InactiveCN113697142AReduce volumeReduce complexityPackaging automatic controlSolid materialDispensing medicationsBiomedical engineering

The invention discloses a rotating disc type medicine dispensing adjusting device and a medicine dispensing adjusting method, and belongs to the technical field of quantitative medicine dispensing. The rotating disc type medicine dispensing adjusting device comprises a support, a rotating disc mechanism, a metering dispensing device, a medicine dispensing driving device and a control assembly; and the rotating disc mechanism comprises a rotating rod and a rotating disc, the rotating rod is vertically arranged on the support, the bottom end of the rotating rod is connected with the support through a rotating assembly, the top end of the rotating rod is connected with the rotating disc, a plurality of mounting holes are formed in the rotating disc in the circumferential direction, a metering and feeding device is arranged in each mounting hole, and the medicine dispensing driving device is arranged on the support and is close to one metering dispensing device. According to the metering and dispensing device for medicine storage, metering configuration of traditional Chinese medicines in the same prescription can be completed without one-to-one matching of the medicine dispensing driving device, the size of the whole device is greatly reduced, the complexity of the whole device and the cost of equipment are reduced, the medicine dispensing process is optimized, and the medicine dispensing efficiency is improved.

Owner:周诚悦

Intelligent banknote recognizer

PendingCN107123186AEasy to input from multiple anglesAvoid miscastingPaper-money testing devicesCoin/currency accepting devicesMan machineEngineering

The invention discloses an intelligent banknote recognizer. The intelligent banknote recognizer comprises a main frame, a touch display screen, a banknote inlet, an identification device and a banknote box, wherein the touch display screen, the banknote inlet, the identification device and the banknote box are arranged in the main frame. The touch display screen is arranged above the main frame and is used for man machine information interaction. The banknote inlet is arranged at the lower part of the main frame and is the porthole through which a banknote is input or withdrawn. The identification device is arranged behind the banknote inlet to identify the authenticity and the nominal value of the banknote. The banknote box is arranged above the identification device and comprises a number of sub-storage boxes used for storing banknotes of different nominal values. According to the invention, the intelligent banknote recognizer integrates the functions such as authentication, identification, storage and management, and can effectively prevent erroneous input of rigid coins; the banknote identification accuracy is improved; and the usage log of the machine can be viewed in real time.

Owner:南京宝坚电子科技有限公司

Network-type garbage fee-based collection method

InactiveCN105197464AStandardize garbage classificationAvoid miscastingRefuse receptaclesRadio frequency signalEncryption

The invention discloses a network-type garbage fee-based collection method. The method comprises the steps that garbage is classified, and classified data are stored to a storage module; an IC card user database is arranged in a classification collection box, and external communication is conducted through radio-frequency signals; a scanning device is arranged in the classification collection box, and scanning data are obtained; the scanning data and the classified data of the storage module are matched and compared through a controller, and classification movement instructions are sent out; a classification mechanism on the classification collection box sends the garbage to different storage bins to be stored according to the classification movement instructions; the controller converts the scanning data into garbage equality value data through a preset conversion rule to be stored in the user database; the user database is stored to a network cloud terminal through network encryption. According to the network-type garbage fee-based collection method, the garbage can be automatically classified and converted into the corresponding equality value data to be stored to the network cloud terminal, garbage classification is normalized, and network communication with an external donation receiving platform can be achieved through a donation execution module, so that the donation function of the garbage equality value data is achieved.

Owner:龚成

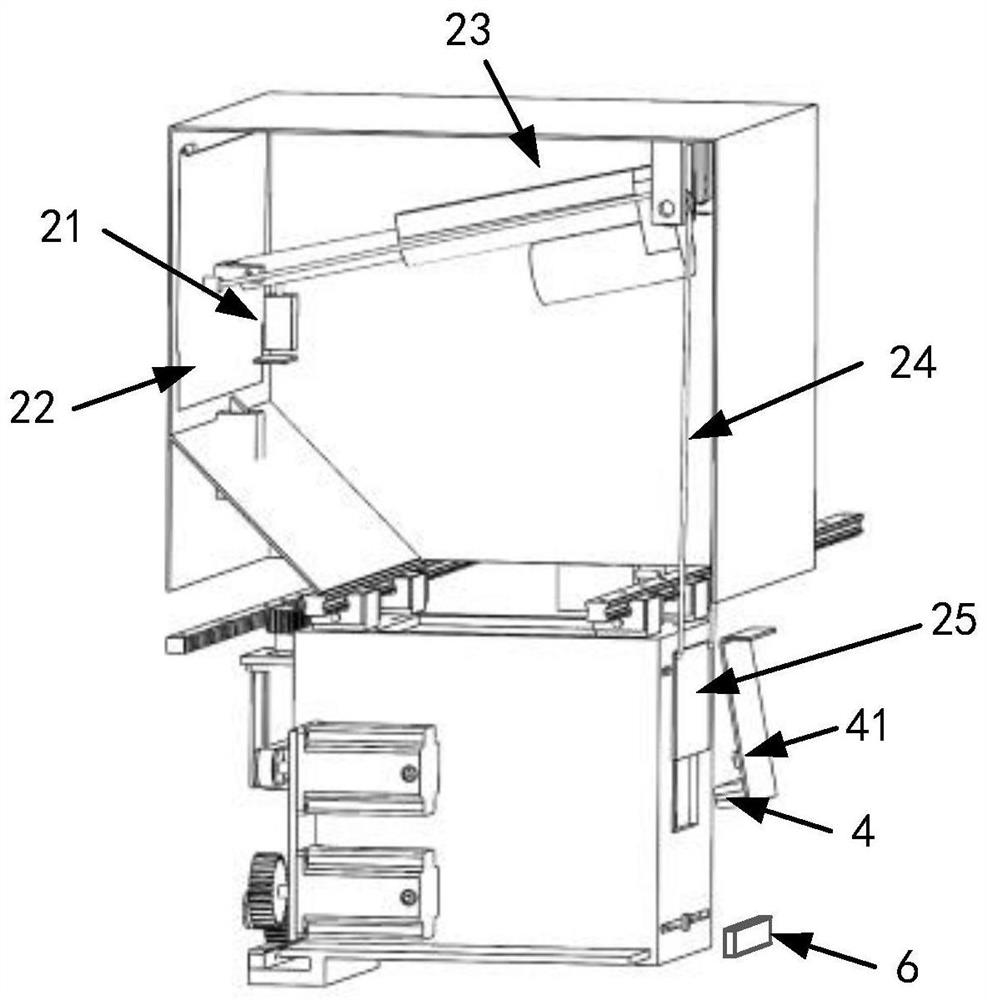

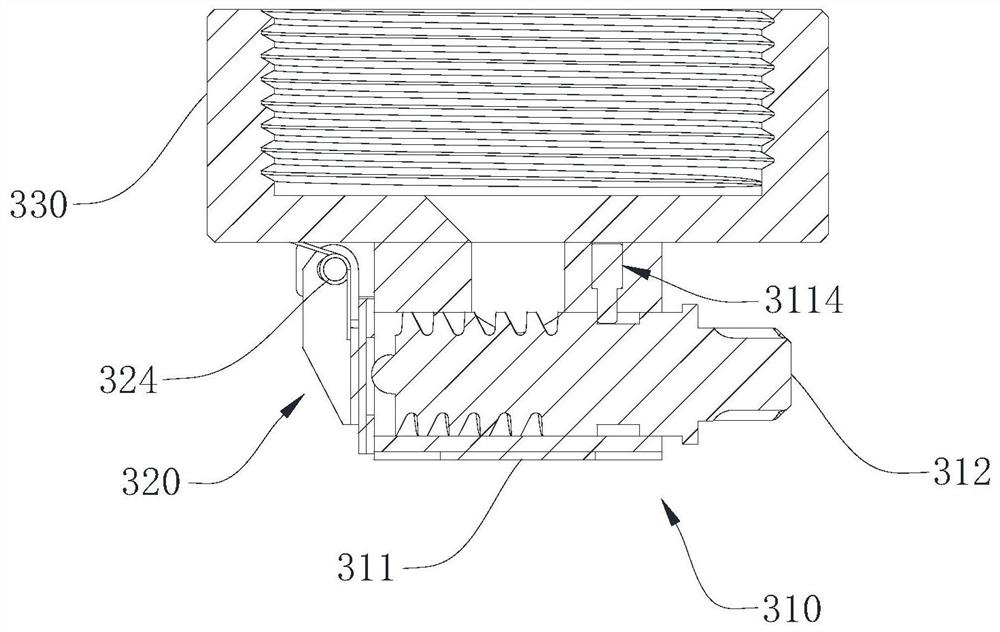

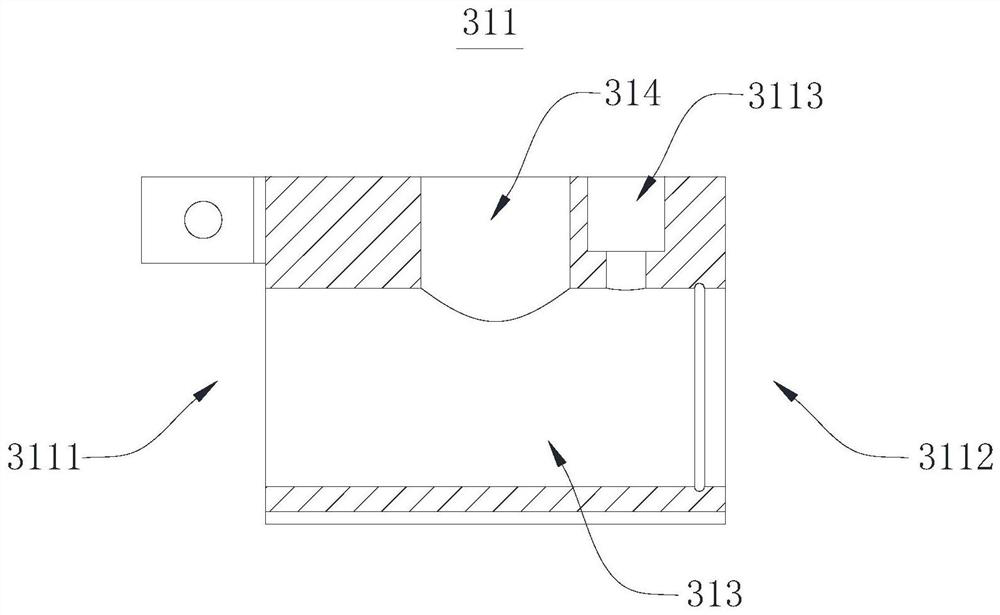

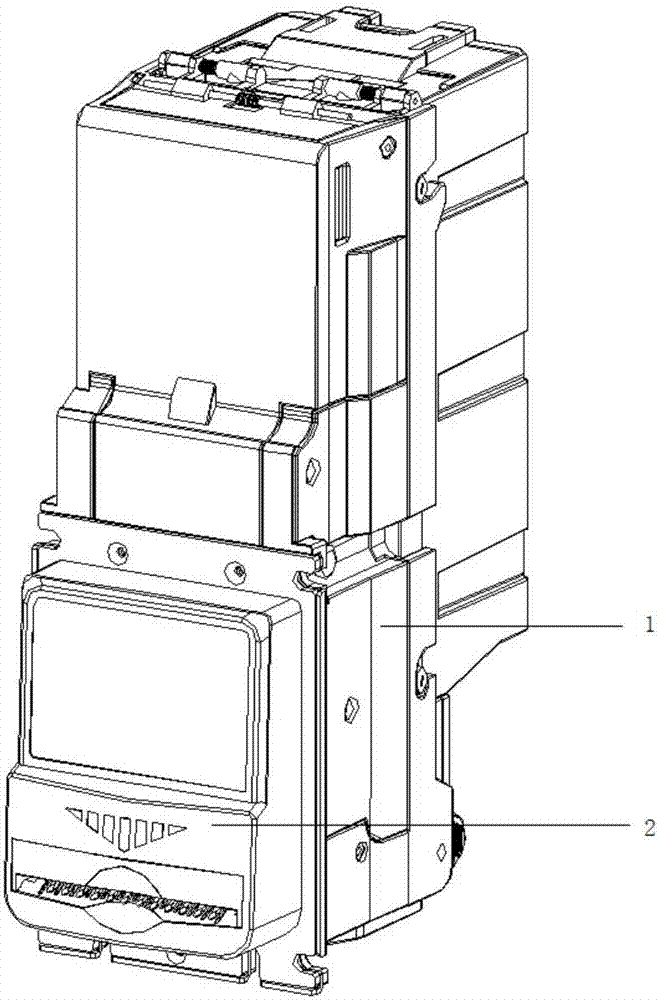

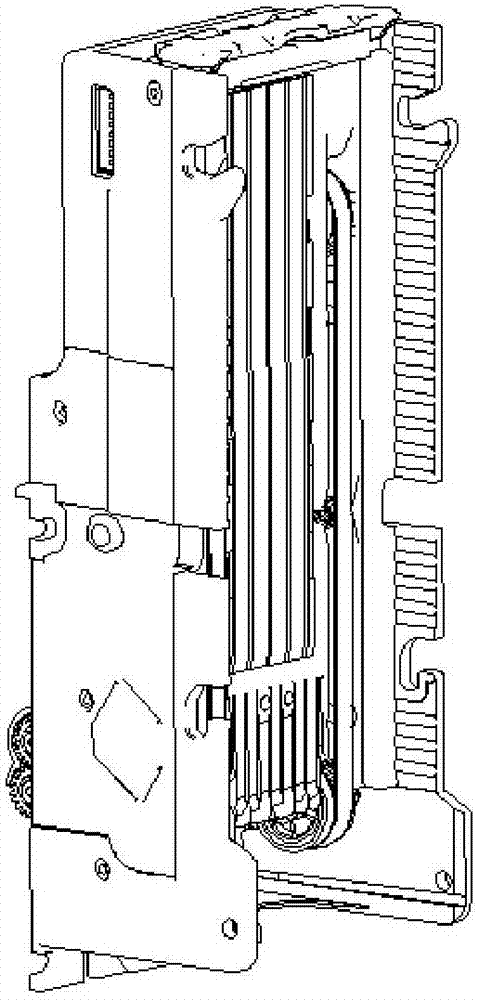

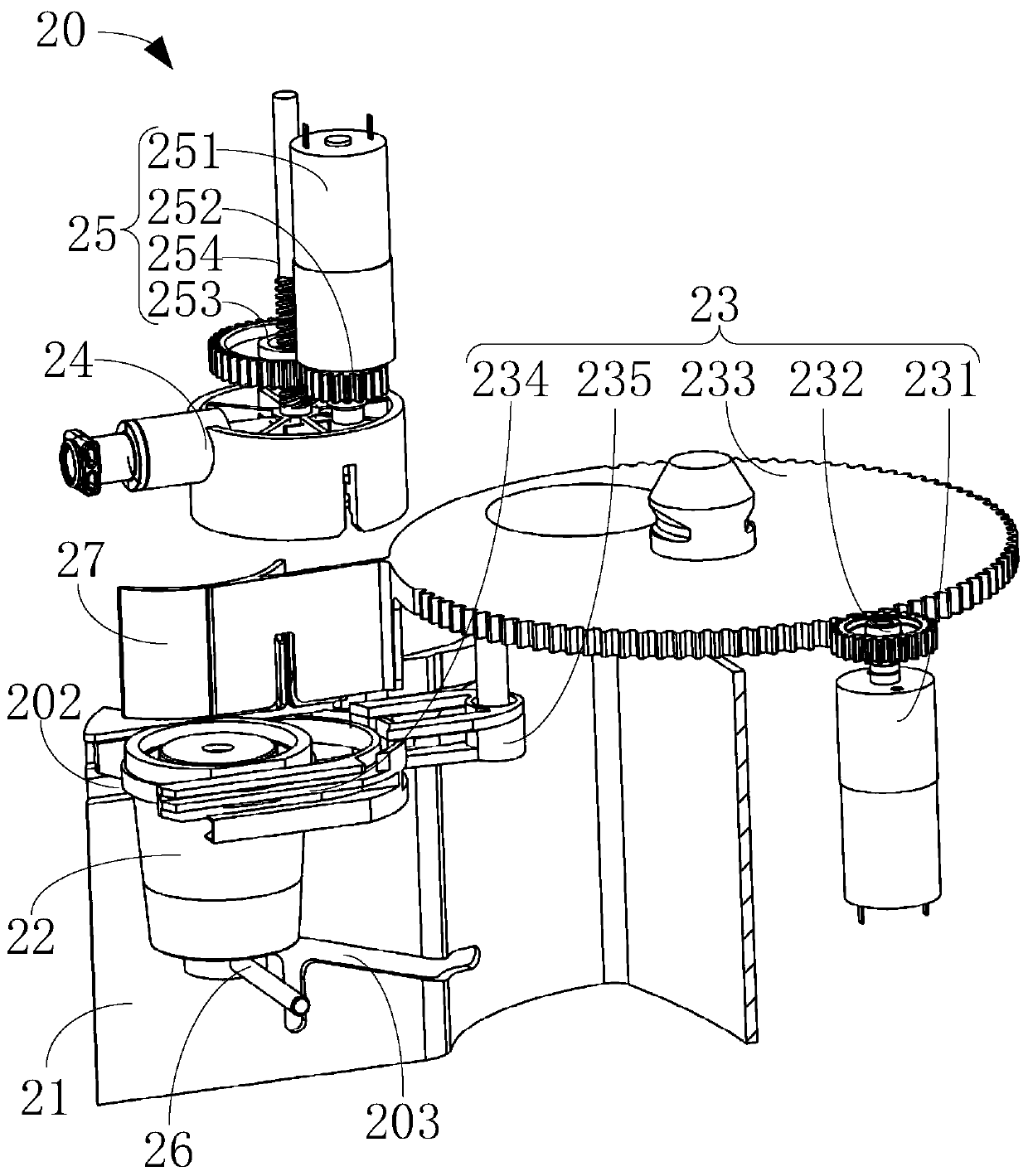

Brewing device and beverage machine

The embodiments of the invention disclose a brewing device and a beverage machine. The brewing device comprises a mounting bracket, a brewing chamber, a brewing head, a first driving assembly and a second driving assembly. The brewing chamber is slidably connected to the mounting bracket; the brewing head is movably arranged on one side of the brewing chamber, and the brewing head can move towardsor away from the brewing chamber relative to the brewing chamber; the first driving assembly comprises a first motor, a gear plate and a connecting rod; the first motor is connected with the gear plate and can drive the gear plate to rotate around the central axis of the gear plate; one end of the connecting rod is arranged in a manner of being offset from the circle center of the gear plate andis rotatably connected with the gear plate; the other end of the connecting rod is movably connected to the brewing chamber; the connecting rod can rotate relative to the brewing chamber and can drivethe brewing chamber to move; the gear plate is provided with a feeding opening, wherein the feeding opening is used for allowing a raw material to pass through and to enter the brewing chamber; and the second driving assembly is connected with the brewing head and can drive the brewing head to move. Through the arrangement, mistake feeding of the raw materials can be effectively prevented, and the structure is simple and compact.

Owner:CINO TECH SHENZHEN LTD

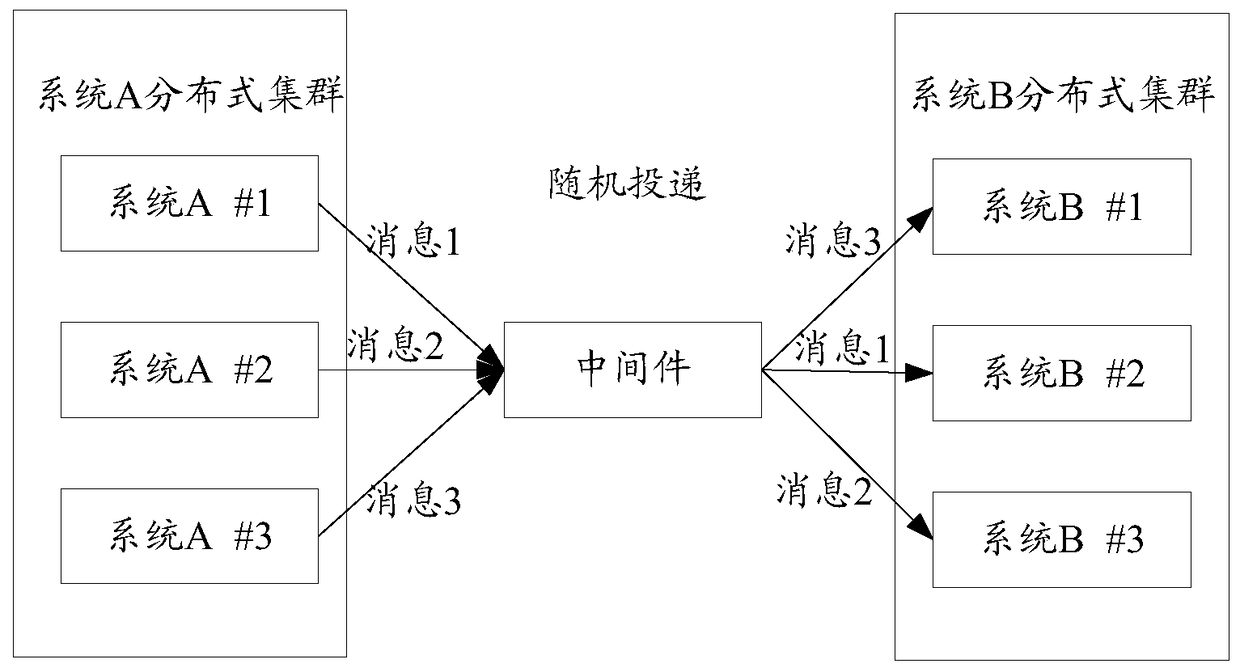

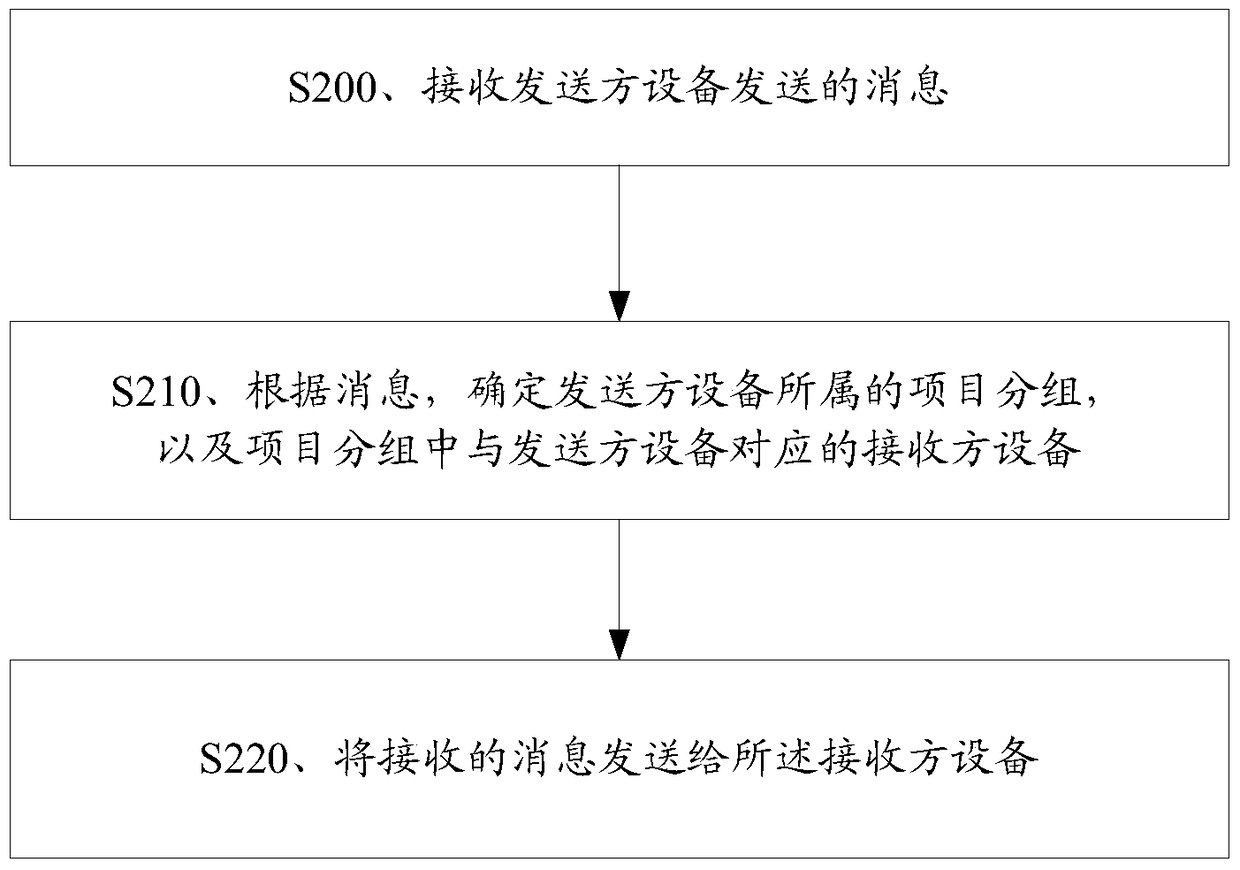

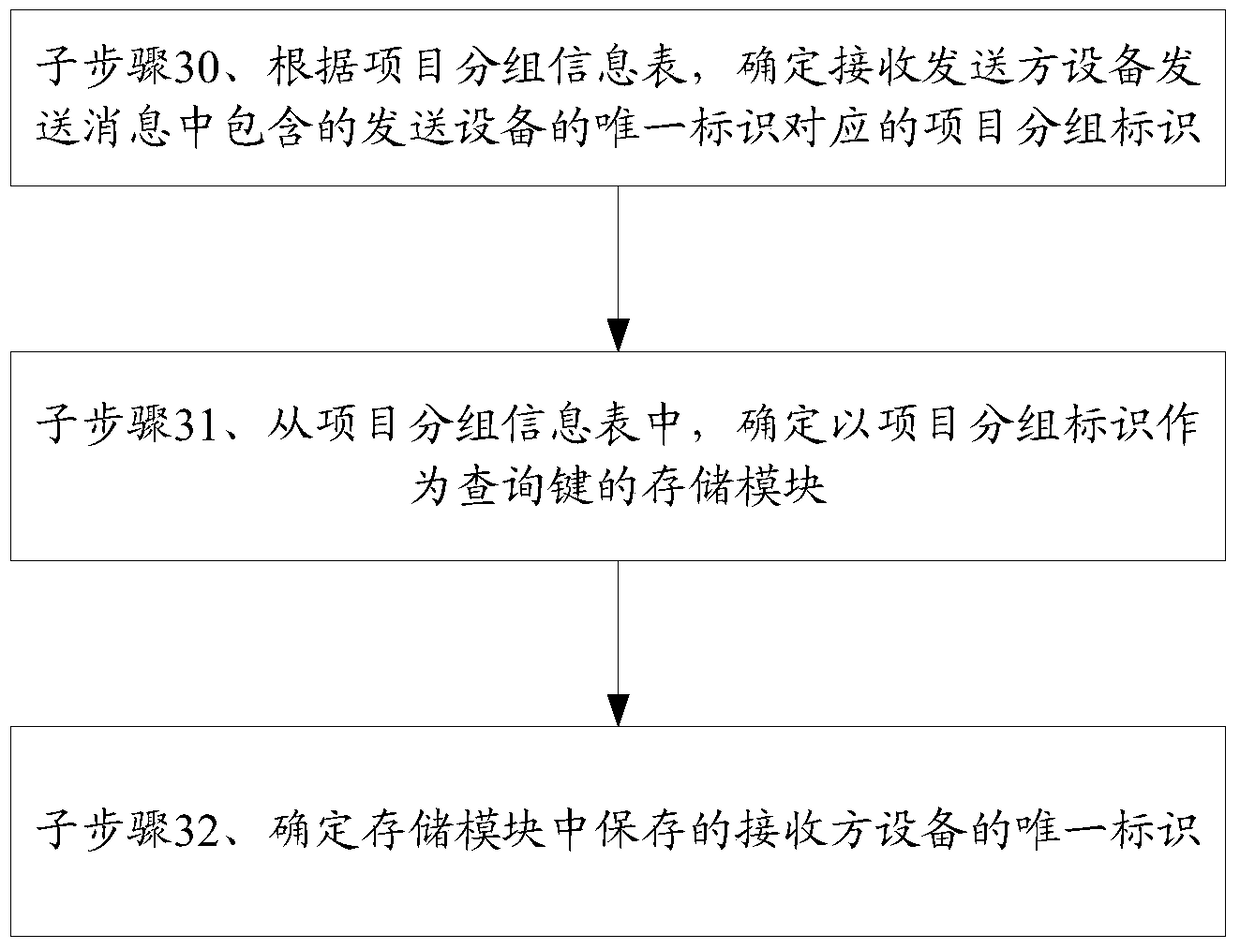

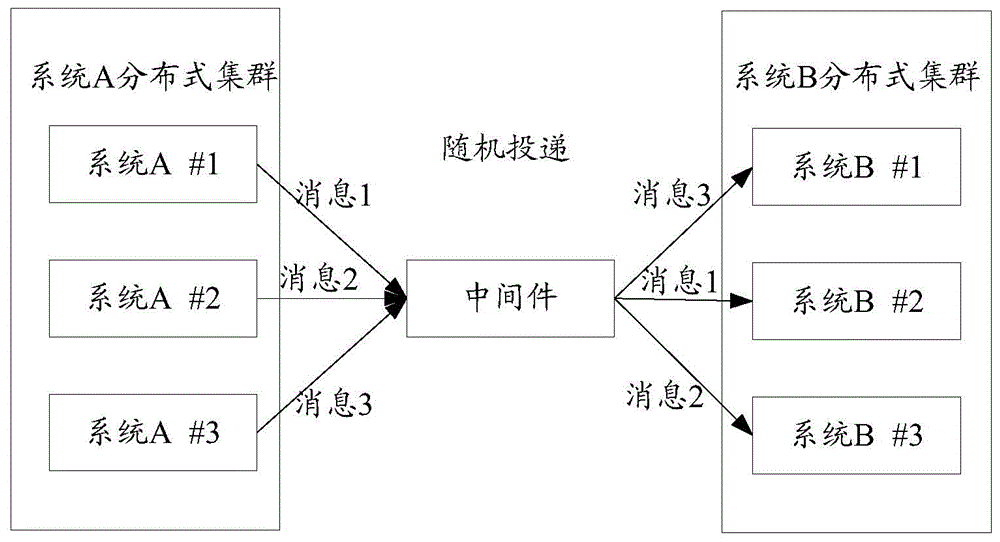

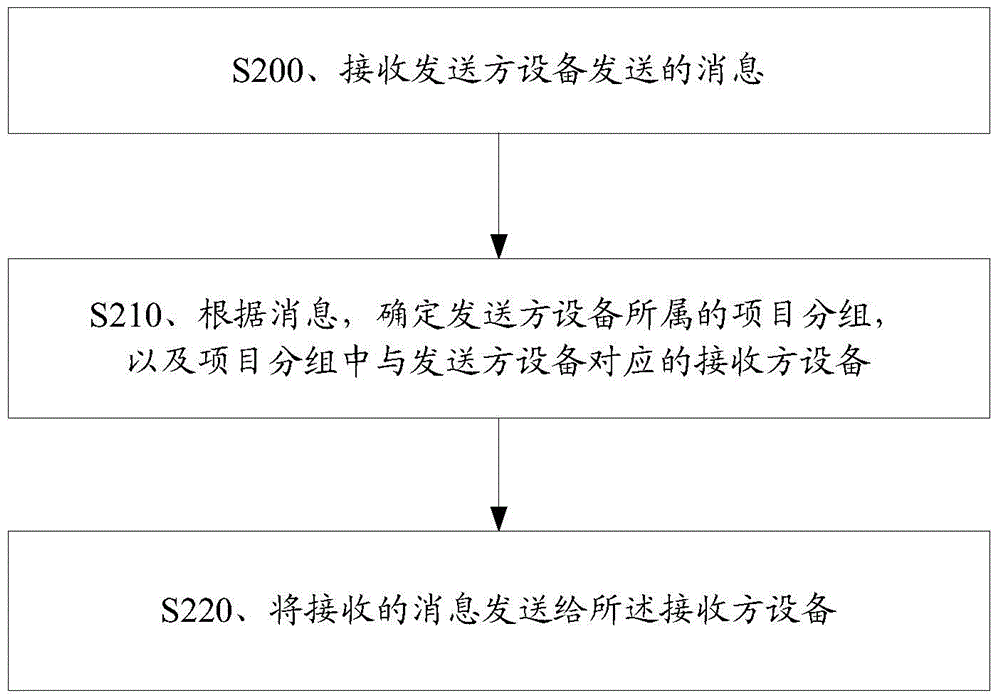

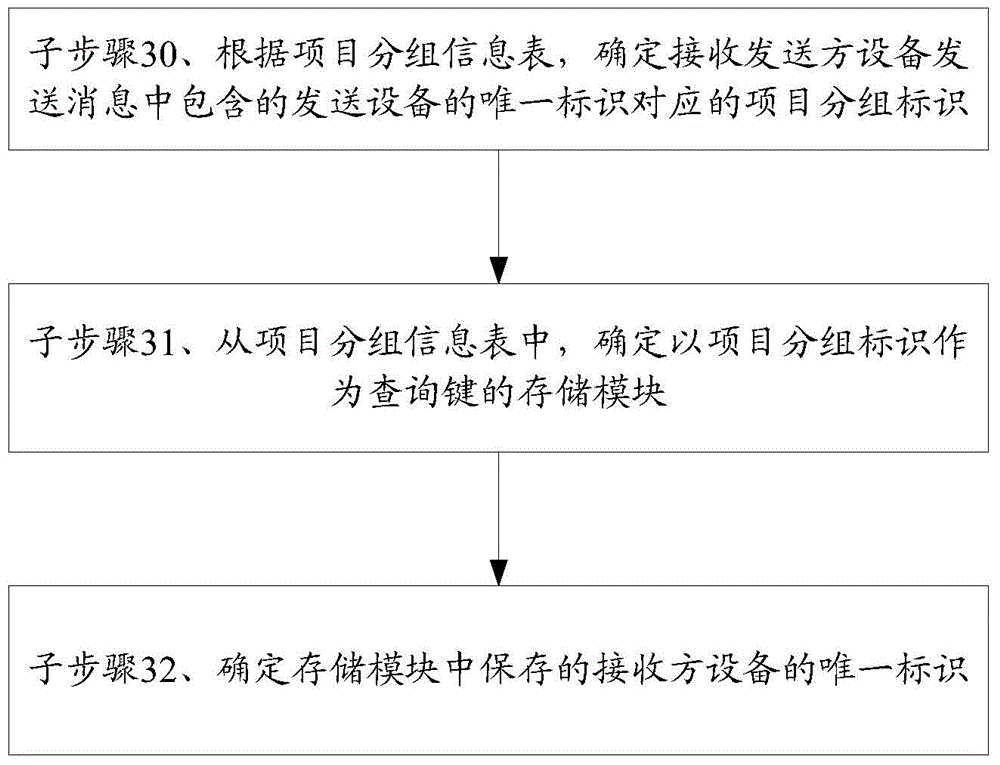

A message transmission method and device

ActiveCN105635230BAccurate transmissionAvoid miscastingTransmissionTelecommunicationsTransfer procedure

The application discloses a method and an apparatus for transmitting a message, applied to the scene that transmitting equipment transmits a message to assigned receiving equipment. The method comprises the steps of: receiving a message transmitted by transmitting equipment; according to the message, determining a project group to which the transmitting equipment belongs and receiving equipment corresponding to the transmitting equipment in the project group; and transmitting the received message to the receiving equipment. According to the method and the apparatus, transmitting equipment and receiving equipment referred by each project can be associated through project group, during a message transmission process, the message can be accurately transmitted to the receiving equipment according to the association, thereby effectively avoiding the phenomenon of mistakenly transmitting the message.

Owner:ADVANCED NEW TECH CO LTD

A method of voice prompting and video image supervision on the scene of garbage sorting and delivery

ActiveCN112597804BImprove classification efficiencyReduce processing costsClosed circuit television systemsBiometric pattern recognitionMobile appsEngineering

The invention discloses a method for voice prompts and video image supervision on the site of garbage classification and delivery. The invention consists of a high-definition network camera + a cloud platform + a mobile APP. The invention monitors the personnel entering the garbage delivery place, and conducts When the garbage is delivered, the sender will be reminded of the type of garbage to avoid people throwing the wrong garbage. When the person does not put the garbage into the garbage can, the sender will be reminded quickly, and the sender will be warned to make correct and effective delivery. Statistics of the garbage categories are carried out to obtain the main local garbage categories, and then the garbage cans of the main garbage categories can be increased and the garbage cans of the non-main garbage categories can be reduced when the garbage cans are placed next time. The invention has beneficial effects such as improving the efficiency of garbage classification, remote monitoring, and improving the classification effect of the garbage classification and delivery site.

Owner:上海阅目环境科技有限公司

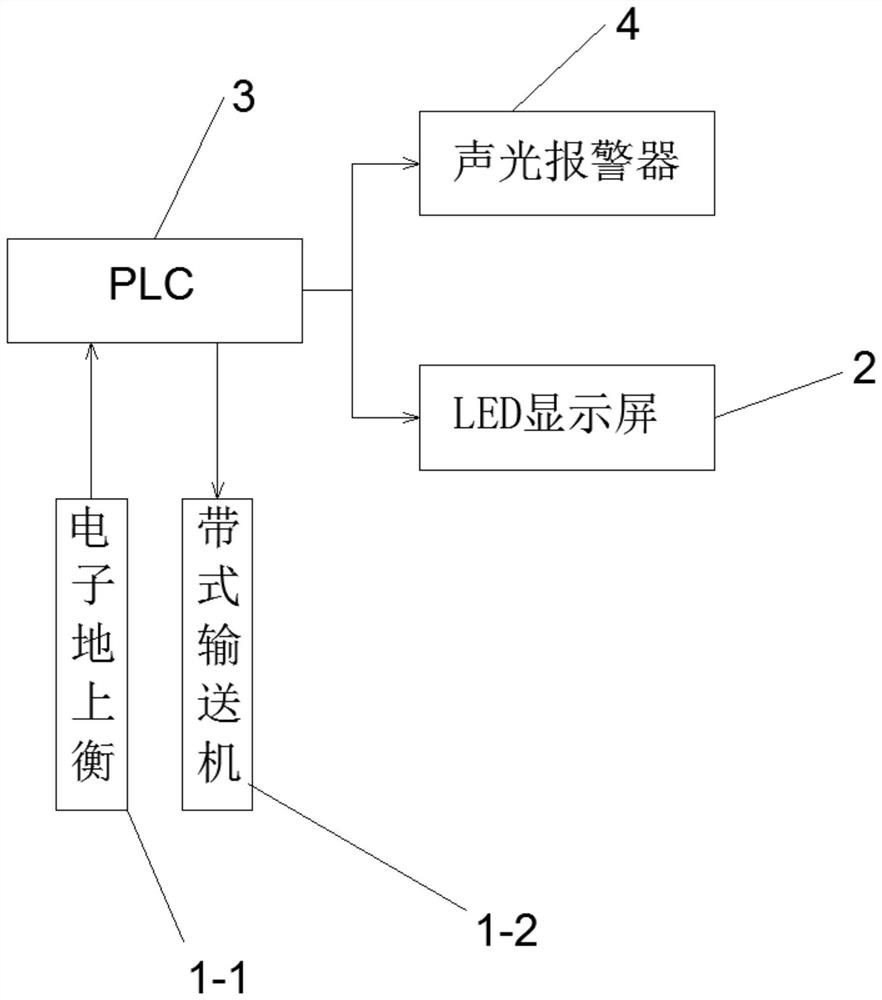

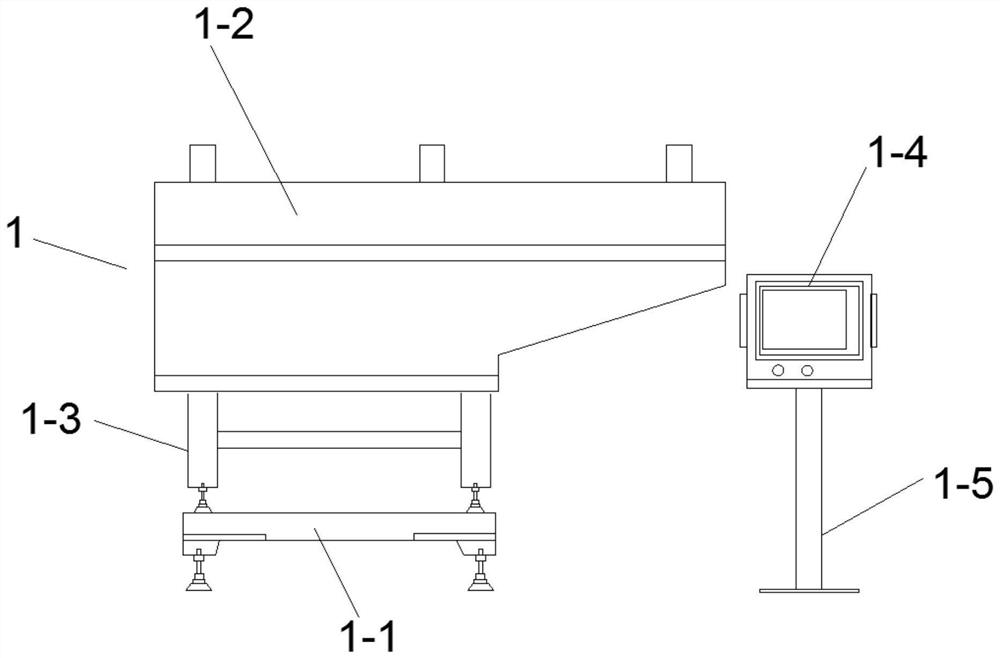

Weighing display system for reducing unit consumption of tobacco leaves

PendingCN113138003ASolve the problem of poor accuracy of discharge and feedingGuaranteed feeding weightWeighing apparatus for materials with special property/formAgricultural scienceAgricultural engineering

According to the weighing display system for reducing the unit consumption of the tobacco leaves, a belt type weighing module comprises an electronic ground scale and a belt type conveyor, and the belt type conveyor is arranged on a weighing platform of the electronic ground scale through an installation support. An instrument panel of the electronic ground scale is supported by the support and then arranged on the outer side of the electronic ground scale, the theoretical weight of the tobacco leaves and the weighed weight of the tobacco leaves are displayed through the instrument panel, the electronic ground scale is connected with the control module through a signal line, and the control module is connected with the belt conveyor, the alarm module and the display module through control lines. According to the system, the problem of poor discharging and feeding accuracy caused by a too large or too small tobacco weighing phenomenon is solved, the display module connected with the control module is arranged, information sharing after tobacco feeding information on an instrument panel of the electronic ground scale is displayed on the display module is achieved, material returning and supplementing workers are clear at a glance, information transmission errors and wrong feeding of returned and supplemented materials are avoided, so that the unit consumption of tobacco leaves is greatly reduced.

Owner:CHINA TOBACCO SHAANXI IND

Intelligent grain threshing integrated device

ActiveCN111656967BNot bad materialAchieves a gentle peeling effectMowersDrying gas arrangementsAgricultural engineeringProcess engineering

Owner:永州市冷水滩区五谷香农产品加工有限责任公司

Method and apparatus for transmitting message

ActiveCN105635230AAccurate transmissionAvoid miscastingTransmissionTelecommunicationsTransfer procedure

The application discloses a method and an apparatus for transmitting a message, applied to the scene that transmitting equipment transmits a message to assigned receiving equipment. The method comprises the steps of: receiving a message transmitted by transmitting equipment; according to the message, determining a project group to which the transmitting equipment belongs and receiving equipment corresponding to the transmitting equipment in the project group; and transmitting the received message to the receiving equipment. According to the method and the apparatus, transmitting equipment and receiving equipment referred by each project can be associated through project group, during a message transmission process, the message can be accurately transmitted to the receiving equipment according to the association, thereby effectively avoiding the phenomenon of mistakenly transmitting the message.

Owner:ADVANCED NEW TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com