Patents

Literature

30results about How to "Reduce sorting work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long fiber reinforced polypropylene/PPE alloy material and its prepn and application

The long fiber reinforced polypropylene / PPE alloy material has oriented fibers in the length over 4 mm and in netted configuration, and thus greatly raised shock resistance, rigidity, creeping resistance and size stability. What is more important is that the material may be mixed with many kinds of other material and thus has wide application range. The material may be prepared through powder soaking process, smelting soaking process, etc. The long fiber reinforced polypropylene / PPE alloy material of the present invention has excellent tensile, bending and anti-shocking performance, and may be used in manufacturing automobile part, pipe, valve part, electric tool, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

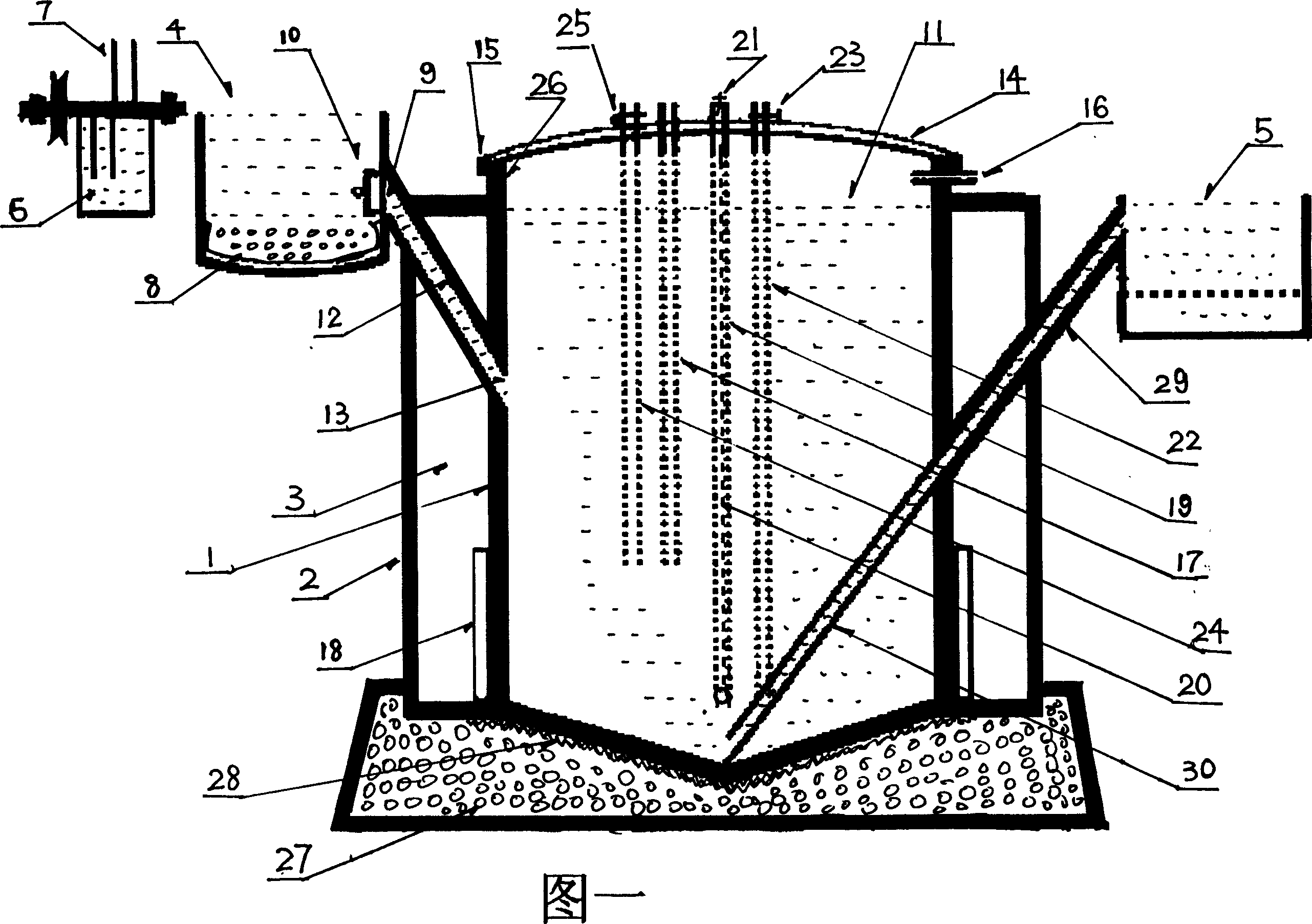

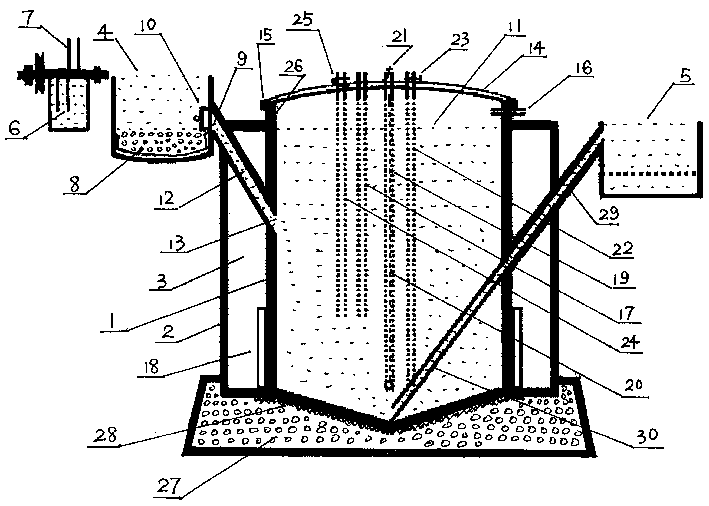

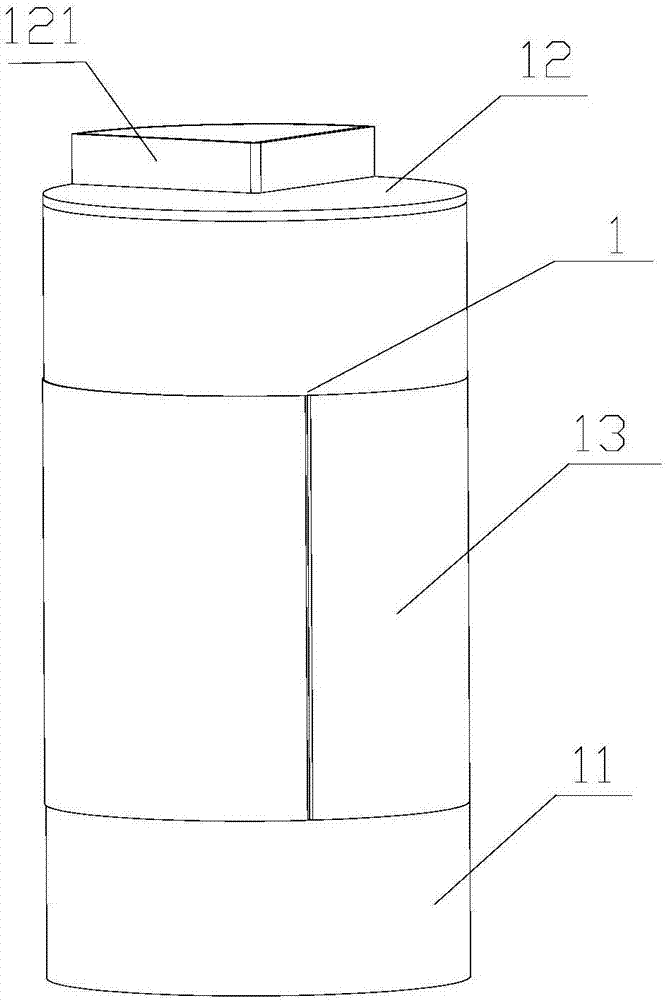

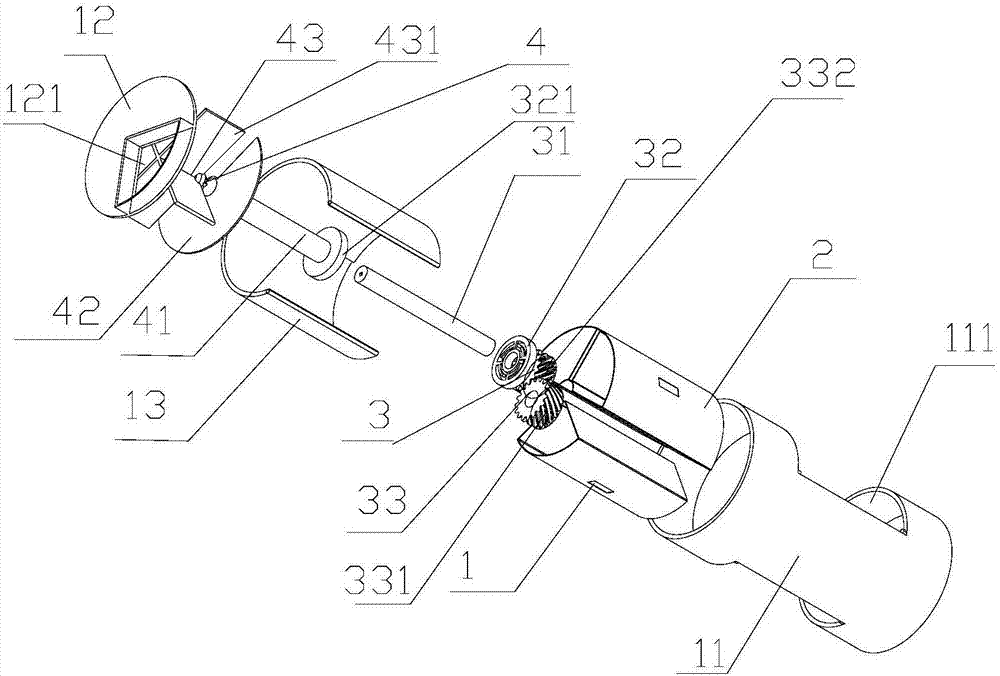

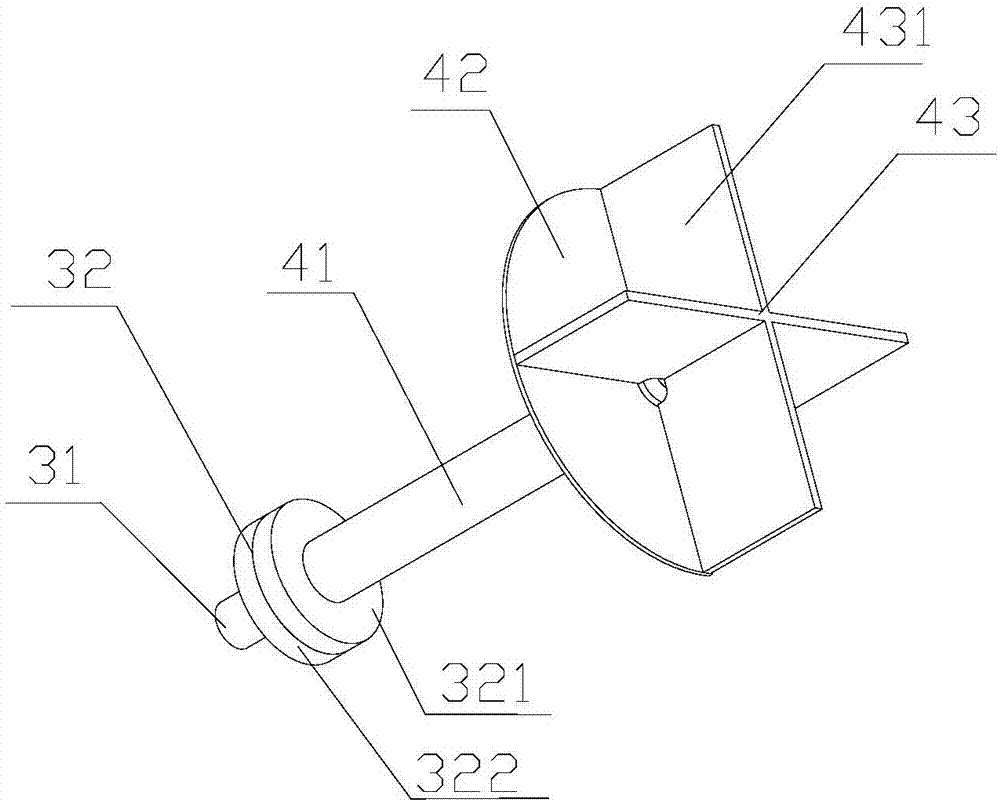

Fermenting tank for treating garbage

InactiveCN1480523ATake advantage ofReduce sorting workBioreactor/fermenter combinationsBiological substance pretreatmentsThermal insulationEngineering

A fermenting pool for treating garbage (city's life garbage) to generator marsh gas features structurally that it has 4 mechanisms respectively used for pulverizing big organic material particles, automatically separating and collecting the inorganic substances, using solar energy or marsh gas to heat the liquid material, and generating the thermal insulation effect by use of air, vacuum and insulating material. Its advantage is short period.

Owner:黄熙瑜

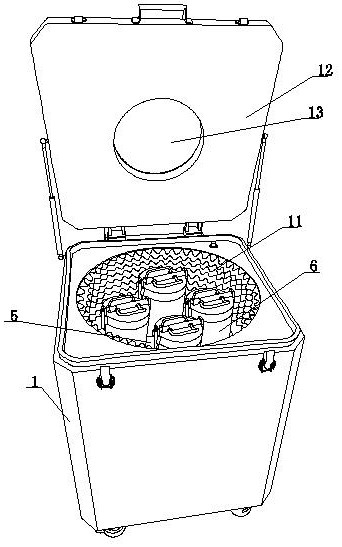

Automatic classification type garbage can

ActiveCN107499775ASolve the costAddressing Structural ComplexityWaste collection and transferRefuse receptaclesScannerControl engineering

An automatic classification type garbage can comprises a garbage outer barrel, a garbage classification scanner, an inner storage barrel, a locating device, a rotating push-conveying mechanism, a controller and a power supply, wherein the inner storage barrel, the locating device, the rotating push-conveying mechanism, the power supply and the controller are arranged in an inner cavity of the garbage outer barrel; the bottom of the locating device is in detachable connection with the inner storage barrel; the power output end of the locating device is connected with the driving end of a rotating pushing mechanism arranged at the top of the inner storage barrel; the signal output end of the garbage classification scanner is electrically connected with the signal input end of the controller, and the control end of the locating device and the control end of the rotating push-conveying mechanism are separately and electrically connected with the signal output end of the controller; and the power transmission end of the garbage classification scanner, the power transmission end of the locating device and the power transmission end of the controller are separately electrically connected with the corresponding power supply ends of the power supply. The automatic classification type garbage can has the beneficial effect that the problems that the classification type garbage can is high in cost, complicated in structure and difficult to repair are solved, manual operation is not needed, and the garbage classification work of a user is reduced.

Owner:ZHEJIANG UNIV OF TECH

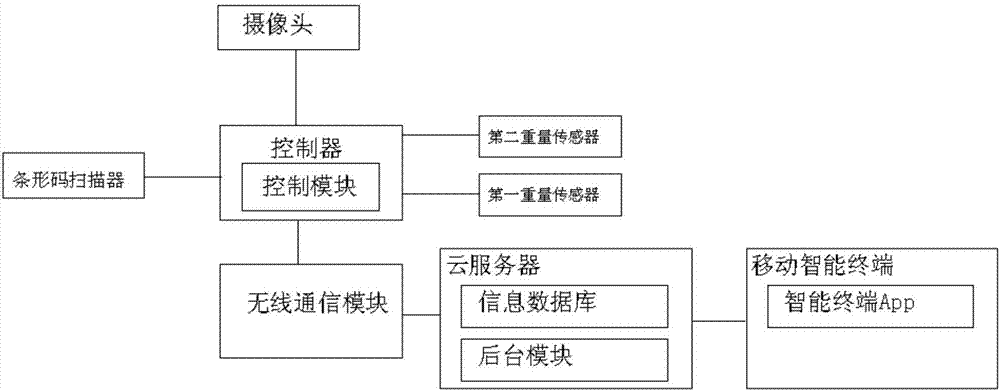

Garbage sorting system and method

InactiveCN106874977AEasy to distinguishReduce sorting workCo-operative working arrangementsRefuse transferringBarcodeEngineering

The invention provides a garbage sorting system and method. The system comprises a garbage station comprising a plurality of dustbins. The system is characterized in that the plurality of dustbins are grouped into a first type of dustbin and a second type of dustbin, wherein the first type of dustbin is a dustbin for holding wet garbage, and the second type of dustbin is a dustbin for holding dry garbage. The system also comprises barcode stickers and mobile intelligent terminals, which are configured to dumpers correspondingly. A barcode on each barcode sticker comprises information of each dumper; and one mobile intelligent terminal is provided with a unique ID. Each mobile intelligent terminal comprises an intelligent terminal App. The mobile intelligent terminals are in communication connection with a cloud server in a cloud platform. The garbage sorting system, combined with the method, can effectively prevent the defects that, in the prior art, since dumpers dump garbage to the dustbins randomly, work intensity of each garbage sorter is high and efficiency thereof is low, and a garbage classified dumping evaluation system for the dumpers is lacked.

Owner:北京虹巢环保科技有限公司

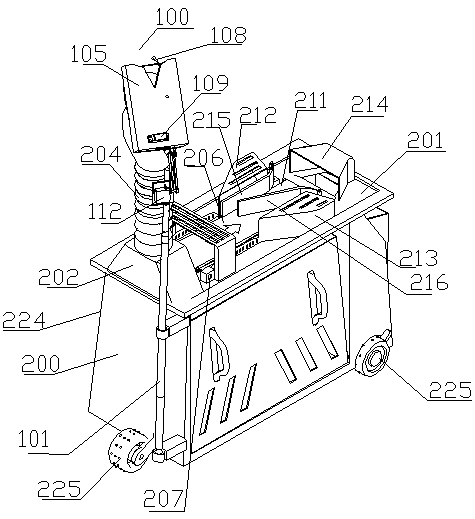

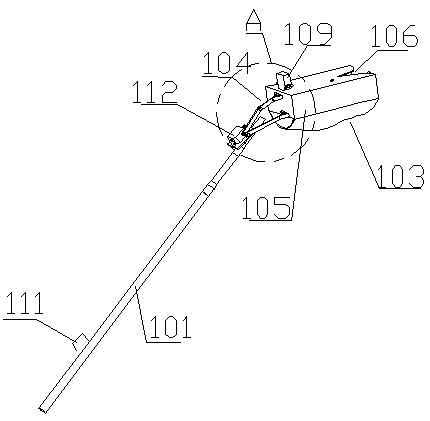

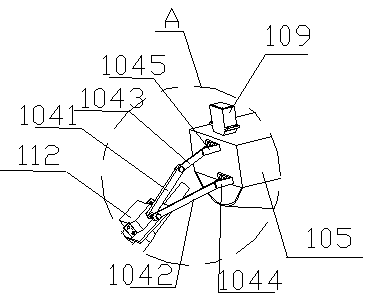

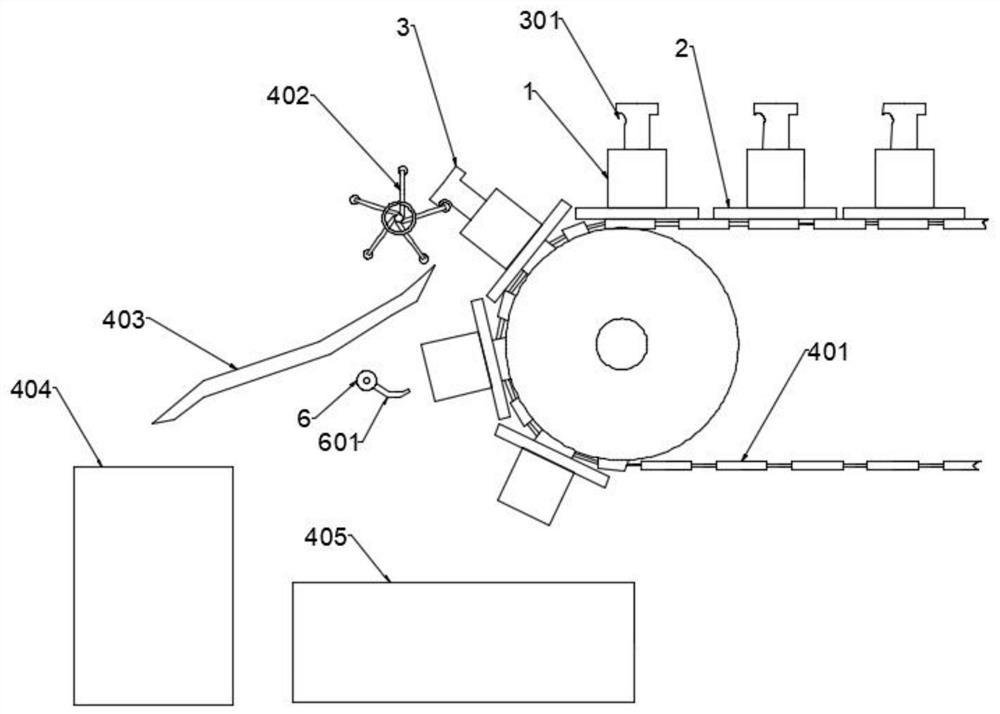

Integrated machine for auxiliary picking and classified collecting of fruits

PendingCN109220194AAccurate classificationImprove efficiencySortingPicking devicesFruit treeSemi automatic

The invention discloses an integrated machine for auxiliary picking and classified collecting of fruits. The integrated machine comprises a picking device and a classifying device, and the picking device can precisely pick the fruits without damaging the fruits; the classifying device can obtain sizes of the fruits by capturing images of the fruits, and then classify the fruits according to the sizes of the fruits. Therefore, the human-assistance semi-automatic mode is adopted for picking, classifying and collecting multiple fruits, and the machine is simple in structure, low in cost, easy tooperate and convenient to move; after being picked, the fruits are directly classified and collected according to the sizes, the damage to the fruits and fruit trees in the picking process is reduced,the safety in the process of picking the fruits is improved, the efficiency of picking, classifying and collecting the fruits is improved, and the labor intensity of fruit farmers is reduced.

Owner:LULIANG UNIV

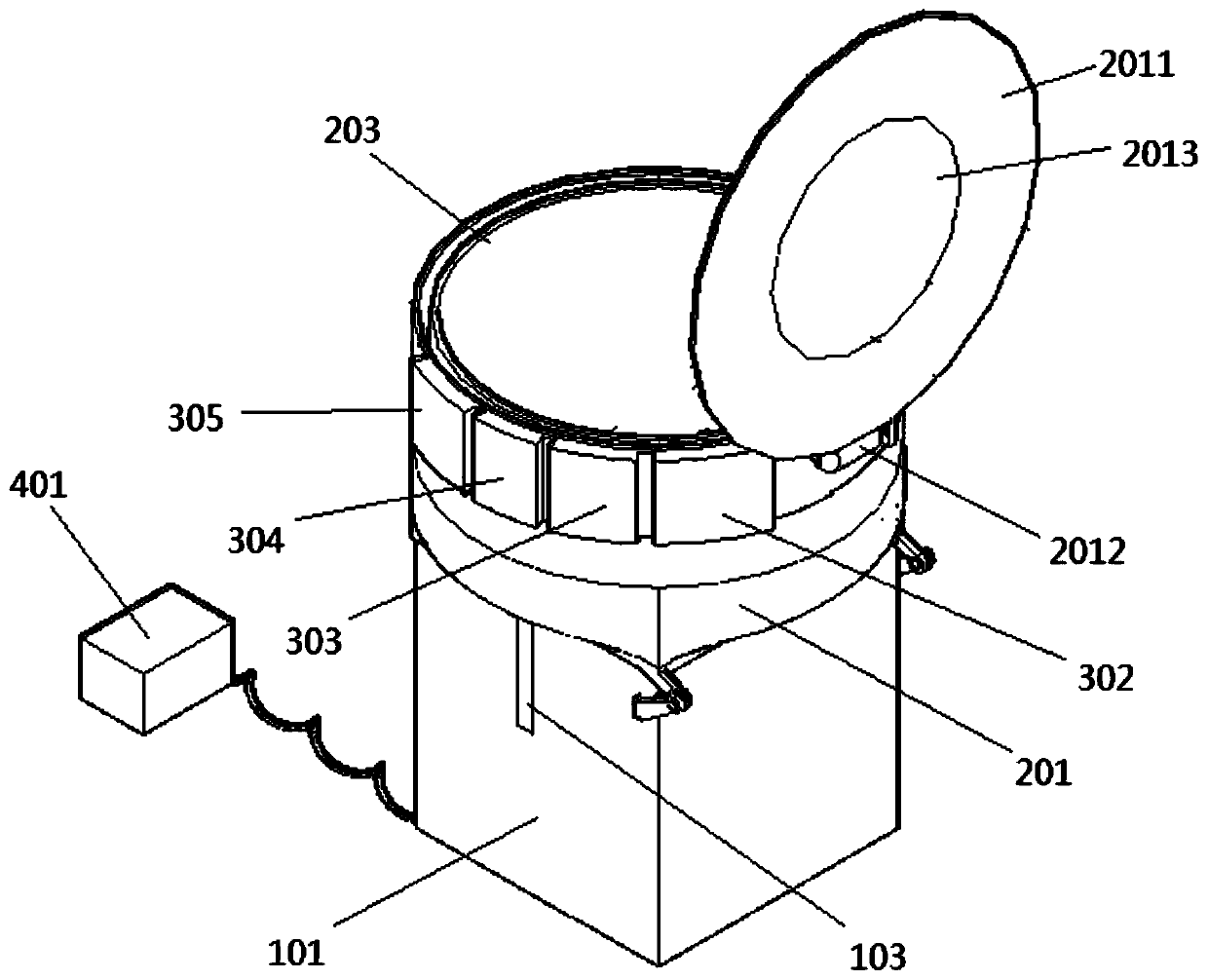

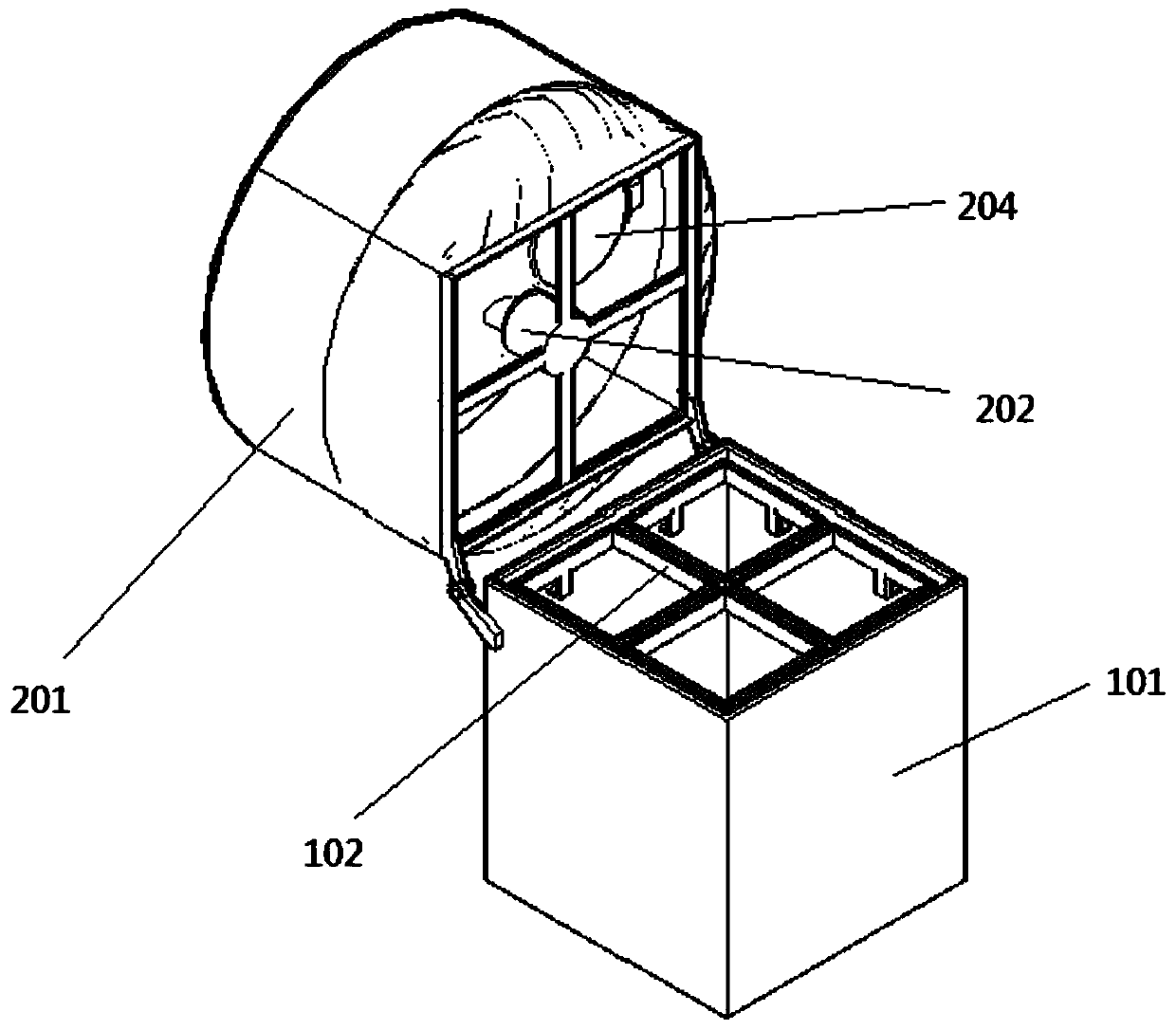

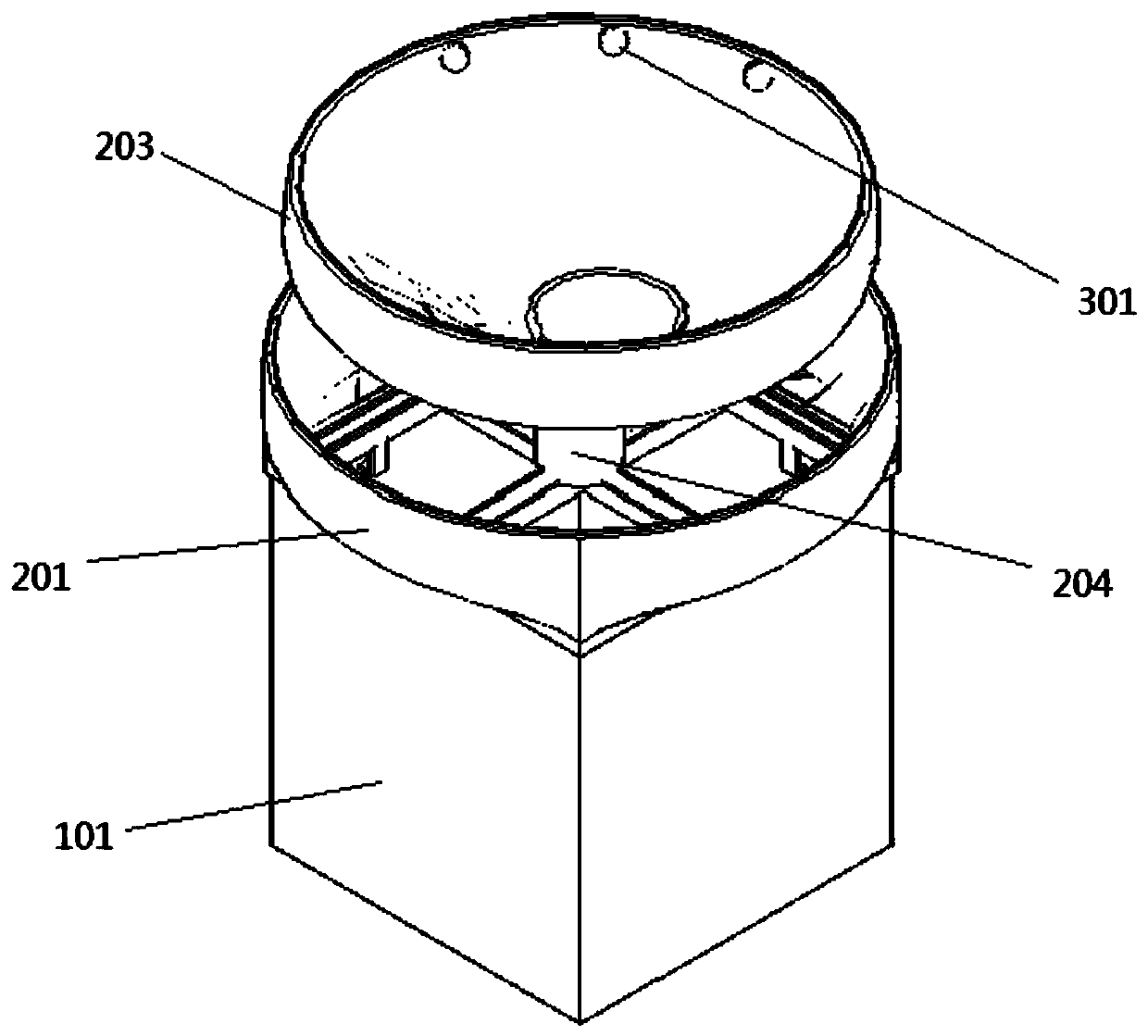

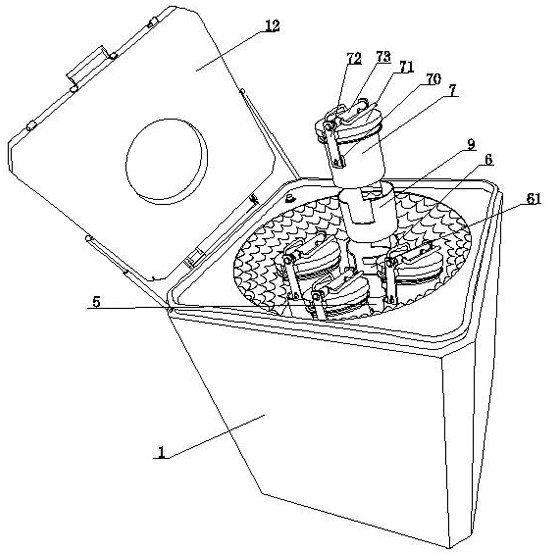

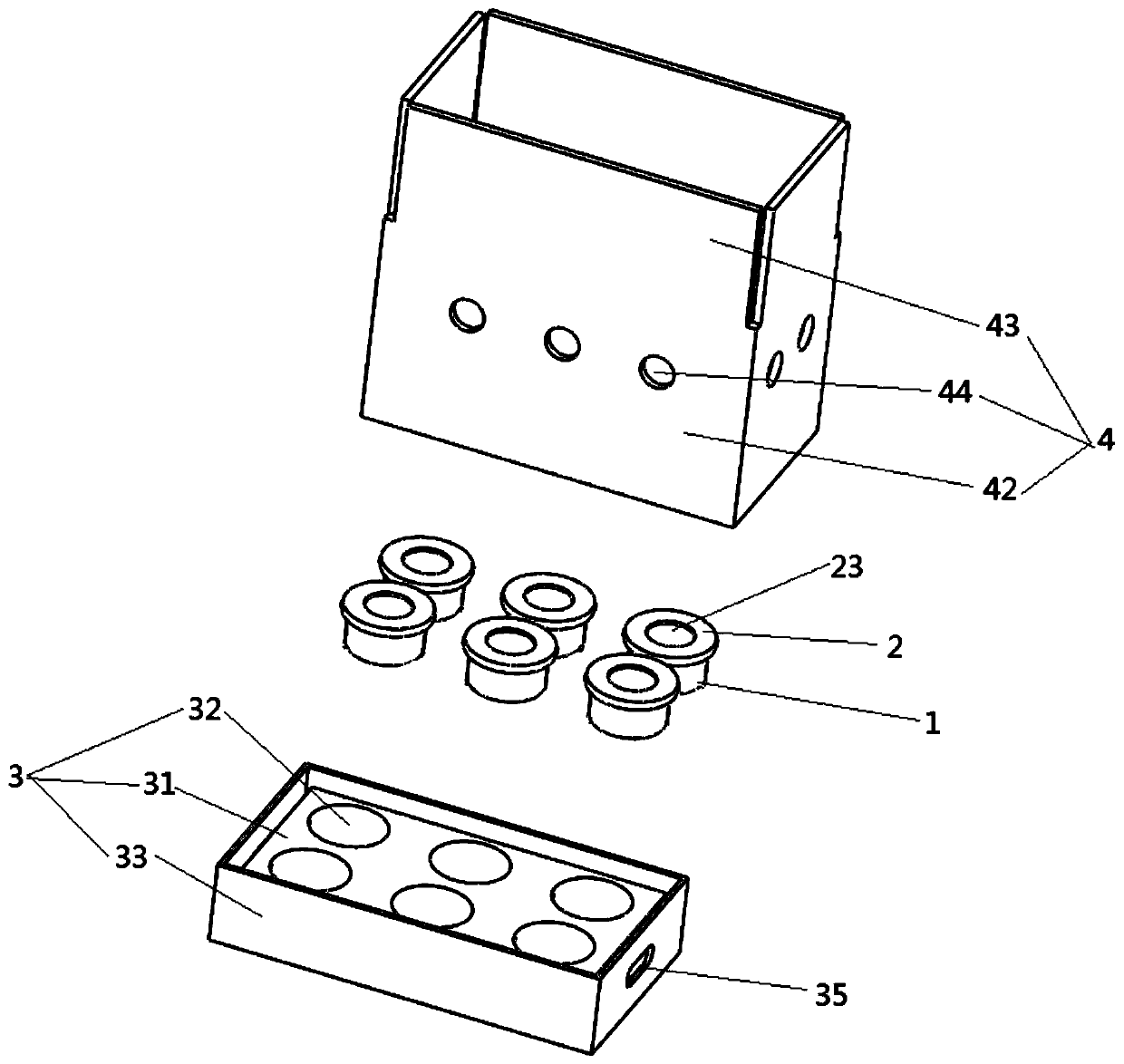

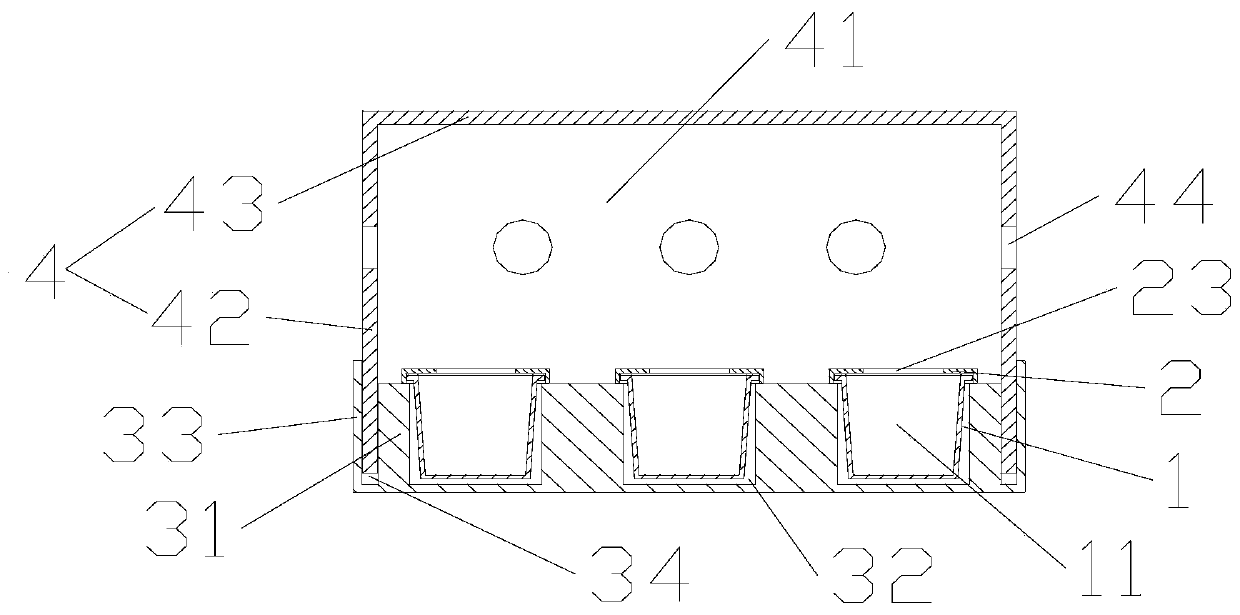

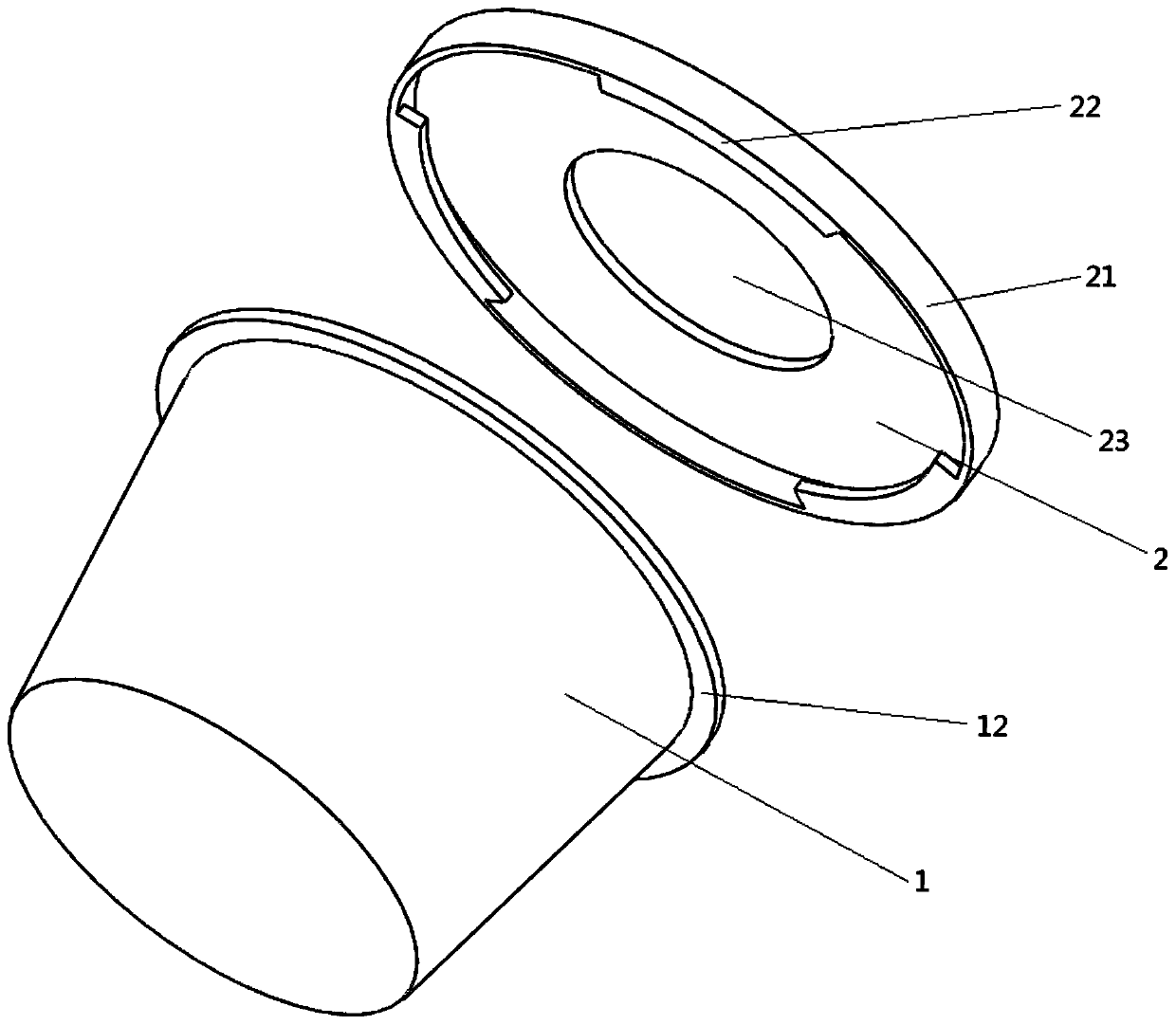

Garbage can for intelligently sorting medical waste and sorting method thereof

InactiveCN109928106AReduce sorting workImprove accuracyWaste collection and transferRefuse receptaclesClassification methodsMedical waste

The invention relates to a garbage can for intelligently sorting medical waste and a sorting method thereof, and belongs to the technical field of auxiliary sorting and recognition. The garbage can comprises a box body assembly, a box cover assembly, an image recognition system and a power supply module, wherein the box body assembly comprises a box body housing and a plurality of built-in garbagecans, the box cover assembly comprises a connecting cover, a central motor and an inner rotating bucket, the image recognition system comprises a camera, an information storage module, an informationprocessor and a human-computer interaction module, the box cover assembly is located above the box body housing, the connecting cover is used for fixing the inner rotating bucket, the central motor and the image recognition system, and the power supply module is connected with power supplies of all devices to which power needs to be supplied in the garbage can for intelligently sorting medical waste. The garbage can for intelligently sorting medical waste has the function of automatically identifying and sorting the medical waste by a machine, the use is convenient, and the sorting accuracy of the medical waste is increased; in addition, according to the garbage can for intelligently sorting medical waste, the number of garbage inlets is reduced, so that the condition of environmental pollution caused by the exposure of the medical waste is avoided, and the effects of cleanness and sanitation are achieved.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

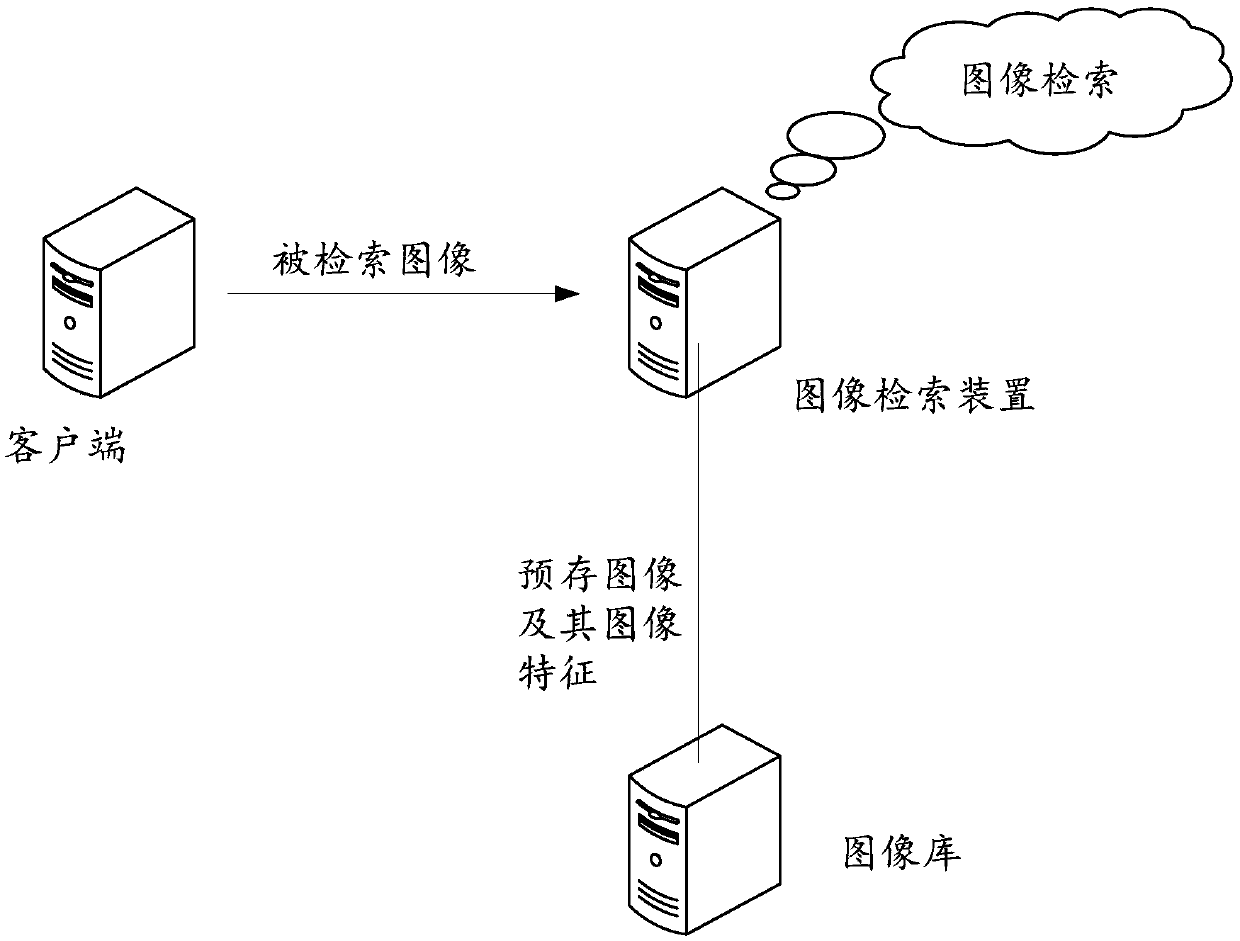

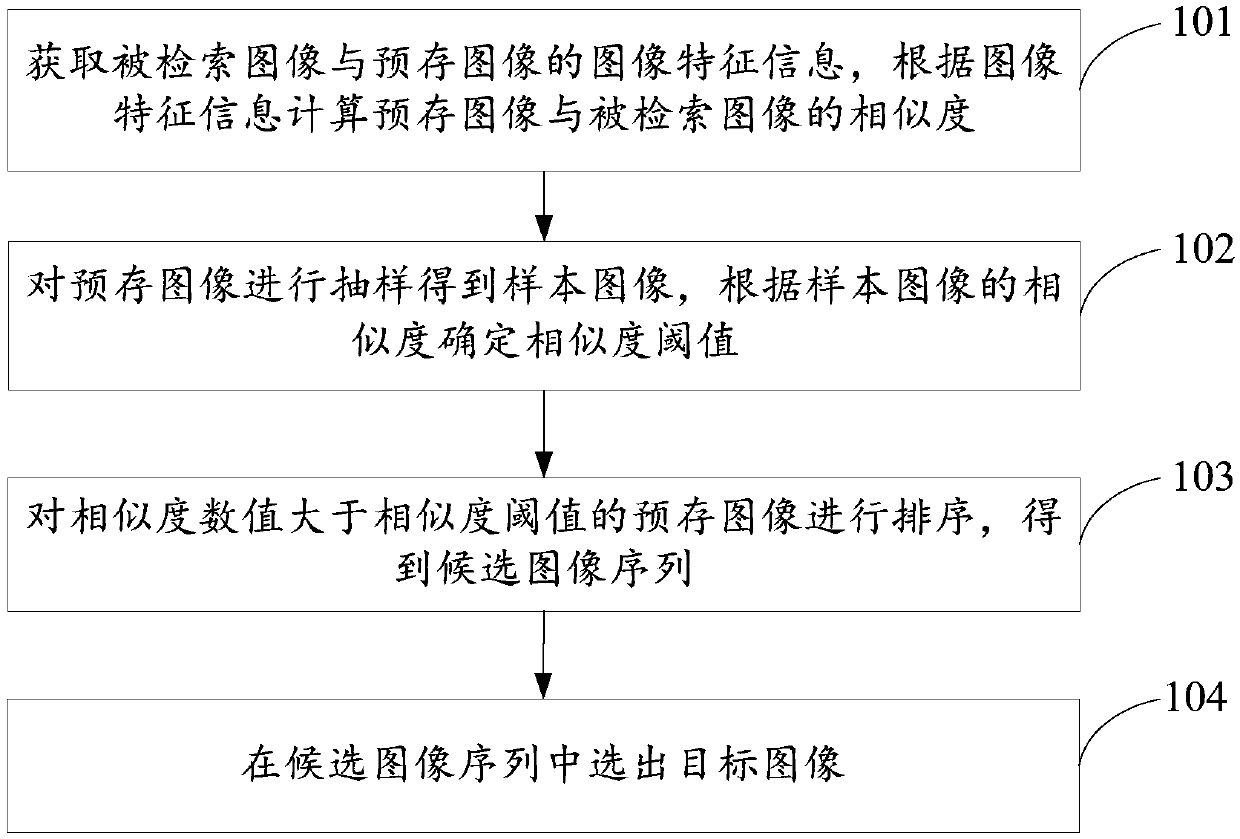

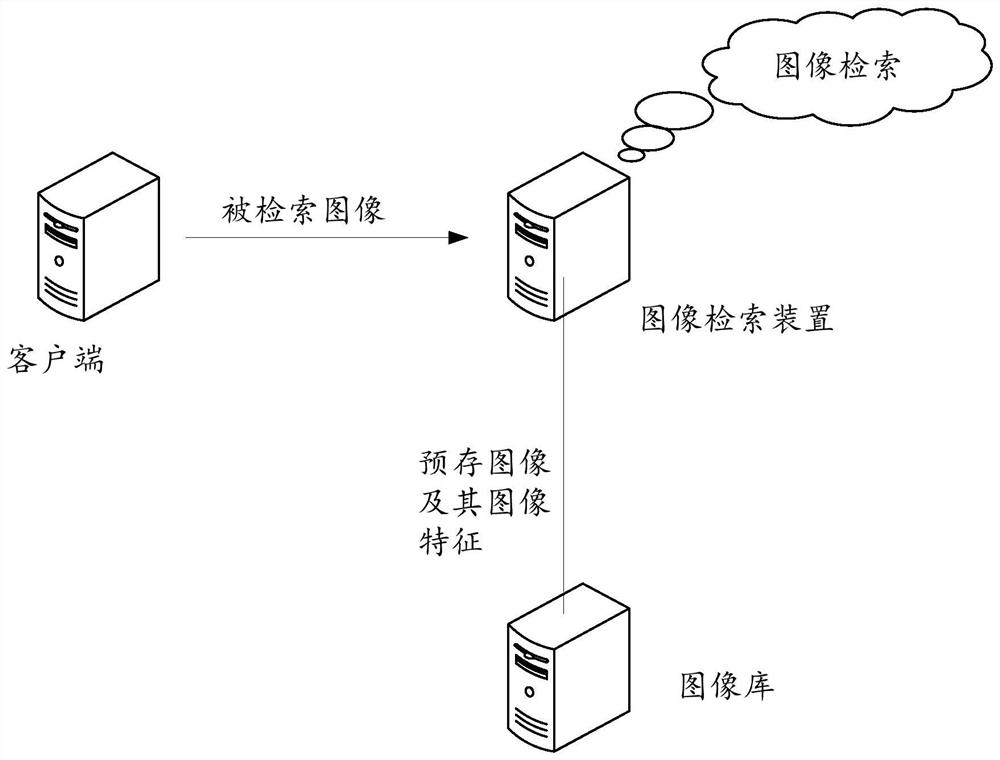

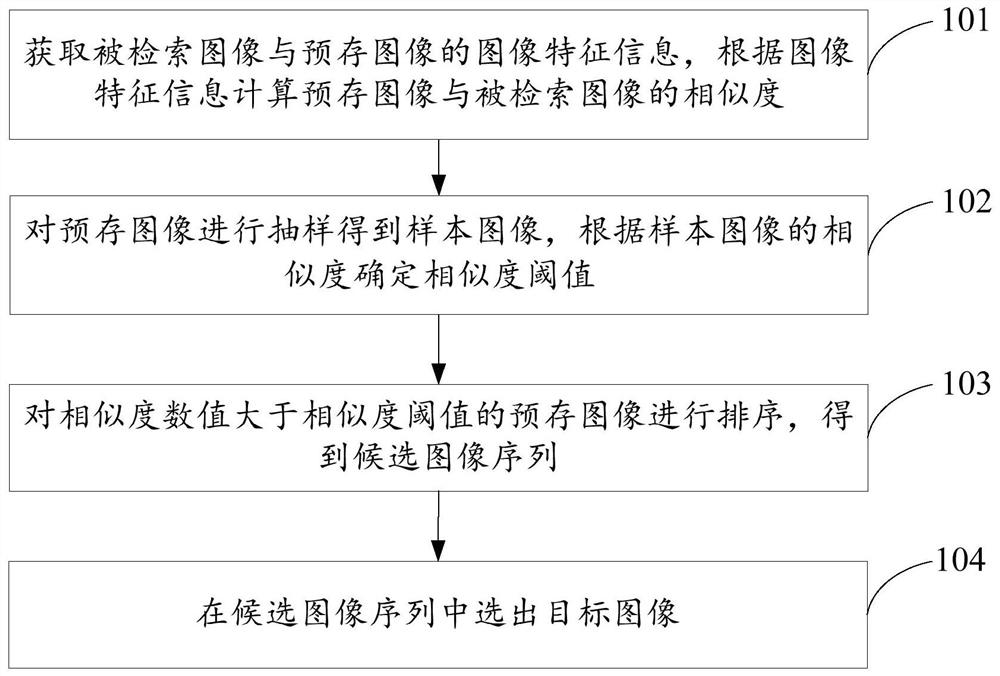

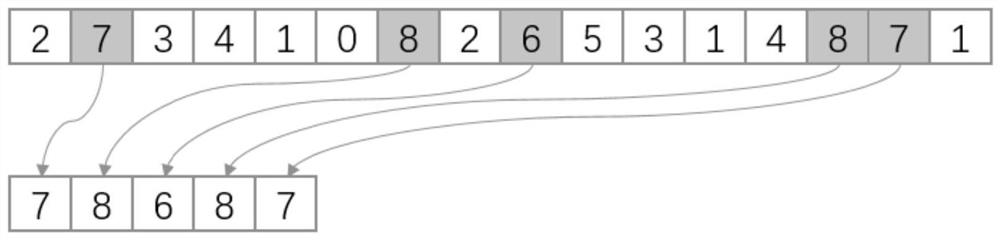

Image retrieval method and device, graphic processor and storage medium

ActiveCN109614510AReduce sorting workShorten the timeDigital data information retrievalSpecial data processing applicationsSample imageImaging Feature

The embodiment of the invention discloses an image retrieval method and device, a graphic processor and a storage medium. According to the embodiment of the invention, The method includes acquiring the image feature information of the retrieved image and the pre-stored image can be acquired, and calculating the similarity between the pre-stored image and the retrieved image is calculated accordingto the image feature information; S; sampling the pre-stored image to obtain a sample image, and determining a similarity threshold value according to the similarity of the sample image; S; sequencing the pre-stored images of which the similarity values are greater than a similarity threshold value to obtain a candidate image sequence; and selecting a target image from the candidate image sequence. Therefore, according to the scheme, the pre-stored images are screened, the sorting work is reduced, the high-quality retrieval result can be obtained only by partially sorting the pre-stored images, the image retrieval time is shortened, resource occupation is reduced, and the image retrieval efficiency is effectively improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

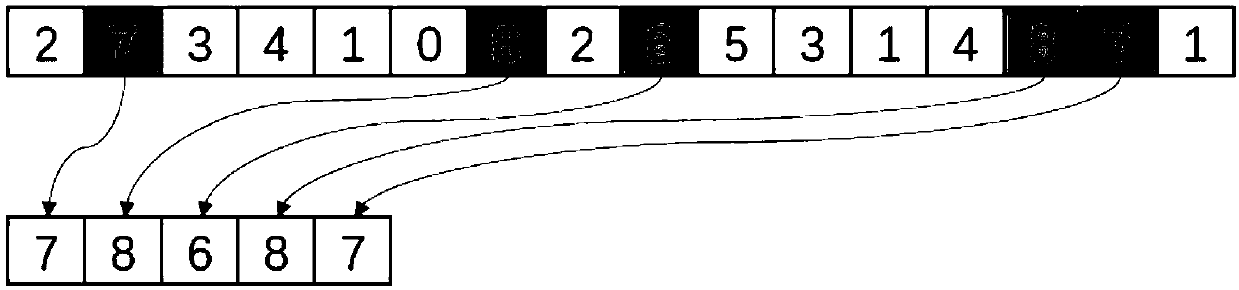

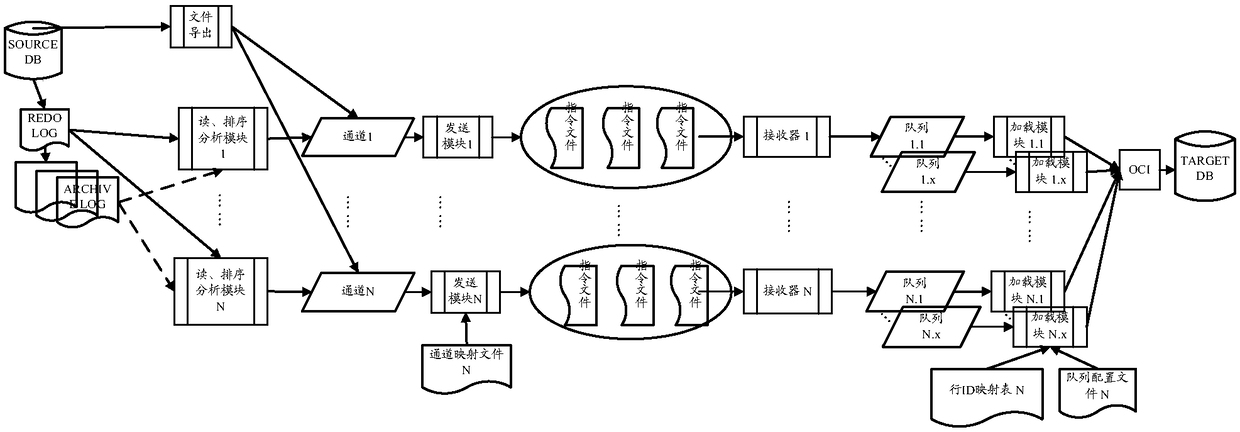

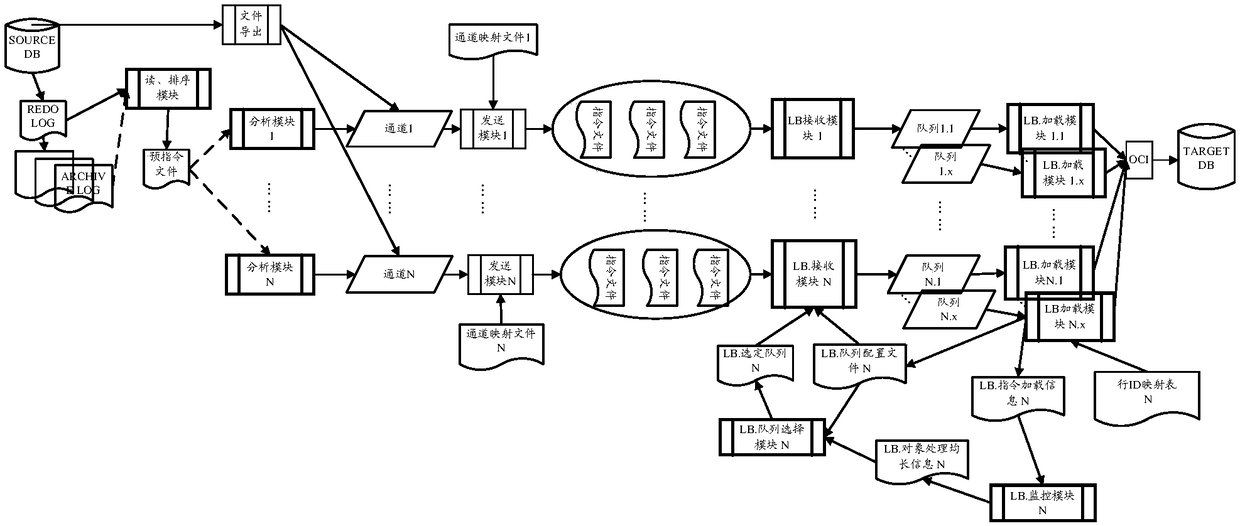

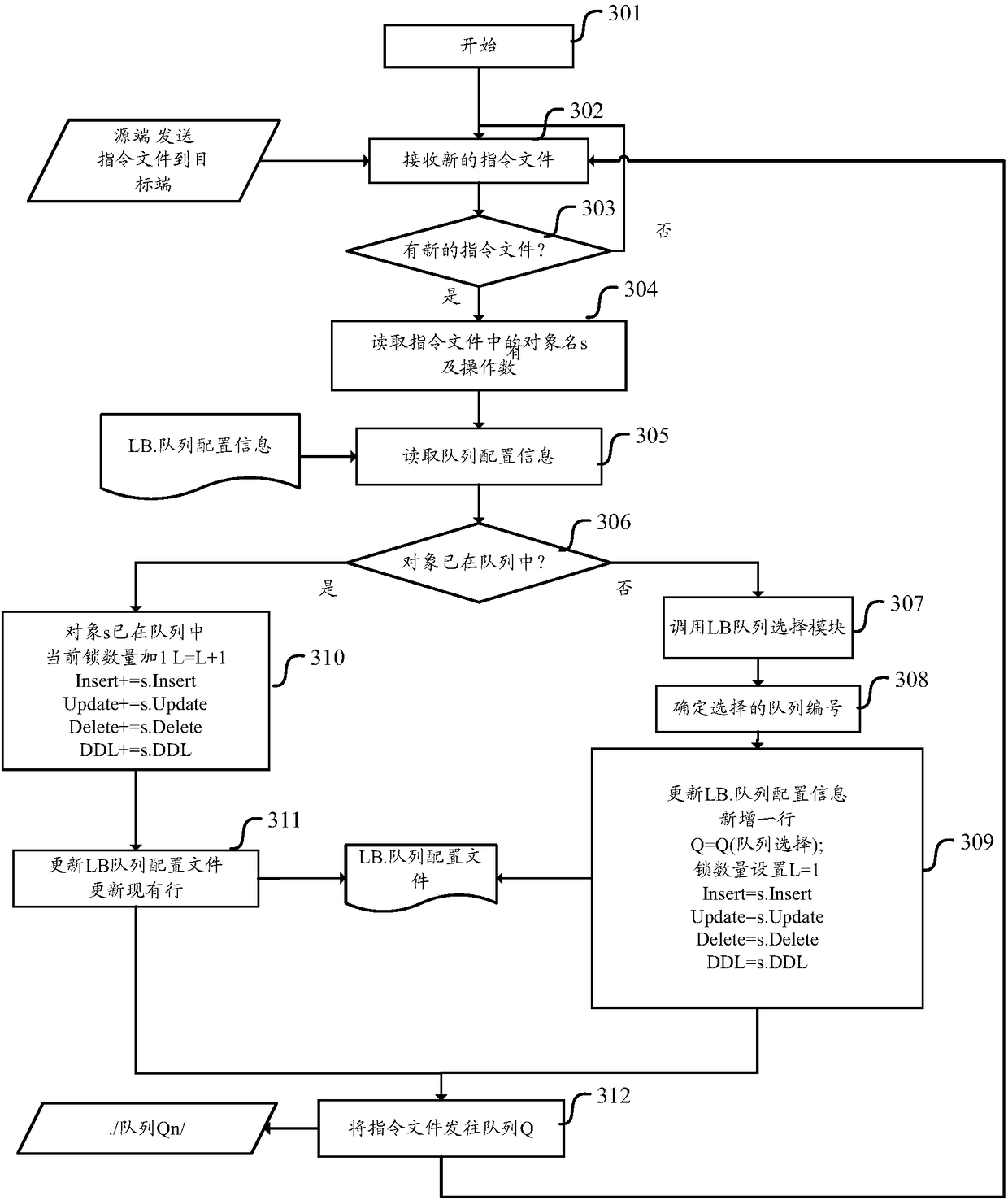

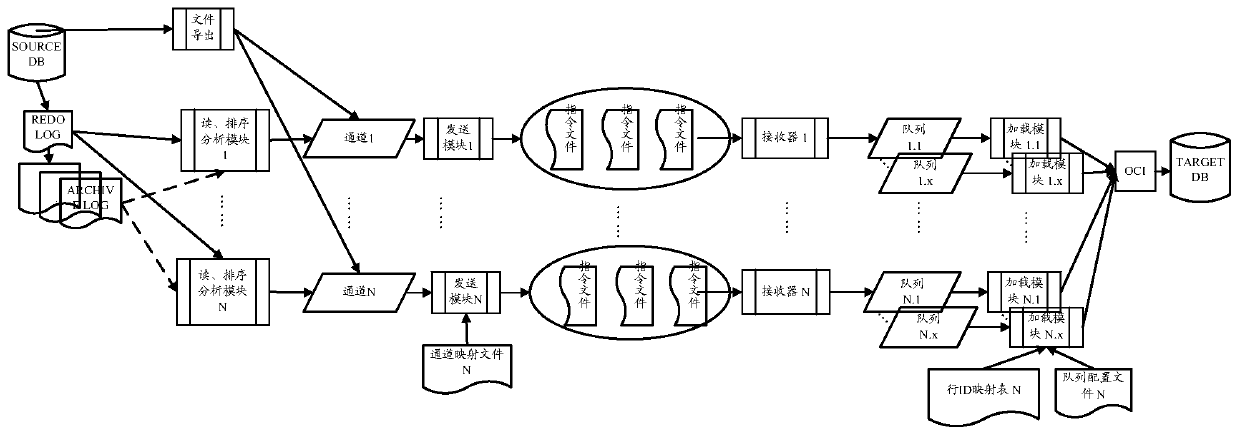

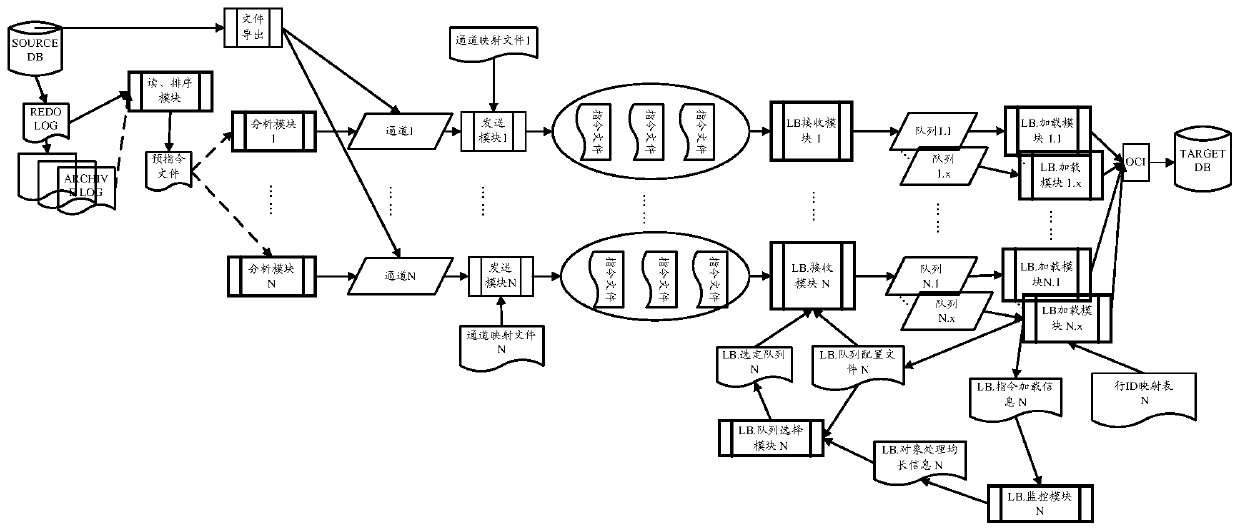

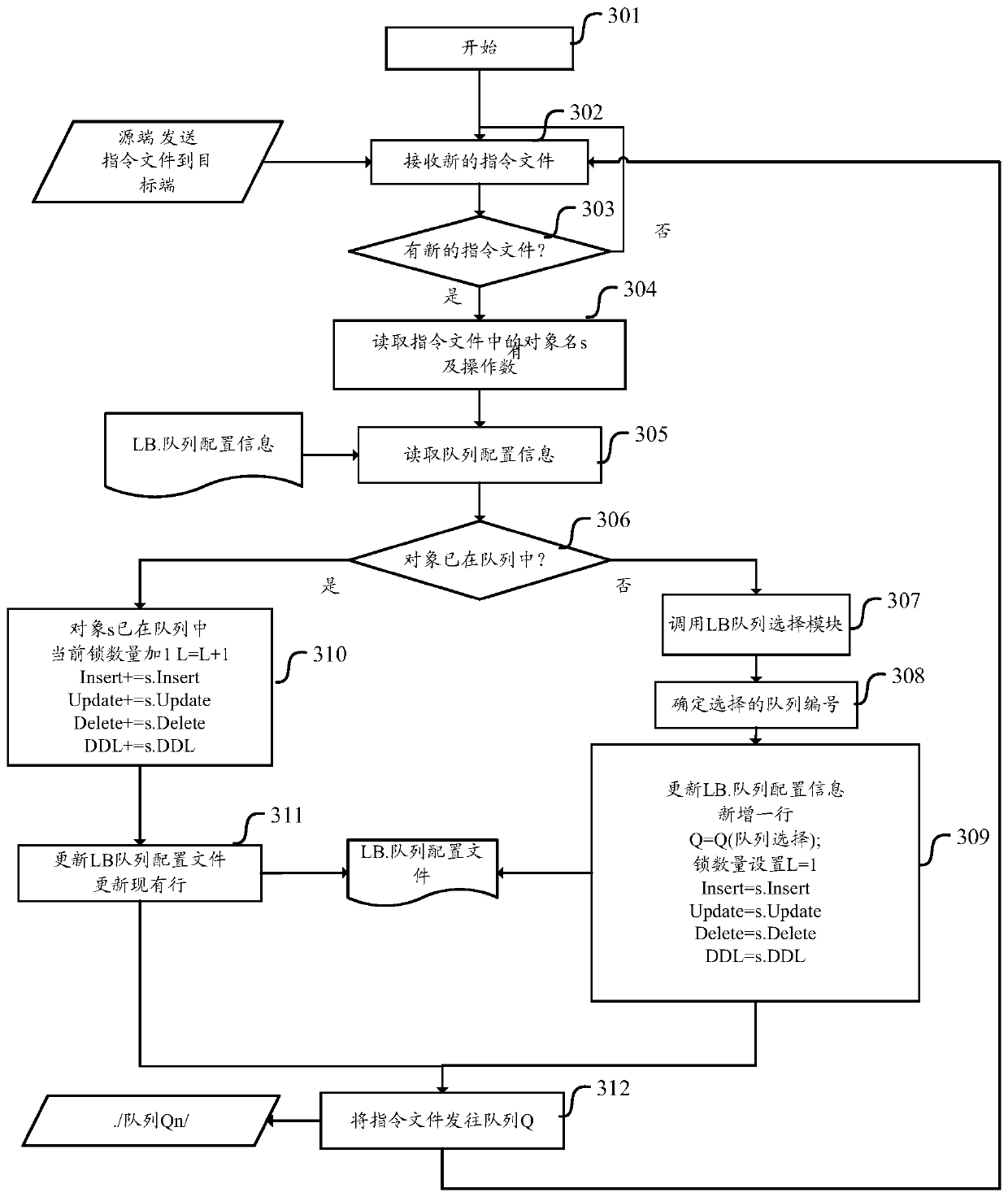

Data synchronization system and method

ActiveCN108073658ATimely processingReduce latencySpecial data processing applicationsData synchronizationProcess duration

The invention discloses a data synchronization system and method. The method comprises the steps that after a target end receives an instruction file sent by a source end, an object is placed into a corresponding to-be-processed queue after information of the object in the instruction file is read; when the object is placed into the corresponding to-be-processed queue, if the object is not in theto-be-processed queue, a row is newly added into a queue configuration file, and if the object is in the to-be-processed queue, 1 is added to the lock quantity L of the object in the queue configuration file; processing duration of all to-be-processed queues is estimated; and the to-be-processed queues are loaded according to the processing duration, and after loading, 1 is subtracted from L, andthe row with L being 0 is deleted. By the adoption of the data synchronization system and method, delay in database synchronization can be shortened.

Owner:中国移动通信集团广西有限公司 +1

Garbage throwing point interaction method

PendingCN110910216AReduce deliveryIncrease motivationCo-operative working arrangementsCharacter and pattern recognitionSoftware engineeringDisplay device

The invention belongs to the field of garbage classification, and discloses a garbage throwing point interaction method, which comprises the following steps that: step 1, a user uses a user login APPon a mobile terminal to scan a two-dimensional code on a display on a garbage recycling bin, so that a user account is associated with a cloud management platform; and step 2, the cloud management platform informs a user that the garbage recycling bin needs to conduct recycling operation, after the induction controller on the garbage throwing opening receives information, the garbage throwing dooris automatically opened, and after the user throws garbage, the garbage throwing door is automatically closed. According to the garbage throwing method provided by the invention, a user scans the two-dimensional code on the display screen after throwing garbage, obtains the red packet and the points through the two-dimensional code, can exchange corresponding commodities through the red packet and the points, stimulates the user to classify and recycle the household garbage, improves the enthusiasm and initiative of the user in throwing the garbage, facilitates the classified throwing of thegarbage, and is simple and efficient.

Owner:上海良韶智能科技有限公司

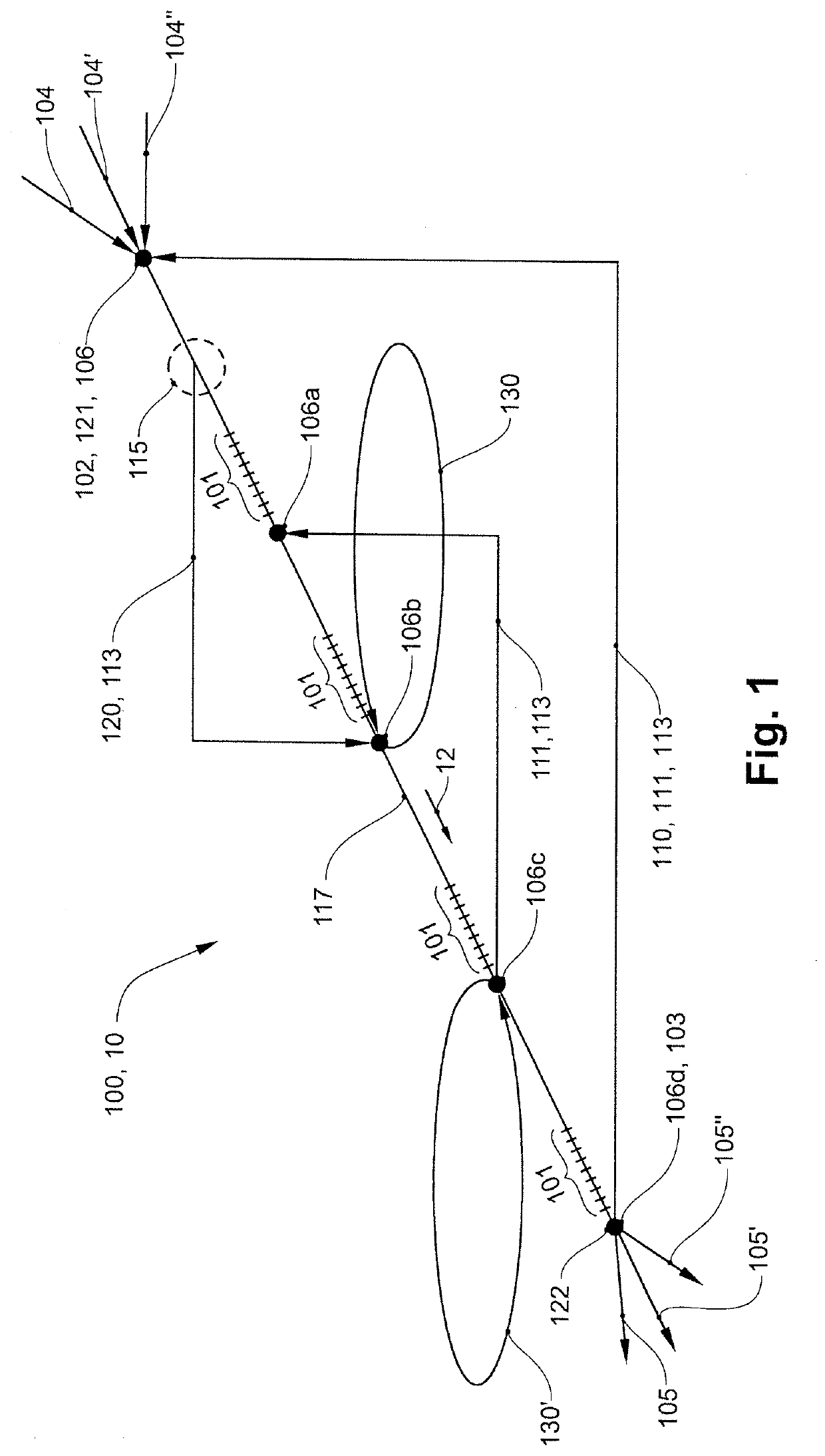

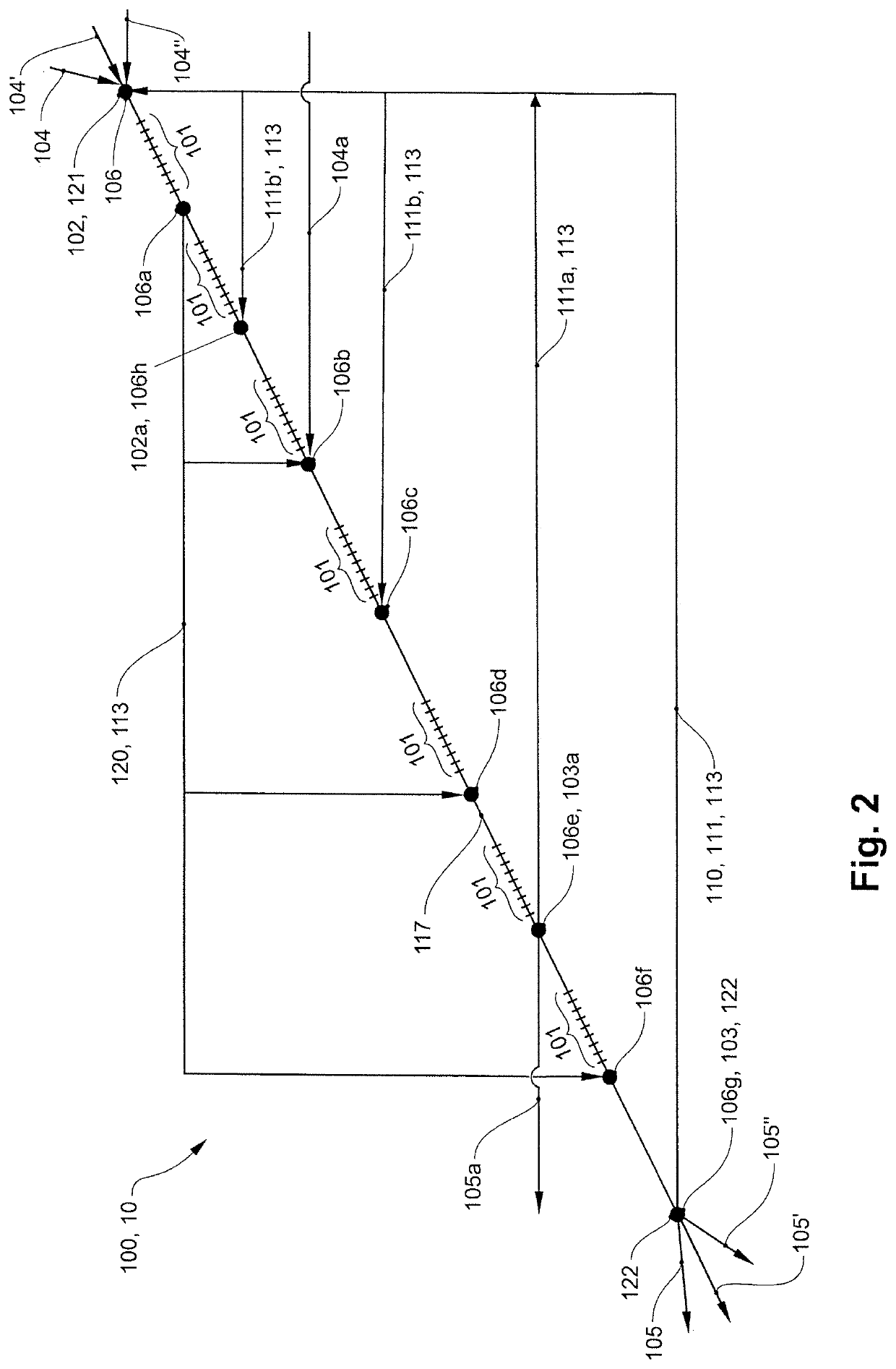

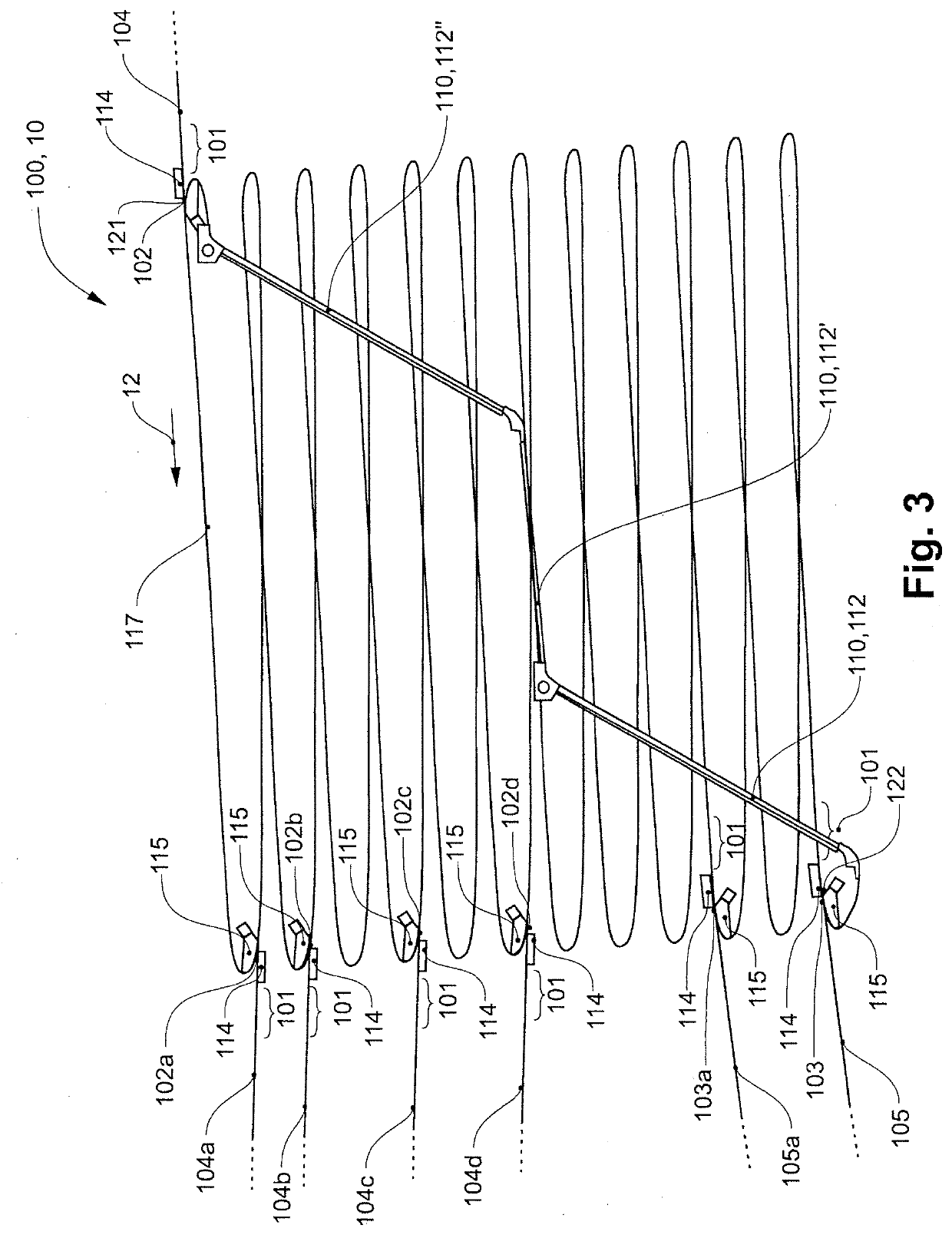

Buffer storage system for overhead conveyor systems

InactiveUS20200216262A1Maximize transportTransport capacity maximizedConveyorsStorage devicesEmbedded systemFeed point

A buffer storage device (100) for an overhead conveyor system (10) having individually conveyable transport units (40), with a closed conveying path that includes a buffer section (117) along which transport units are conveyable downstream, a feed section (104) for feeding transport units to a feed point (102) of the buffer section, a discharge section (105) for discharging transport units from a discharge point (103) of the buffer section, and one or more additional bypass sections (113) which in each case connect a starting point along the buffer section to a destination point along the buffer section.

Owner:FERAG AG

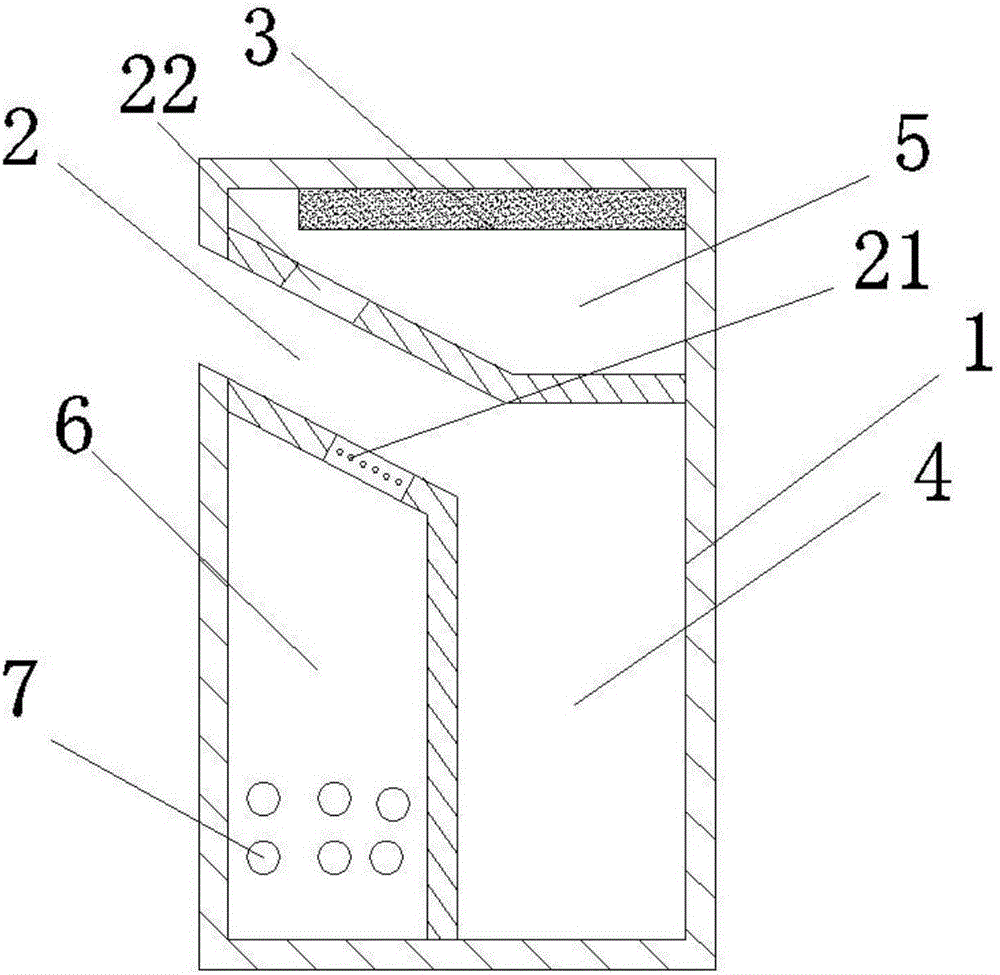

Slot machine capable of automatically classifying money,

InactiveCN102568091AReduce sorting workConvenient lifeCoin/paper handlersEngineeringElectrical and Electronics engineering

The invention embodiment discloses a slot machine capable of automatically classifying money, which includes a slot used for receiving money; a money identifying device arranged below the slot and used for identifying the thrown-in money; an elastic ramp device connected with the money identifying device, arranged below the money identifying device, and used for triggering to open a paper money box inlet or a coin passage inlet according to an identification result of the money identifying device; a paper money box used for storing the paper money, wherein an inlet of the paper money box is directly connected with the elastic ramp device; a coil passage arranged below the elastic ramp device and used for transmitting the coin, wherein an inlet of the coin passage is directly connected with the elastic ramp device; and one or more than one coin boxes arranged beside the paper money box and used for storing the coin, wherein the diameters of the inlets of the coin boxes are different and the multiple coin boxes are sequentially arranged. The slot machine capable of automatically classifying the money reduces the follow-up money classifying work for the slot machine by the working staff, thereby bringing great convenience.

Owner:SHANGHAI CITY CHANGNING DISTRICT JUNIOR SCI &TECH GUIDANCE STATION +1

Partition dustbin

The invention discloses a partition dustbin. The partition dustbin comprises a dustbin body, a throwing channel and a magnet; the interior of the dustbin body is divided into three areas including a plastic area, a metal area and an unrecoverable garbage area; the throwing channel is arranged in the dustbin body in an inclined manner and is directly communicated with the plastic area; the metal area is arranged on the plastic area, the left side of the plastic area is adjacent to the unrecoverable garbage area, the lower surface of the throwing channel is provided with a fence communicated with the unrecoverable garbage area, the upper surface of the throwing channel is provided with a metal area channel communicated with the metal area, and the magnet is arranged at the position, close to the metal area channel, of the top of the metal area. The partition dustbin is simple in structural design and high in practicability, when garbage is put, garbage partition can be autonomously selected, the garbage can be classified, the classifying work of a garbage recycling station is reduced, and the good popularization prospect is achieved.

Owner:GUANGXI UNIV

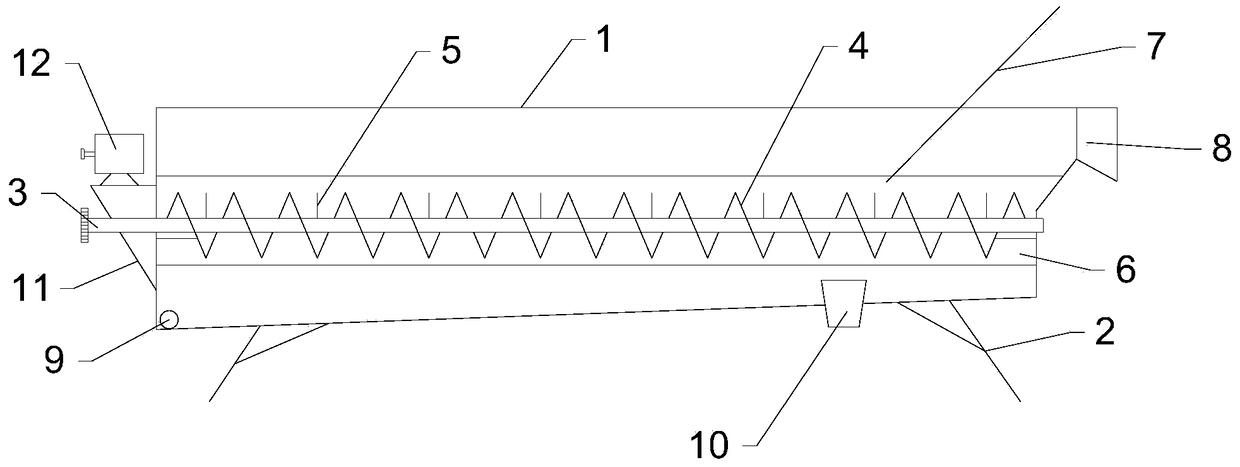

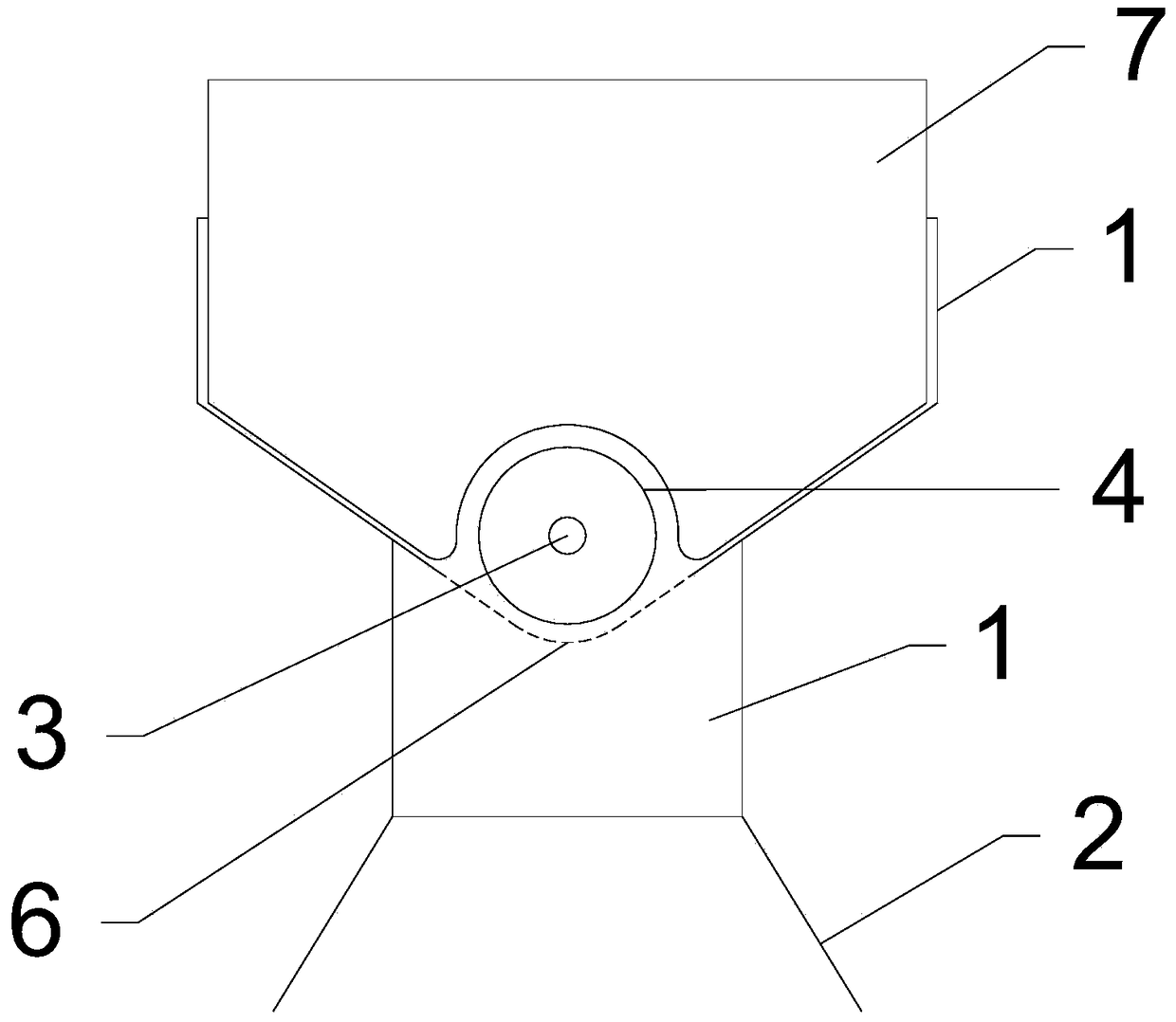

Landscaping waste sorting and breaking device and breaking method applying device

InactiveCN113083431AImprove crushing efficiencyOpen and close controllableCocoaGrain treatmentsLandscapingProcess engineering

The invention relates to the field of resource recycling, particularly discloses a landscaping waste sorting and breaking device and a breaking method applying the device, and relates to the technical field of landscaping maintenance equipment. The landscaping waste sorting and breaking device comprises a shell, wherein a partition plate is arranged in the shell and divides the shell into a breaking area and a sorting area; a preliminary breaking chamber and a fine grinding chamber arranged at an outlet of the preliminary breaking chamber are arranged in the breaking area, and the preliminary breaking chamber and the fine grinding chamber are connected through a breaking channel; and a sorting conveying belt is arranged in the sorting area, one end of the sorting conveying belt directly faces an outlet of the fine grinding chamber, and the other end of the sorting conveying belt extends out of the shell. According to the scheme, waste can be broken before being fermented, so that the efficiency of recyclable resources is higher.

Owner:王一毅

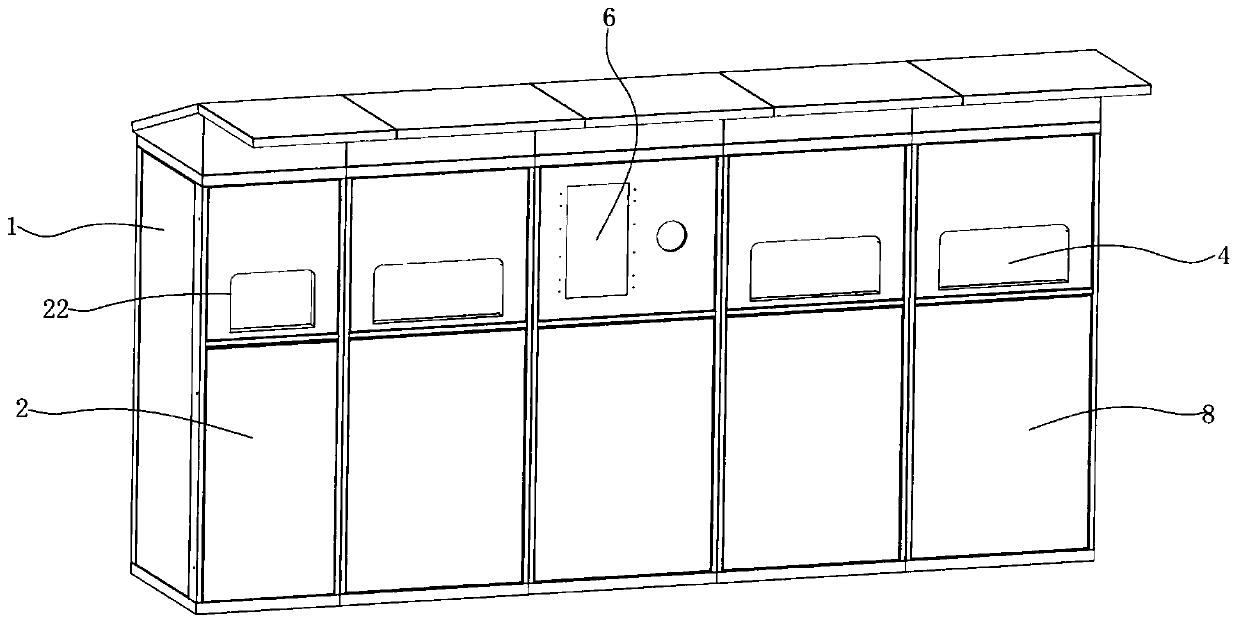

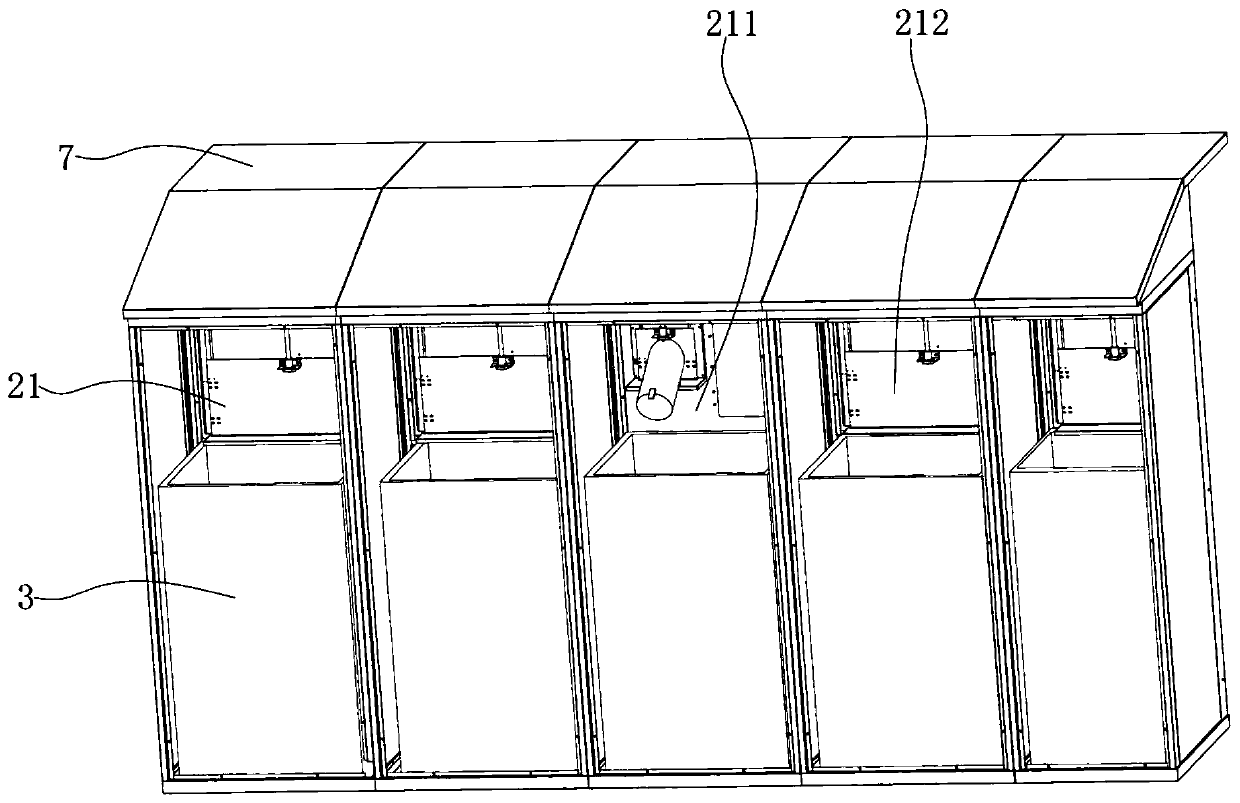

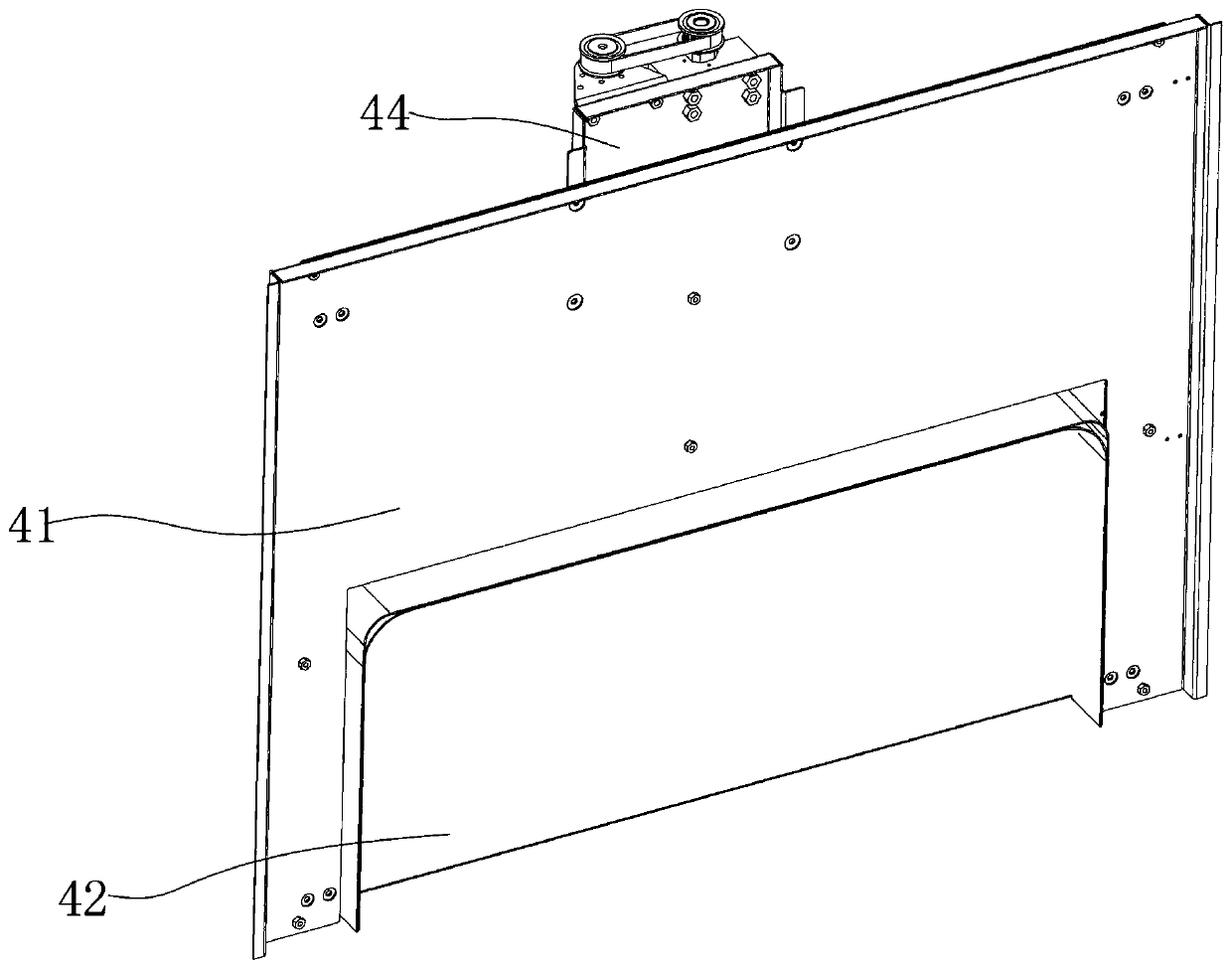

Intelligent garbage recycling device

InactiveCN110803407AReduce sorting workIncrease motivationRefuse receptaclesComputer hardwareRefuse collection

The invention discloses an intelligent garbage recycling device. The intelligent garbage recycling device comprises a device body, a background system and a mobile phone mini program. The device bodycomprises a shell, storage cages, motor lifting doors, a counting device, weighing scales, a main control circuit board, a display screen, a power source control box, power source branch console boxesand a rainshed. The interior of the shell is divided into multiple independent sub spaces, the sub spaces comprise at least one bottle and can collecting space and multiple other garbage collecting spaces, the storage cages are arranged in the sub spaces, putting openings are formed in the front faces of the sub spaces, the motor lifting doors are arranged on the putting openings, the counting device is arranged at the end of an inclined cylinder, the weighing scales are detachably mounted on the lower surfaces of the storage cages in the other garbage collecting spaces, the display screen isconnected with the background system through a wireless network, the main control circuit board and the background system are connected through the wireless network, the background system is connected with the mobile phone mini program through the wireless network, and the motor, the counting device, and the weighing scales are electrically connected with the power source main control box or corresponding power source branch console boxes. The putting process is easy to operate, intuitive in feedback and good in user experience.

Owner:宁波太空侠智能环保科技有限公司

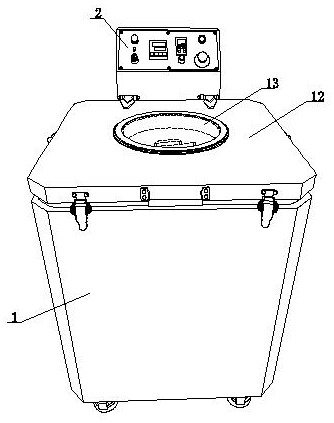

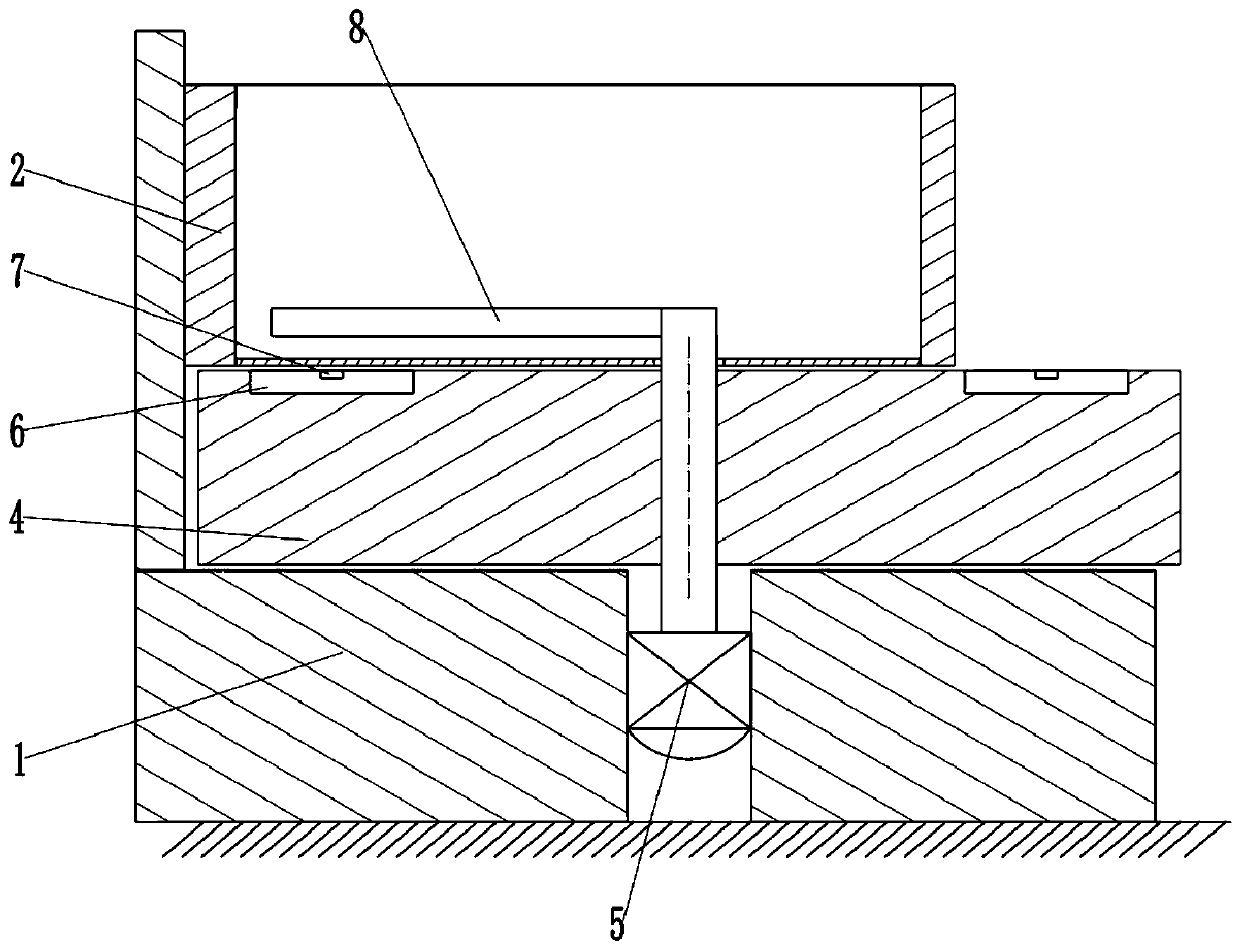

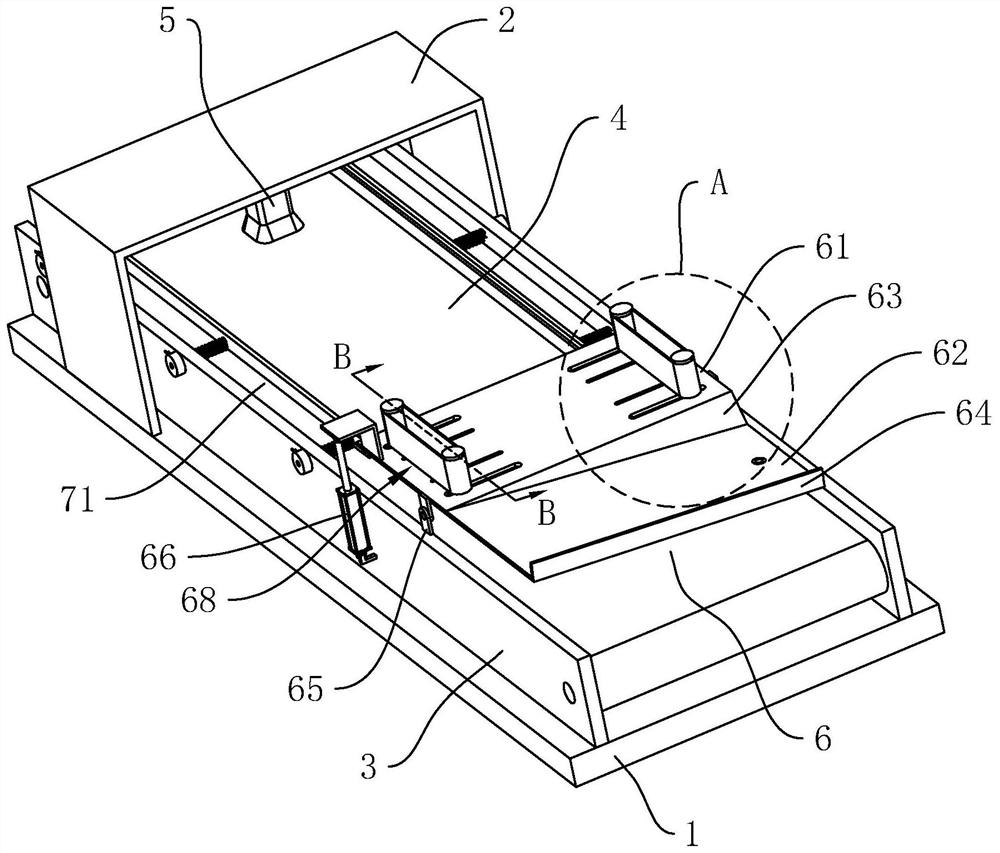

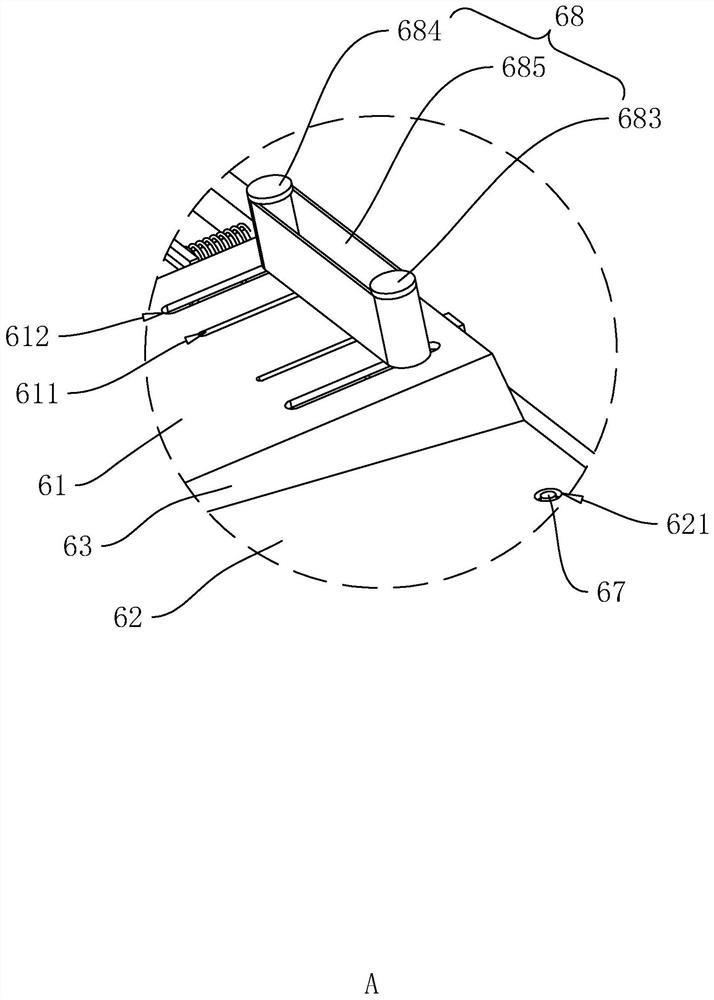

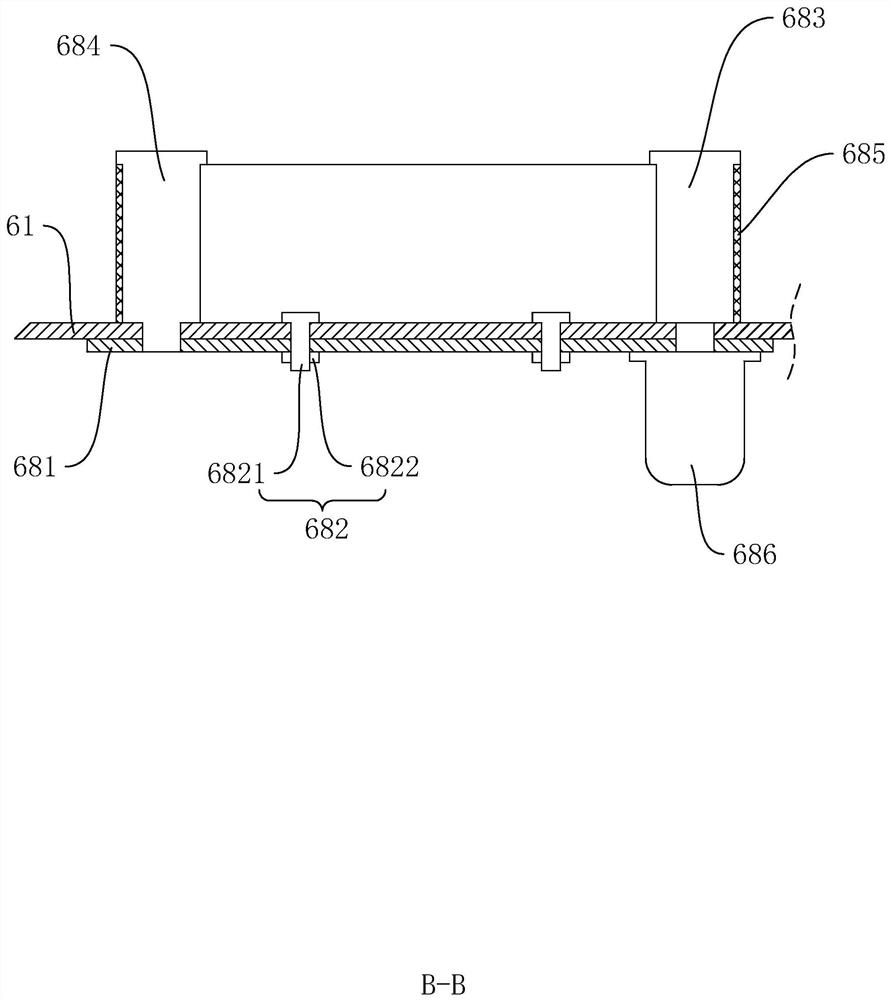

Low-noise high-speed centrifugal grinding and polishing machine

PendingCN111716233AReduce weightEasy loading and unloadingEdge grinding machinesPolishing machinesEngineeringMachine

The invention discloses a low-noise high-speed centrifugal grinding and polishing machine. The centrifugal grinding and polishing machine comprises an outer shell, an industrial control system, a driving device and a centrifugal polishing device, and is characterized in that the centrifugal polishing device comprises a vertical main rotating shaft arranged in an inner cavity of the outer shell andin transmission connection with the driving device, a main rotating disc arranged at the top of the main rotating shaft, at least two vertical centrifugal barrel bases arranged on the main rotating disc, and centrifugal grinding barrels capable of being arranged in the centrifugal barrel bases in a loading and unloading mode; and the centrifugal barrel bases are rotationally connected to the mainrotary disc through centrifugal rotary shafts penetrating through the main rotary disc, the lower ends of the centrifugal rotary shafts are connected with the main rotary shaft through transmission assemblies, and the centrifugal barrel bases and the centrifugal grinding barrels are driven to centrifugally rotate at a high speed through the transmission assemblies and the centrifugal rotary shafts while the main rotary shafts drive the main rotary disc to rotate. According to the low-noise high-speed centrifugal grinding and polishing machine, during polishing operation, material taking and discharging operation is simple and easy, various parts can be classified in different centrifugal grinding cylinders to be ground and polished at the same time, the working efficiency is high, and noise is low during operation.

Owner:方国权

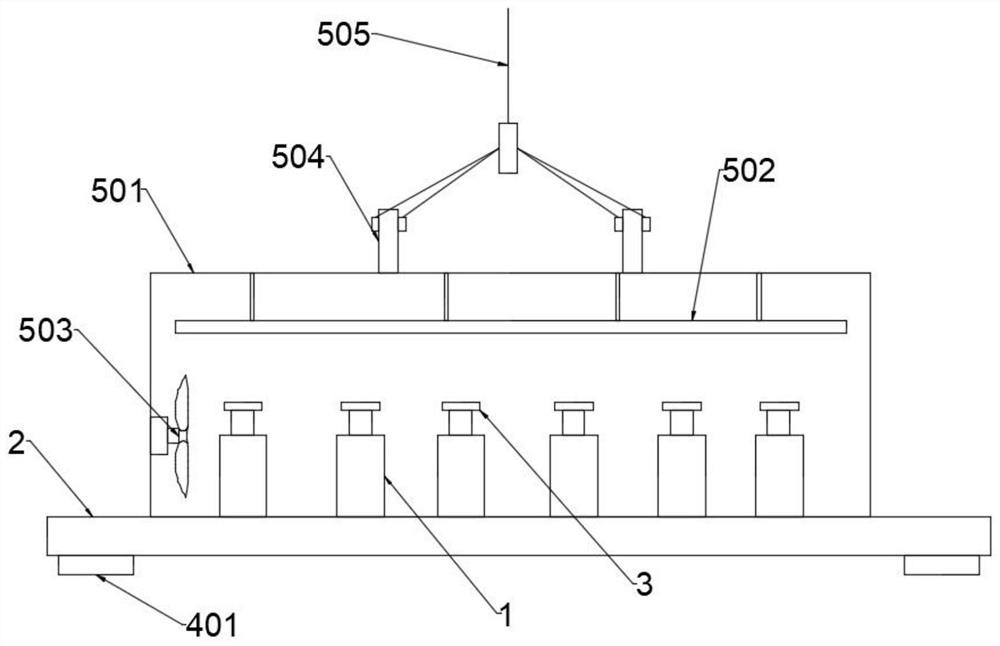

Specimen automatic sorting system

The invention relates to the technical field of auxiliary tools for clinical labs, and discloses a specimen automatic sorting system. The specimen automatic sorting system comprises a posture adjusting mechanism. The posture adjusting mechanism comprises a rack, a vibration screen and a conveying disc. The vibration screen is fixedly connected with the rack, and through holes used for allowing specimens to penetrate are formed in the bottom of the vibration screen. The conveying disc is rotationally connected with the rack, containing grooves used for bearing the specimens are arranged on theconveying disc, the conveying disc is located under the vibration screen, a gap used for exposing the conveying disc is arranged on the vibration screen, and the specimens on the conveying disc can bepicked up through the gap. By means of the scheme, the situation that in the prior art, the automation degree of specimen sorting is not high, consequently, the test speed is low, and efficiency is low can be solved.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

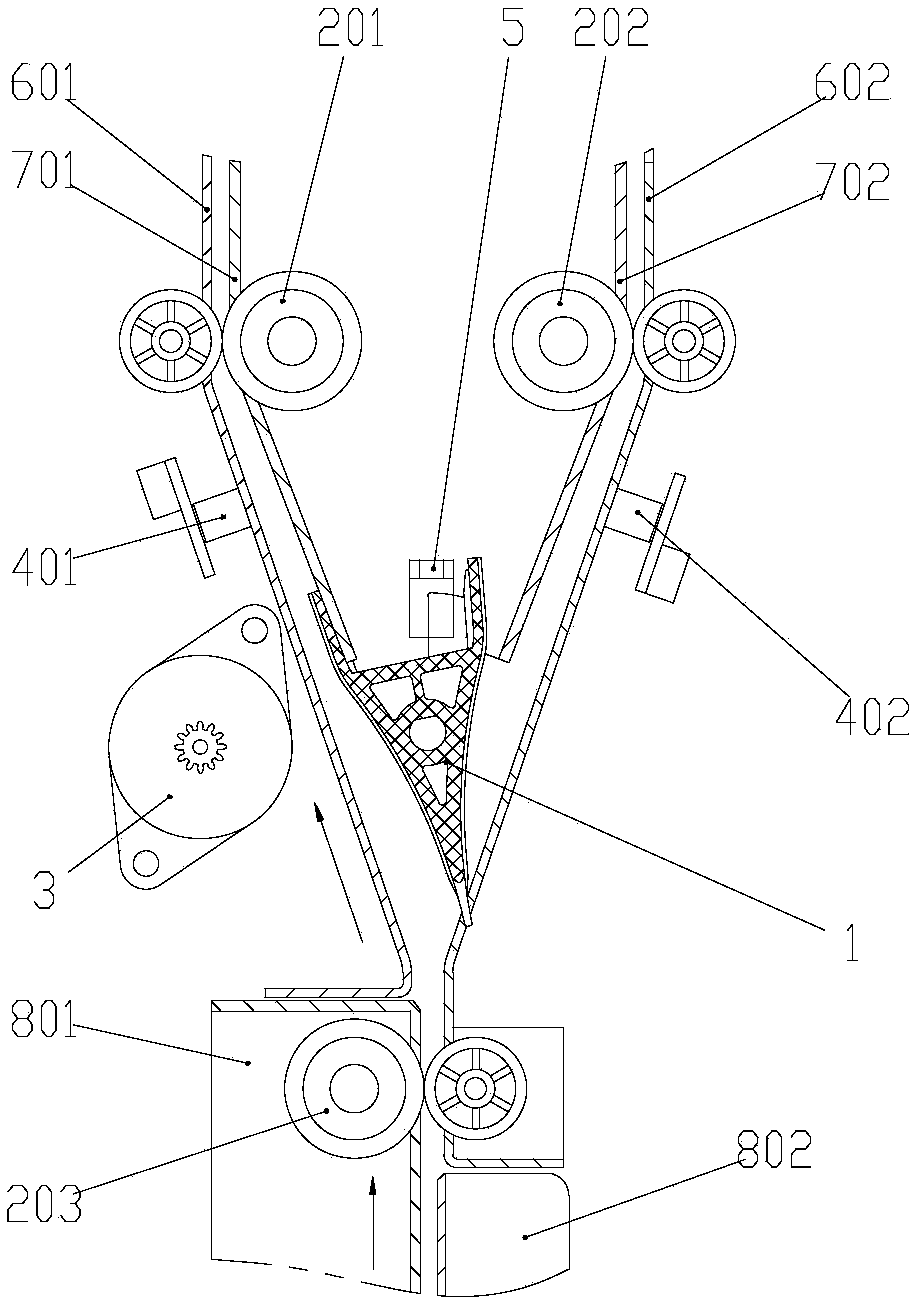

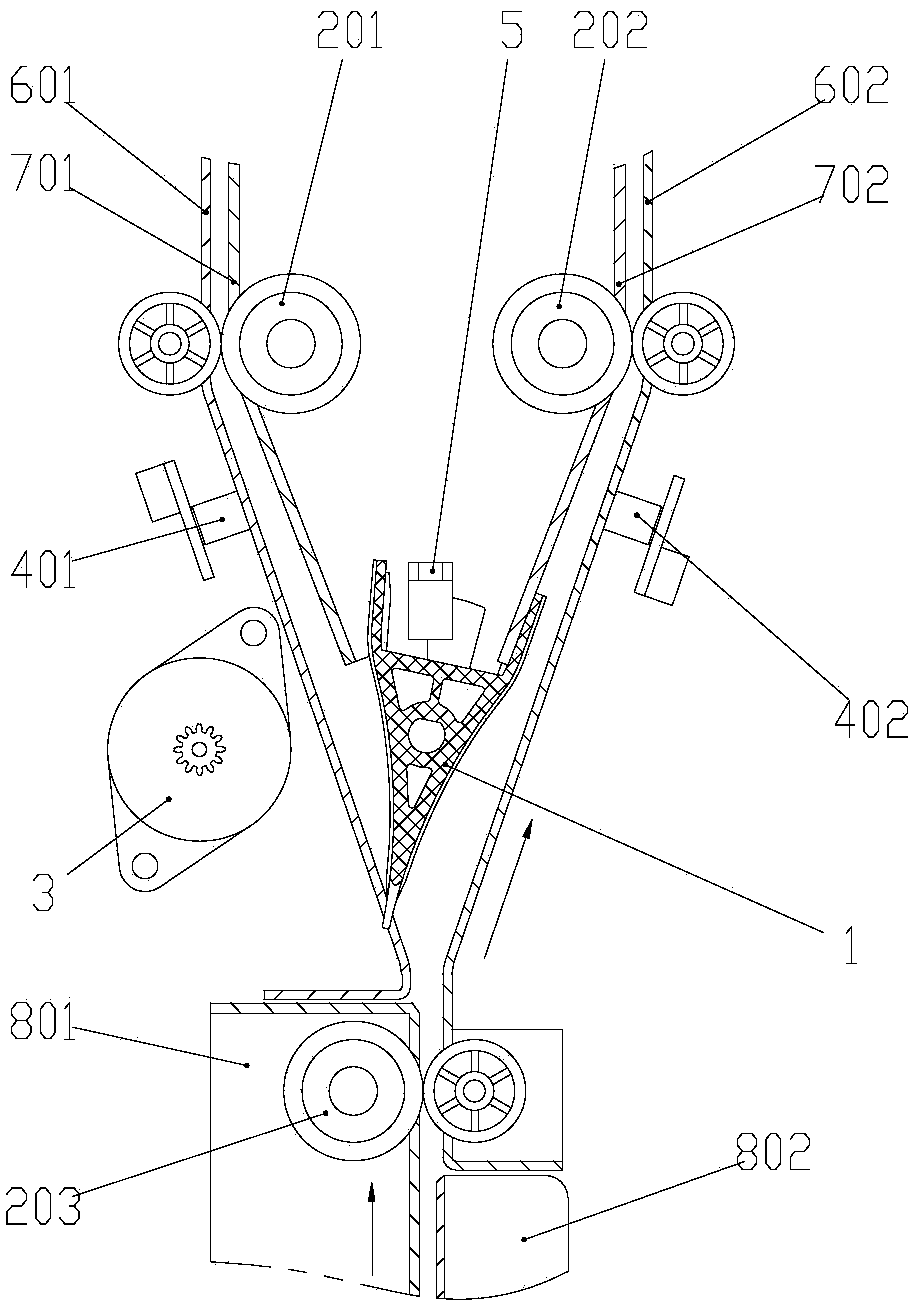

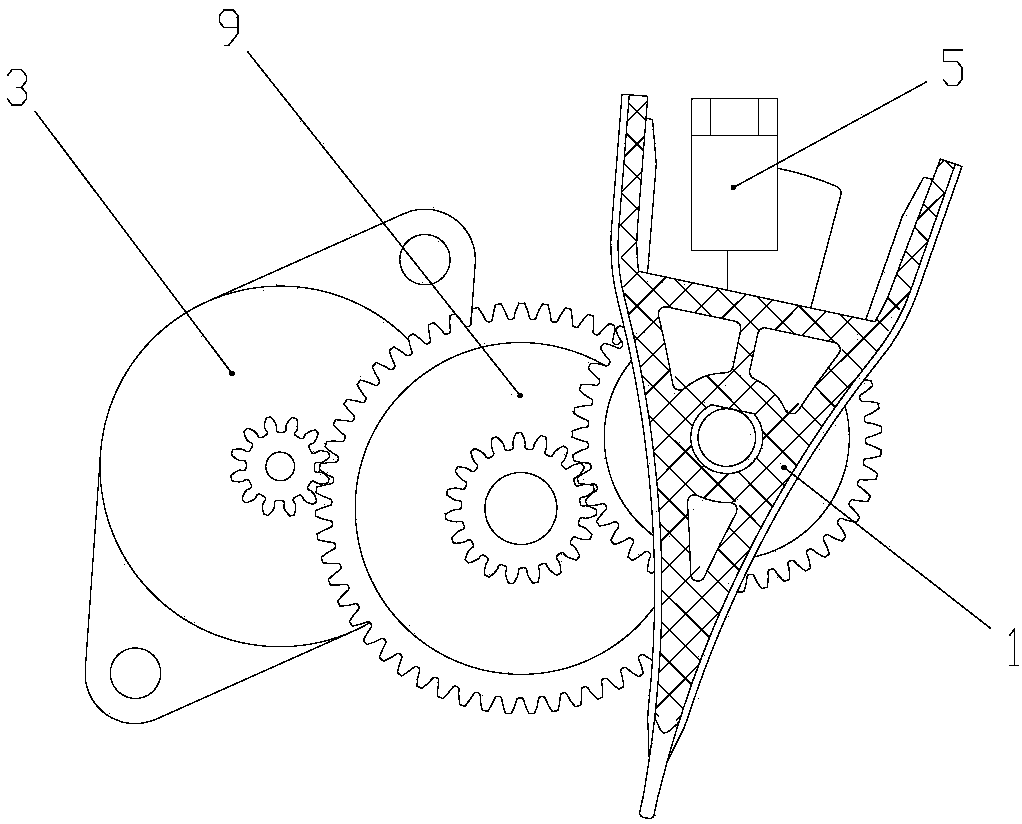

Swing bill sorting device and bill processing equipment

The invention discloses a swing bill sorting device and bill processing equipment. The device comprises a front channel left side plate, a front channel right side plate, a left channel outer side plate, a right channel outer side plate, a left channel inner side plate and a right channel inner side plate, wherein the gap between the front channel left side plate and the front channel right side plate is matched with the size of a bill so as to form a front channel for the bill to enter; a bill passing roller set for driving the bill to move from an inlet of the front channel to an outlet of the front channel is arranged in the front channel; the gap between the left channel outer side plate and the left channel inner side plate forms a left bill passing channel matched with the size of the bill; the gap between the right channel outer side plate and the right channel inner side plate form a right bill passing channel matched with the size of the bill; the left bill passing channel isprovided with a left bill passing roller set for driving the bill to move; the right bill passing channel is provided with a right bill passing roller set for driving the bill to move; the outlet of the front channel communicates with an inlet of the left bill passing channel and an inlet of the right bill passing channel; and the front channel controls the outlet of the front channel to communicate with the left channel or the right channel through the swing of a bill sorting swing rod. According to the swing bill sorting device and the bill processing equipment, the structure is simple and compact, automatic identification processing of the bills can be achieved, the bills are stored in two different storage boxes according to different types of the bills, thus automatic classification and storage can be realized, and the later-stage bill classification work can be reduced.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

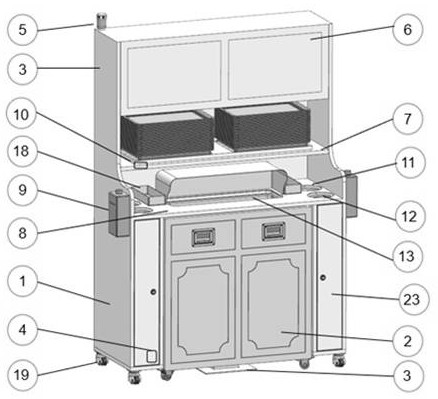

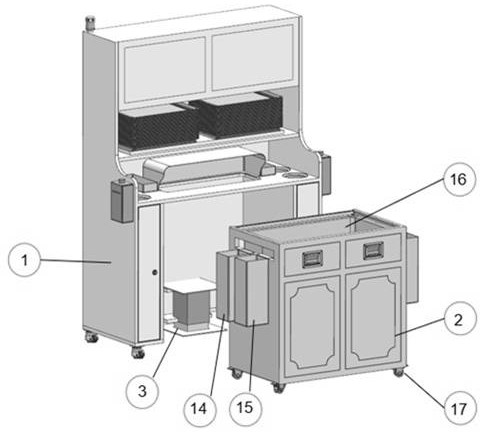

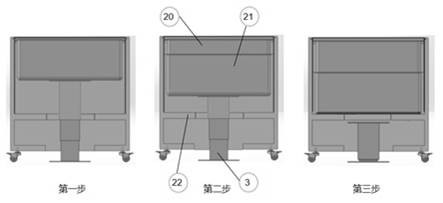

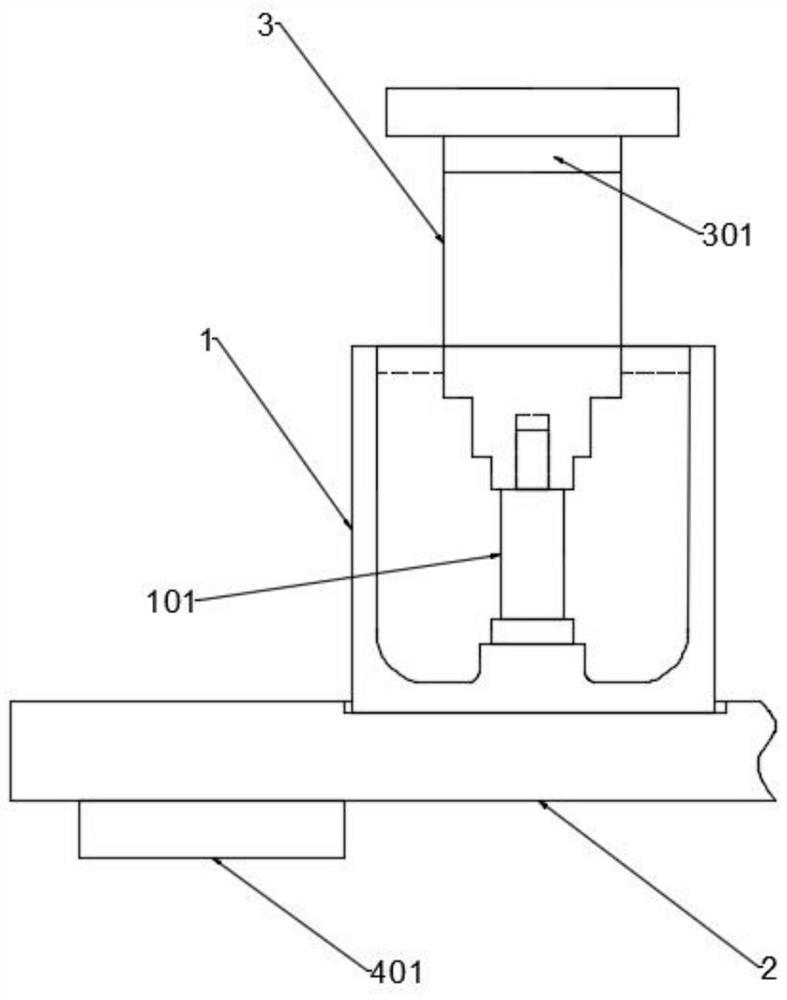

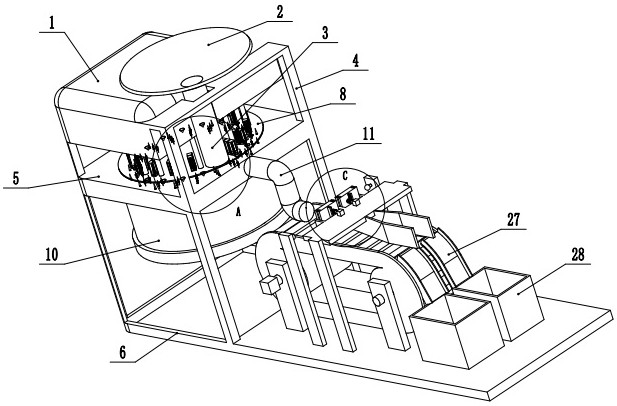

Self-service tableware recycling device

PendingCN113040522AReduce breakageReduce bruisesServing tablesSortingSmall footprintIndustrial engineering

The invention relates to a self-service tableware recycling device which comprises a main cabinet body 1, a sub-trolley 2 and a lifting module 3, the main cabinet body is provided with a control module 4, a communication early warning module 5, a display screen 6, a dinner plate frame 7, a classification plate 8, an identification module 10 and an interaction module 9, and the sub-trolley 2 is contained in the main cabinet body 1 and can be separated from the main cabinet body 1. A tableware collecting container 16 used for containing tableware and universal wheels 17 are arranged on the sub-trolley 2, and the lifting module 3 is arranged below the main cabinet body 1 and the sub-trolley 2. The recycling device is small in occupied area and can be flexibly arranged at different positions of a restaurant, customers and service personnel can conveniently put back tableware nearby, and dry and wet garbage and dinner plates and tableware can be classified and collected; the tableware collection container realizes automatic expansion and lifting, and damage to tableware is reduced while large-capacity storage is realized; the sub-trolley can realize the centralized and rapid carrying of tableware; the recycling device can give an alarm when being fully loaded; the recycling device also realizes the function of identifying the behavior of putting back the tableware by the customers in the collection process, and attracts and encourages the customers to recover by themselves in combination with the display screen and the interaction module. In conclusion, the labor cost for recycling and classifying the tableware and the dry and wet garbage is greatly saved for the restaurant.

Owner:BEIJING CHUANGXIANG XINYU TECH

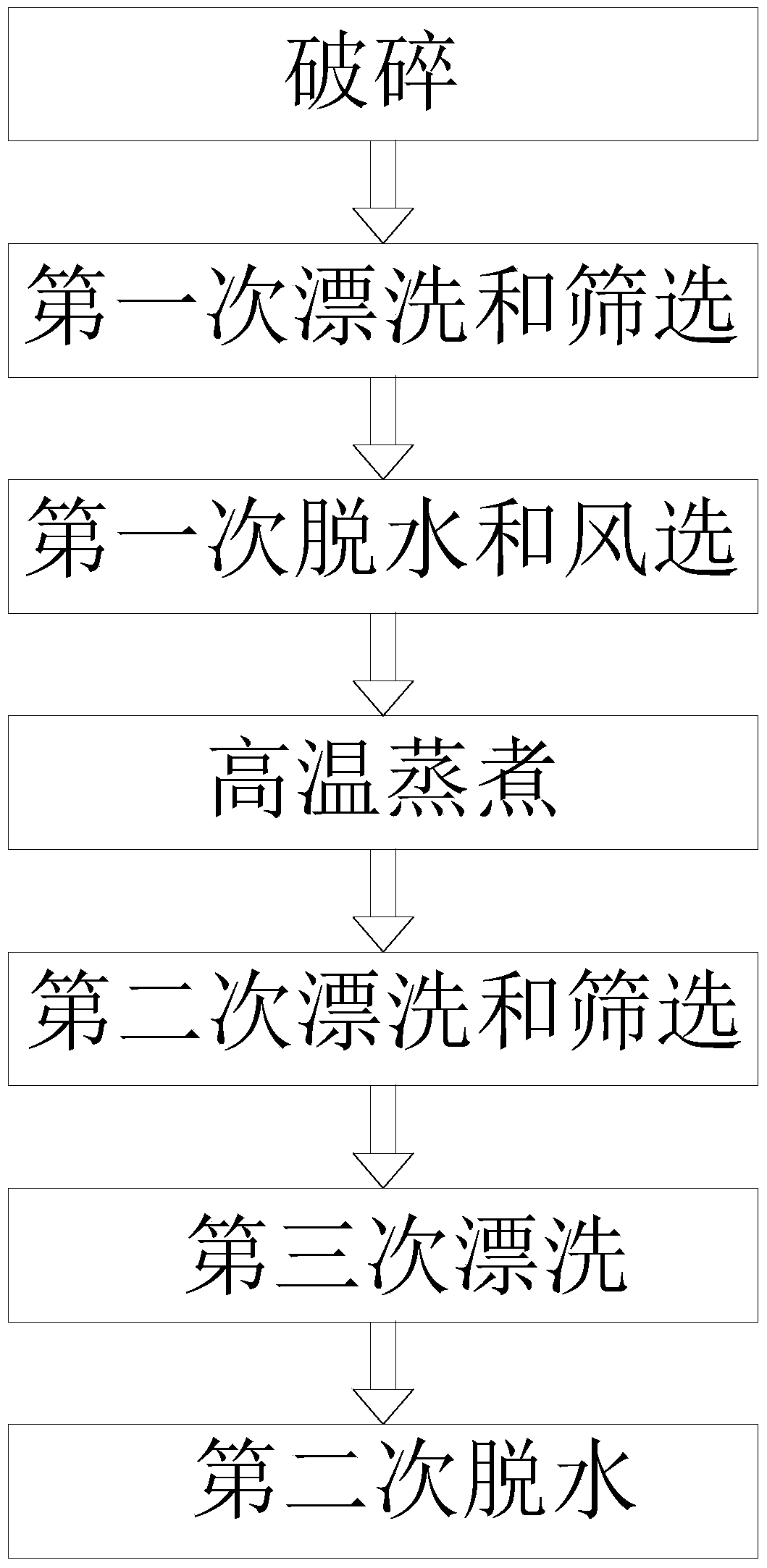

A kind of waste plastic recycling processing method

Owner:万年县金兔裕发实业有限公司

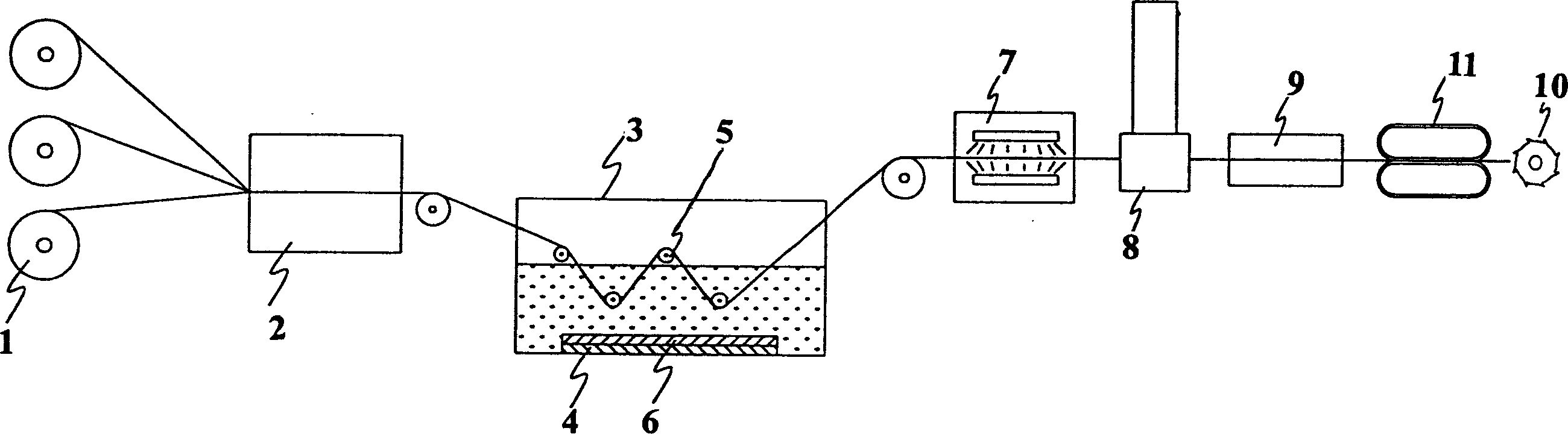

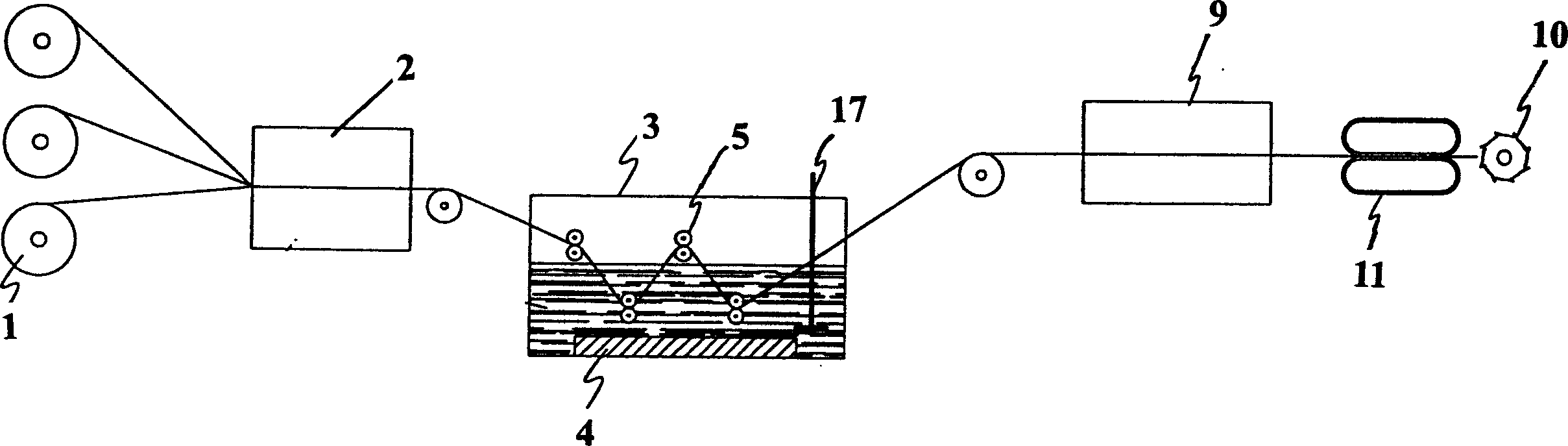

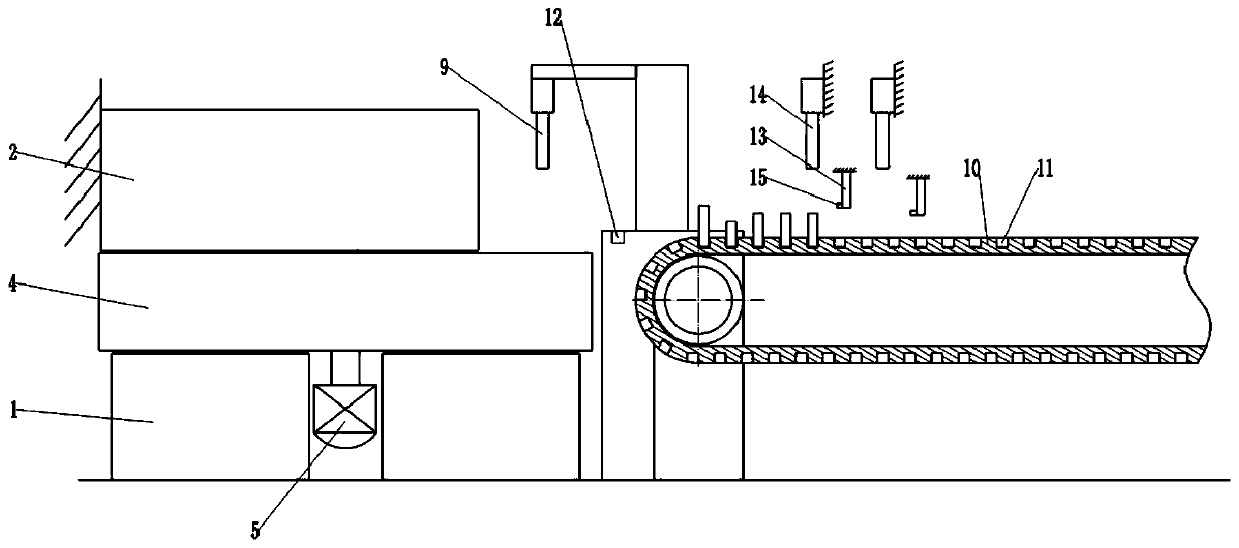

Equipment for manufacturing wheel tires

ActiveCN113290899AReduce sorting workReduce workloadPlastic recyclingTyresTextile printerAssembly line

The invention discloses equipment for manufacturing wheel tires. The equipment comprises an injection molding device, a curing device, a trimming device, a printing device and a glue sealing device, and further comprises a mold, a bottom plate, an ejector block and a demolding device. The demolding device comprises a conveying chain, a rotating frame, a drainage plate, a top block collecting box and a tire collecting box. An axis rod is arranged in the mold. The axis rod is vertically arranged, the lower end of the axis rod is fixedly connected with the mold, and the upper end of the axis rod is sleeved with the lower end of the ejector block. The bottom of the mold is fixedly connected with the bottom plate. The bottom plate is fixedly connected with the conveying chain. The curing device is positioned above the conveying chain. A top block collecting box is arranged under a discharge hole of the drainage plate. The tire collecting box is located under the left end of the conveying chain. The curing device and the demolding device are arranged on the conveying chain, so that an assembly line is formed in product production, the sorting work of workers is relieved, the automation degree of equipment is improved, the workload of the workers is reduced, and the production efficiency is improved.

Owner:化州市联合民生轮业有限公司

Image retrieval method, device, graphics processor and storage medium

ActiveCN109614510BQuality improvementReduce occupancyDigital data information retrievalSpecial data processing applicationsGraphicsImage retrieval

Owner:TENCENT TECH (SHENZHEN) CO LTD

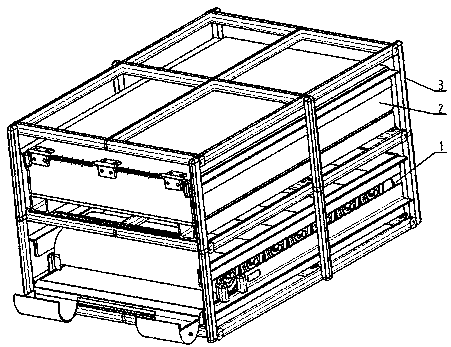

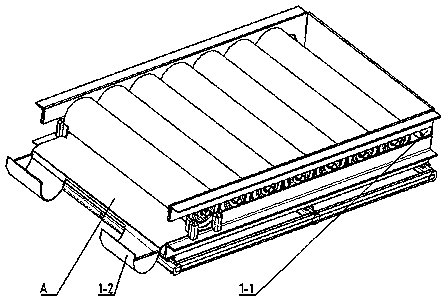

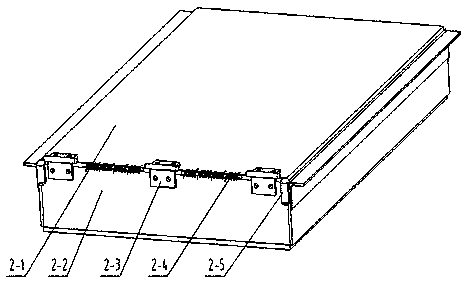

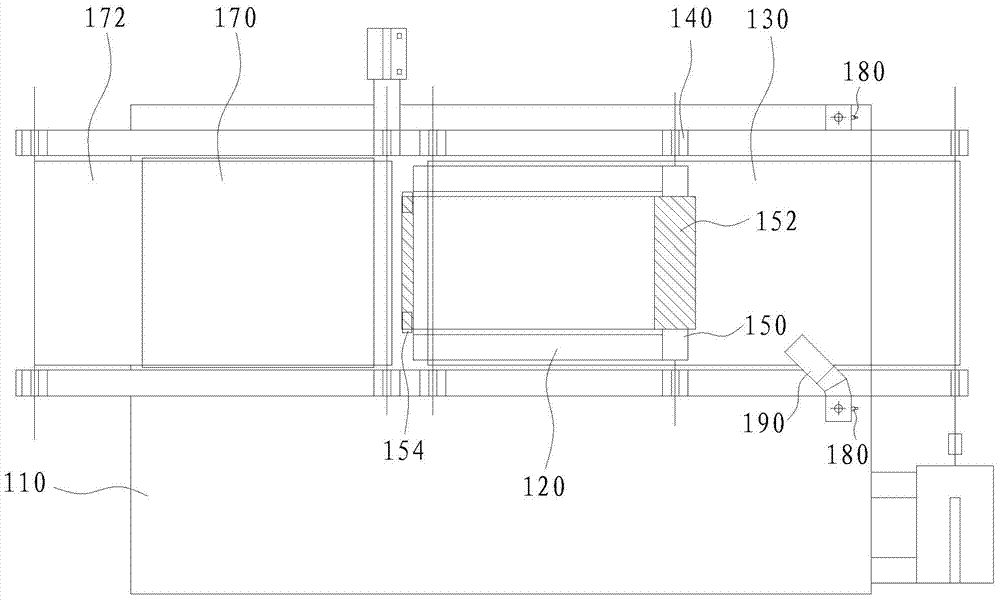

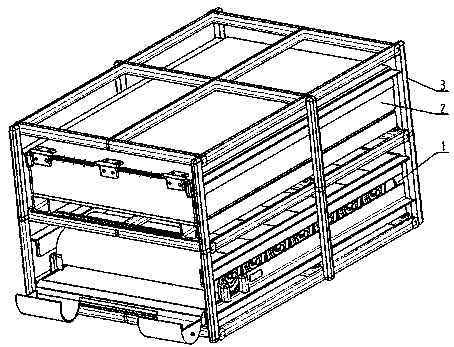

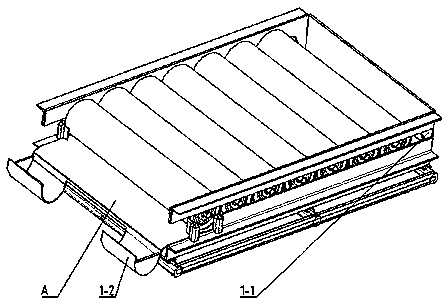

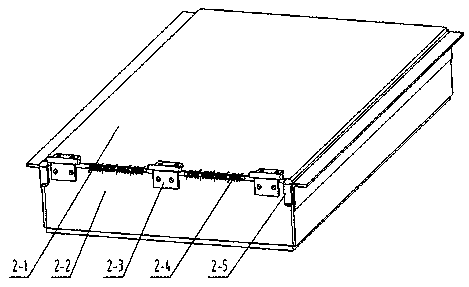

Carrier roller supplying and recycling equipment

Carrier roller supplying and recycling equipment is provided. The carrier roller supplying and recycling equipment comprises an automatic supplying bin, a recycling bin and an adjustable sliding railouter frame, the automatic supplying bin is arranged on the lower layer of the adjustable sliding rail outer frame, and the recycling bin is arranged on the upper layer of the adjustable sliding railouter frame; the recycling bin is formed by welding sectional bar and steel plate structures; the automatic supplying bin is composed of a first box and a roller receiving groove, the roller receivinggroove is formed in the left end of the box, a carrier roller inlet and outlet A is formed in the left end of the box and the upper portion of the roller receiving groove, the box is of a welding structure by steel plates and angle steel, the roller receiving groove is formed by welding the steel plates, and the two outer ends of the roller receiving groove are sealed semi-cylindrical grooves; and a second box and a turnover plate are connected to be a whole through hinges and springs, limiting blocks are arranged on the second box and the two ends of the turnover plate, a sliding rail clampis arranged on the left side of a rail frame in the shape like the Chinese character 'tian', and a counter is arranged on the right side of the rail frame in the shape like the Chinese character 'tian'. According to the carrier roller supplying and recycling equipment, storing and packing of carrier rollers is optimized, loading and unloading and transporting of the carrier rollers are convenient,classified storing of the carrier rollers is achieved, using is convenient, taking is quick, the mounting time is shortened, the mounting efficiency is improved, and the carrier roller supplying andrecycling equipment is applied to the field of conveyors.

Owner:NORTHERN HEAVY IND GRP CO LTD

Storage and transportation box for vegetable transportation

PendingCN111439487ADo not squeeze each otherEasy to packLiving organism packagingPackaging under vacuum/special atmosphereNutritionAgricultural engineering

The invention provides a storage and transportation box for vegetable transportation. The box comprises at least one hydroponic bowl, cover bodies capable of covering the hydroponic bowls and a housing; the cover bodies are provided with through holes, and the cover bodies and the hydroponic bowls define root cultivating cavities in an enclosing mode; and the hydroponic bowls can be arranged in the housing, and vegetable placing space is reserved at the position, above the hydroponic bowls, of the interior of the housing. According to the box, the hydroponic bowls are adopted to contain nutrient solution for vegetables so that different vegetables can receive corresponding nutrition; the cover bodies are adopted to avoid the situation that the nutrient solution spills out of the hydroponicbowls due to vibration in the transportation process; and the housing is adopted to reserve the vegetable placing space so that the vegetables cannot be mutually extruded in the transportation process.

Owner:代尔夫(天津)农业科技有限责任公司

A data synchronization system and method

ActiveCN108073658BTimely processingReduce latencyDatabase distribution/replicationSpecial data processing applicationsComputer hardwareData synchronization

The invention discloses a data synchronization system and method. The method comprises the steps that after a target end receives an instruction file sent by a source end, an object is placed into a corresponding to-be-processed queue after information of the object in the instruction file is read; when the object is placed into the corresponding to-be-processed queue, if the object is not in theto-be-processed queue, a row is newly added into a queue configuration file, and if the object is in the to-be-processed queue, 1 is added to the lock quantity L of the object in the queue configuration file; processing duration of all to-be-processed queues is estimated; and the to-be-processed queues are loaded according to the processing duration, and after loading, 1 is subtracted from L, andthe row with L being 0 is deleted. By the adoption of the data synchronization system and method, delay in database synchronization can be shortened.

Owner:中国移动通信集团广西有限公司 +1

SMT surface-mount detection device

ActiveCN113680674AReduce sorting workSmooth climbOptically investigating flaws/contaminationSortingOptical detectorsOptical detector

The invention relates to an SMT surface-mount detection device. The device comprises a base and a cover body, two supporting plates are fixedly arranged on the upper surface of the base, and a conveying belt used for conveying a PCB is arranged between the two supporting plates; the inner side of the cover body is provided with an automatic optical detector used for detecting SMT surface-mount; a removing mechanism is arranged above the conveying belt and comprises a bottom plate, the two opposite sides of the bottom plate are hinged to two supporting plates respectively, and the supporting plates are provided with driving parts for driving the bottom plate to swing; a discharging plate is fixed to the side, away from the feeding side of the conveying belt, of the bottom plate; two clamping material conveying belts are arranged above the bottom plate and are used for clamping and conveying PCBs to the discharging plate; the discharging plate is provided with a proximity switch; when the automatic optical detector detects the PCBs which do not meet the standard, the driving parts drives the bottom plate to swing until the edge of one side, away from the discharging plate, of the bottom plate is propped against the upper surface of the conveying belt; and when the proximity switch detects the PCBs, the driving parts drive the bottom plate to swing for resetting. The removing mechanism can remove the PCBs which do not meet the standard from the conveying belt.

Owner:深圳市中纬智能有限公司

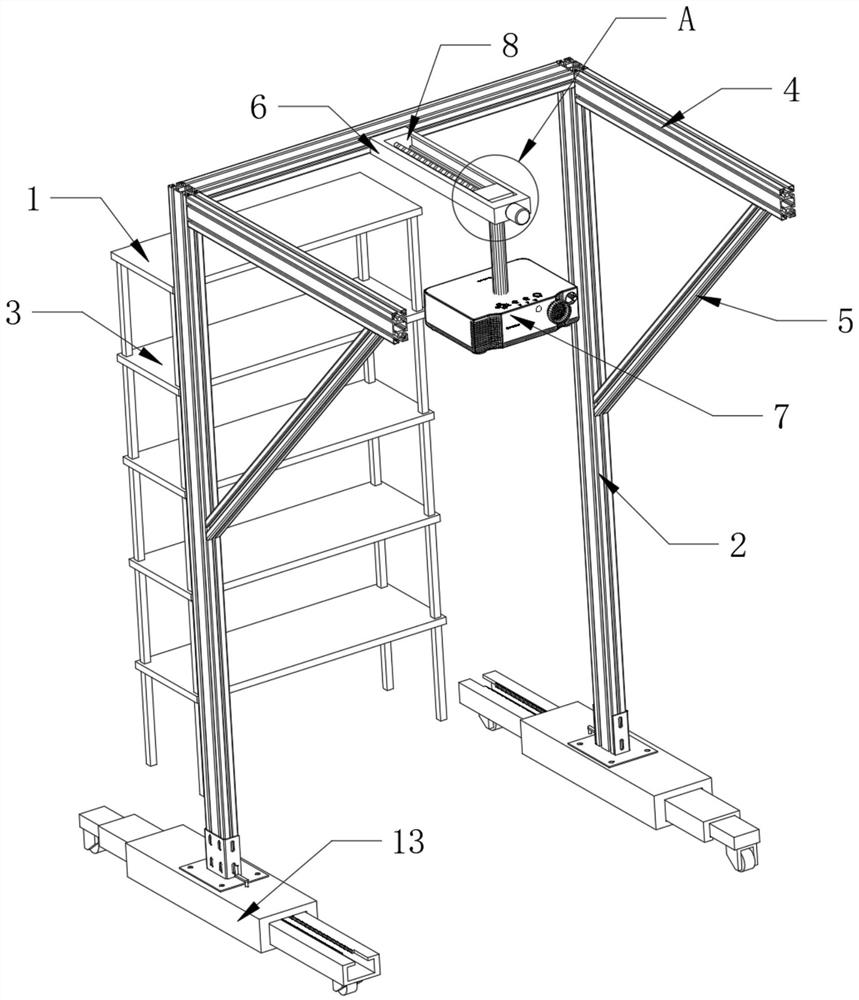

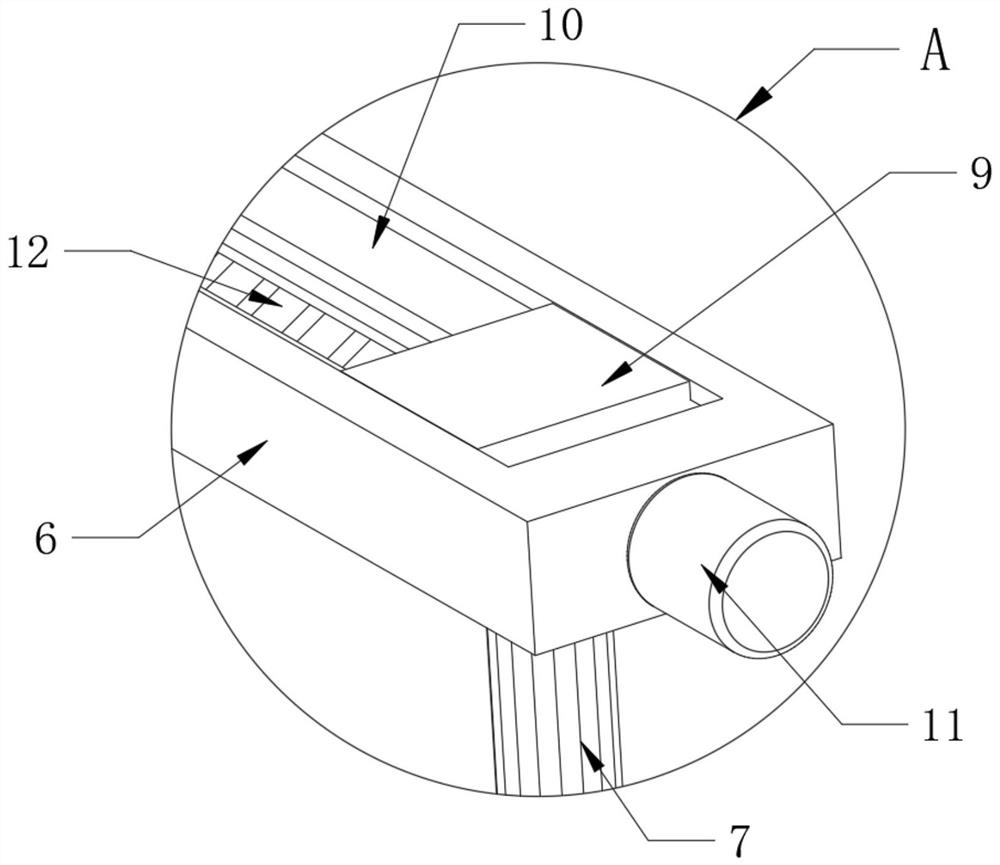

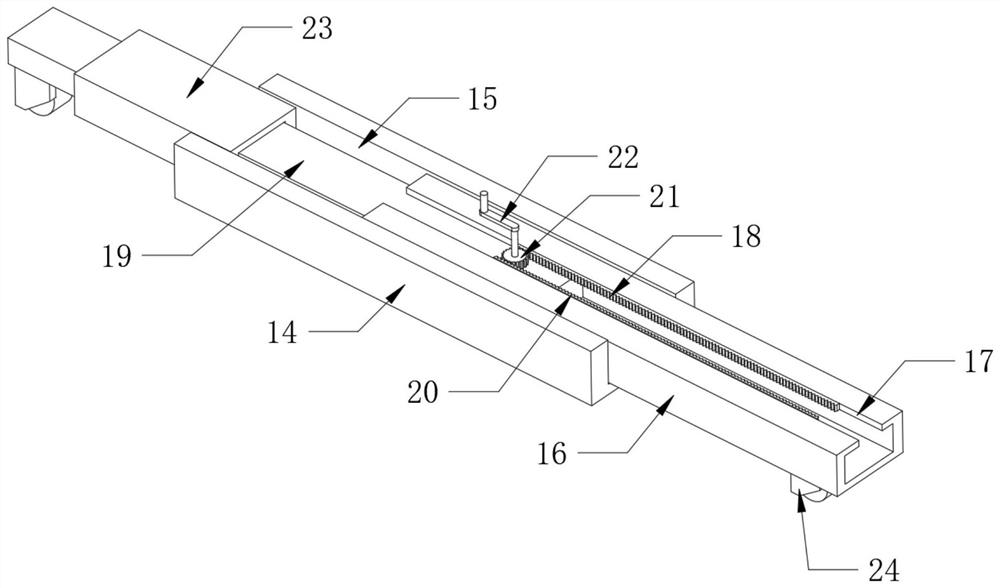

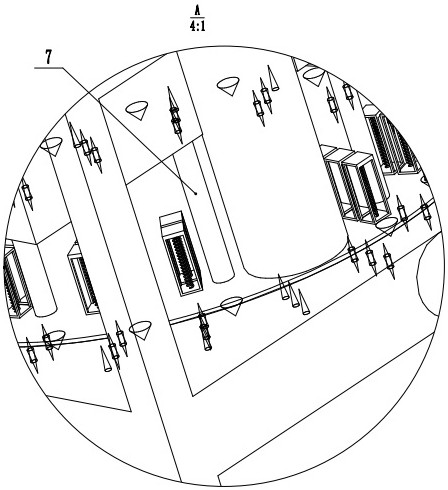

Light-assisted sorting equipment

The invention discloses light-assisted sorting equipment. The light-assisted sorting equipment comprises a goods shelf and a supporting frame, the goods shelf and the supporting frame are both made of light stainless steel materials, goods shelf plates are symmetrically fixed to the middle of the goods shelf, a first connecting rod is fixed to the top of the supporting frame, a bearing rod is fixed between the first connecting rod and the supporting frame, and a second connecting rod is fixed in the middle position of the top of the supporting frame. According to the light-assisted sorting equipment, an upper computer unit is organically connected with a plurality of corresponding ports of a projection unit and a handheld terminal unit, and the upper computer unit is used for storing position information of goods on the goods shelf and calculating the goods taking-out sequence in an order, meanwhile, information mutual transmission with the handheld terminal unit is carried out, the projection unit receives a projection position instruction sent by the upper computer unit, a projector emits light rays, the light rays are projected to the position indicated by an upper computer, workers are guided to sort, confirmation and information input are achieved through the handheld terminal, and the equipment has the characteristics of low cost, fast guidance and the like.

Owner:浙江华眼视觉科技有限公司

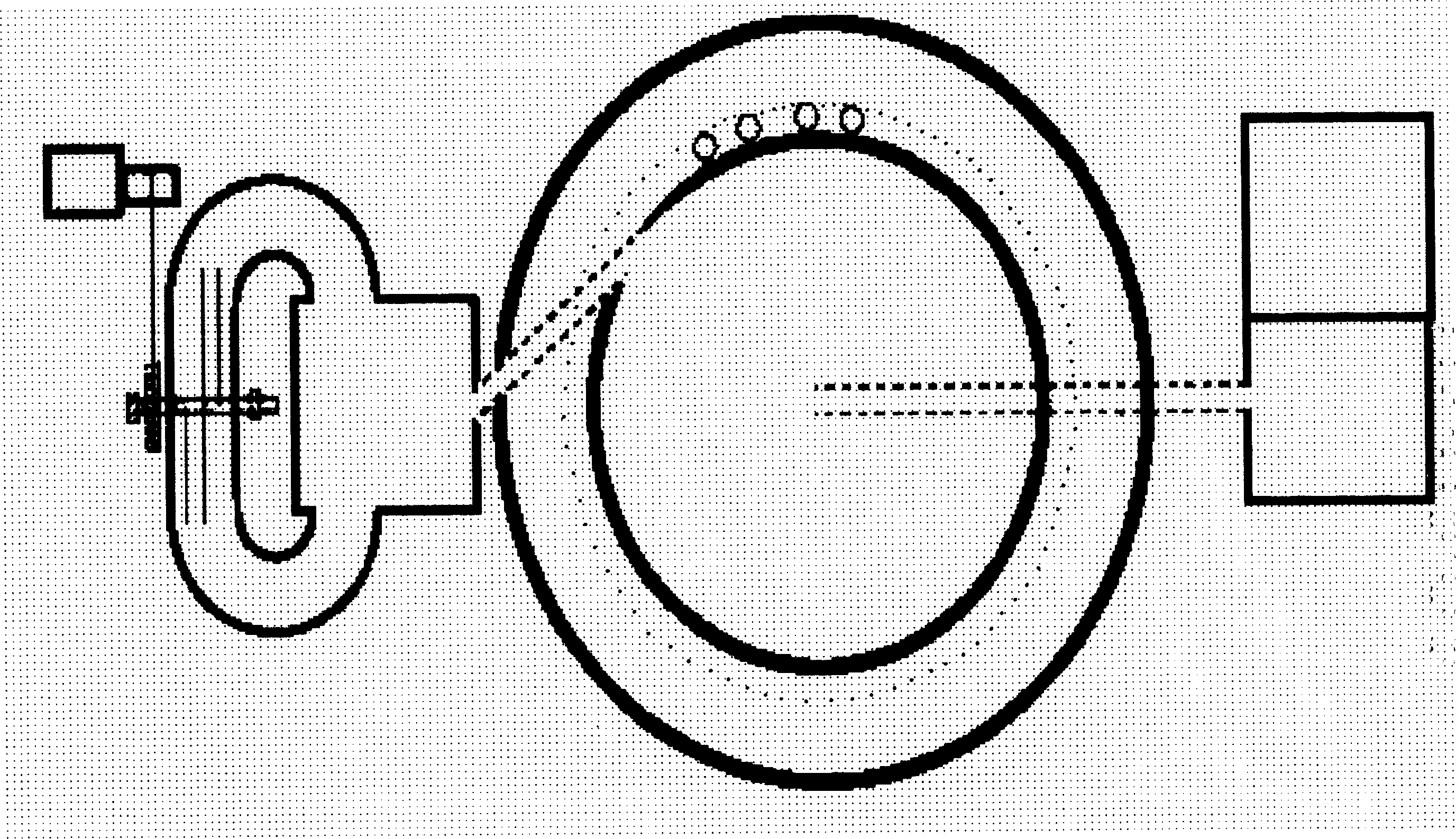

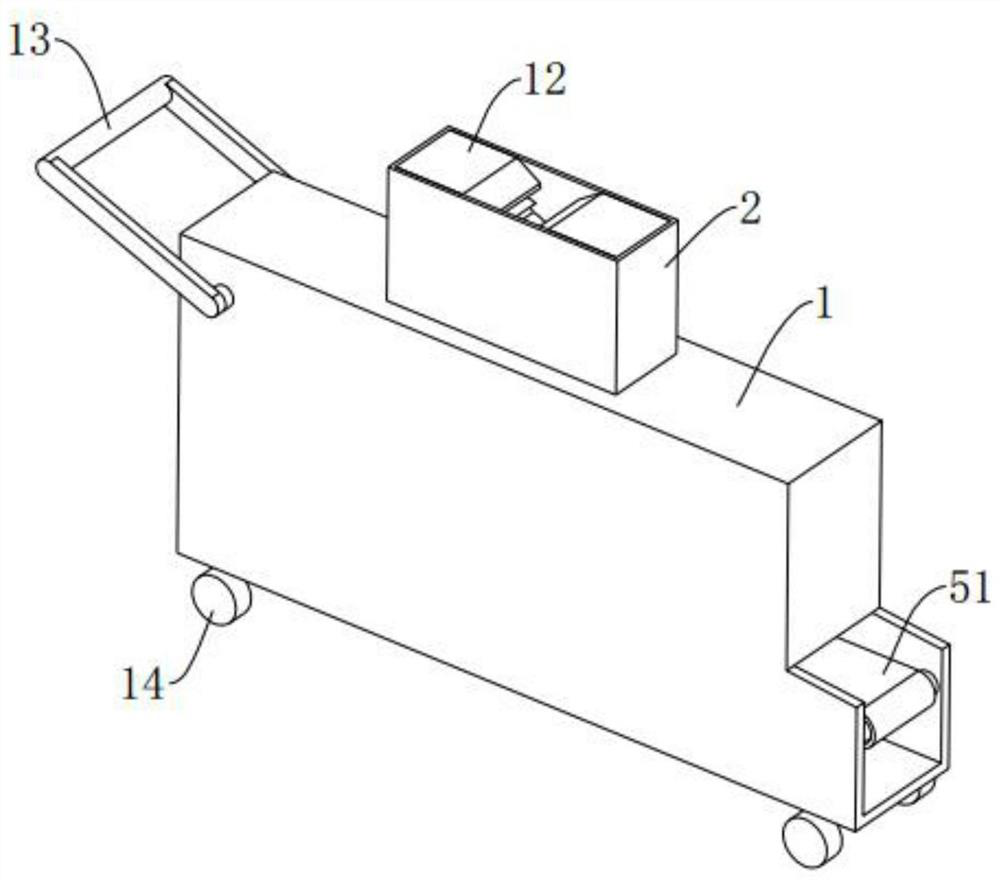

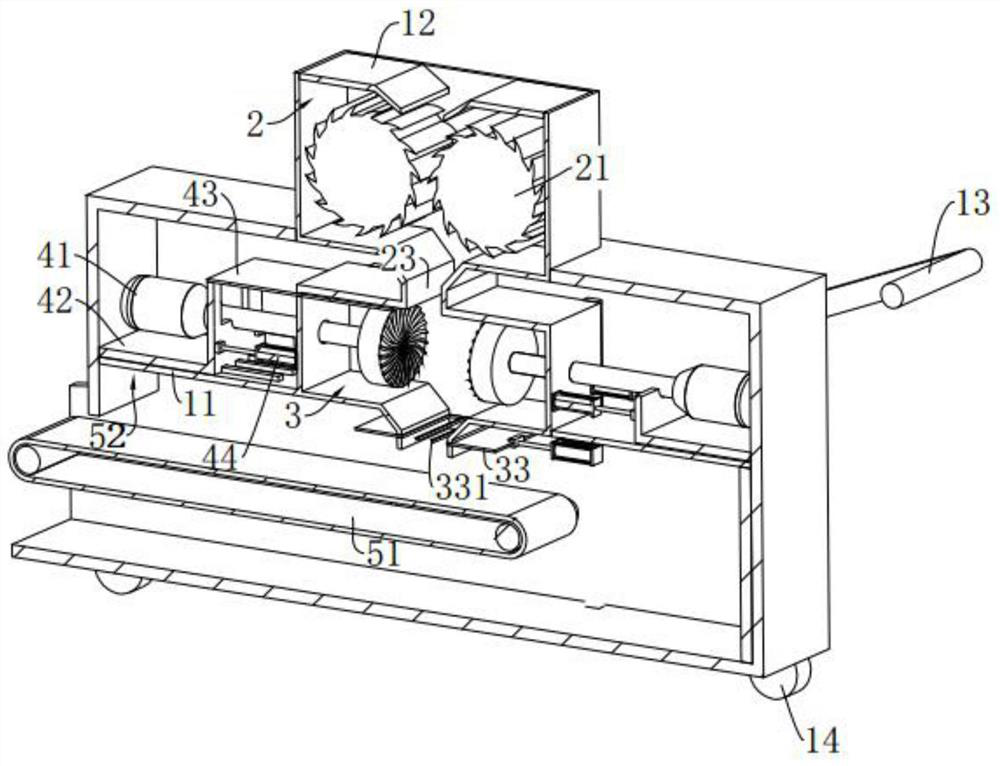

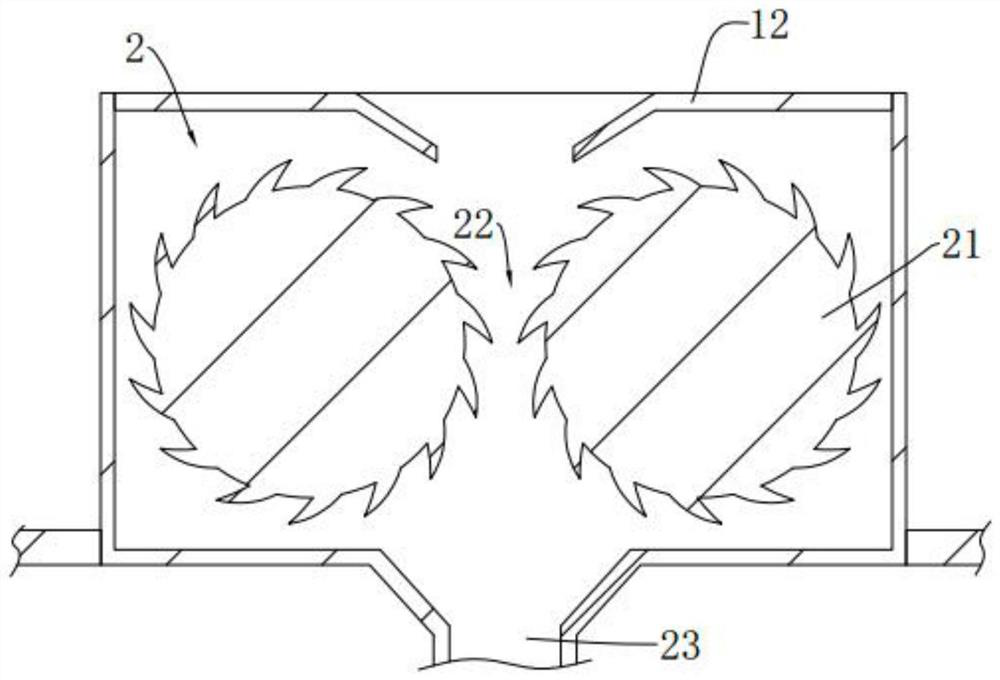

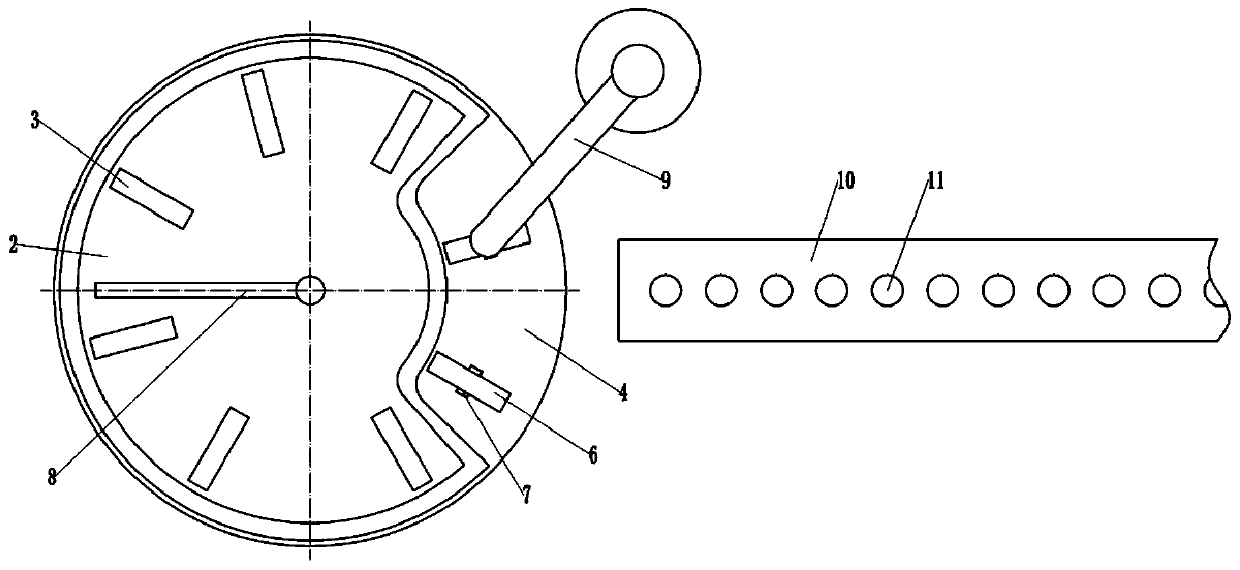

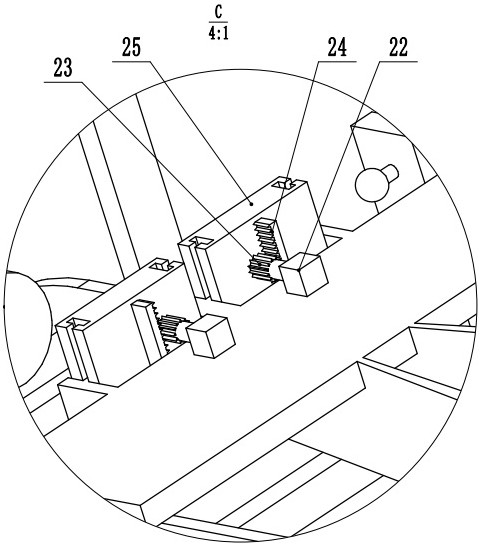

A kind of grinding disc type machine for removing walnut green skin

ActiveCN108208862BRealize the work of cleaning walnutsReduce sorting workHuskingHullingWalnut NutProcess engineering

The invention provides a millstone type machine for removing green peels of walnuts. The millstone type machine comprises a water tank, a funnel, a leaking pipe, an upper bracket, a working supportingplatform, a lower bracket, a set of water pipes, an upper stripping machine and a lower stripping machine. The millstone type machine is characterized in that the water tank is fixedly mounted on theupper bracket; and the upper bracket is fixedly mounted on the upper end surface of the working supporting platform. According to the millstone type machine disclosed by the invention, the strippingof the green peels of the walnuts is realized through mutual rotation of an upper stripping platform and a lower stripping platform, and the pre-tightening force of springs behind corresponding steelbrushes is adjusted, so that in the course of stripping of the walnuts, the walnuts are not damaged; a high-pressure water spraying device is arranged on the upper stripping platform, so that in the course of stripping of the walnuts, the work of washing the walnuts is realized; and a detecting device is arranged, the walnuts which are qualified in peeling are separated from the walnuts which areunqualified in peeling, and then the unqualified walnuts are peeled, so that the sorting work of separating the walnuts which are qualified in peeling from the walnuts which are unqualified in peelingis reduced.

Owner:义乌市富顺箱包有限公司

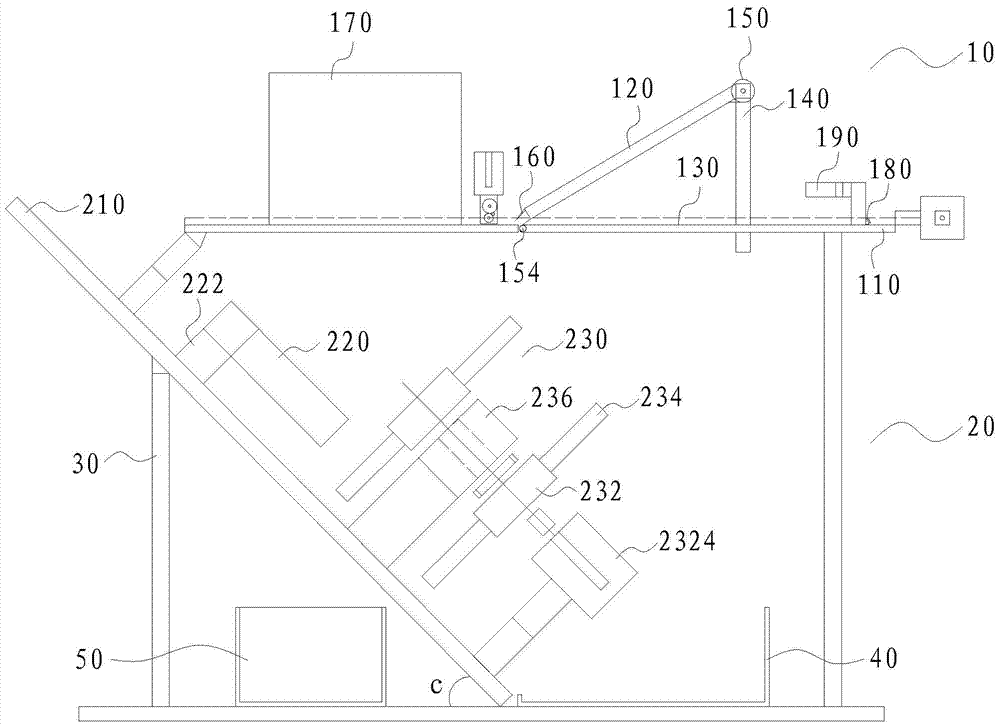

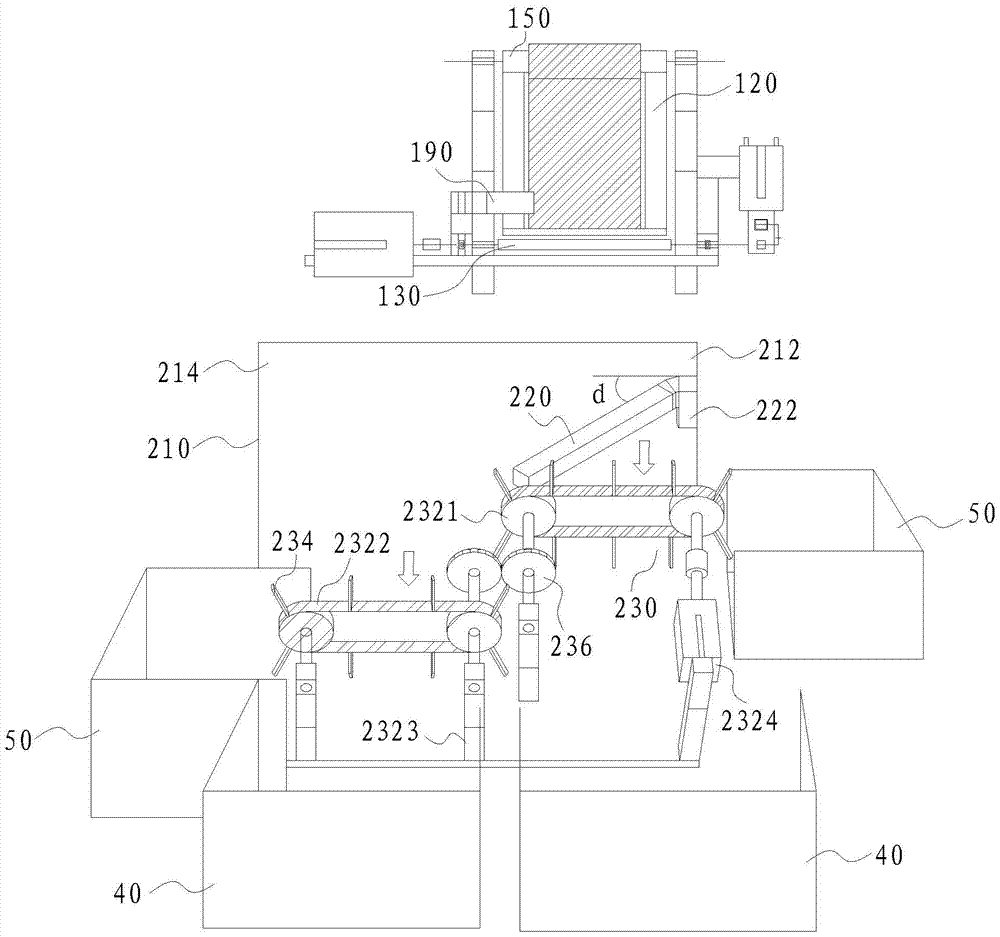

Automatic packaging and classification integrated machine and packaging classification method

InactiveCN105501498BReduce sorting workHigh degree of integrationWrapping material feeding apparatusConveyor wrappingDevice formClassification methods

Owner:GUANGDONG INST OF SCI & TECH

A roller supply recovery equipment

Carrier roller supplying and recycling equipment is provided. The carrier roller supplying and recycling equipment comprises an automatic supplying bin, a recycling bin and an adjustable sliding railouter frame, the automatic supplying bin is arranged on the lower layer of the adjustable sliding rail outer frame, and the recycling bin is arranged on the upper layer of the adjustable sliding railouter frame; the recycling bin is formed by welding sectional bar and steel plate structures; the automatic supplying bin is composed of a first box and a roller receiving groove, the roller receivinggroove is formed in the left end of the box, a carrier roller inlet and outlet A is formed in the left end of the box and the upper portion of the roller receiving groove, the box is of a welding structure by steel plates and angle steel, the roller receiving groove is formed by welding the steel plates, and the two outer ends of the roller receiving groove are sealed semi-cylindrical grooves; and a second box and a turnover plate are connected to be a whole through hinges and springs, limiting blocks are arranged on the second box and the two ends of the turnover plate, a sliding rail clampis arranged on the left side of a rail frame in the shape like the Chinese character 'tian', and a counter is arranged on the right side of the rail frame in the shape like the Chinese character 'tian'. According to the carrier roller supplying and recycling equipment, storing and packing of carrier rollers is optimized, loading and unloading and transporting of the carrier rollers are convenient,classified storing of the carrier rollers is achieved, using is convenient, taking is quick, the mounting time is shortened, the mounting efficiency is improved, and the carrier roller supplying andrecycling equipment is applied to the field of conveyors.

Owner:NORTHERN HEAVY IND GRP CO LTD

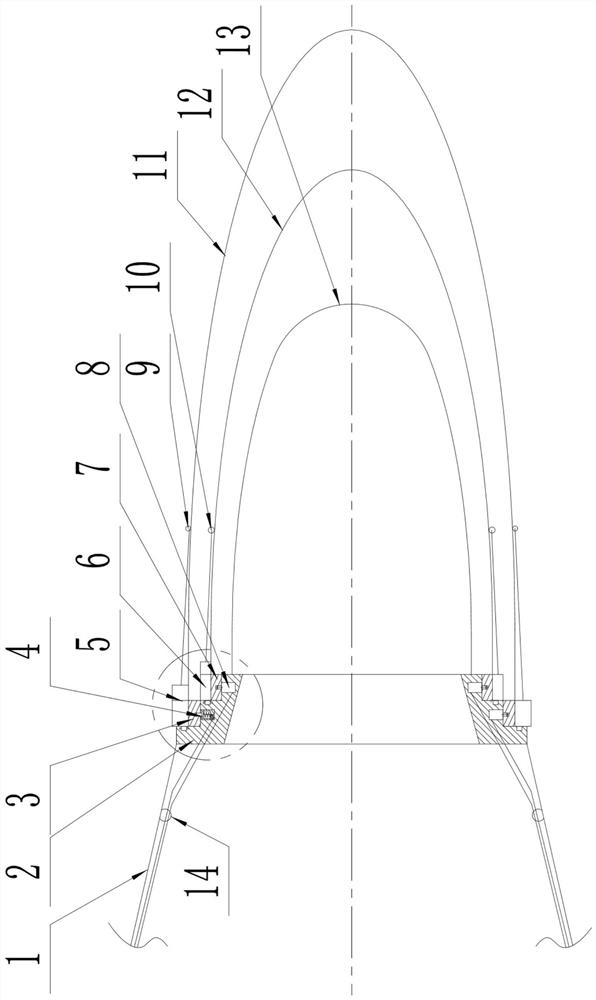

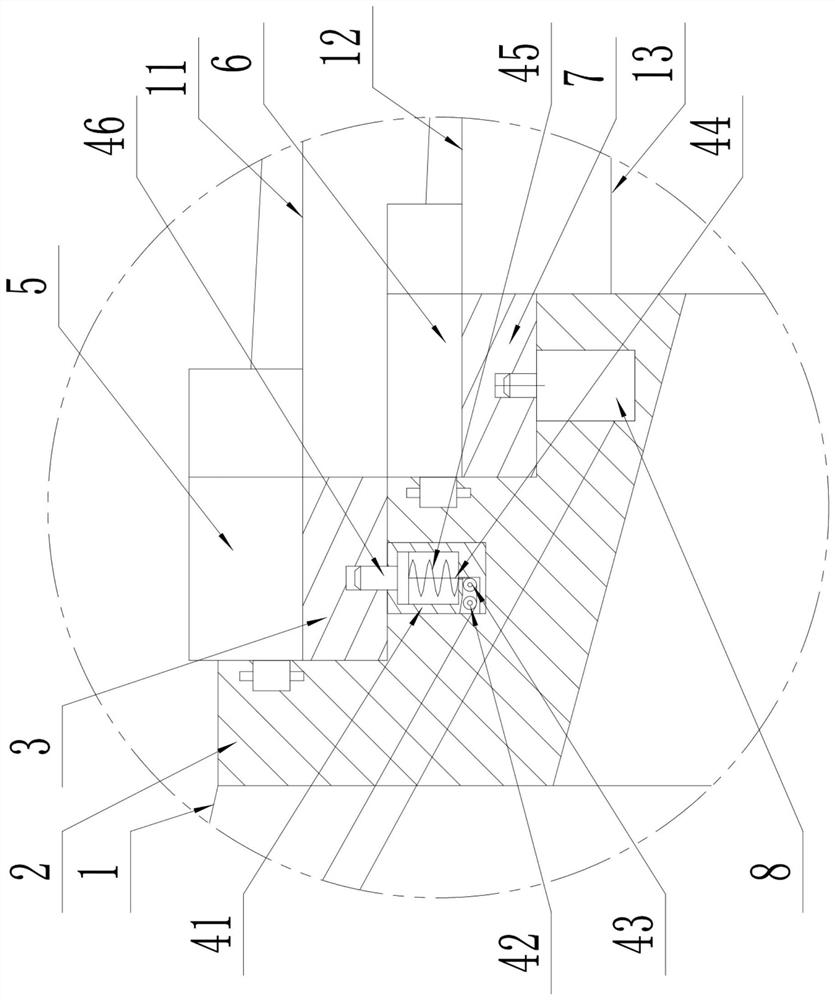

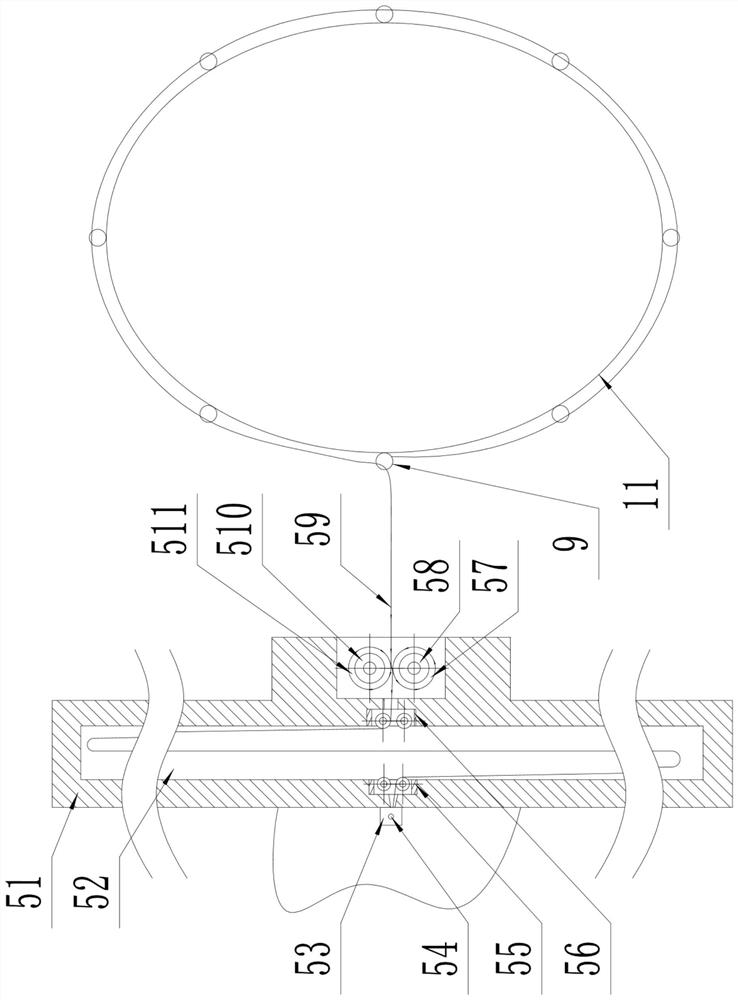

A nested detachable catch separation trawl mesh bag and its operation method

ActiveCN110521681BSmall sizeReduce sorting workFishing netsPisciculture and aquariaFisheryEngineering

The invention discloses a nested detachable trawl net bag and an operation method for separating catches, including a fixed frame, a connecting frame 1, a locking device 1, a large mesh bag and a guide ring, etc.; the design of the mesh bag in the present invention Form multiple nested mesh pockets, and the mesh size of each mesh pocket is different; the mesh size of the innermost mesh pocket is the largest, and the mesh wire is the thickest; thus, the mesh size of the mesh pockets is sequentially reduced from the inside to the outside , reduce the wire diameter; the mesh size of the outermost net bag is the smallest, and the wire is the thinnest; in this way, the separation of different catch sizes can be reasonably realized, and the sorting work of the staff is alleviated; when falling off in the present invention It starts to fall off from the outermost layer. Because the outermost layer is the thinnest net wire, most of the fish are loaded with smaller fish. The tolerance of small-sized fish is lower than that of large-sized fish, and they are more likely to die. , and the survival ability of large fish is relatively strong, and this shedding sequence is also in line with this rule, reducing fish death.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com