A kind of grinding disc type machine for removing walnut green skin

A technology of walnut green peeling and disc grinding, which is applied in the fields of shelling, pod removal, food science, etc., and can solve the problems of unqualified peeling and manual re-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

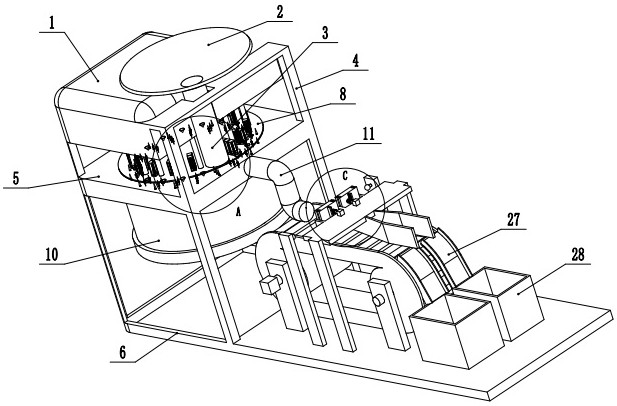

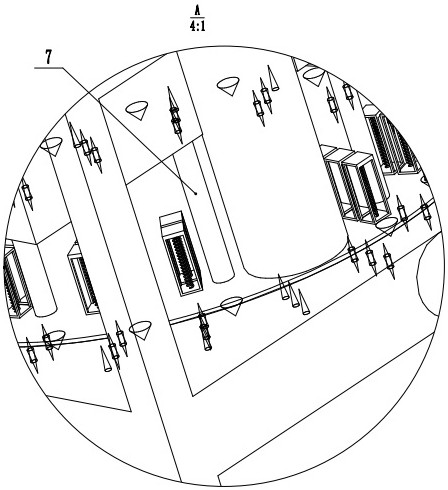

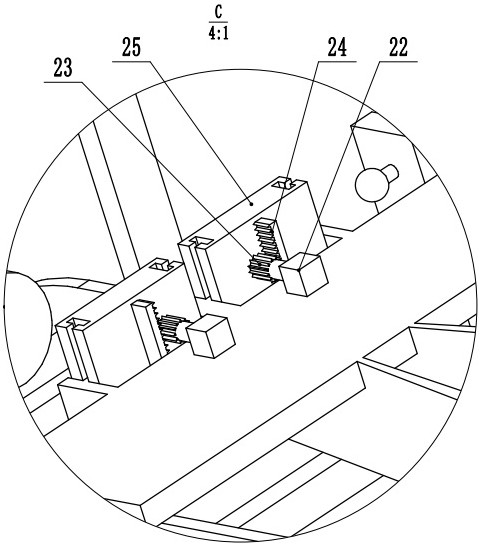

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a mill type walnut peeling machine includes a water tank 1, a funnel 2, a drain pipe 3, an upper support 4, a working support table 5, a lower support 6, a set of water pipes 7, an upper stripper 8, and a lower stripper 9. Green skin collection port 10, walnut discharge pipe 11, two pulleys 12, first motor 13, conveyor belt 14, a set of conveyor rollers 15, two detection support plates 16, four pulley support plates 17, two Sorting support plate 18, sorting table 19, four guide rails 20, bottom plate 21, two second motors 22, two gears 23, two racks 24, two sorting baffles 25, two sorting baffles 26. Two connection trays 27, two walnut collection boxes 28, and two detectors 29 are characterized in that: the water tank 1 is fixedly installed on the upper bracket 4, and the upper bracket 4 is fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com