Self-service tableware recycling device

A technology for recycling devices and tableware, which is applied to household utensils, service tables, sorting, etc., can solve the problems of high drop height of tableware, large floor space, limited capacity, etc., achieve effective use of space, save labor costs, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

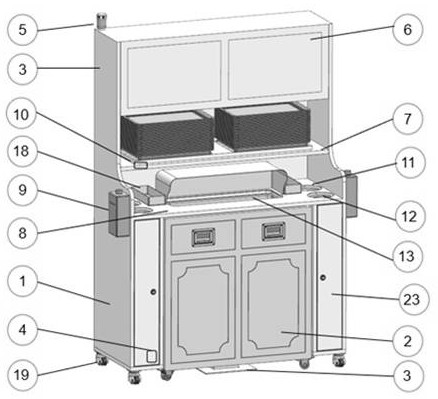

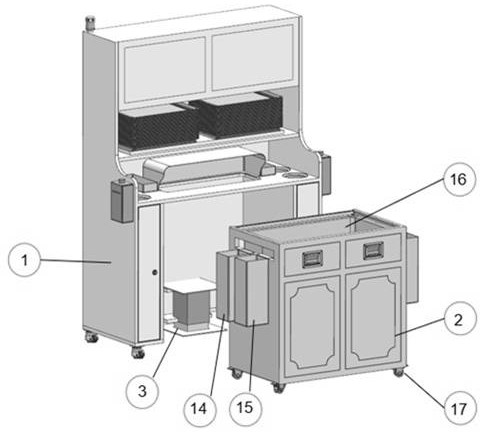

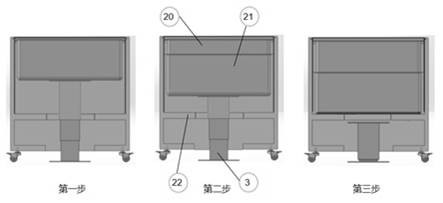

[0040] figure 1 , figure 2 It is one of the specific embodiments of a self-service tableware recovery device of the present invention, figure 1 It is a schematic structural view of a self-service tableware recycling device in the present invention when it is in use, figure 2 It is a schematic structural diagram of a self-service tableware recovery device in the present invention when the main cabinet and the sub-cart are in a separated state.

[0041] like figure 1 , figure 2 As shown, the tableware recovery device includes three parts: a main cabinet body 1 , a sub-cart 2 and a lifting module 3 . Of course, the lifting module 3 can also be integrated into the main cabinet body 1 .

[0042] The main cabinet body 1 is the main fuselage and appearance part of the tableware recovery device, as well as the interface part used by the user. The main cabinet body 1 is provided with a control module 4 , a communication early warning module 5 , a display screen 6 , a plate rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com