Landscaping waste sorting and breaking device and breaking method applying device

A landscaping and crushing device technology, applied in the fields of application, grain processing, food science, etc., can solve the problems of insufficient fermentation and slow fermentation speed, and achieve the effect of easy separation process and convenient collection and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

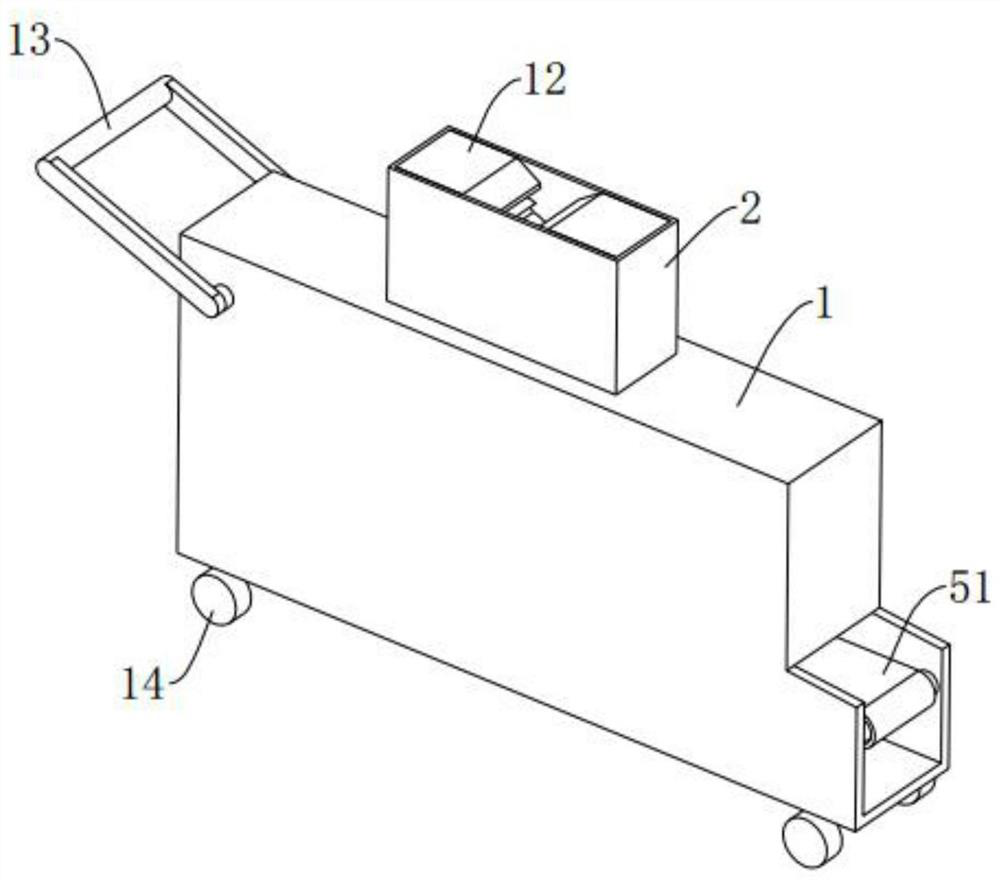

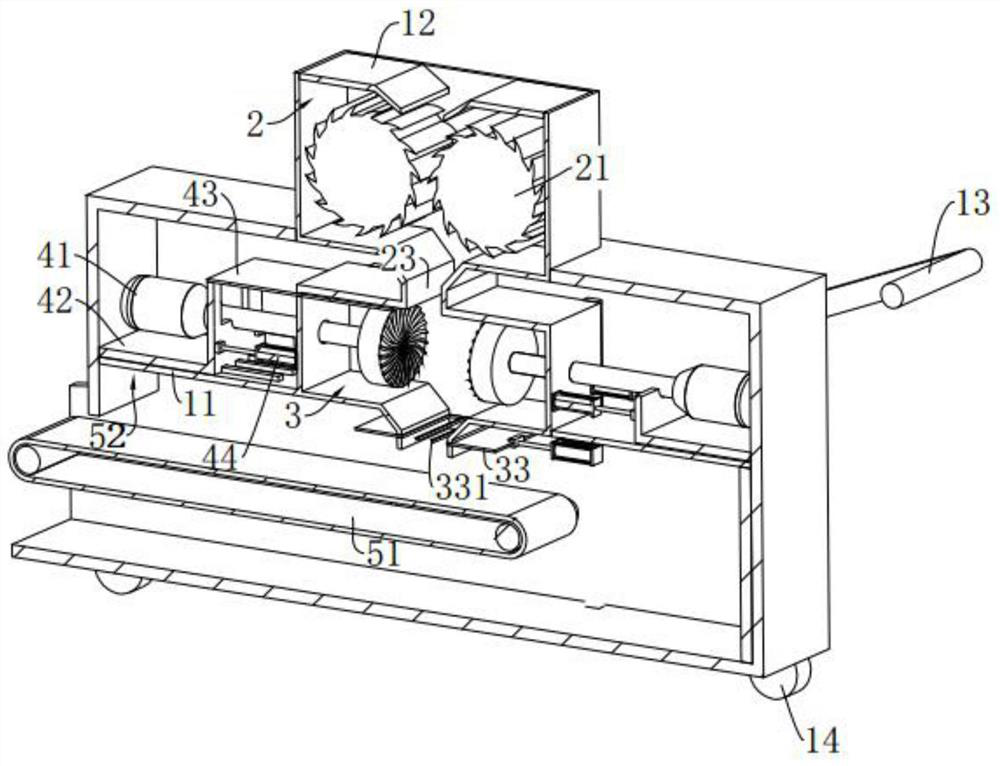

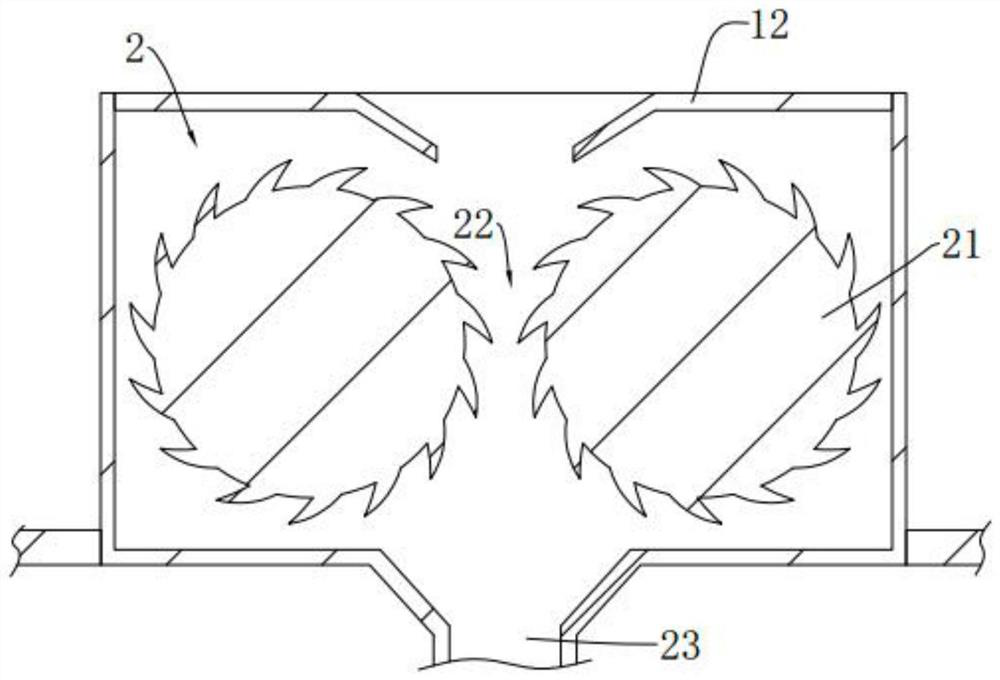

[0025] A landscaping waste sorting and crushing device, as shown in the figure, includes a casing 1, and a partition 11 is arranged inside the casing 1, and the partition 11 separates the casing 1 into a crushing area and a sorting area 5, and the crushing area There is a preliminary crushing chamber 2 and a fine grinding chamber 3 located at the outlet of the preliminary crushing chamber 2, the preliminary crushing chamber 2 and the fine grinding chamber 3 are connected through a crushing channel 23, and a sorting conveyor belt 51 is provided in the sorting area 5, and the sorting conveyor belt 51 One end is facing the outlet of the fine grinding chamber 3, and the other end protrudes from the housing 1.

[0026] A sorting electromagnetic plate 52 is provided on the side of the separator 11 facing the sorting conveyor belt 51 . The sorting electromagnetic plate 52 can separate most of the metal impurities and magnetic fragments from the traditional landscaping waste by adsorp...

Embodiment 2

[0035] A method of using the landscaping waste sorting and crushing device of Embodiment 1 to crush landscaping waste:

[0036] S1: first pour the waste from the opening of the primary crushing chamber 2 on the shell 1 into the primary crushing chamber 2, the guard plate 12 at the opening serves to guide the waste into the crushing gap 22, and also prevents workers from touching it To the crushing wheel 21, the spoiler 43 is in the state of closing the crushing passage 23;

[0037] S2: The rotation of the two crushing wheels 21 causes the waste in the crushing gap 22 to be initially crushed, and then the two driving seats 42 are controlled to move away from the fine grinding chamber 3, so that the two fine grinding discs 31 are separated from each other, and the spoiler 43 is withdrawn from the crushing passage 23. Drop the preliminarily crushed waste in the primary crushing chamber 2 between the two fine grinding discs 31;

[0038] S3: Start the drive motor 41 to make the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com