A kind of waste plastic recycling processing method

A processing method and technology of waste plastics, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of low purity of plastic recycling, low production efficiency, and simple processing equipment, so as to save sorting work, high production efficiency, The effect of high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

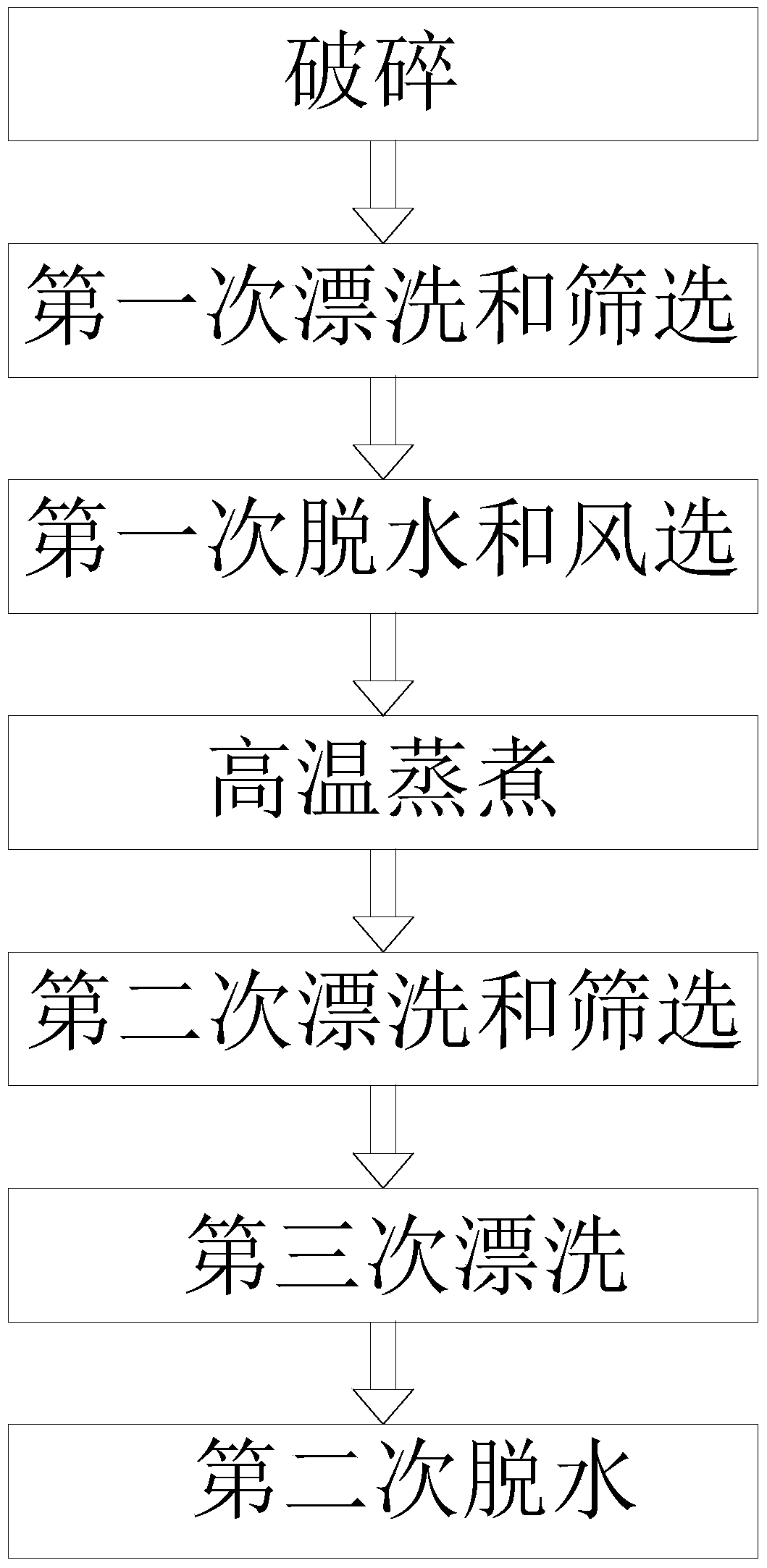

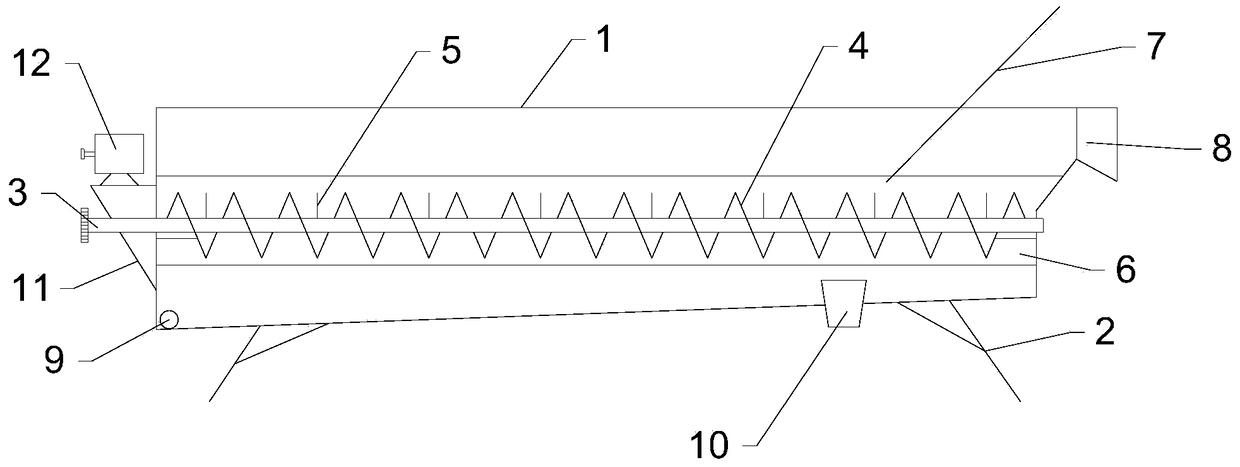

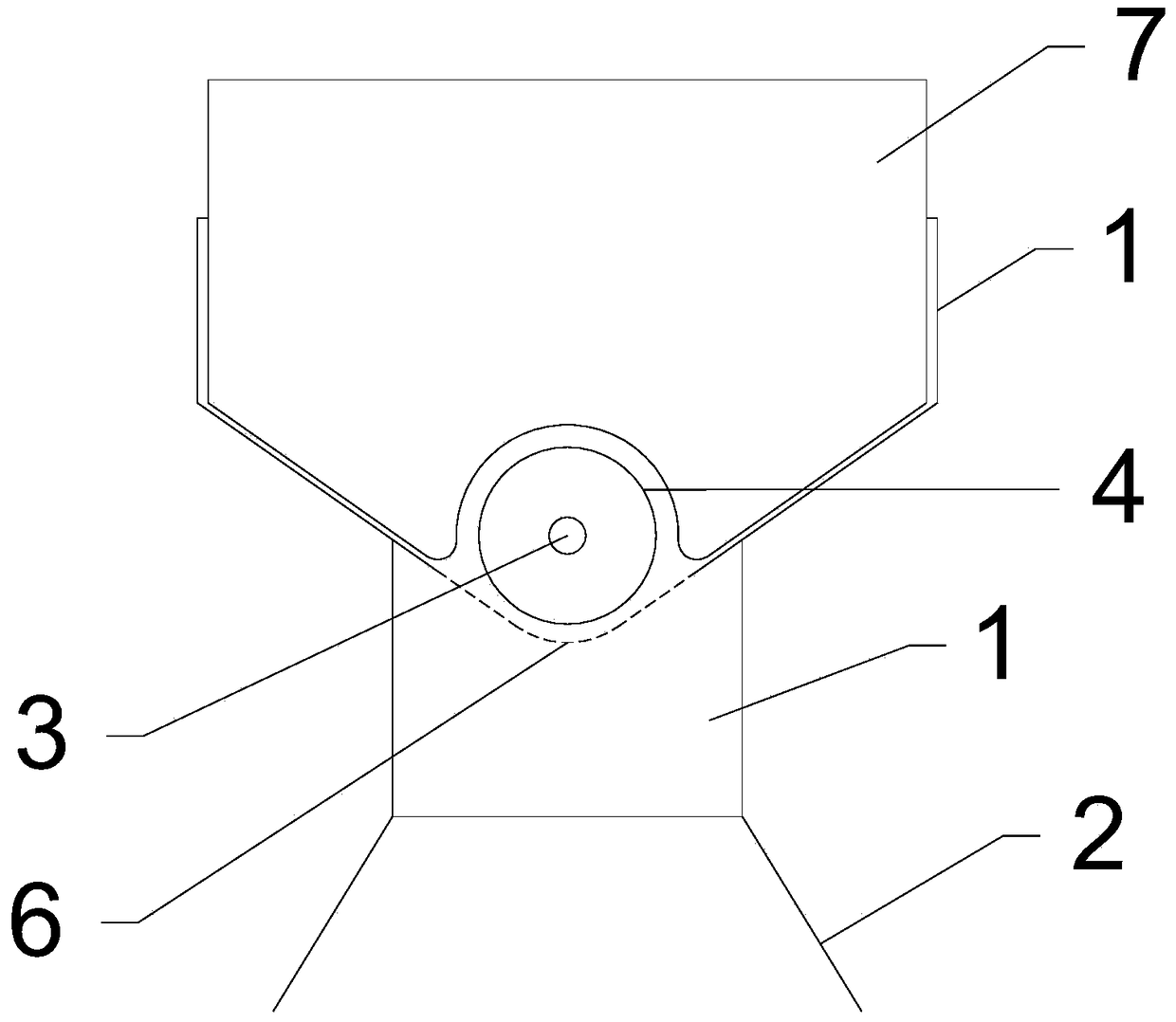

[0030] Such as Figure 1 to Figure 3 Shown, a kind of waste plastic recycling processing method comprises the following steps:

[0031] A. Crushing, sending waste mineral water bottles and waste carbonated beverage bottles into the crusher to break to obtain plastic fragments;

[0032] B. For the first rinsing and screening, put the plastic fragments obtained in step A into the screw propeller for the first rinsing and screening to remove floating objects such as sediment and bottle caps;

[0033] C, the first dehydration and winnowing, put the plastic fragments obtained through step B into the drying machine for the first dehydration and carry out upward winnowing simultaneously, to select plastic fragments with low water content;

[0034] D, high-temperature cooking, high-temperature cooking the plastic fragments obtained through step C, adding caustic soda to the high-temperature cooking solution, the temperature of the high-temperature cooking solution is 65-75 ° C, to re...

Embodiment 2

[0042] A method for recycling and processing waste plastics, comprising the following steps:

[0043] A. Crushing, sending waste mineral water bottles and waste carbonated beverage bottles into the crusher to break to obtain plastic fragments;

[0044] B. For the first rinsing and screening, put the plastic fragments obtained in step A into the screw propeller for the first rinsing and screening to remove floating objects such as sediment and bottle caps;

[0045] C, the first dehydration and winnowing, put the plastic fragments obtained through step B into the drying machine for the first dehydration and carry out upward winnowing simultaneously, to select plastic fragments with low water content;

[0046]D, high-temperature cooking, high-temperature cooking the plastic fragments obtained through step C, adding caustic soda to the high-temperature cooking solution, the temperature of the high-temperature cooking solution is 75-85 ° C, to remove the stickiness of the label on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com