Equipment for manufacturing wheel tires

A technology of tires and equipment, applied in the direction of tires, applications, household appliances, etc., can solve the problems of increasing production costs, increasing the burden of staff, and low production efficiency, so as to improve production efficiency, reduce sorting work, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

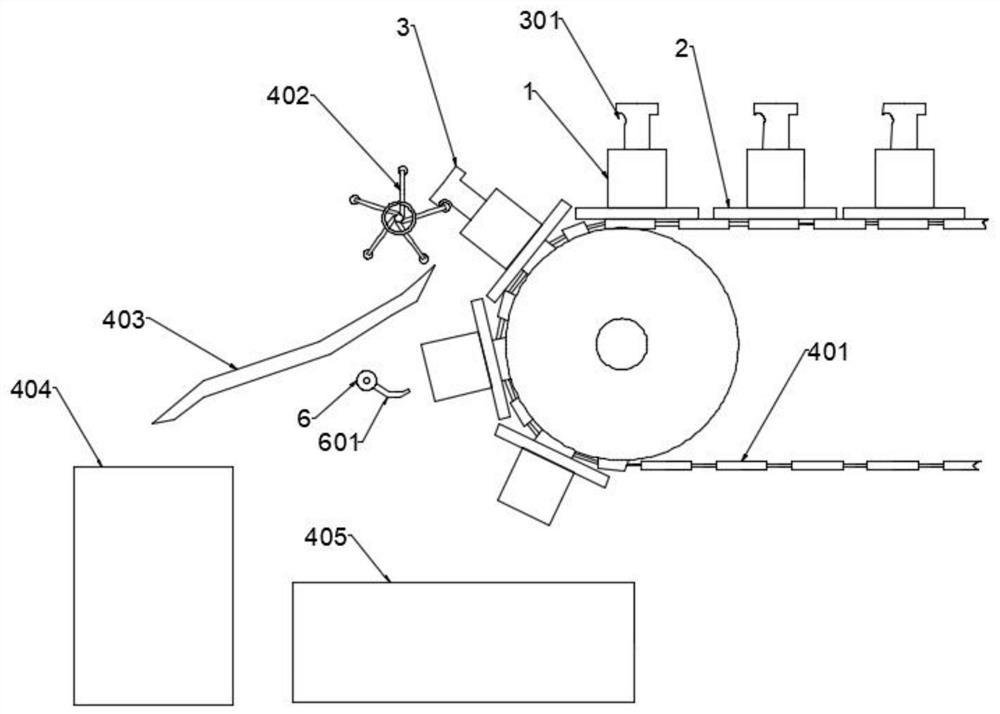

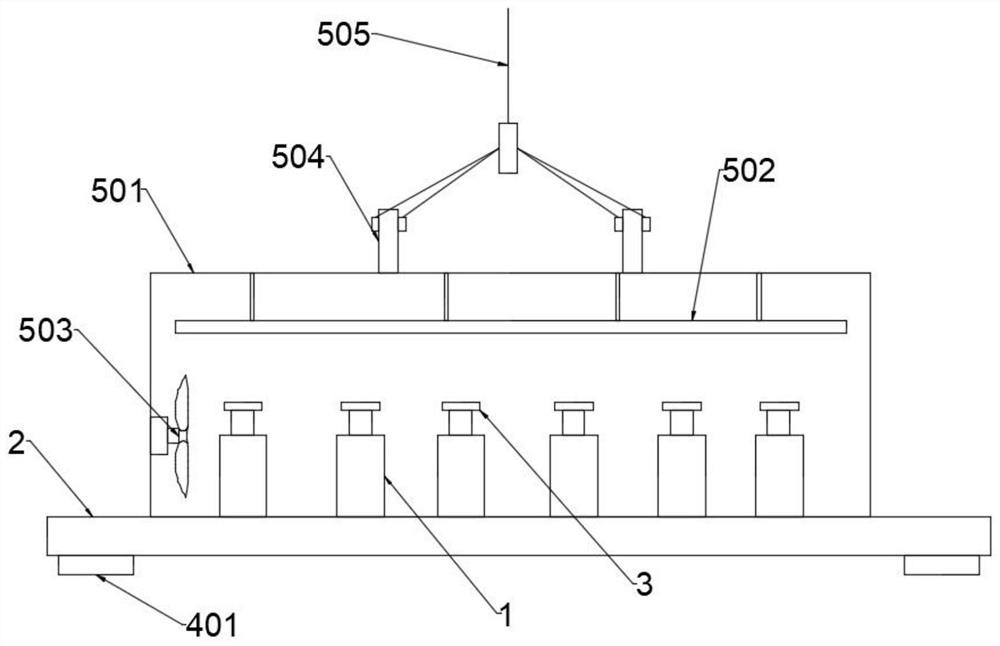

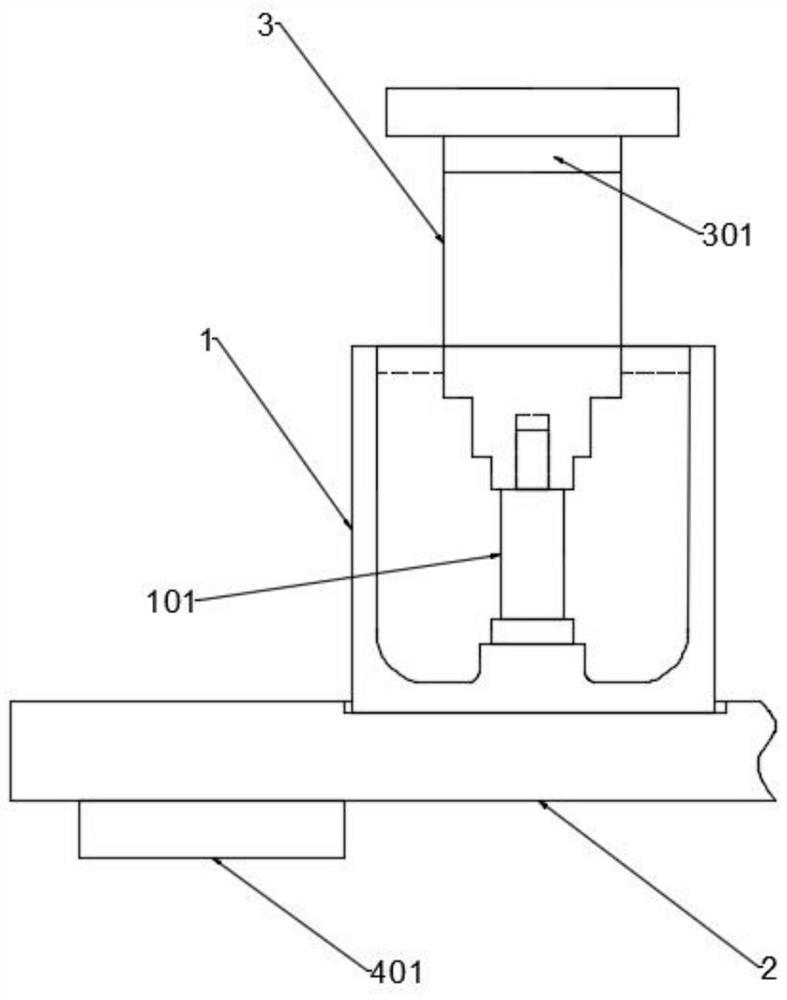

[0027] A kind of equipment for manufacturing wheel tires, including injection molding device, curing device 5, trimming device, printing device and sealing device, also includes mold 1, bottom plate 2, top block 3 and demoulding device 4; The demoulding device 4 comprises Conveyor chain 401, swivel frame 402, diversion plate 403, top block collection box 404 and tire collection box 405; mold 1 is provided with an axis rod; the axis rod is vertically arranged and the lower end of the axis rod is fixedly connected to the upper end of the mold It is socketed with the lower end of the top block 3; the upper part of the top block 3 is a T-shaped structure; the bottom of the mold 1 is fixedly connected with the bottom plate 2; the bottom plate 2 is fixedly connected with the transmission chain 401; the curing device 5 is located above the transmission chain 401; the transmission chain The left side of 401 is the rotating frame 402; the below of the rotating frame 402 is the drain pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com