Fermenting tank for treating garbage

A technology of waste treatment and fermentation tank, which is applied in the field of biogas digesters, and can solve the problems that there is no heating and heat preservation technology, and the treatment of waste cannot be completely applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

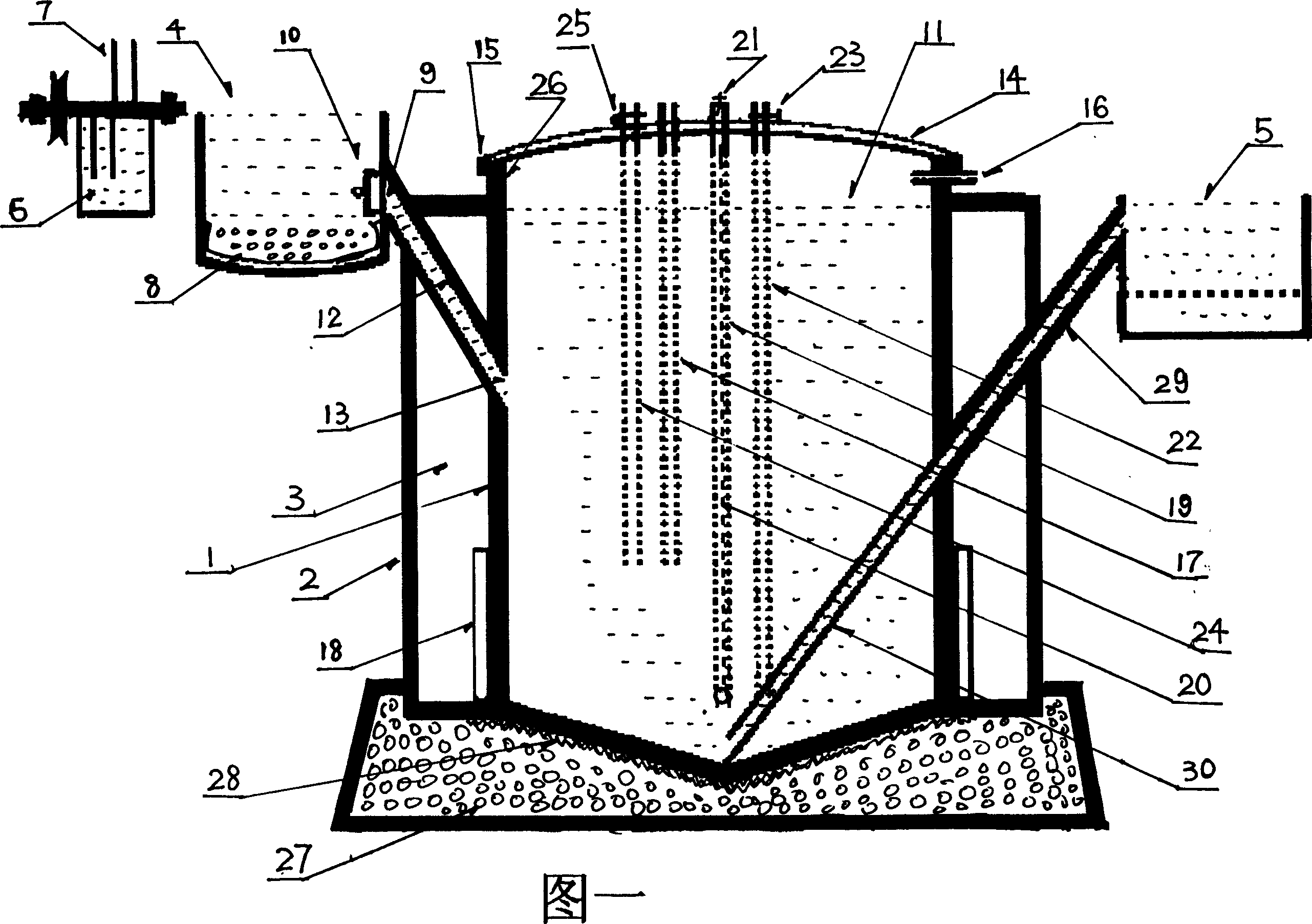

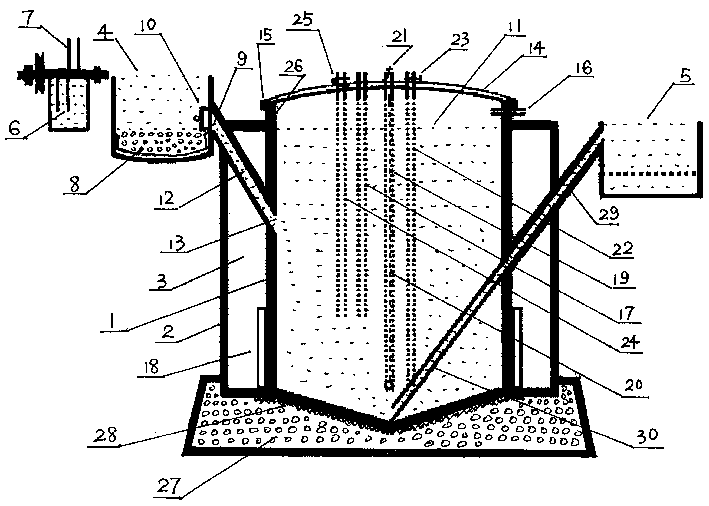

[0010] In a specific embodiment of the present invention, after the feed tank 4 is loaded with rubbish, the volume is 1.5 / 10 to 1 / 5 of the fermentation tank liner 1, and it is chopped by the pulverizer blade 7 in the chopping tank 6, and the material is chopped The groove and the feeding pool are connected in a "racetrack shape". When the blade rotates and chops, only the organic matter and various inorganic suspended matter are chopped, and according to the direction of the blade rotation, the water flow drives all the suspended matter to detour and crush to an ideal size. Fineness, while various inorganic sediments in the garbage are driven by the water flow to accumulate in the filter water sediment pan 8 at the bottom of the feed tank 4, and are automatically separated by the sediment pan 8, and are crushed into very fine organic matter and various A kind of inorganic matter suspended matter, when opening the live cold cover 10 of the upper mouth 9 of the discharge pool in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com