Method and device for winding metal strip material

A technology of metal belts and cores, applied in transportation and packaging, winding strips, sleeve/socket connections, etc., can solve problems such as problems with coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

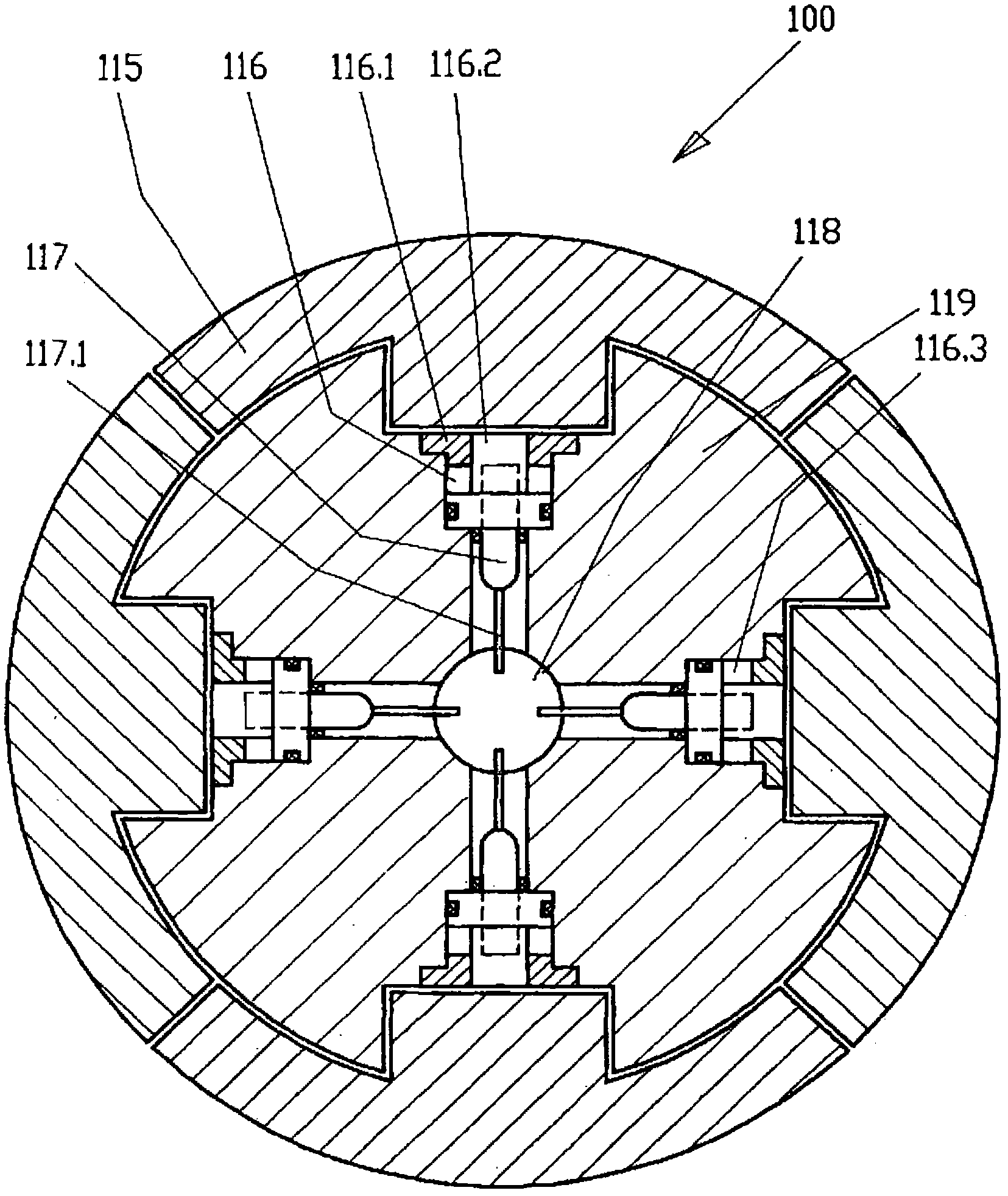

[0045] as in Figures 3 to 5 As shown in FIG. 1 , a coiler mandrel 100 according to the invention is constructed in a winding unit 120 with a cylinder 116 and a balancing cylinder 121 . Cylinder 116 and balancing cylinder 121 move and / or stop segment 115 . For example, cylinder 116 and balancing cylinder 121 are operated hydraulically. Besides oil, other media such as grease can also be used. Cylinder 116 is used to transmit or generate expansion force and movement of section 115 . As shown, the cylinder 116 with its cylinder head 116.1 and with its cylinder piston 116.2 is inserted directly into the spindle body 119 . However, it is also conceivable that the entire cylinder 116 is installed as a unit in the coiler shaft 100 . Preferably, each cylinder 116 is equipped with a position detector 117 to enable the exact position of the cylinder piston 116.2 to be determined and controlled or adjusted. The cable 117.1 of the position detector 117 is sent to the rotary conveyor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com