Manufacturing method of semiconductor device

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of inability to form aluminum sidewall protection film, difficulty in forming large pseudo-patterns, and inability to supply corrosion resistance Agent decomposition and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

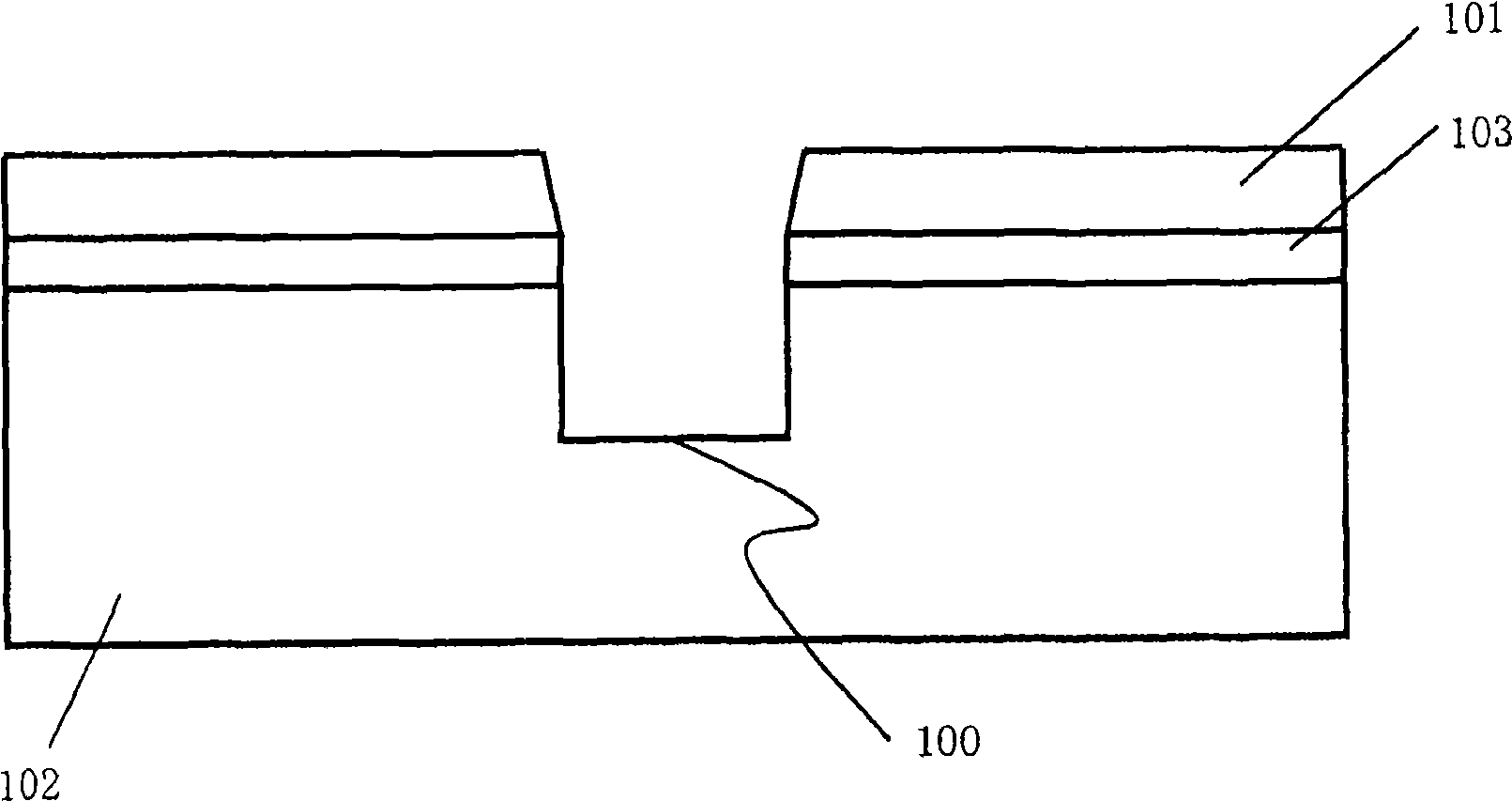

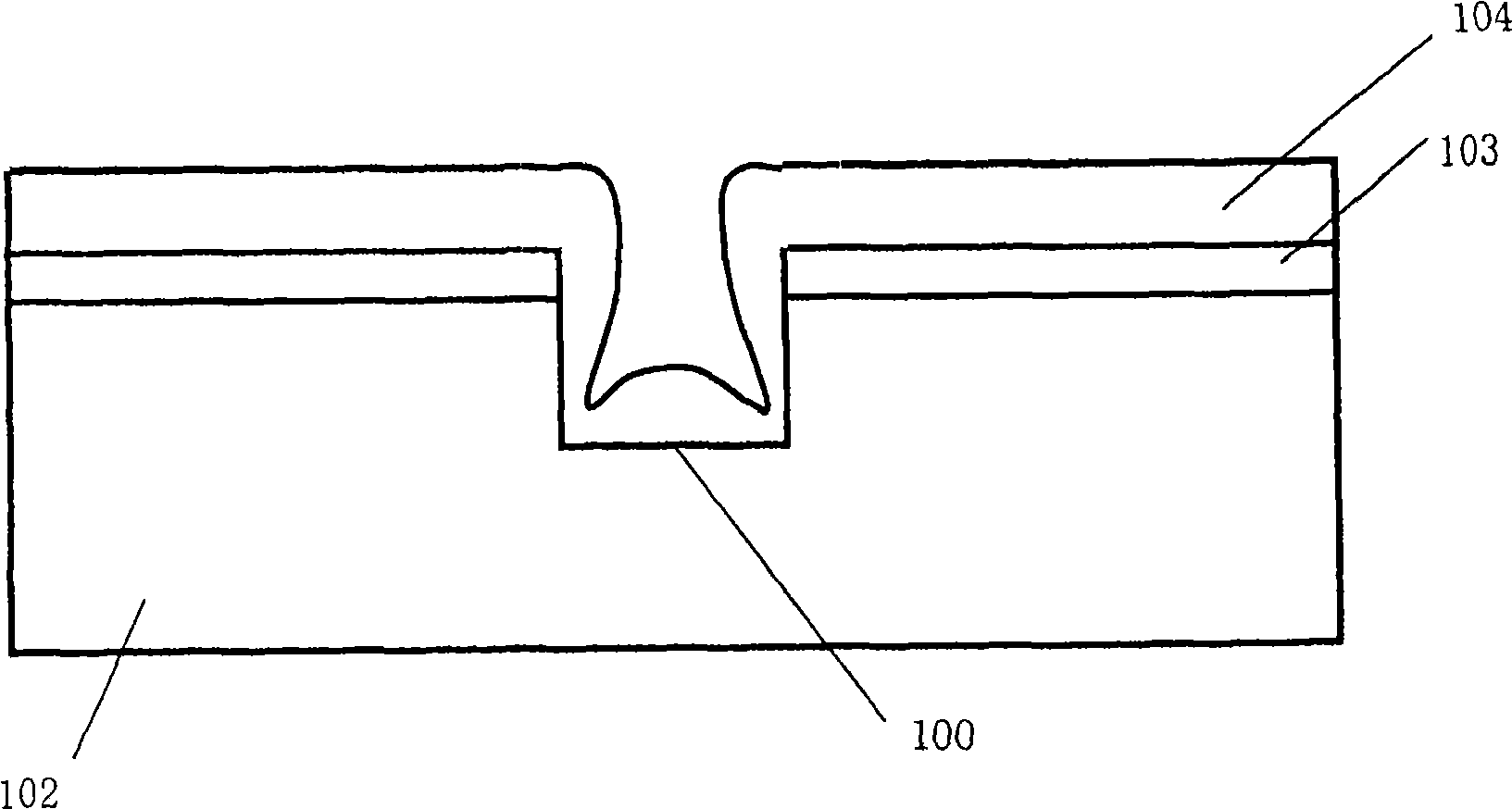

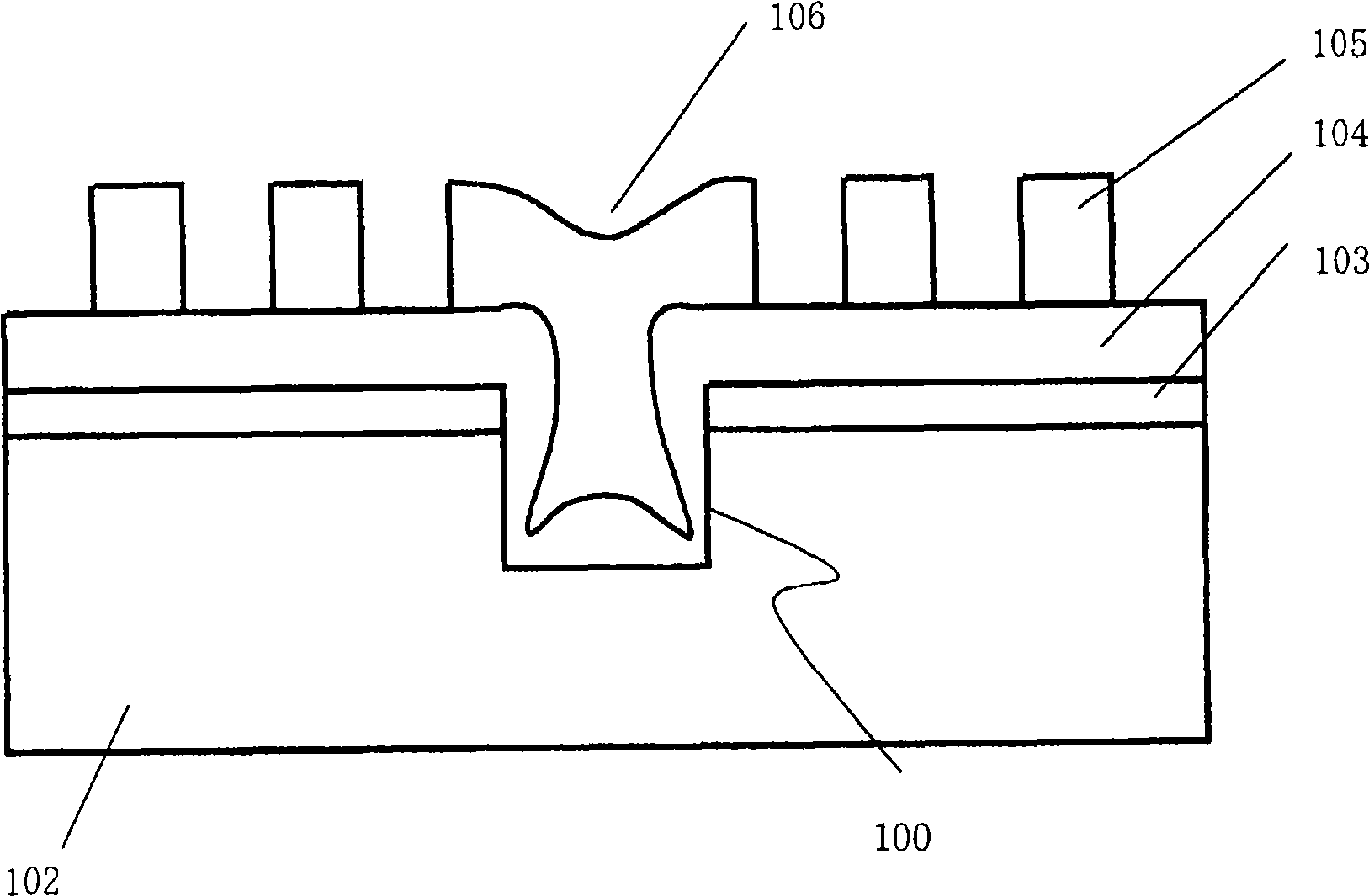

[0014] Hereinafter, an embodiment of the present invention will be described based on FIGS. 1 and 2.

[0015] Fig. 1 is a process sectional view showing a first embodiment of the present invention.

[0016] 1(A) shows a process in the middle of forming a semiconductor element on a semiconductor substrate 102, and is a cross-sectional view showing a process of forming a trench 100 after forming a contact hole of the semiconductor element. An interlayer insulating film 103 is formed on the semiconductor substrate 102, and a resist 101 is coated on the interlayer insulating film. The resist 101 is patterned, and using it as a mask, trenches 100 in the form of openings are formed in the underlying interlayer insulating film 103 and the semiconductor substrate 102 by etching. When the semiconductor element does not have a trench structure, a mask is added after forming the contact hole to form the trench 100 as in this embodiment. However, if it is a semiconductor element with a trench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com