Manufacturing method of hollow reconstituted wood material for structure

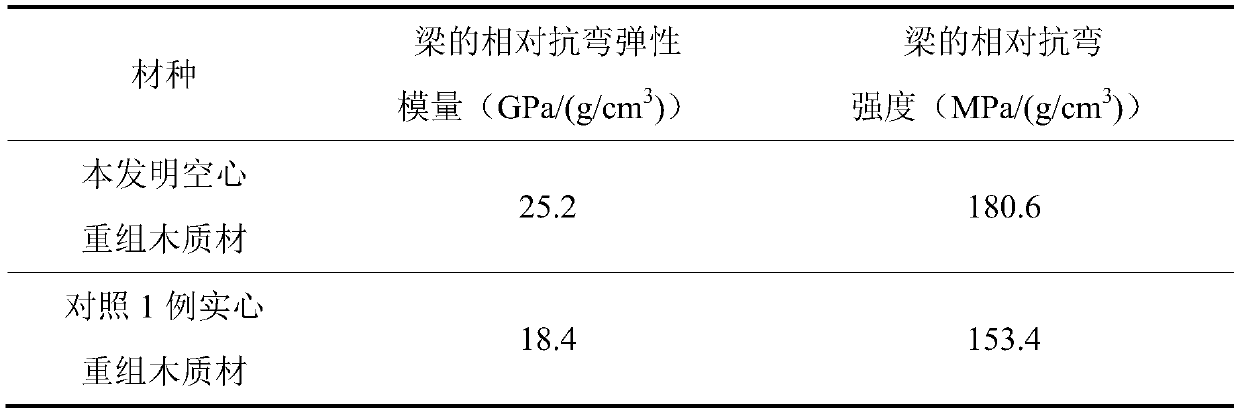

A manufacturing method and hollow technology, applied in the field of green building materials, can solve the problems of low relative mechanical properties of structural components, difficult promotion of recombined wood materials, high manufacturing costs, etc., and achieve the effect of increasing relative mechanical properties, low cost and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) former bamboo is unpacked into bamboo bundle unit 1, makes the thickness of bamboo bundle unit be 10mm, and the length of bamboo bundle unit is 2500mm, and the width of bamboo bundle unit is 100mm;

[0036] (2) Drying the above-mentioned bamboo bundle unit by using hot air as a medium, the drying temperature is 50° C., and the drying time is 8 hours;

[0037] (3) impregnating the above-mentioned dried bamboo bundle unit in a phenolic resin solution, the solid content concentration of the phenolic resin solution is 10%, the immersion temperature is 25° C., and the immersion time is 10 minutes;

[0038] (4) the impregnated bamboo bundle unit pavement that step (3) obtains makes the number of layers of the bamboo bundle unit layer be 20 layers, and obtains the pre-pavement layer;

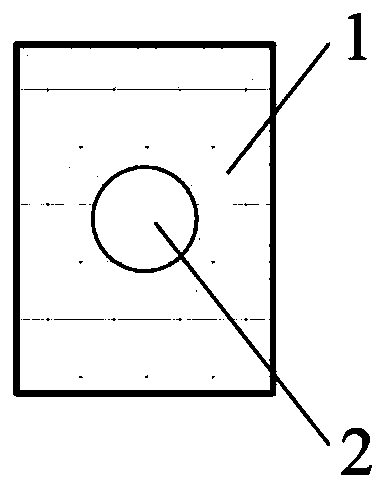

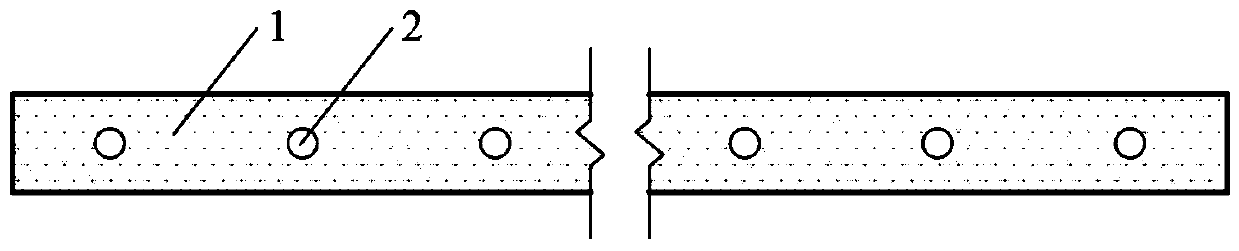

[0039] (5) The circular solid steel section bar 2 that is coated with release agent on all sides is paved on the pre-pavement layer obtained in step (4) and is positioned at the mid-width po...

Embodiment 2

[0053] (1) former bamboo is unpacked into bamboo bundle unit 1, makes the thickness of bamboo bundle unit be 10mm, and the length of bamboo bundle unit is 2500mm, and the width of bamboo bundle unit is 100mm;

[0054] (2) Drying the above-mentioned bamboo bundle unit by using hot air as a medium, the drying temperature is 50° C., and the drying time is 8 hours;

[0055] (3) impregnating the above-mentioned dried bamboo bundle unit in a phenolic resin solution, the solid content concentration of the phenolic resin solution is 10%, the immersion temperature is 25° C., and the immersion time is 10 minutes;

[0056] (4) the impregnated bamboo bundle unit that step (3) obtains is paved along the thickness direction, makes the number of layers of the bamboo bundle unit layer be 10 layers, obtains pre-pavement layer;

[0057] (5) the circular solid steel section bar 2 that is coated with release agent is paved on the pre-pavement layer obtained in step (4), and the diameter of the ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com