A structural design method and device for increasing the energy storage density of a flywheel rotor

A flywheel rotor and energy storage density technology, applied in design optimization/simulation, calculation, instrumentation, etc., can solve problems such as difficult cross-sectional shape design, and achieve the effect of improving energy conversion efficiency and energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of the present invention will be described below in conjunction with the technical scheme and the accompanying drawings.

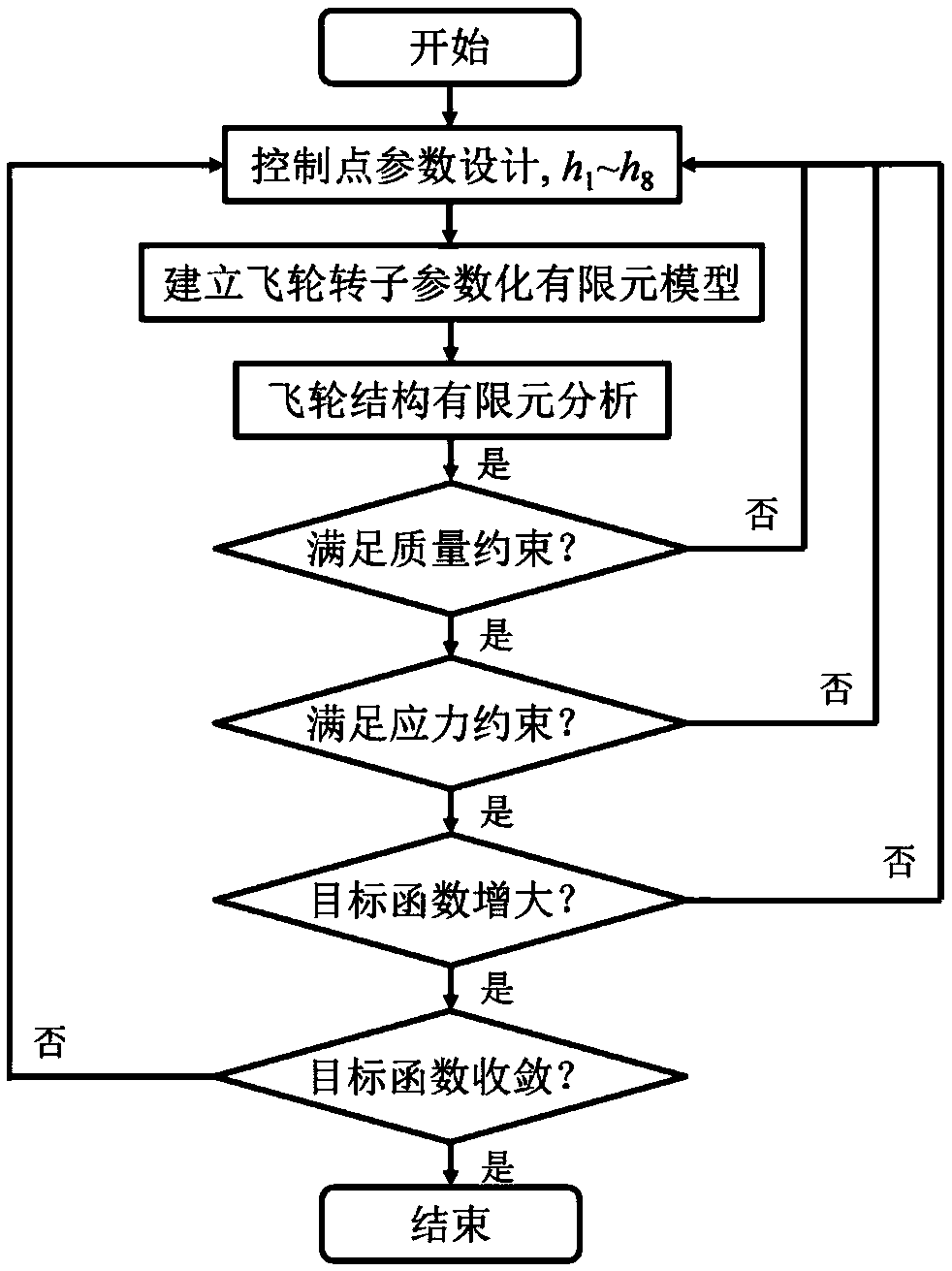

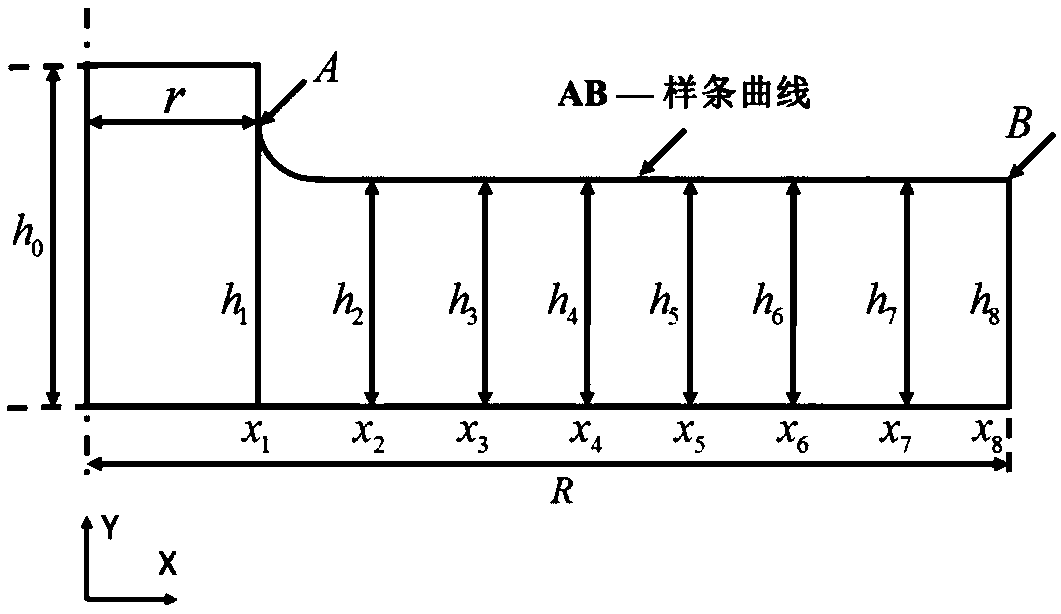

[0036] first step, such as figure 2As shown, the geometric modeling of the pre-processing process is carried out in the finite element ANSYS software. First, create 8 control points (Keypoints) evenly along the radial direction of the rotor, and then use the spline curve fitting creation method (Spline thru KPs) in the curve creation method in ANSYS to form a curve through these 8 points in turn, so that Describe the thickness distribution curve of the rotor along the radial direction, and then create the upper and lower boundaries and the right boundary of the main shaft and rotor. Among them, the coordinate parameters of the 8 control points, that is, the vertical coordinates, are the design parameters, given h 1 initial value, h i (i=2,...,8) initial value, and set h 1 greater than h i the initial value of . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com