A photosensitive resin composition and a method forming a pattern using the same

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve problems such as long drying time, achieve the effect of uniform film thickness, good performance and reduction of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

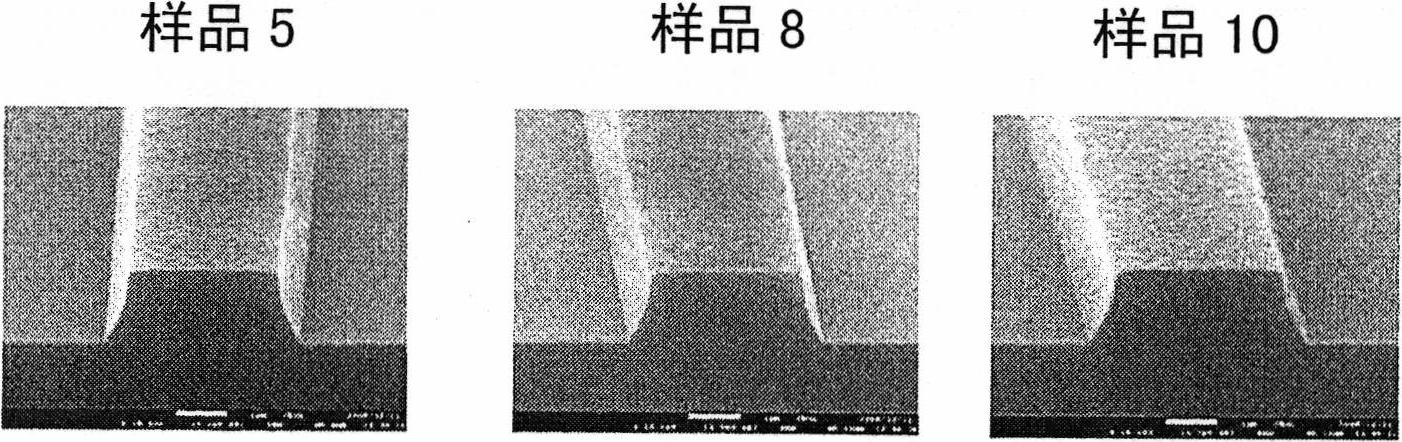

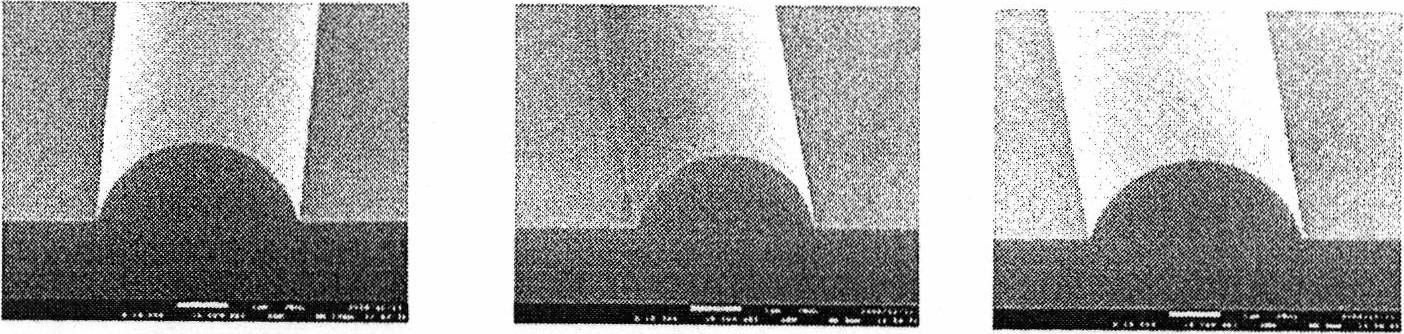

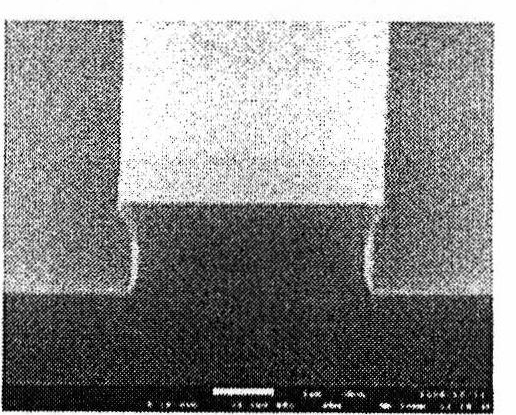

Image

Examples

Embodiment 1

[0054] 2,3,4,4'-Tetrahydroxybenzophenone and 1, 25 parts by weight of the esterified product of 2-naphthoquinonediazide-5-sulfonyl chloride is used as a sensitizer, and a fluorosurfactant (nonionic surface active agent produced by Dainippon Ink Chemical Industry Co., Ltd. Active agent), then add a mixed solvent (mixing weight ratio: 90:10) of propylene glycol monomethyl ether acetate (PGMEA) and n-butyl acetate (nBA) (boiling point 126.1 ° C, evaporation rate 100), stir with 0.2 μm filter was used to prepare photosensitive resin composition 1 having a solvent content of 86% by weight.

Embodiment 2

[0056] Except that the solvent is replaced by a mixed solvent (mixing weight ratio of 70:30) of propylene glycol monomethyl ether acetate (PGMEA) and n-butyl acetate (nBA) (boiling point 126.1 ° C, evaporation rate 100), the same as in Example 1 It carried out similarly, and the photosensitive resin composition 2 was obtained.

Embodiment 3

[0058] Except that the solvent is replaced by a mixed solvent (mixing weight ratio of 50:50) of propylene glycol monomethyl ether acetate (PGMEA) and n-butyl acetate (nBA) (boiling point 126.1 ° C, evaporation rate 100), the same as in Example 1 It carried out similarly, and the photosensitive resin composition 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com