Composition for reflection reducing coating

An anti-reflection coating and composition technology, applied in coatings, instruments, opto-mechanical equipment, etc., can solve the problems of post-exposure delay, insufficient anti-reflection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] By heating at 70°C, 1.0 parts of poly(vinylpyrrolidone) with a weight average molecular weight of 3,000, 4.0 parts of C 8 f 17 SO 3 H, 0.35 parts of monoethanolamine and 0.1 parts of C 6 f 13 SO 2 NH 2 Uniformly dissolved in 94.55 parts of pure water. The solution was cooled to room temperature (23° C.), and the solution was confirmed to be homogeneous. Then, the obtained solution was passed through a 0.05 μm filter to prepare an antireflection coating composition. The pH of this antireflective coating composition was 1.63 at 23°C. Table 1 shows the dynamic and static surface tensions of the formed antireflective coating compositions and the contact angles (degrees) when the compositions were dropped on the resist surface.

[0066] Static surface tension, dynamic surface tension, and contact angle (degrees) were determined by the following measurement methods.

[0067] Static Surface Tension:

[0068] By the Wilhelmy method, it was measured at 23° C. using a ...

Embodiment 2~15

[0074] Example 1 was repeated using the compounds in the amounts (parts) shown in Tables 1 and 2 to obtain antireflective coating compositions in Examples 2-15. The pH values of the formed antireflective coating compositions are shown in Table 1 and Table 2.

[0075] The static surface tension, dynamic surface tension and contact angle of the antireflective coating composition in each example were measured in the same manner as in Example 1. The results are shown in Table 1 and Table 2.

[0076] Example

[0077] Example

Embodiment 16

[0083] The coating properties, coating stability, refractive index and lithographic characteristics of the antireflective coating compositions obtained in Examples 1 to 15 were evaluated according to the following evaluation methods. The results are shown in Table 4 and Table 5. The refractive index in the table is the value at 248 nm.

[0084] Evaluate coating performance:

[0085] Chemically amplified positive resist [AZ DX1100 (Clariant (Japan) K.K.)] is coated on an 8-inch HMDS-treated silicon wafer with a thickness of 0.75 μm after baking, and is baked on a heating plate at 110 ° C for 60 seconds to obtain Substrate for evaluation. Then, the anti-reflective coating composition sample is dropped and coated on the above-mentioned substrate by a resist coating machine LARC-ULTIMA 1000 (Lithoteck Ltd.), and the minimum amount of the dropped composition must be within 8 inches of silicon A uniform coating was formed on the sheet, and a comparative evaluation was perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

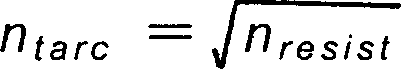

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com