Preparation method for chromium-free ZrO2-CaO.ZrO2 composite material for coal-water slurry gasification furnace

A composite material and gasifier technology, applied in the field of refractory materials, can solve the problems of poor thermal shock resistance of high-chrome bricks, affecting the use of gasifiers, spalling, etc., and achieve excellent performance indicators, good social and economic benefits, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

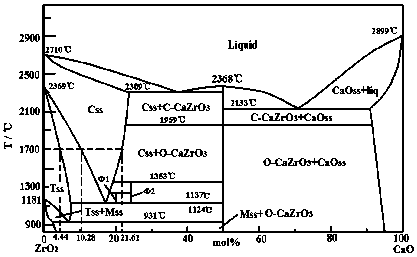

[0016] A kind of chromium-free ZrO for coal-water slurry gasifier 2 -CaO·ZrO 2 The preparation method of composite material, (1) by mole percentage, 10% CaO and 90% ZrO 2 , sintered at 1500-1750°C for a certain period of time to prepare CaO·ZrO 2 Composite material; (2) by mass percentage, 60% ZrO 2 , 40% CaO·ZrO 2 Composite materials, plus 3% zirconium sol as a binder, during production, first weigh various raw materials according to the ratio, mix them evenly, and get mud after mixing, and then press them into shape with a friction press, first at 120-250 ° C Dry for 10-25 hours, and then sinter at a high temperature of 1550°C-1800°C for 5-12h.

[0017] The performance index of the obtained product is: apparent porosity 15%, bulk density 3.85g / cm 3 , normal temperature compressive strength 140MPa, thermal shock stability (1100°C, water cooling) 27 times, high temperature flexural strength 20MPa, and good hydration resistance, redox resistance, coal ash slag erosion resi...

Embodiment 2

[0019] A kind of chromium-free ZrO for coal-water slurry gasifier 2 -CaO·ZrO 2 The preparation method of composite material, (1) by mole percentage, 20% CaO and 80% ZrO 2 , sintered at 1500-1750°C for a certain period of time to prepare CaO·ZrO 2 Composite material; (2) by mass percentage, 65% ZrO 2 , 35% CaO·ZrO 2 Composite materials, plus 3% dextrin as a binder, during production, first weigh various raw materials according to the proportion, mix them evenly, and get mud after mixing, and then press them into shape with a friction press, first at 120-250°C Dry for 10-25 hours, and then sinter at a high temperature of 1550°C-1800°C for 5-12h.

[0020] The performance index of the obtained product is: apparent porosity 14.3%, bulk density 3.92g / cm 3 , normal temperature compressive strength 155MPa, thermal shock stability (1100°C, water cooling) 29 times, high temperature flexural strength 33MPa, and good hydration resistance, redox resistance, coal ash slag erosion resis...

Embodiment 3

[0022] A kind of chromium-free ZrO for coal-water slurry gasifier 2 -CaO·ZrO 2 The preparation method of composite material, (1) by mole percentage, 30% CaO and 70% ZrO 2 , sintered at 1500-1750°C for a certain period of time to prepare CaO·ZrO 2 Composite material; (2) by mass percentage, 60% ZrO 2 , 40% CaO·ZrO 2 Composite materials, plus 3% zirconium sol as a binder, during production, first weigh various raw materials according to the ratio, mix them evenly, and get mud after mixing, and then press them into shape with a friction press, first at 120-250 ° C Dry for 10-25 hours, and then sinter at a high temperature of 1550°C-1800°C for 5-12h.

[0023] The performance index of the obtained product is: apparent porosity 13.5%, bulk density 3.97g / cm 3 , normal temperature compressive strength 186MPa, thermal shock stability (1100°C, water cooling) 32 times, high temperature flexural strength 48MPa, and good hydration resistance, redox resistance, coal ash slag erosion re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| High temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com