Recycling method of waste mining machinery tire

A technology of tires and machinery, which is applied in the field of recycling waste mechanical tires, can solve the problems of affecting the normal use of tires, high impurity components, low tensile strength and service life, etc., to achieve outstanding economic and social benefits, good effect, The effect of increasing the plasticity of Weishi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

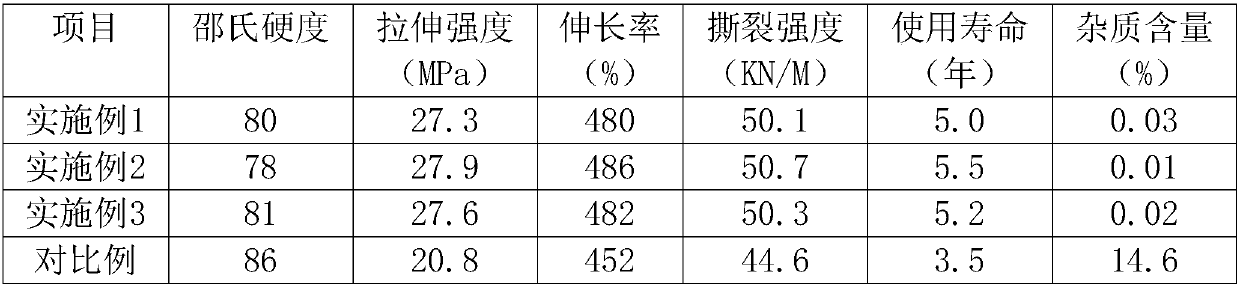

Examples

Embodiment 1

[0023] A method for reusing waste mine machinery tires, comprising the steps of:

[0024] 1) Pulverization: Use waste mechanical tires with a tensile strength of 30 MPa and an elongation at break of 300%, place them in an environment with a temperature of -4°C for 25 minutes, place them in a pulverizer, and pulverize them until the particle size is 60 mesh. Pulverize into powder, then mix and seal the tire rubber powder with desulfurizing agent and aromatic hydrocarbon oil, and then masticate in an open mill, then cut and pulverize to obtain desulfurized tire rubber powder.

[0025] 2) Powerful magnetic separation: the rubber powder processed in step 1) is separated in a wet electromagnetic strong magnetic separator, the magnetic field strength is 15000 gauss, and the pulp flow rate is 1.8cm / scm / s.

[0026] 3) Modification: Put the rubber powder treated above through the feeding device of the screw extruder and add the modifier p-tert-butylphenol formaldehyde resin, maleic anh...

Embodiment 2

[0031] A method for reusing waste mine machinery tires, comprising the steps of:

[0032] 1) Pulverization: Use waste mechanical tires with a tensile strength of 35 MPa and an elongation at break of 350%, place them in an environment with a temperature of -2°C for 27 minutes, place them in a pulverizer, and pulverize them until the particle size is 60 mesh. Pulverize into powder, then mix and seal the tire rubber powder with desulfurizing agent and aromatic hydrocarbon oil, and then masticate in an open mill, then cut and pulverize to obtain desulfurized tire rubber powder.

[0033] 2) Powerful magnetic separation: the rubber powder treated in step 1) is separated in a wet electromagnetic strong magnetic separator, the magnetic field strength is 15500 gauss, and the pulp flow rate is 1.9 cm / s.

[0034] 3) Modification: Put the rubber powder treated above through the feeding device of the screw extruder and add the modifier p-tert-butylphenol formaldehyde resin, maleic anhydrid...

Embodiment 3

[0039] A method for reusing waste mine machinery tires, comprising the steps of:

[0040] 1) Pulverization: Use waste mechanical tires with a tensile strength of 40 MPa and an elongation at break of 400%, place them in an environment with a temperature of -1°C for 30 minutes, place them in a pulverizer, and pulverize them until the particle size is 60 mesh. Pulverize into powder, then mix and seal the tire rubber powder with desulfurizing agent and aromatic hydrocarbon oil, and then masticate in an open mill, then cut and pulverize to obtain desulfurized tire rubber powder.

[0041] 2) Powerful magnetic separation: the rubber powder processed in step 1) is separated in a wet electromagnetic strong magnetic separator, the magnetic field strength is 16000 gauss, and the pulp flow rate is 2.0 cm / s.

[0042] 3) Modification: Put the rubber powder treated above through the feeding device of the screw extruder and add the modifier p-tert-butylphenol formaldehyde resin, maleic anhydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com