Preparation method of glass fiber-reinforced halogen-free environmentally friendly flame-retardant modified polyester material

A flame-retardant modified polyester, environmentally friendly technology, applied in the field of preparation of halogen-free environmentally friendly flame-retardant modified polyester materials, can solve the problems of non-standard flame-retardant effect, material becoming brittle, high shear heat, etc., to achieve Good physical properties, shortened residence time, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

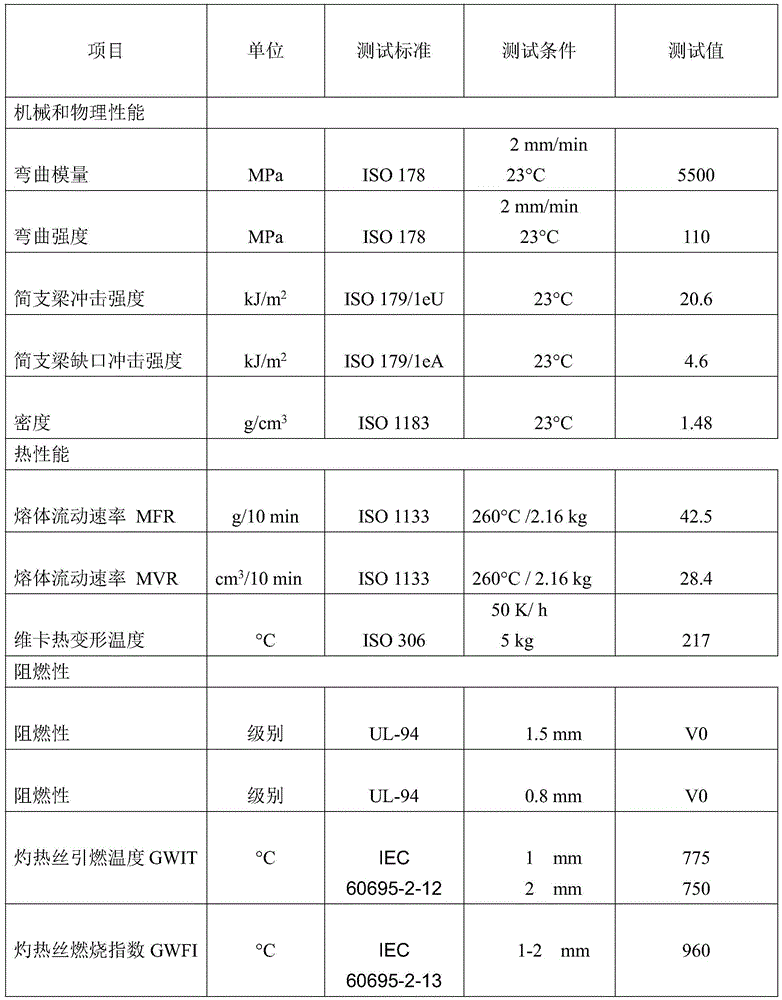

[0018] A method for preparing a glass fiber-reinforced halogen-free environmentally friendly flame-retardant modified polyester material, comprising the following steps:

[0019] 1) Take raw materials by weight percentage: PBT79%, calcium hypophosphite 10%, PETS0.5%, anti-dripping agent PTFE0.3%, antioxidant 1680.1%, antioxidant 10100.1%; short glass fiber 10% ( OCV952A);

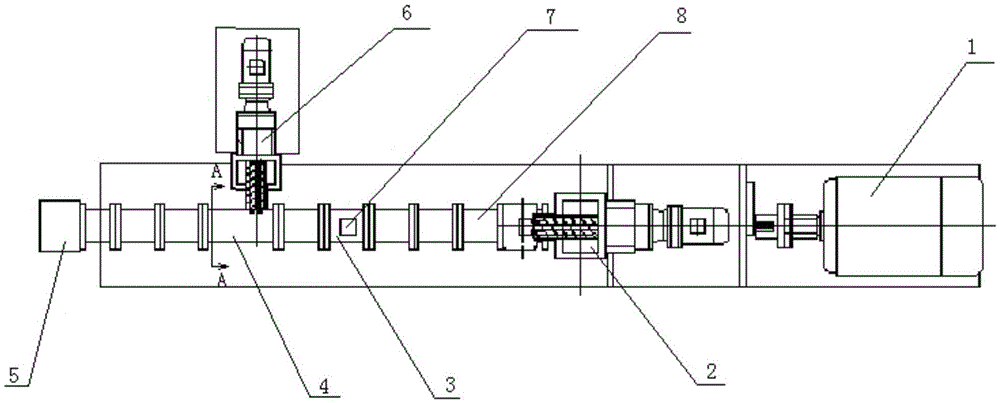

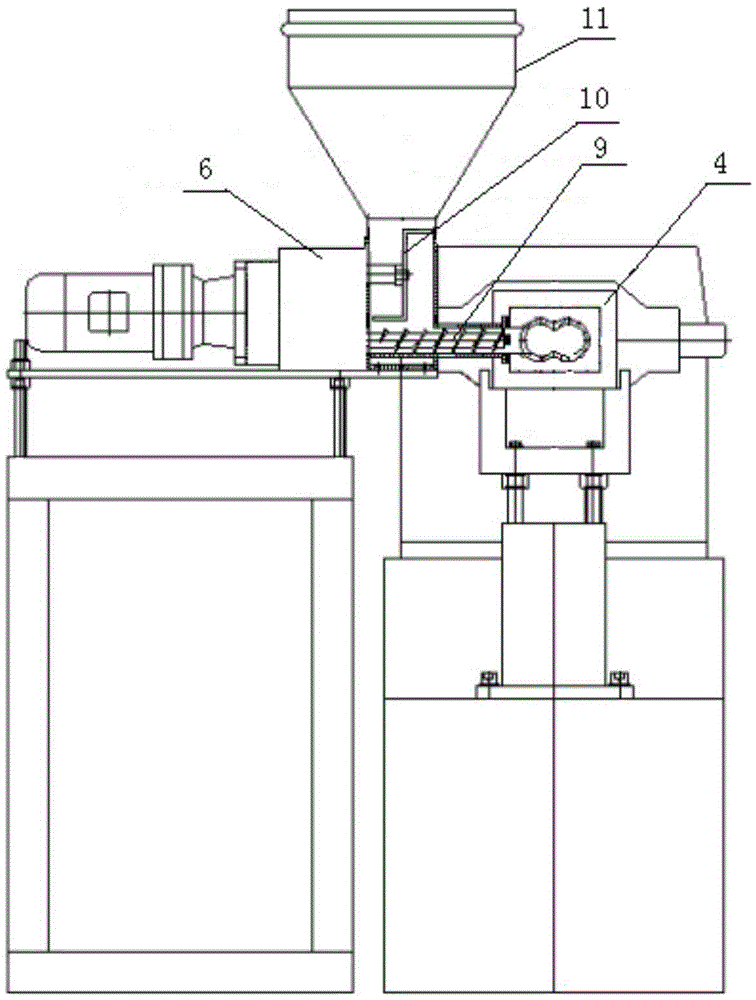

[0020] 2) A modified parallel co-rotating twin-screw extruder, including a main motor 1, a main feeding device 2, a main machine barrel 8, a machine head 5, and the seventh zone 4 of the main machine barrel is connected to the auxiliary feeding device 6 through a flange, The auxiliary feeding device includes an AC motor, and the AC motor drives a one-to-three distribution reducer, one of the shafts of the distribution reducer is equipped with a stirring paddle 10, and the other two shafts drive parallel twin-screws 9 in the same direction. A short glass fiber inlet 7 is provided on the fifth zone 3 of the ...

Embodiment 2

[0025] A method for preparing a glass fiber-reinforced halogen-free environmentally friendly flame-retardant modified polyester material, comprising the following steps:

[0026] 1) Weigh raw materials by weight percentage: PBT59%, calcium hypophosphite 20.3%, anti-dripping agent PTFE0.3%, antioxidant 1680.2%, antioxidant 10100.2%; short glass fiber 20% (OCV952A);

[0027] 2)-3) are the same as 2)-3) of embodiment 1.

[0028] The technical performance table of the glass fiber-reinforced halogen-free environmentally friendly flame-retardant modified polyester material prepared in Example 2

[0029]

Embodiment 3

[0031] A method for preparing a glass fiber-reinforced halogen-free environmentally friendly flame-retardant modified polyester material, comprising the following steps:

[0032] 1) raw materials are taken by weight percentage: PBT45%, calcium hypophosphite 24%, PETS0.5%, anti-dripping agent PTFE0.1%, antioxidant 1680.2%, antioxidant 10100.2%; short glass fiber 30% ( OCV952A);

[0033] 2)-3) are the same as 2)-3) of embodiment 1.

[0034] The technical performance table of the glass fiber-reinforced halogen-free environmentally friendly flame-retardant modified polyester material prepared in Example 3

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com