Moisture absorption polyamide 6 fibre and production method thereof

A production method, polyamide technology, applied in the direction of single-component polyamide rayon, fiber treatment, filament/thread forming, etc., can solve problems such as unevenness, difficulty in micropore size, and unstable spinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Hygroscopic Polyamide 6DTY

[0028] (a) Preparation of polyamide 6POY

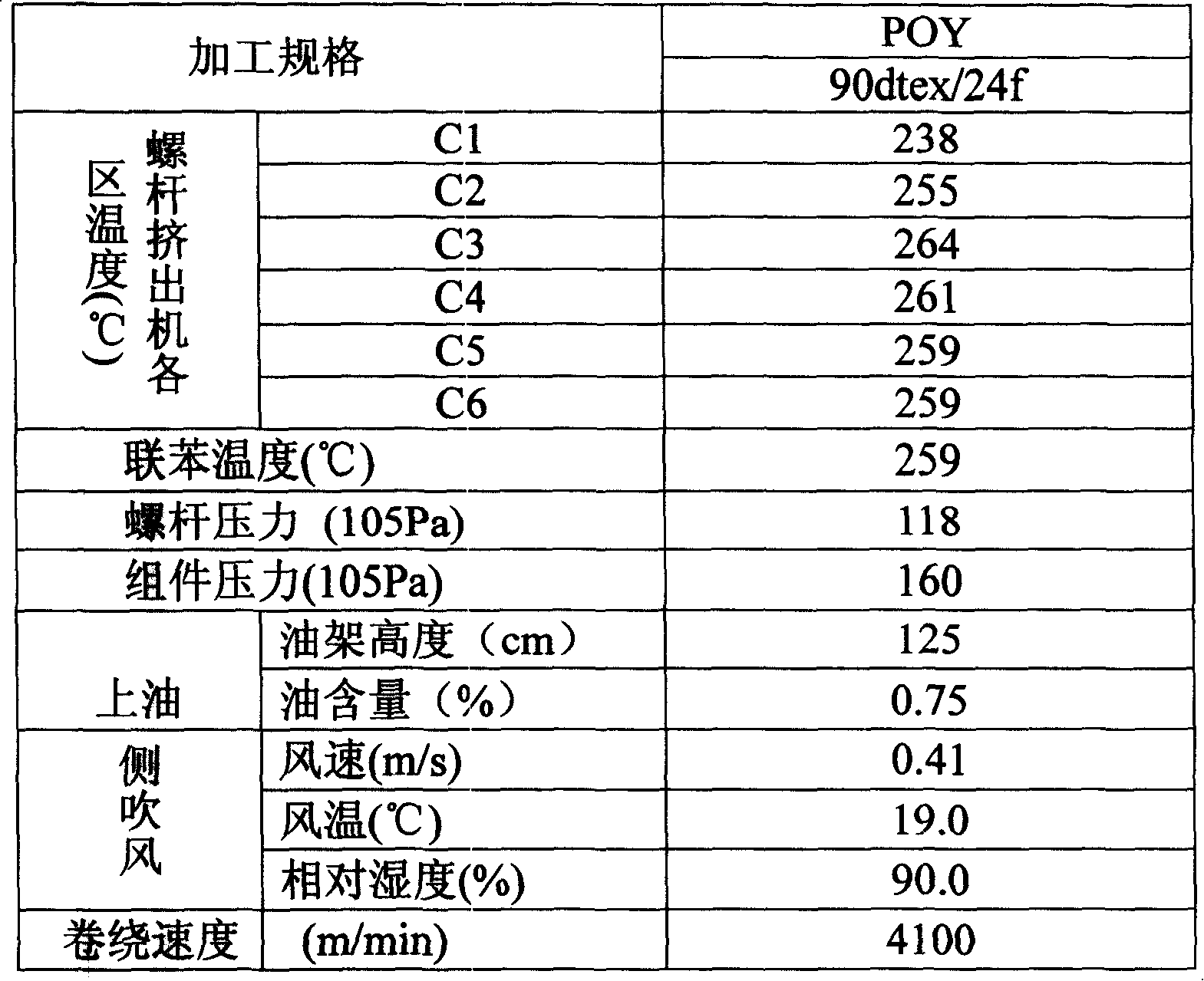

[0029] Product specifications POY 90dtex / 24f, polyamide 6 slices, adopt melt spinning machine, and adopt cross-shaped spinneret, its micropore size: length 0.6mm, width 0.08mm, aspect ratio 7.5:1, its specific production The process parameters are shown in Table 1

[0030] Table 1

[0031]

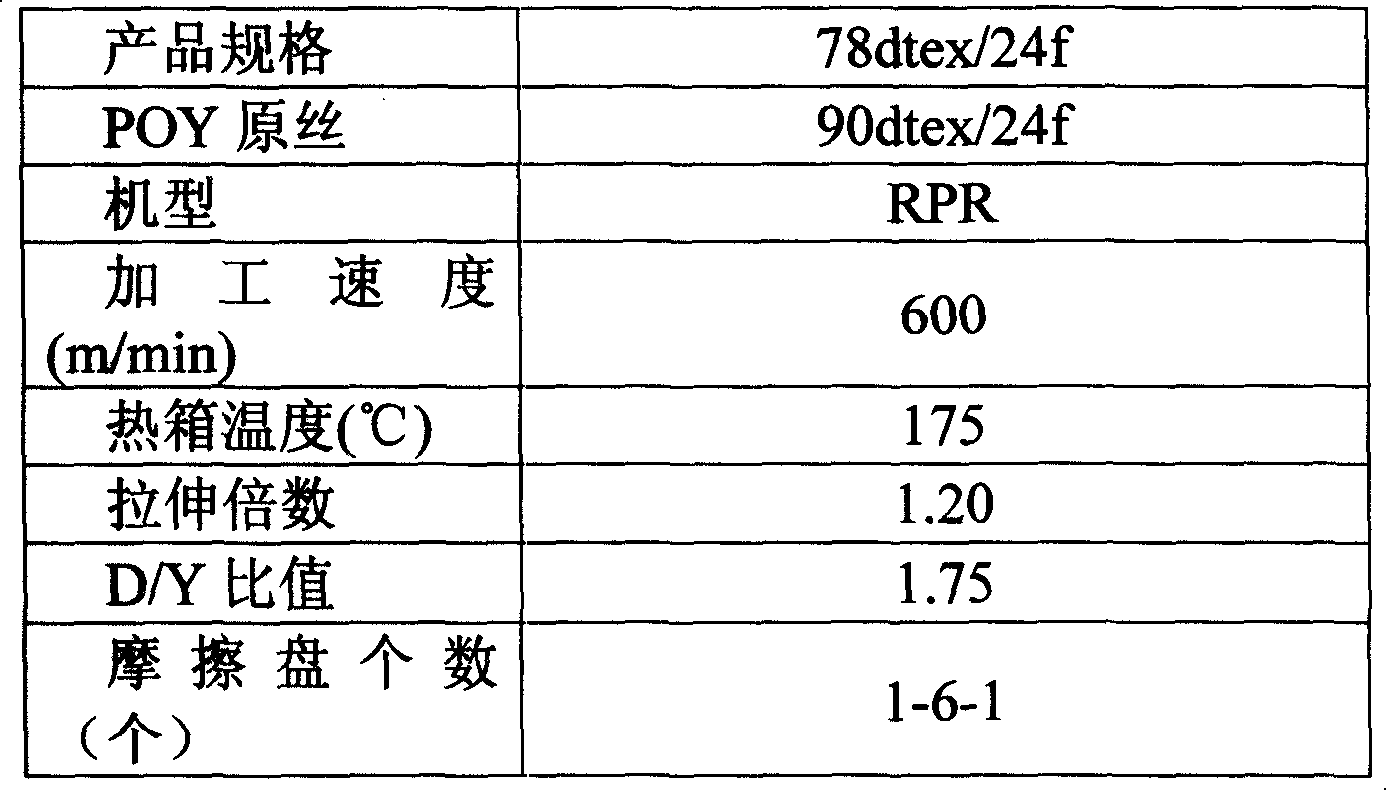

[0032] (b) Preparation of DTY

[0033] Texturize the POY produced by the above method, equipment: Italian RPR texturing machine, POY properties: breaking strength 3.67cN / dtex, breaking elongation 62%, evenness 0.81%. Its specific parameters are shown in Table 2

[0034] Table 2

[0035]

Embodiment 2

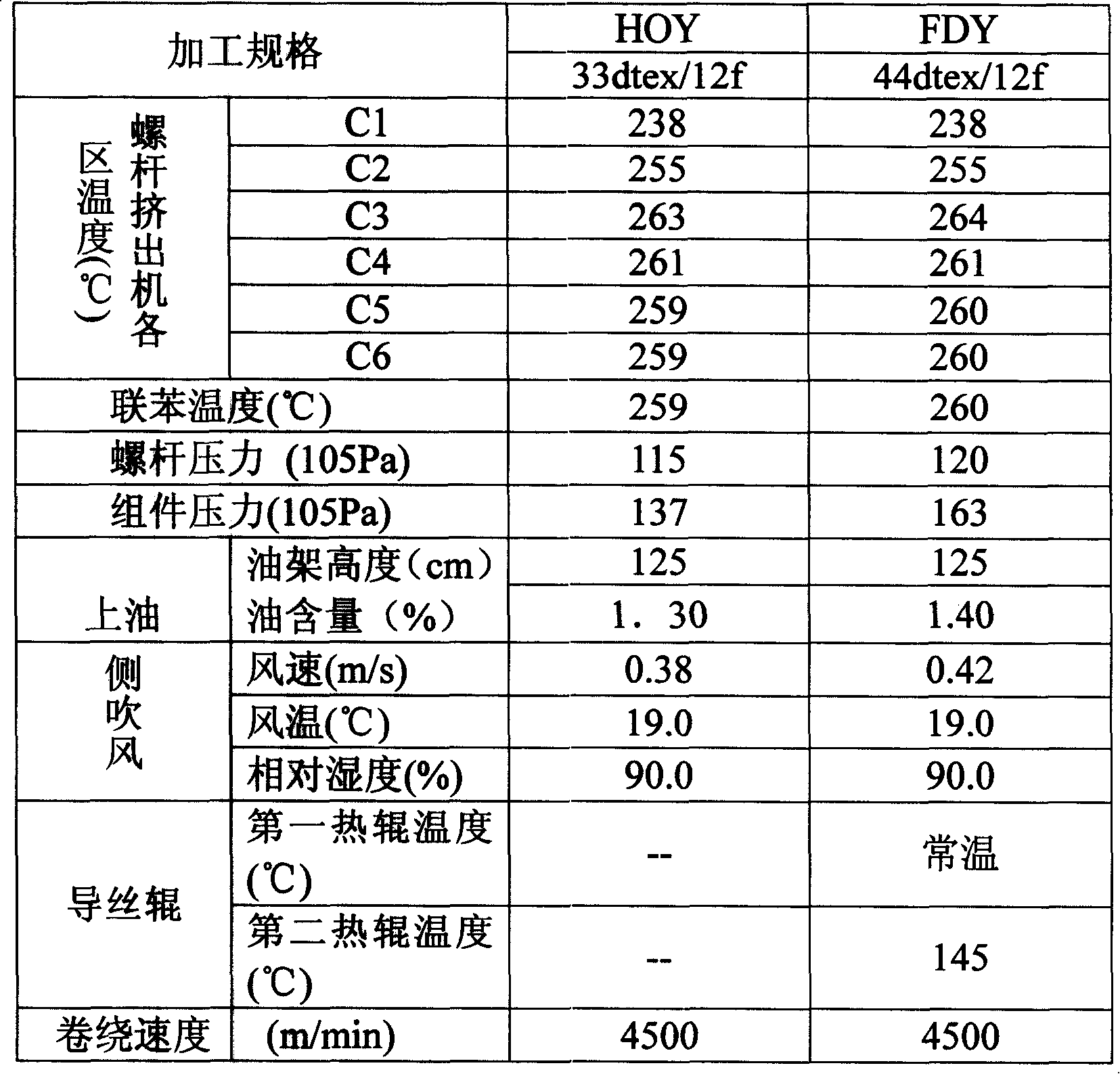

[0037] Preparation of Hygroscopic Polyamide 6HOY and FDY

[0038] Product specifications HOY 33dtex / 12f, FDY 44dtex / 12f, polyamide 6 slices as the basic raw material, melt spinning machine, and cross-shaped spinneret, the micropore size: length 0.56mm, width 0.07mm, length and width The ratio is 8:1. The specific production process parameters are shown in Table 3.

[0039] table 3

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com