HPCP resin with polyhydroxy structure and preparation method thereof

A technology of cyclotriphosphazene and polyhydroxyl, which is applied in the field of cyclotriphosphazene resin and its preparation, and can solve the problems of high price, lack of large-scale application, difficult processing and moldability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Synthesis of Ethylene Glycol Etherified Dihydroxycyclotriphosphazene Resin

[0057] 1) Product Description

[0058] Product Name: Ethylene Glycol Etherified Dihydroxycyclotriphosphazene Resin

[0059] Molecular weight: 381.14

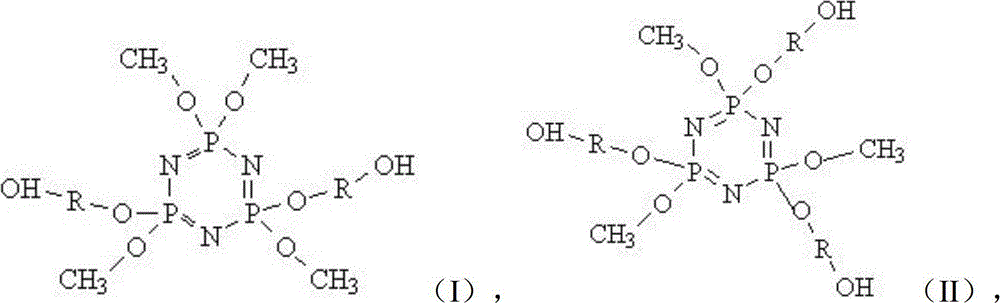

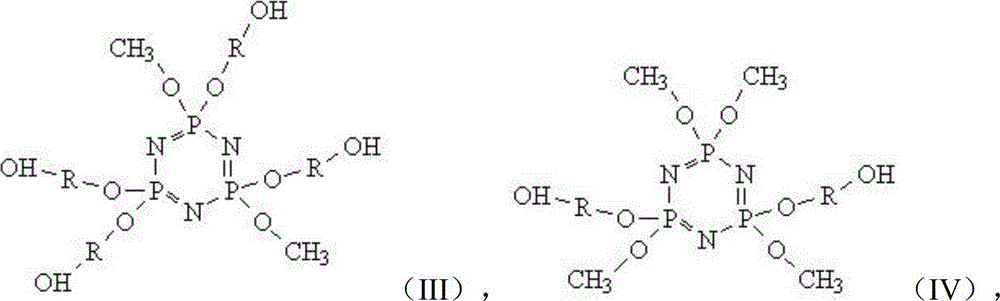

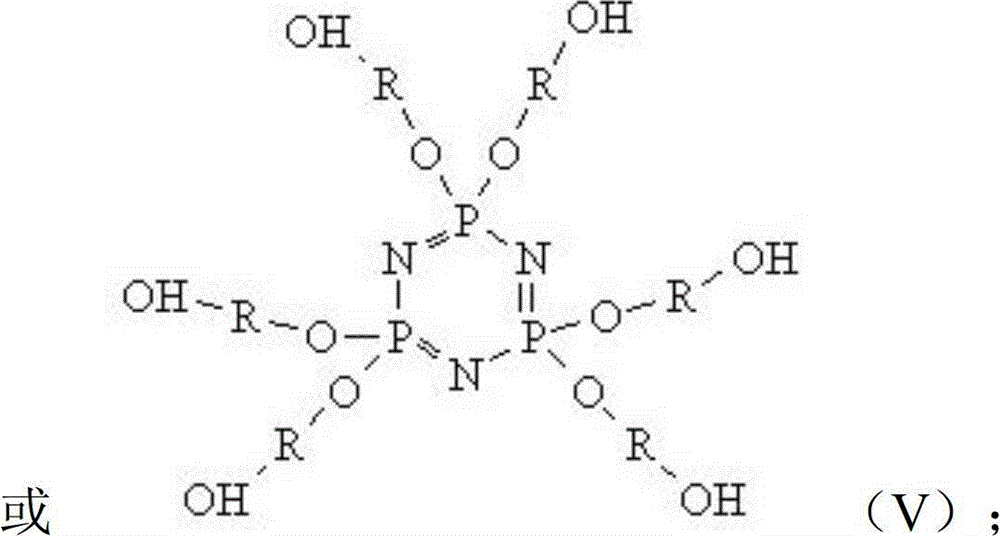

[0060] Molecular Structure:

[0061]

[0062] Quality Index:

[0063] Appearance: light yellow transparent viscous liquid

[0064] Acid value: (mgKOH / g) ≤0.2

[0065] Chromaticity: (APHA) ≤55

[0066] Ignition point: ℃ ------

[0067] Specific gravity: (20 / 25°C) 1.117-1.123

[0068] Moisture: Wt.% ≤0.5

[0069] Soluble in water, alcohol, phosphate ester and other solvents.

[0070] Uses: Reactive P-N polyurethane resin flame retardant. Flame retardant polyether starter.

[0071] 2) Synthesis technology

[0072] The hexamethoxycyclotriphosphazene resin and ethylene glycol undergo ether exchange reaction to generate ethylene glycol etherified dihydroxycyclotriphosphazene resin.

[0073] Raw material ratio

[0074]

[0075] Che...

Embodiment 2

[0079] Ethylene Glycol Etherified Trihydroxycyclotriphosphoryl Resin

[0080] Raw material ratio

[0081]

[0082] Chemical reaction formula:

[0083]

[0084] In the reactor, add ethylene glycol: 37.24Kg, add hexamethoxycyclotriphosphazene resin (VI): 64.23Kg, add zirconium sulfate catalyst: 1.2Kg. Raise the temperature to 110-130°C, carry out the ether exchange reaction for 4-5 hours, distill off the methanol generated in the reaction, cool to room temperature, filter out the catalyst (reuse 8-10 times), and obtain the product: Ethylene glycol etherified trihydroxyl ring Triphosphonitrile resin: 81.25Kg. Yield: 98.8%, viscosity: 7680mPa.S / 25℃.

Embodiment 3

[0086] Ethylene Glycol Etherified Tetrahydroxycyclotriphosphoryl Resin

[0087] Raw material ratio

[0088]

[0089] Chemical reaction formula:

[0090]

[0091] In the reaction kettle, add ethylene glycol: 49.66Kg, add hexamethoxy cyclotriphosphazene resin (VI): 64.23Kg, add zirconium sulfate: 1.3Kg. Raise the temperature to 110-130°C, carry out the ether exchange reaction for 4-5 hours, distill off the methanol generated in the reaction, cool to room temperature, filter out the catalyst (reuse 8-10 times), and obtain the product: tetrahydroxyl ring etherified with ethylene glycol Triphosphazene resin: 87.26Kg. Yield: 98.9%, viscosity: 7460mPa.S / 25℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com