Fur and leather integrated composite material and preparation method thereof

A composite material and wool-integrated technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve problems such as the technical concept that solvent-based polyurethane coatings are difficult to achieve recyclable production, and achieve quality stability. And the effect of good consistency, high environmental protection efficiency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

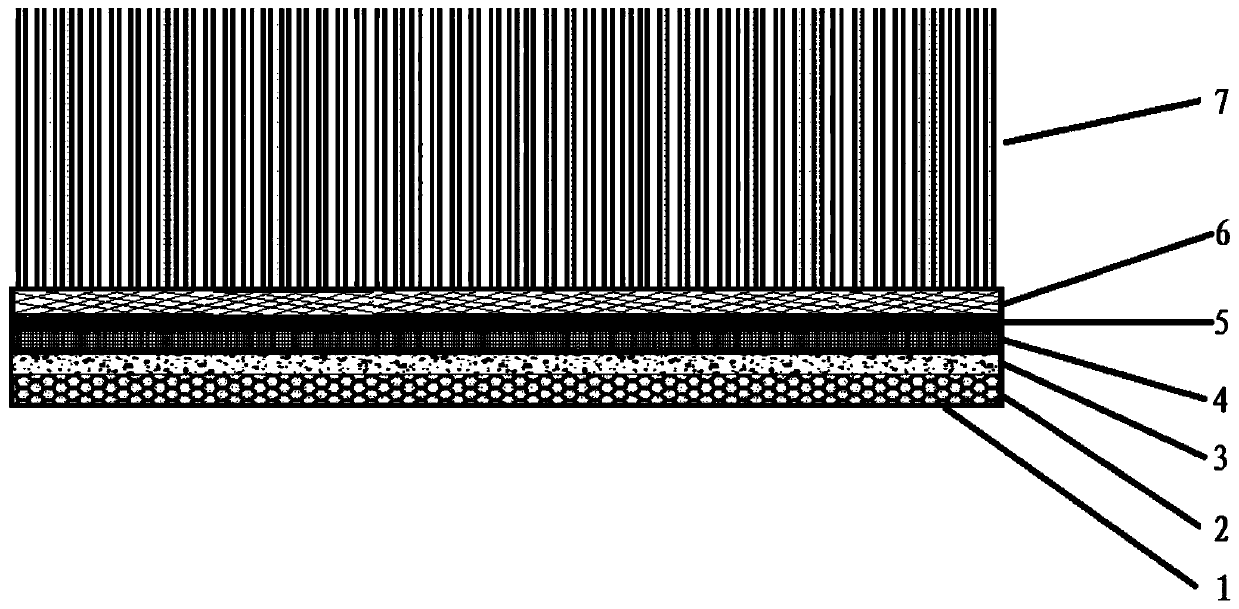

[0144] The invention provides a kind of preparation method of wool leather integrated composite material, comprises the following steps:

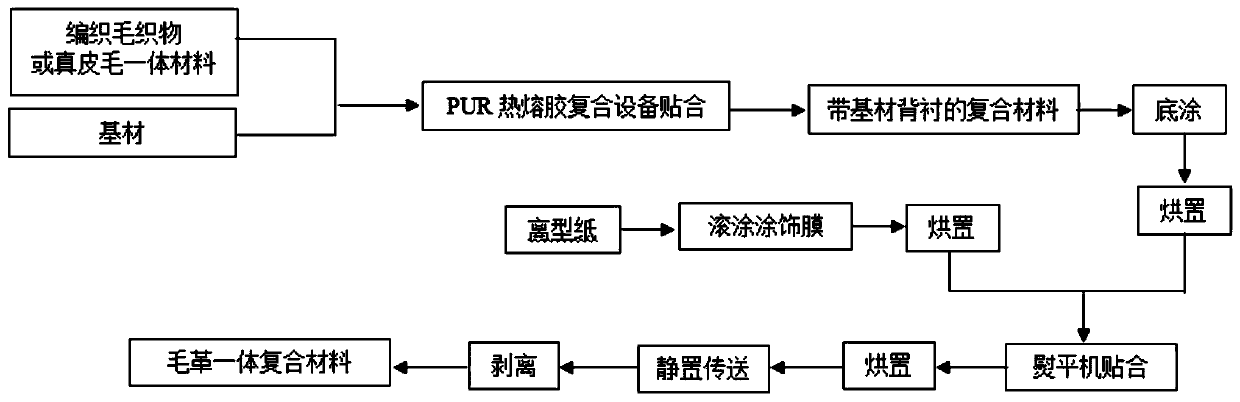

[0145] 1) After bonding the braided fabric with wool layer or the integrated material of real fur with the base material through adhesive glue, a composite material with a base material backing is obtained;

[0146] 2) After compounding the primer layer on the base material surface of the composite material with the base material backing obtained in the above steps, after drying, a semi-finished product is obtained;

[0147] 3) Ironing and laminating the coating film surface of the release paper coated with the coating film and the base coat of the semi-finished product obtained in the above steps, and then drying again to obtain a wool-leather integrated composite material.

[0148] Concrete can be the following steps:

[0149] 1`) After bonding the braided fabric with wool layer or the integrated material of real fur and the base materia...

Embodiment 1

[0219] Fur-leather integrated composite material with braided wool

[0220] The first step: use PUR hot melt adhesive to apply the hot melt adhesive on the suede through the composite laminating equipment and laminate it with the knitted fabric surface to form a composite knitted wool material with a base fabric backing.

[0221] Among them, suede thickness: 0.4mm, suede weight: 210g / m 2 ;

[0222] Hot melt adhesive bonding pressure: 60kg / cm 2 , Hot melt adhesive bonding speed: 4m / min, bonding temperature 140°C.

[0223] The second step: release paper coating: the coating film material with the following formula is used for coating with a roller coating machine, and then dried in an oven.

[0224] Among them, the coating film layer process formula:

[0225] Waterborne polyurethane resin 1225: 27%

[0226] Polyurethane Dispersion 127: 23%

[0227] Water-soluble synthetic resin RC-2349: 16%

[0228] Hand Wax 253: 3.5%

[0229] Pigment Paste 780: 10%

[0230] Leveling ag...

Embodiment 2

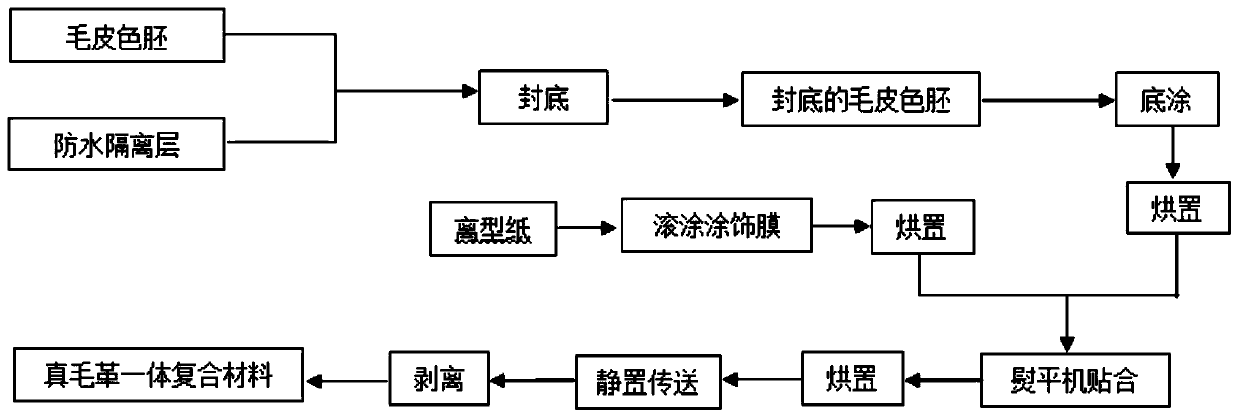

[0251] Fur-leather integrated composite material with real fur-leather integrated material

[0252] Step 1: Use a skinning machine to remove a part of the leather surface of the integrated real fur leather material, remove the reticular layer fiber structure of the cortex, and leave a grain layer fiber structure of about 0.2mm.

[0253] Step 2: Use PUR hot melt adhesive to apply the hot melt adhesive on the suede through composite laminating equipment and bond it with the leather surface of the real fur leather integrated material to form a composite real fur leather with base fabric backing Material.

[0254] Among them, the weight of suede: 230g / m 2 ;

[0255] Hot melt adhesive bonding pressure: 80kg / cm 2 , Hot melt adhesive bonding speed: 3.5m / min, bonding temperature 143 ℃.

[0256] The third step: release paper coating: the coating film material with the following formula is used for coating with a roller coating machine, and then dried in an oven.

[0257] Among the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com