Recycling method of glass ceramic material

A glass-ceramic and waste technology, applied in the field of glass-ceramic manufacturing, can solve problems such as deformation, product explosion, energy consumption, etc., and achieve the effects of simple process, reduced material brittleness, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

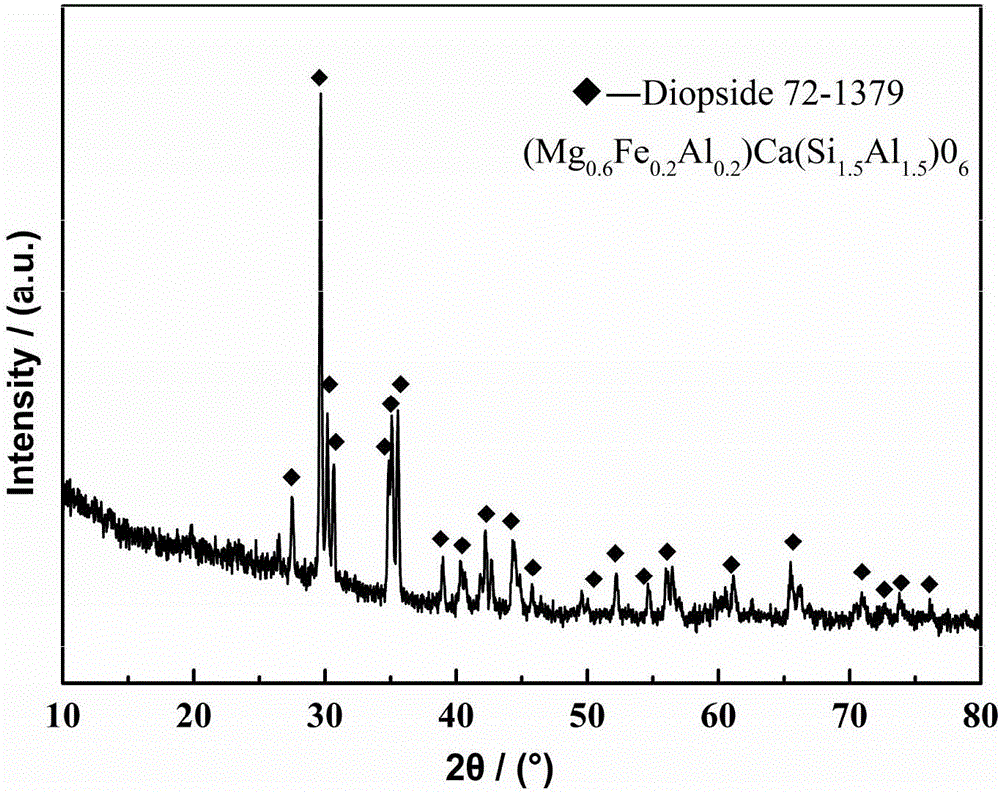

Image

Examples

Embodiment 1

[0026] Example 1: A recycling method for glass-ceramic materials, using the waste produced in the production of glass-ceramics as the main raw material, through crushing, sieving, grading, adding binder, mixing and milling, compression molding, drying, hot air Hardening and other processes are carried out for regeneration treatment to obtain recycled glass-ceramic products. The specific process steps are as follows:

[0027] The chemical composition range of glass-ceramic waste is: SiO 2 40-60%, CaO 10-20%, Al 2 o 3 5-20%, MgO 3-7%, CaF 2 3-10%, Fe 2 o 3 +FeO 5-12%, REO 0.1-2%, R 2 O 2-5%, Cr 2 o 3 0.1-0.5%.

[0028] 1) Remove the surface dirt from the large pieces of waste generated in the production of glass-ceramic, and put them into the jaw crusher or roller crusher for crushing after coarse crushing. The crushed materials are conveyed to the vibrating screen by the belt conveyor. points, and screen out the granular material with a particle size below 3mm. The ...

Embodiment 2

[0038] Embodiment 2: A kind of recycling of glass-ceramic material and its manufacturing method, its technological steps are as follows:

[0039] 1) Remove the surface dirt from the large pieces of waste generated in the production of glass-ceramic, and put them into the jaw crusher or roller crusher for crushing after coarse crushing. The crushed materials are conveyed to the vibrating screen by the belt conveyor. points, and screen out the granular material with a particle size below 3mm. The granular material with a particle size greater than or equal to 3mm is returned to the roller machine by the belt conveyor to continue crushing until the particle size is less than or equal to 3mm.

[0040] 2) The finely broken granular material is transported to the vibrating screen through the belt conveyor, and after being sieved by the vibrating screen, three different particle sizes of 0.1-1mm, 1-2mm, and 2-3mm are obtained, and then the sieved The residue is processed into a fine...

Embodiment 3

[0048] Embodiment 3: A kind of recycling of glass-ceramic material and its manufacturing method, its technological steps are as follows:

[0049] The chemical composition range of glass-ceramic waste is: SiO 2 40-60%, CaO 10-20%, Al 2 o 3 5-20%, MgO 3-7%, CaF 2 3-10%, Fe 2 o 3 +FeO 5-12%, REO 0.1-2%, R 2 O 2-5%, Cr 2 o 3 0.1-0.5%.

[0050] 1) Remove the surface dirt from the large pieces of waste generated in the production of glass-ceramic, and put them into the jaw crusher or roller crusher for crushing after coarse crushing. The crushed materials are conveyed to the vibrating screen by the belt conveyor. points, and screen out the granular material with a particle size below 3mm. The granular material with a particle size greater than or equal to 3mm is returned to the roller machine by the belt conveyor to continue crushing until the particle size is less than or equal to 3mm.

[0051] 2) The finely broken granular material is transported to the vibrating scree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com