Patents

Literature

35results about How to "Good corrosion resistance and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

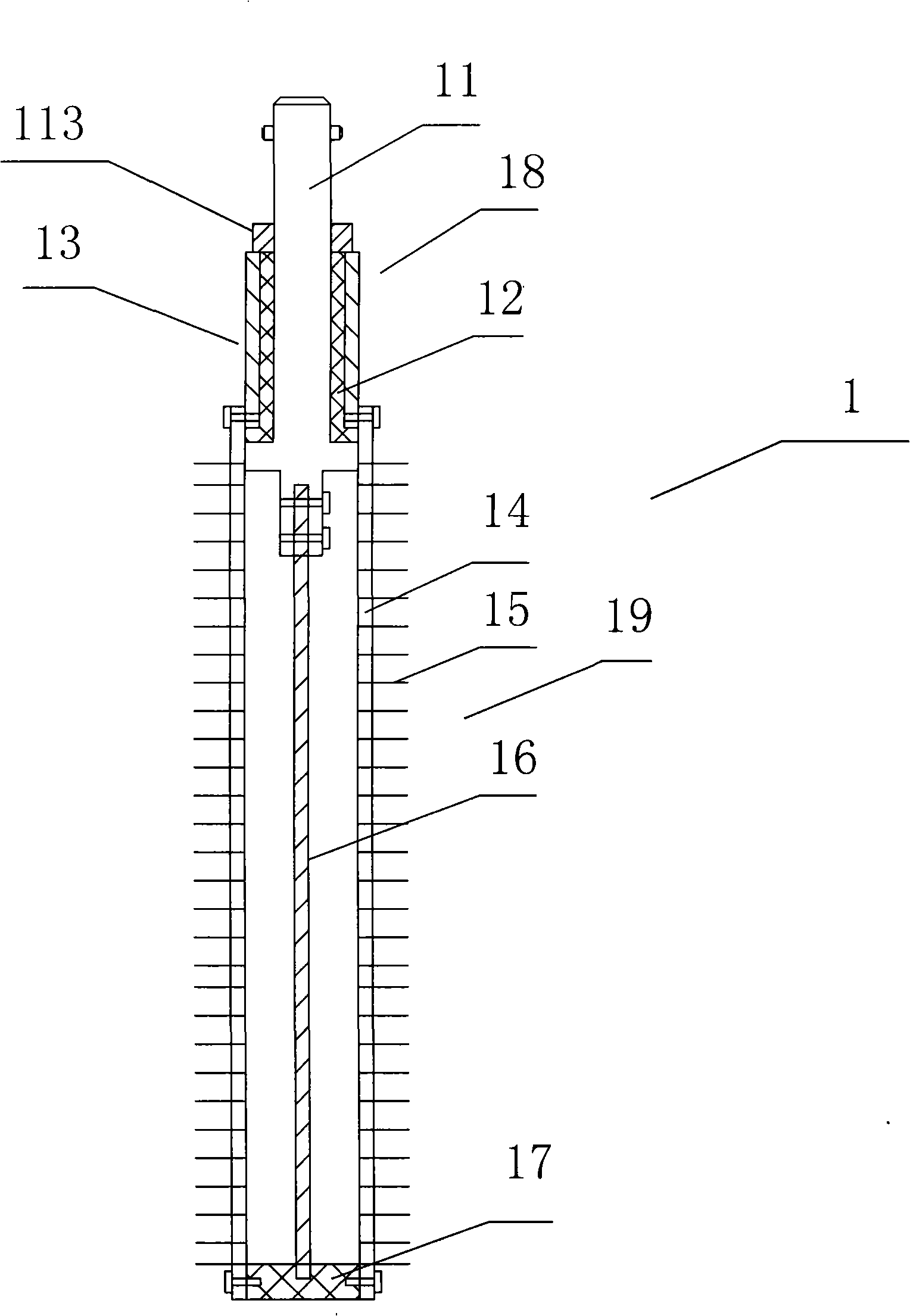

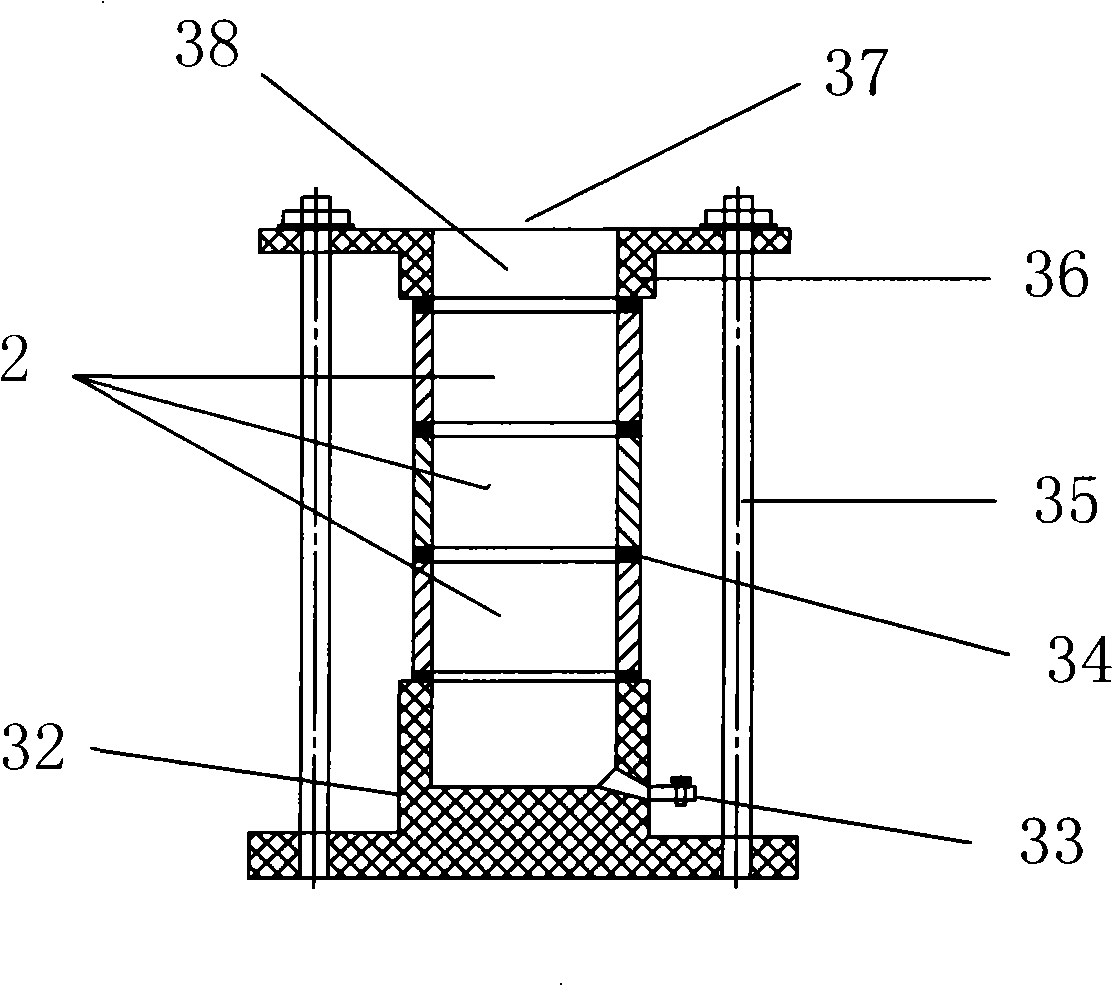

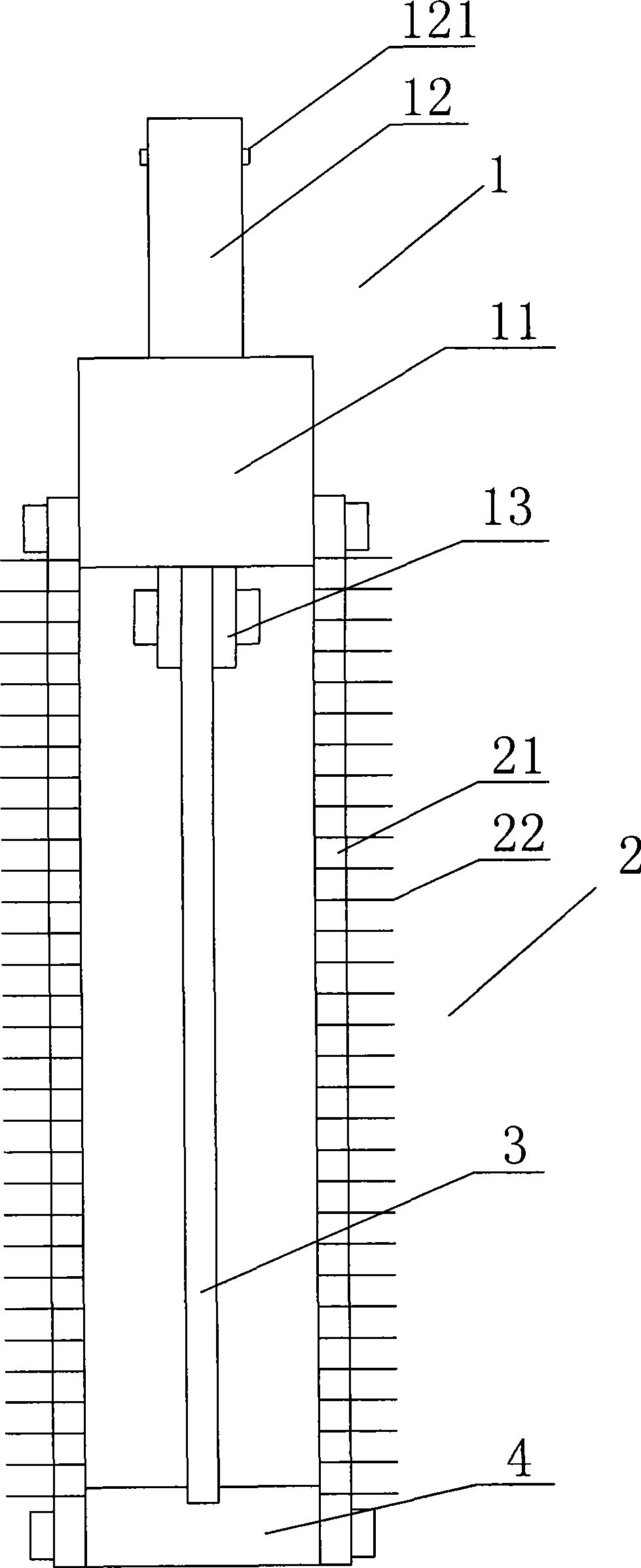

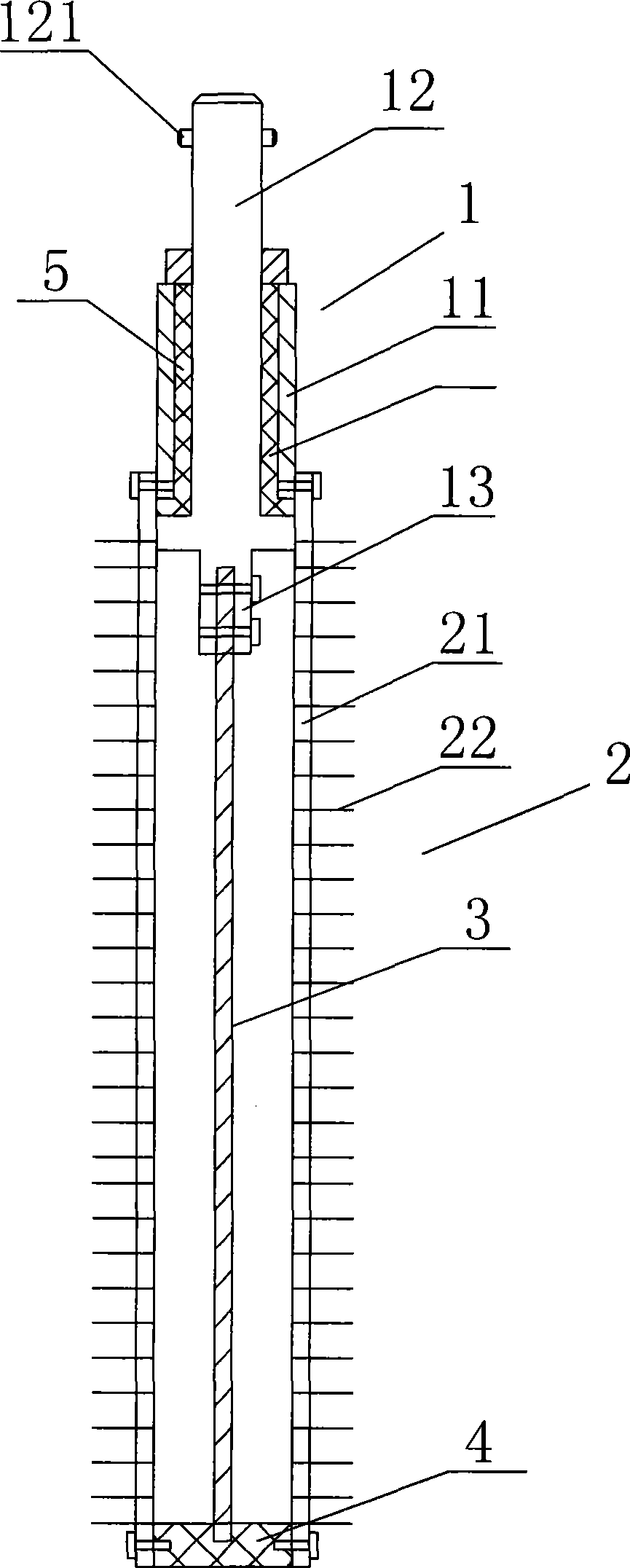

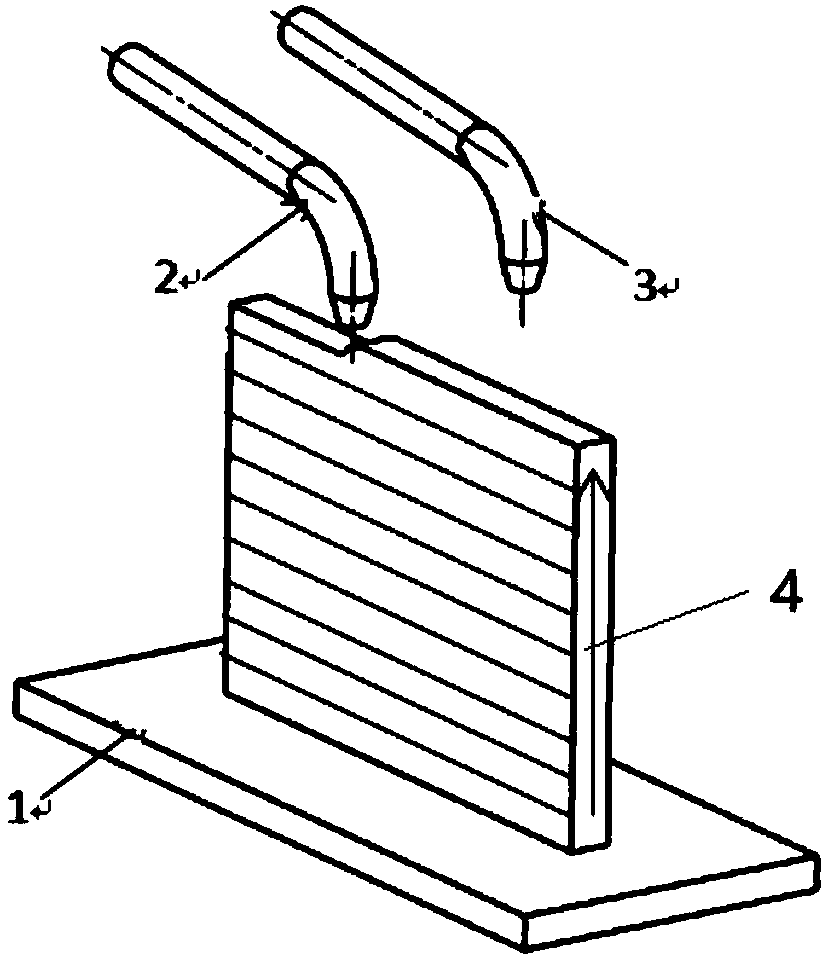

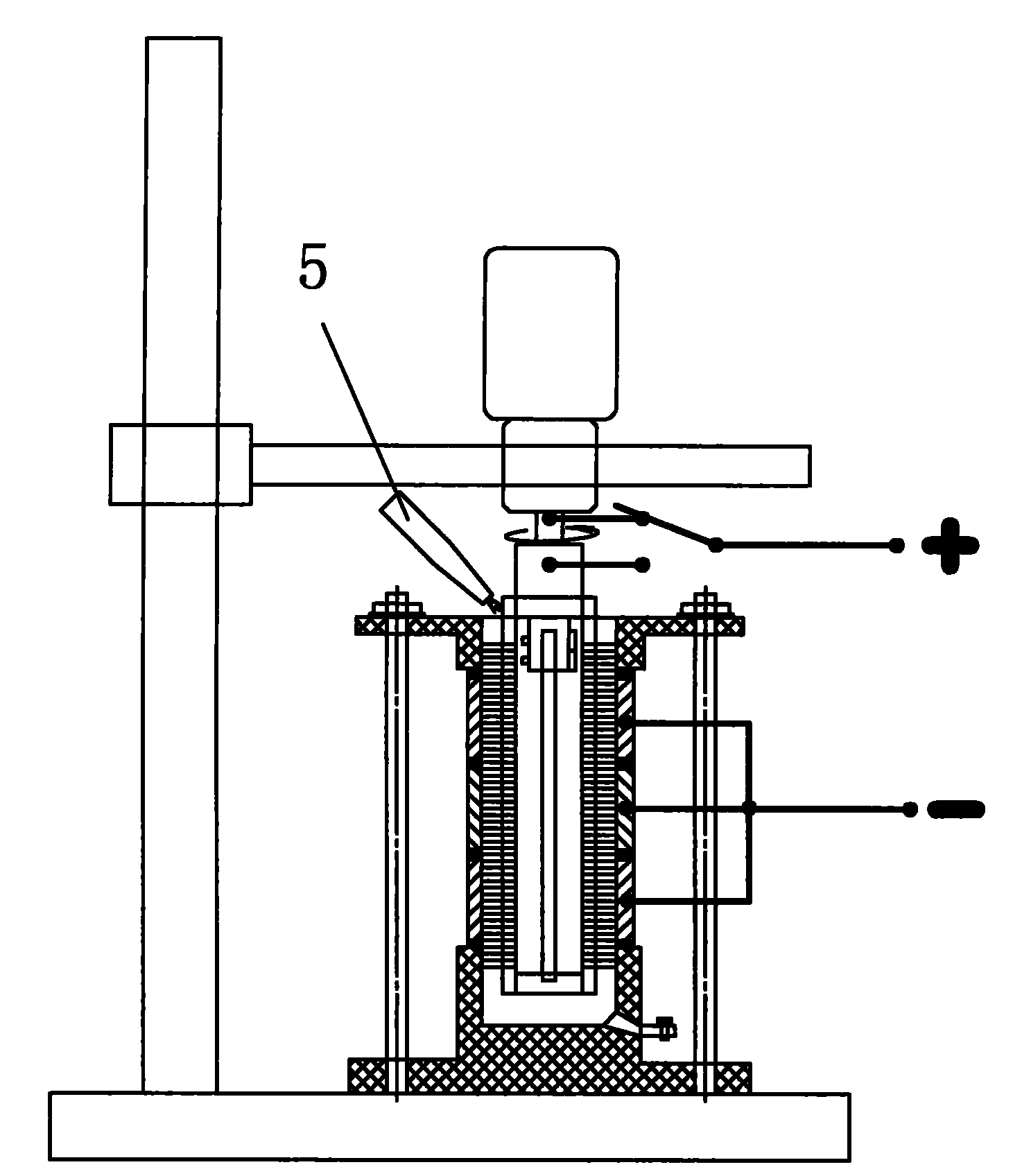

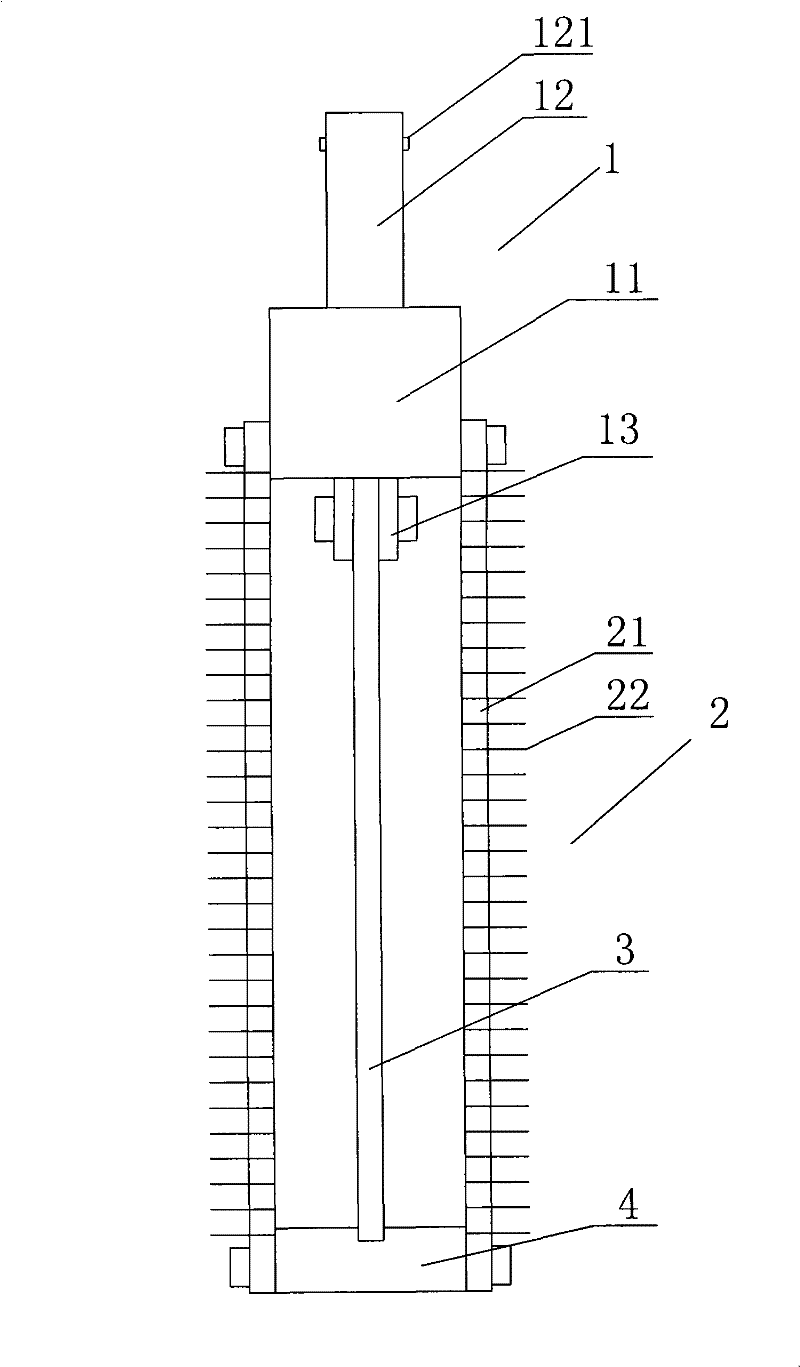

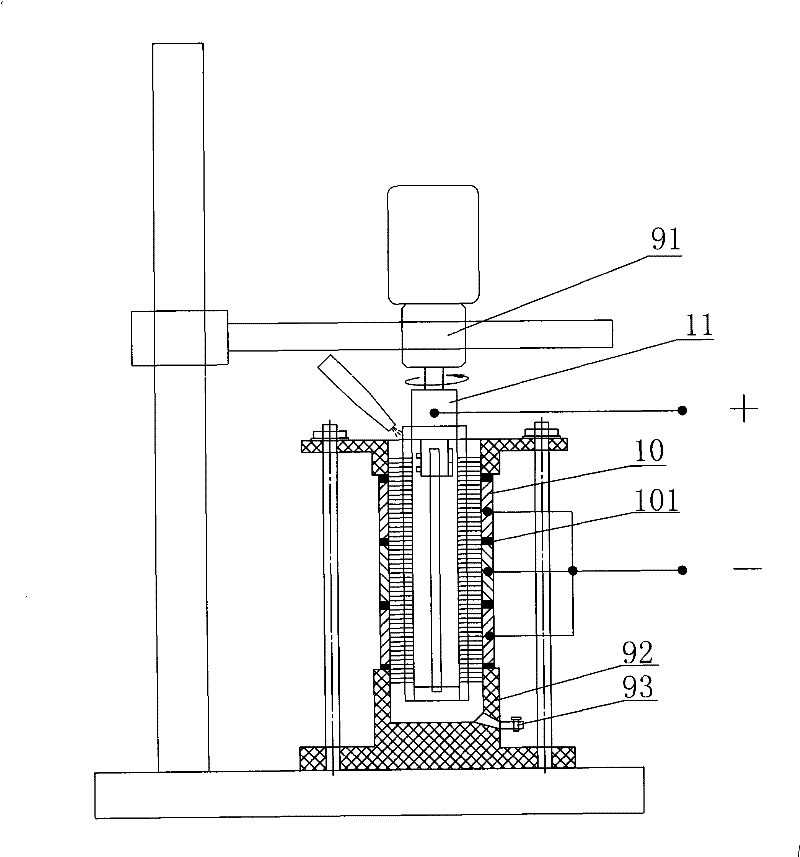

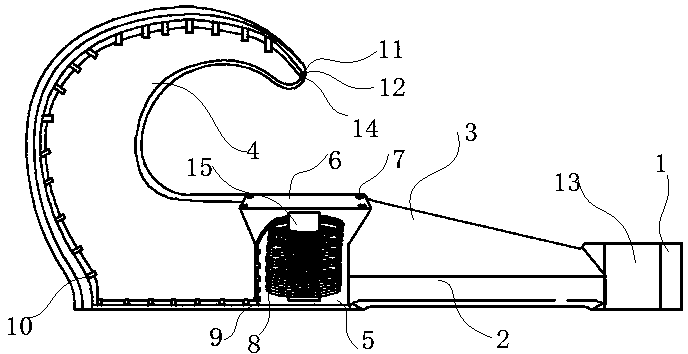

Device and method for inner bore type component brush plating

The invention provides a device and method for inner bore type component brush plating. The device comprises a workpiece to be plated, a workpiece clamping sealing device, a plating pen special for inner bore brush plating, and a plating pen rotary actuator. The workpiece to be plated and the clamping sealing device together form a container having an opening at the top; in plating process, the workpiece is the cathode, and the plating pen is the anode. The device and method realize that plating is prepared at the surface of the inner bore of the inner bore type component by using the technology of brush plating, thereby being applied to strengthening for new workpiece and also being applied to batch repair and remanufacturing for damaged pieces.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

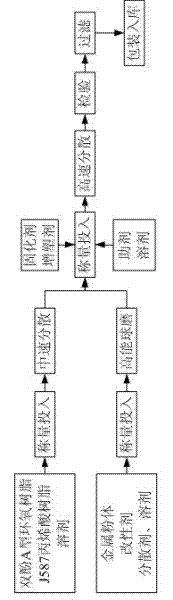

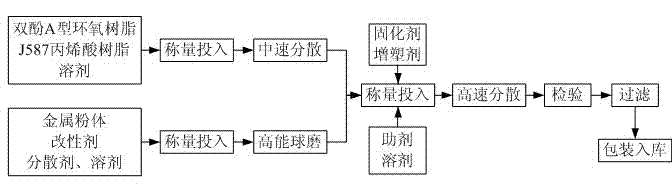

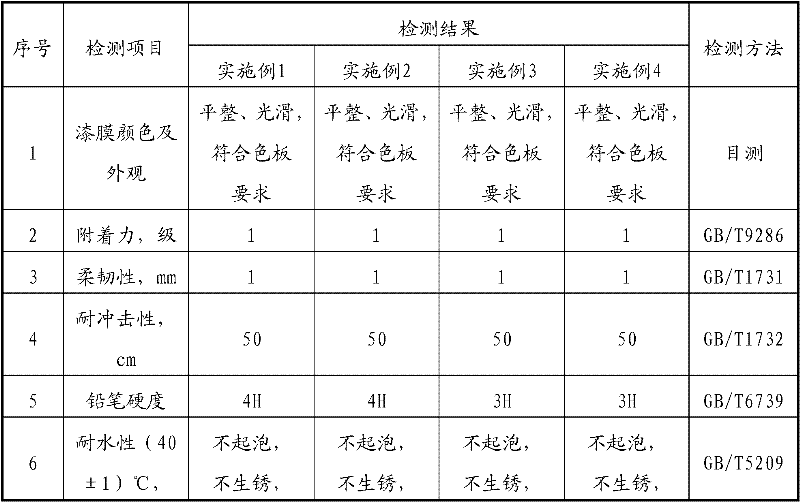

Anticorrosive wear-resistant paint for magnesium alloy and preparation method thereof

InactiveCN102352168AImprove wear resistanceImprove the lubrication effectAnti-corrosive paintsEpoxy resin coatingsAcrylic resinWear resistant

The invention relates to an anticorrosive wear-resistant paint for magnesium alloy. The paint provided by the invention is made from the following components of: a modified epoxy resin liquid which is prepared by dissolving and dispersing bisphenol A-type epoxy resin, J587 acrylic resin and the balance solvent, a metal nanometer polymer formed by Ti, Al2O3, MoS2 and the like, and a curing agent, a plasticizer, an auxiliary agent and a solvent which are commonly used for paints. The preparation method comprises the following steps of: adding the metal nanometer polymer into the modified epoxy resin liquid for dispersion, adding the curing agent, the plasticizer, the auxiliary agent and the solvent with fully stirring and uniformly dispersing, filtering and standing to prepare the anticorrosive wear-resistant paint. The preparation technology and operation are both simple with each step carried out at normal temperature and normal pressure, and are convenient for industrial production. The prepared paint is widely applied, has strong bonding force between the coating layer and the matrix and good anticorrosive and abrasion resistant performance, and has a long-acting effect of protecting magnesium alloy member.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Cold-spraying and micro-arc oxidation combined workpiece surface treatment method

InactiveCN110158134AWill not deformKeep raw material componentsAnodisationPressure inorganic powder coatingMetal coatingMicro arc oxidation

The invention provides a cold-spraying and micro-arc oxidation combined workpiece surface treatment method. The method comprises the following steps that S1, oil stains on the surface of a workpiece are removed, and the surface of the workpiece is subjected to sand blasting; S2, the surface, subjected to sand blasting, of the workpiece is subjected to cold spraying, and a cold-spraying metal coating is formed on the surface of the workpiece; S3, the surface, subjected to cold spraying, of the workpiece is subjected to polishing treatment; S4, the workpiece subjected to cold spraying and polishing treatment is subjected to micro-arc oxidation, and a micro-arc oxidation metal ceramic layer is formed on the surface of the workpiece; and S5, the surface, coated with the micro-arc oxidation metal ceramic layer, of the workpiece is subjected to polishing after-treatment. The surface corrosion-resistant wear-resistant treatment method combining cold spraying and micro-arc oxidation technologies can be applied to surface corrosion resistance and repair remanufacturing of workpieces made of any material; and compared with an existing process, the wear-resistant and corrosion-resistant strengthening properties are improved, and meanwhile applicability, economical efficiency and environmental conservation are all considered, so that great market promotion value is achieved.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Processing method of improved 6061 aluminum alloy refrigerator foaming die cast

InactiveCN103014448AHigh strengthImprove wear resistanceFoundry moulding apparatusRare-earth elementIcebox

The invention discloses a processing method of an improved 6061 aluminum alloy refrigerator foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and carrying out thermal treatment. According to the invention, an appropriate amount of rare earth elements Nd, Ce and Sc are added to the improved 6061 aluminum alloy, so that the size of eutectic phase is significantly reduced, the as-cast structure of the alloy is uniformed and refined, and the strength as well as corrosion resistance and wear resistance of the alloy are improved. The processed aluminum alloy refrigerator foaming die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州佳诚模具制造有限公司

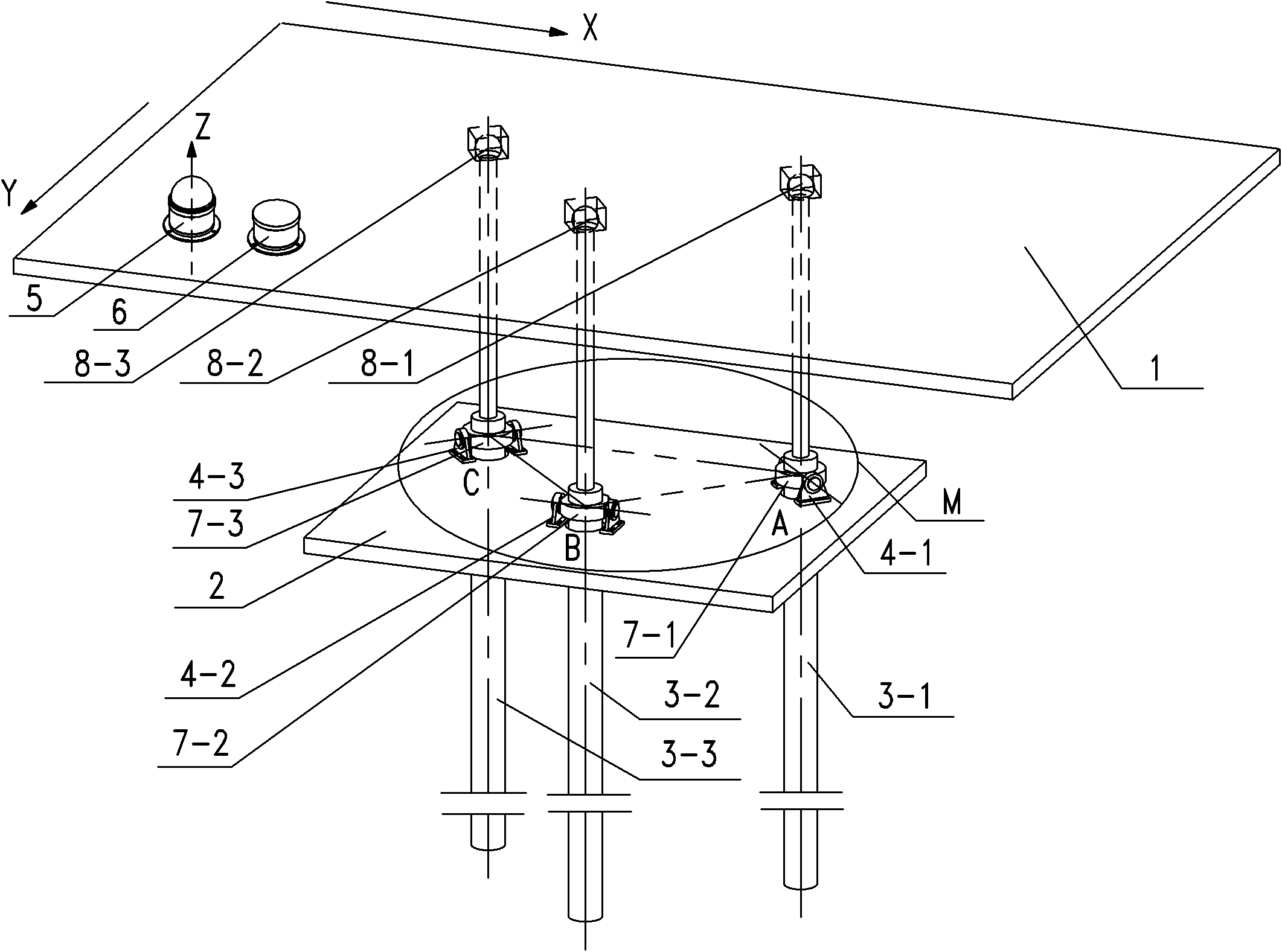

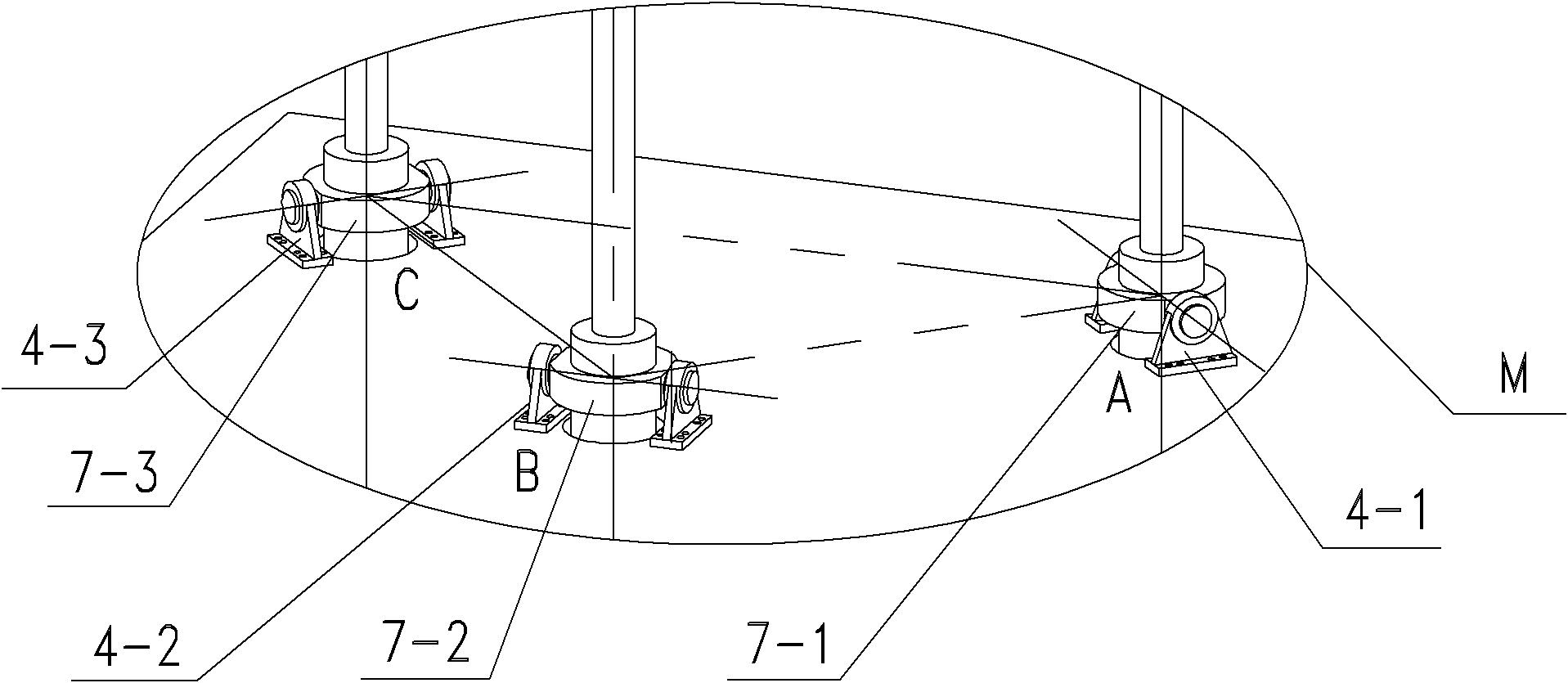

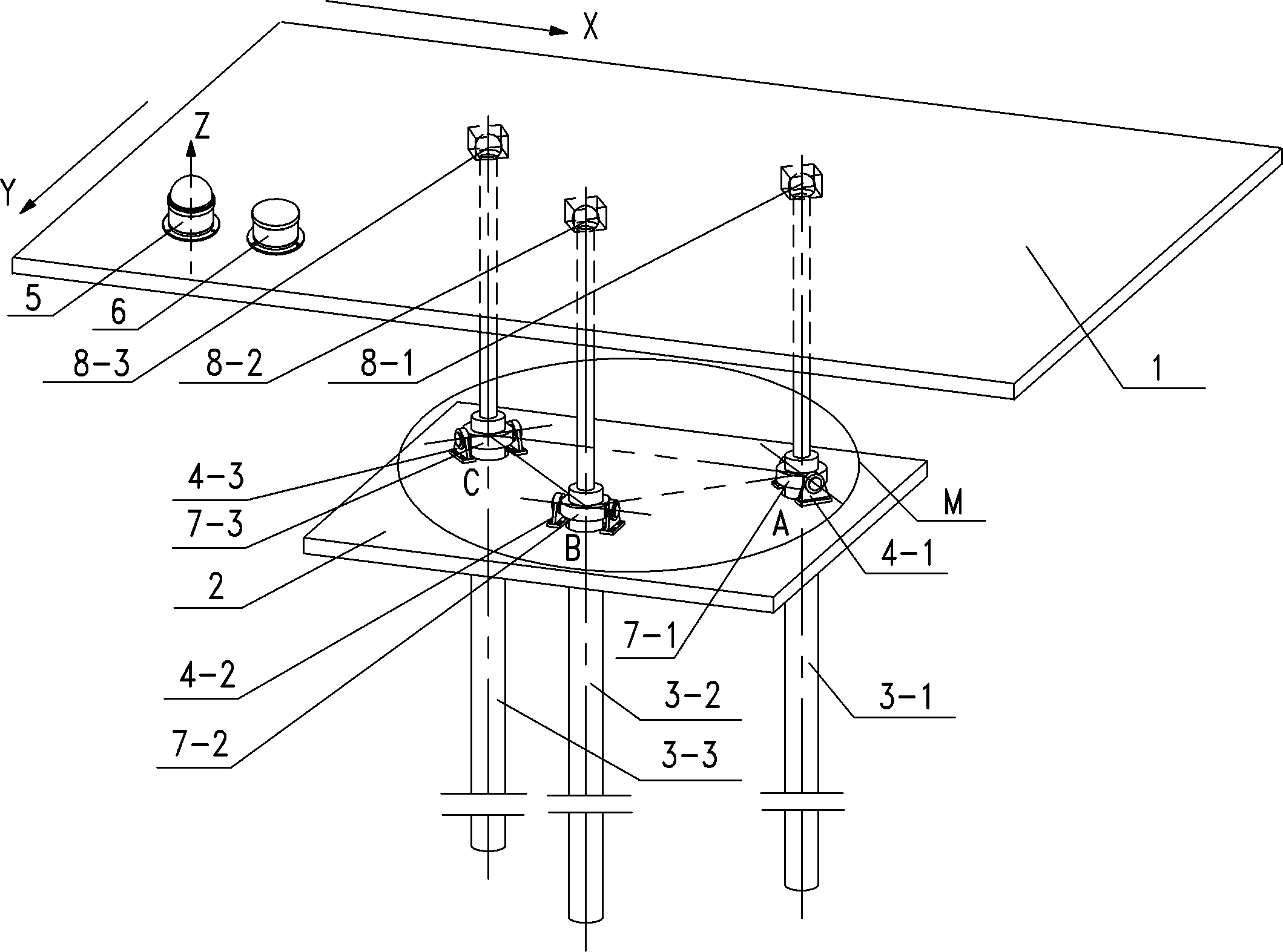

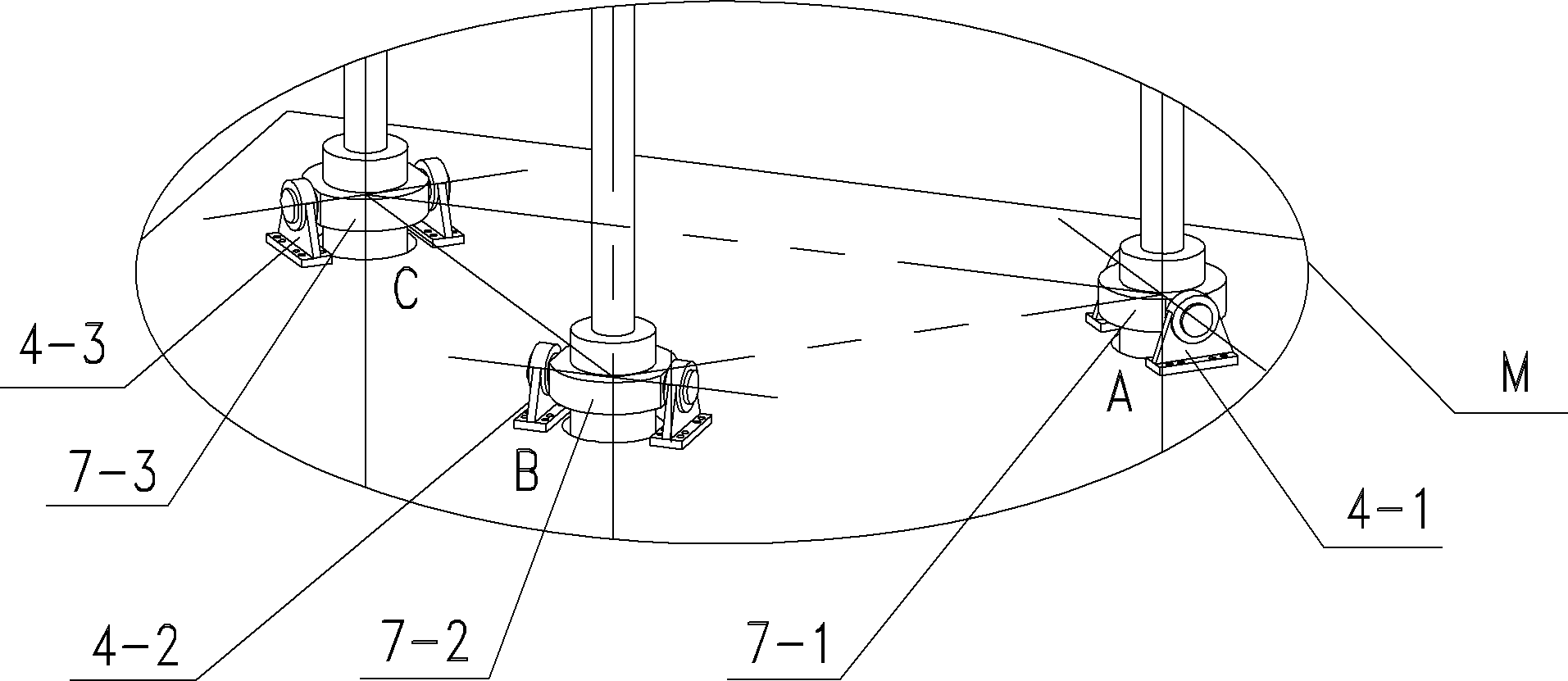

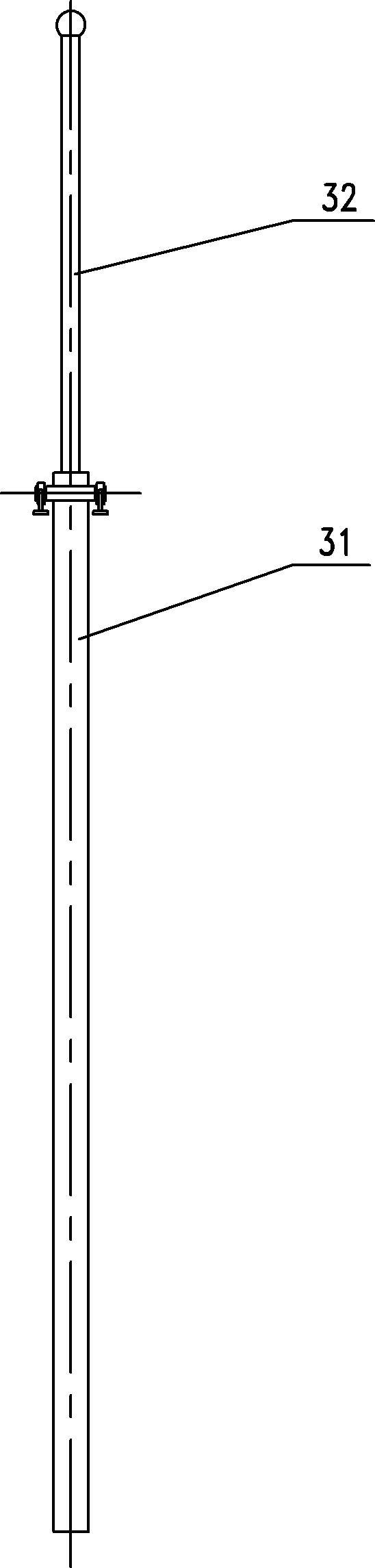

All-day automatic tracking system

InactiveCN102109852AGood corrosion resistance and wear resistanceImprove protectionControl using feedbackTrunnionTilt sensor

The invention relates to an all-day automatic tracking system. The system comprises a photovoltaic assembly, an installation platform, hydraulic cylinders, hydraulic cylinder installation seats and a hydraulic control power unit which adjusts the strokes of the hydraulic cylinders; the hydraulic cylinder installation seats are all arranged on the installation platform; the hydraulic cylinders arearranged on the installation platform; each hydraulic cylinder comprises a cylinder body and a piston rod; the cylinder bodies are connected with the hydraulic cylinder installation seats through trunnions; the end of the piston rod of each hydraulic cylinder is connected with the fixed end of the lower surface of the photovoltaic assembly through a universal joint; the all-day automatic trackingsystem also comprises an electric centralized control system for controlling the hydraulic control power unit to act, a follow light sensor used for measuring the required offset adjusting value of the photovoltaic assembly and an inclined sensor used for measuring the position offset adjustment value of the photovoltaic assembly; the horizontal reference surface of the inclined sensor is parallel to the surface of the photovoltaic assembly; and the orientation shaft Z of the follow light sensor is vertical to the surface of the photovoltaic assembly. The all-day tracking system can be used for atrocious weather, can realize accurate automatic tracking and consumes less electricity.

Owner:JIANGSU WUJIN HYDRAULIC HOIST

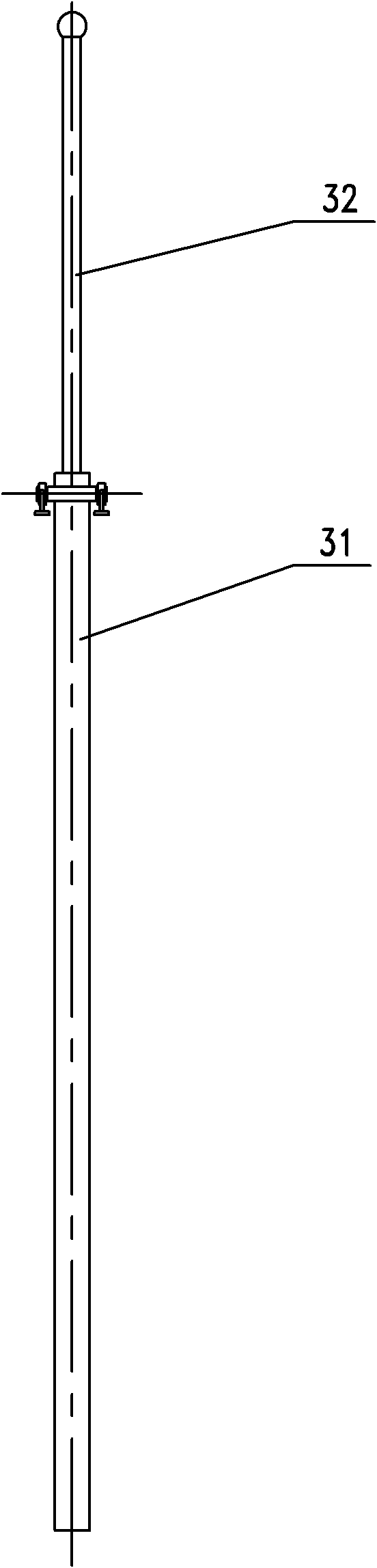

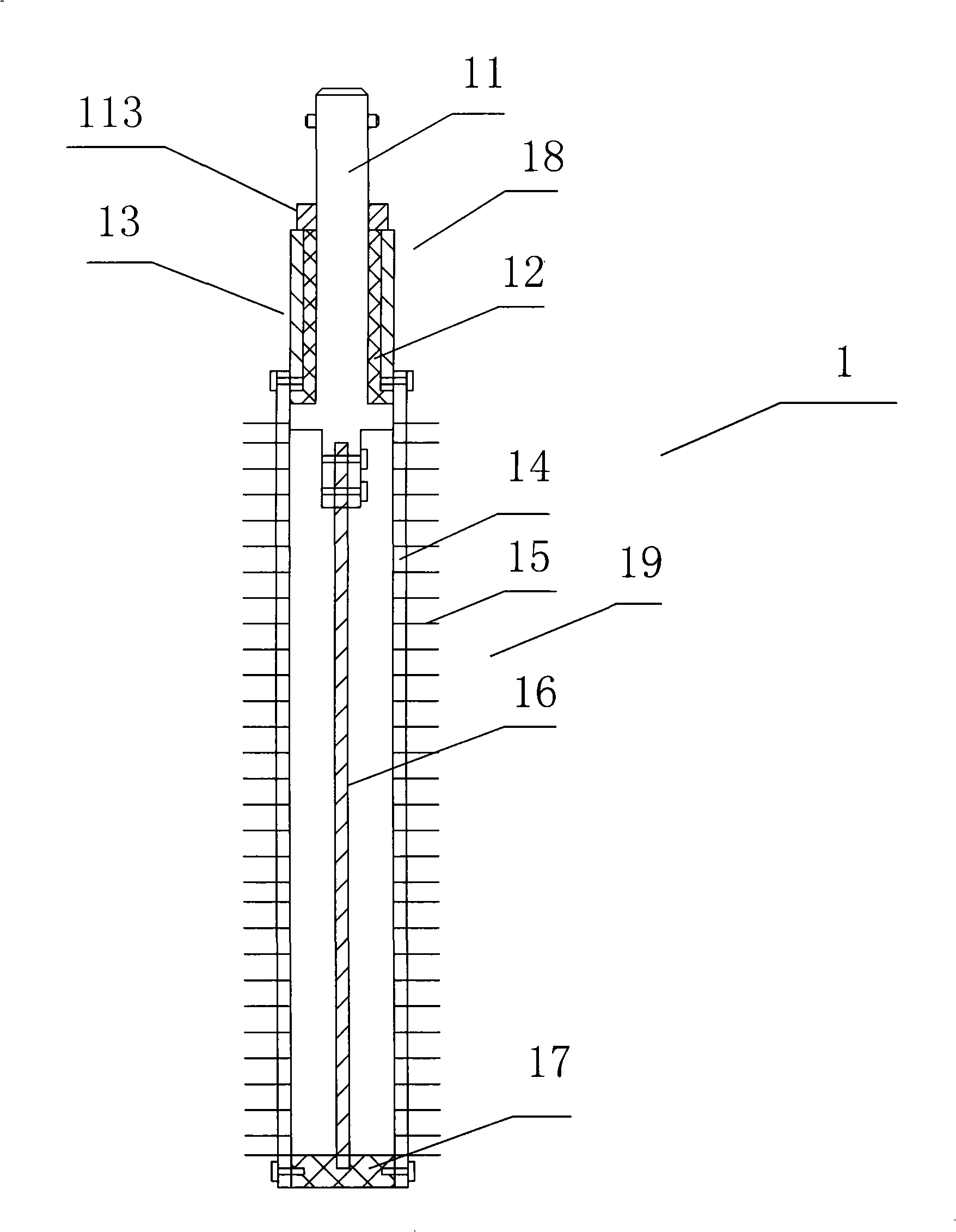

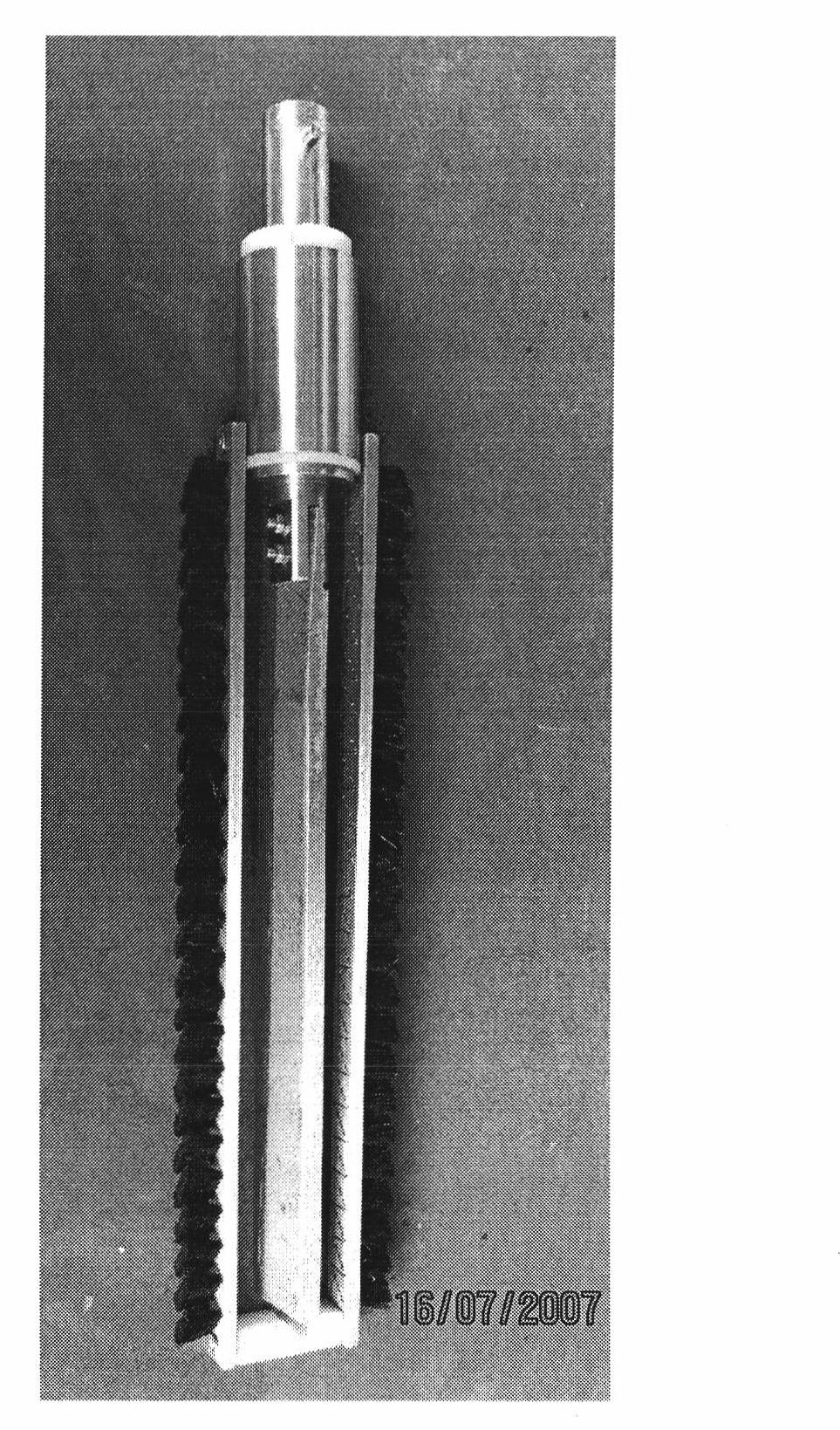

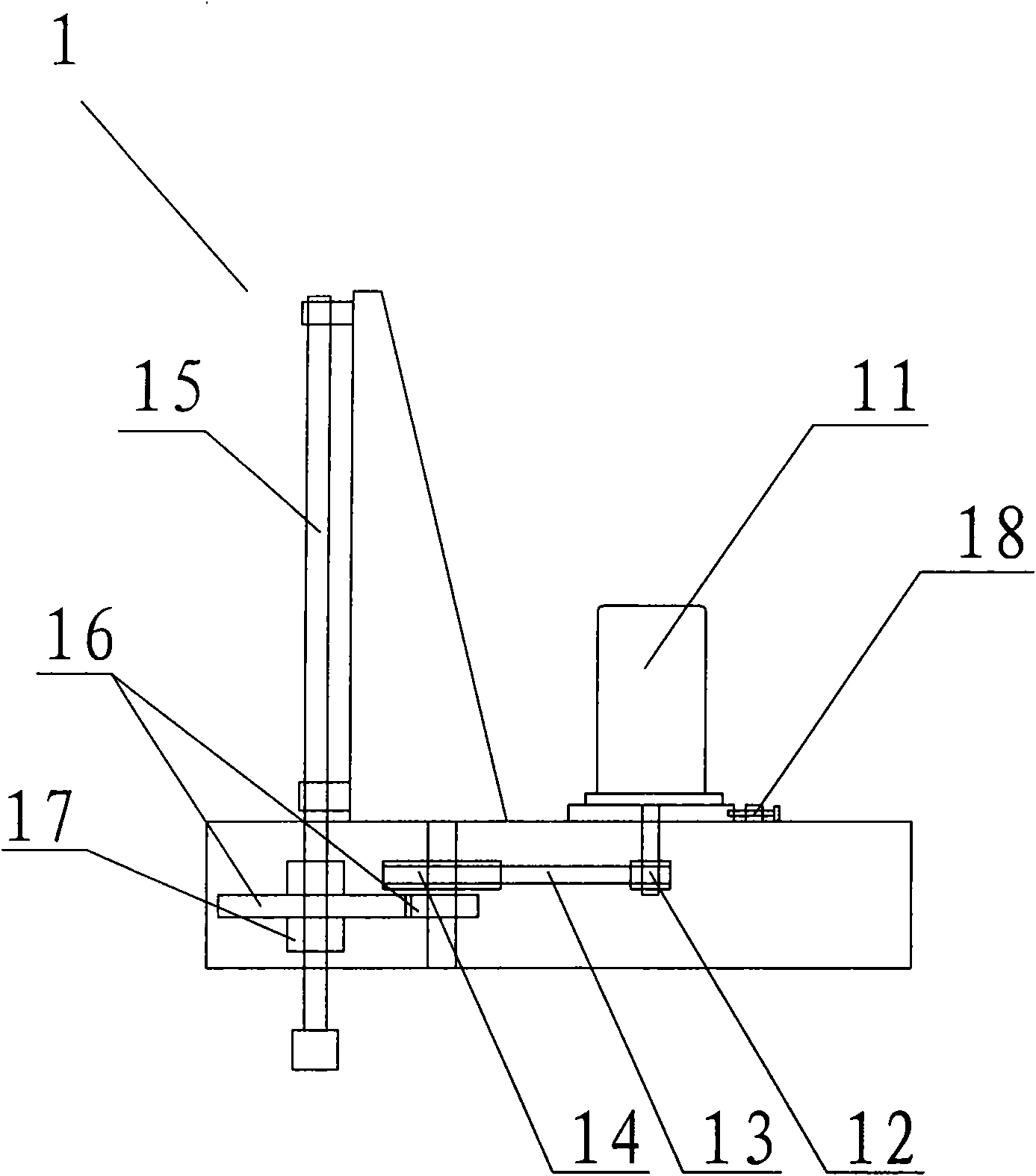

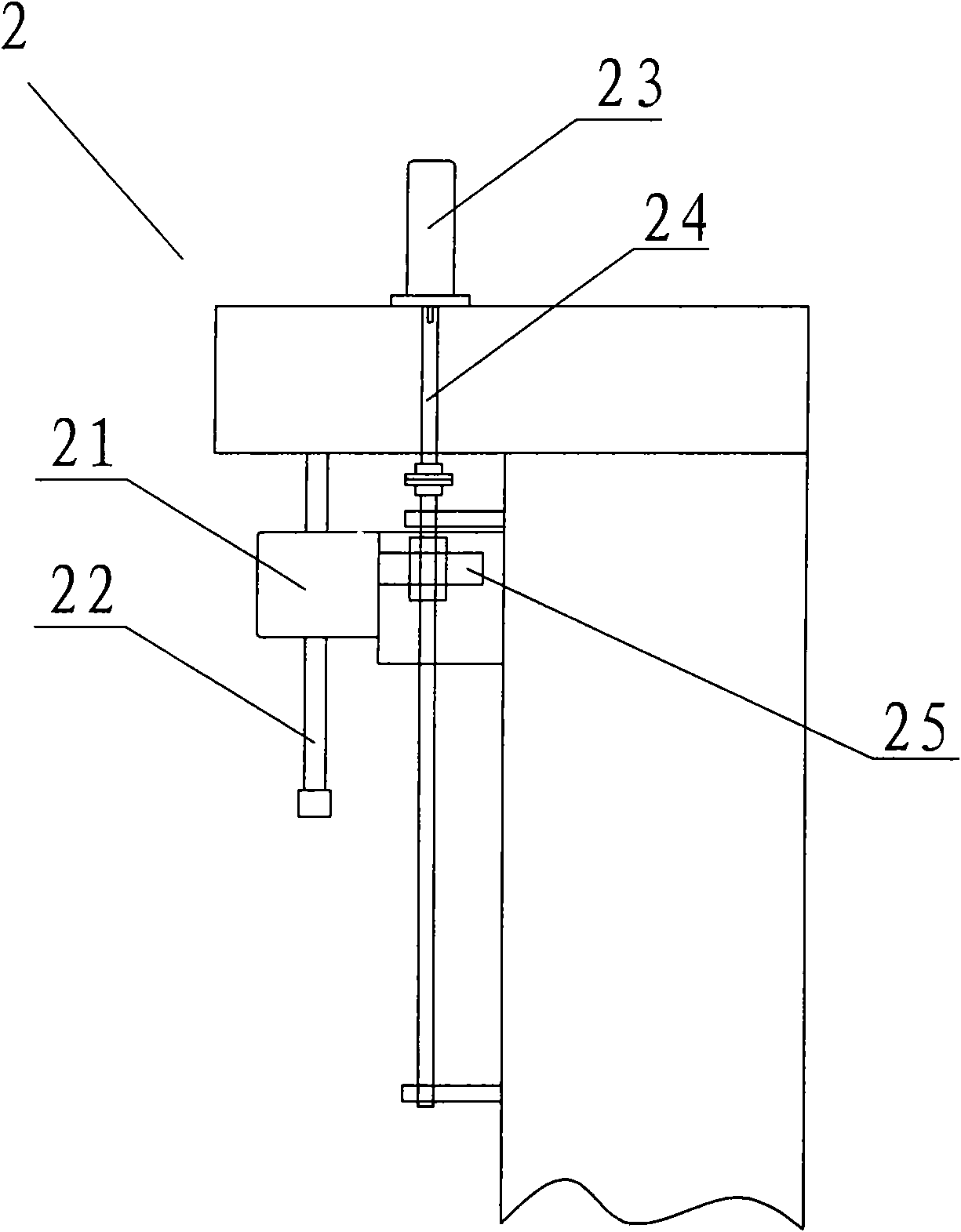

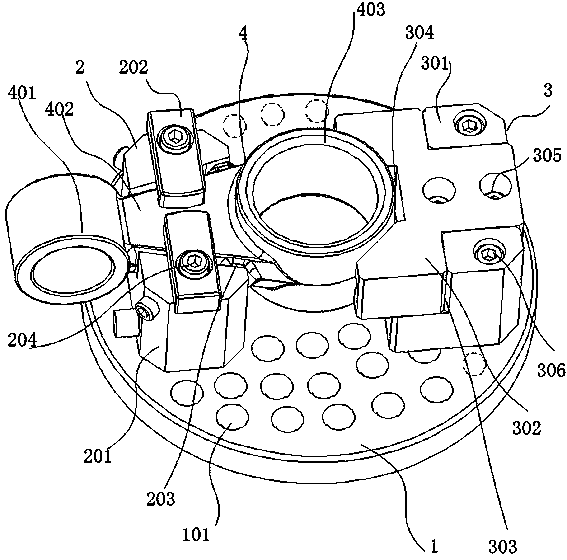

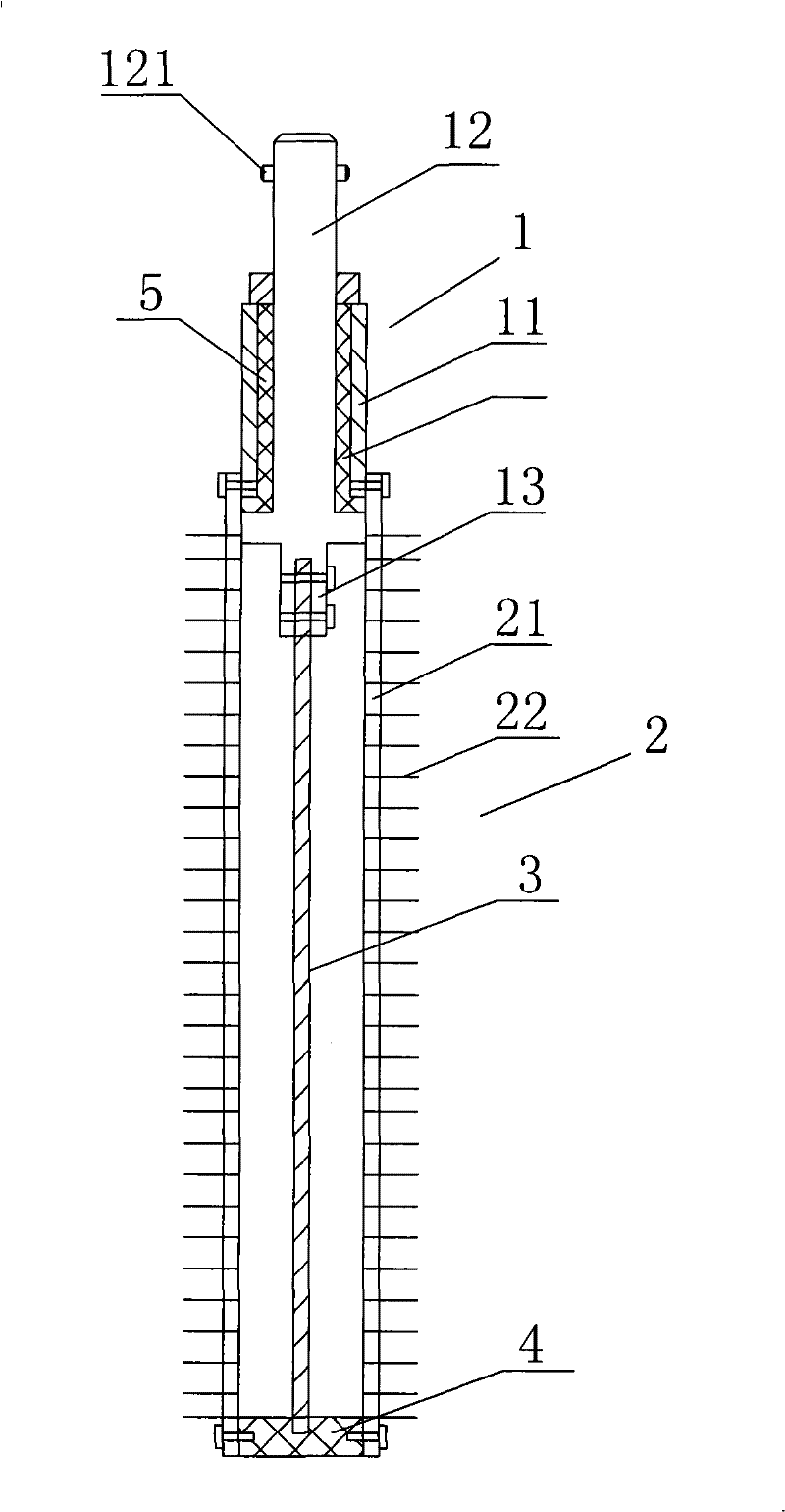

Plating pen for electro-brush plating inner bore parts

The invention discloses a plating pen for the electrical brush plating of an inner hole type spare part, which comprises a pen holder and a pen body, wherein the pen holder comprises a pen holder main body with a hanging part at the upper part and a clamping part at the lower part, and the pen body comprises at least two plate bodies and brush bristles, and the brush bristles are respectively arranged on one side of either plate body which is connected with the pen holder main body; an anode is clamped by the clamping part, the two plate bodies are parallel to both sides of the anode, and the bottom ends of the two plate bodies and the anode are all arranged on an insulated beam and do not mutually contact. The plating pen has simple structure and low manufacture cost, prolongs the service life of the plating pen, saves the consumption of plating liquid, greatly improves the brush plating work efficiency and has favorable market prospects and application prospects.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for manufacturing dissimilar aluminum alloy composite materials by arc added materials

InactiveCN108098112AGood corrosion resistance and wear resistanceHigh tensile strengthWelding accessoriesAlloy substrateAlloy composite

The invention relates to a method for manufacturing dissimilar aluminum alloy composite materials by arc added materials. The manufacturing method comprises the following steps: (1) aluminum alloy substrates are selected; 4043 aluminum alloy wires and 5356 aluminum alloy wires are adopted; (2) aluminum alloy composite materials are prepared and stacked layer by layer through a CMT+Advanced process; and (3) the added material manufacturing process is performed in an inertia gas atmosphere; inertia gas is helium or argon; layer-by-layer stacking is mutual superposition and deposition of the 4043aluminum alloy wires and the 5356 aluminum alloy wires in sequence; and the aluminum alloy stacking process is finished through alternate wire discharge by double gun heads.

Owner:SHANGHAI UNIV OF ENG SCI

Vehicle light-hydrocarbon fuel containing dimethyl carbonate

InactiveCN101177637AEasy to prepareImprove environmental performanceLiquid carbonaceous fuelsEnvironmental effectMethyl carbonate

The invention discloses a vehicle light hydrocarbon fuel containing methyl-carbonate and the components comprise 100 weight portions of light hydrocarbon, 5 to 46 weight portions of aromatic hydrocarbon, 1 to 11 weight portions of di methyl carbonate (DMC) and 0.004 to 0.4 weight portion of positive ion perfluorocarbon surface active agent. The product of the invention is the vehicle fuel which has high research octane number (RON) of 90 to 95, low cost, good environmental effect, no corrosion and good abrasion resistance.

Owner:SHANGHAI CHINAMAX NEW ENERGY

Alloy material with wear-resistance, heat-resistance, corrosion-resistance, high hardness

ActiveCN102676882ALow costGood corrosion resistance and wear resistanceSmelting processMetallurgical industry

The invention relates to an alloy material with wear-resistance, heat-resistance, corrosion-resistance, high hardness. The alloy is composed of, in wt%, 1.3-1.8 of C, 19-23 of Cr, 13-17 of W, 2.5-3.5 of B, 1-3 of Si, less than or equal to 5.0 of Fe, 5.0 of Ni, and the balance being Co and impurities caused by smelting processes. The alloy material relates to cobalt-based alloy, can ensure good performances of wear-resistance and corrosion-resistance, has relatively low cost, and is suitable for applications in the fields of mining machinery, metallurgical industry, national defense and military, etc.

Owner:JIANGYIN DADI EQUIP

Device and method for inner bore type component brush plating

The invention provides a device and method for inner bore type component brush plating. The device comprises a workpiece to be plated, a workpiece clamping sealing device, a plating pen special for inner bore brush plating, and a plating pen rotary actuator. The workpiece to be plated and the clamping sealing device together form a container having an opening at the top; in plating process, the workpiece is the cathode, and the plating pen is the anode. The device and method realize that plating is prepared at the surface of the inner bore of the inner bore type component by using the technology of brush plating, thereby being applied to strengthening for new workpiece and also being applied to batch repair and remanufacturing for damaged pieces.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

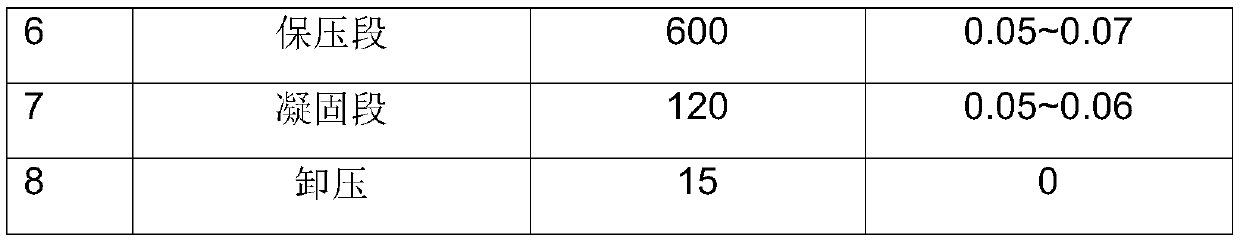

Low-pressure casting method for abrasion-resistant aluminum alloy bicycle accessory

The invention belongs to the technical field of aluminum alloy producing and machining, and particularly relates to a low-pressure casting method for an abrasion-resistant aluminum alloy bicycle accessory. The low-pressure casting method comprises the following steps that a) aluminum alloy melt is prepared; b) a mold and a cast are prepared before pouring; c) low-pressure pouring is carried out, wherein a deigned pressure time curve is called, low-pressure pouring is carried out, solidification is carried out under pressure, liquid lifting, mold filling, supercharging, pressure maintaining, solidification and pressure relieving are included, and the aluminum alloy bicycle accessory is formed; d) cooling and demolding are carried out; and e) thermal treatment is carried out, wherein after the obtained aluminum alloy bicycle accessory is subjected to solution treatment, quenching treatment and quenching treatment, natural cooling is carried out, and the finished aluminum alloy bicycle accessory is obtained. The tensile strength of the aluminum alloy bicycle accessory is larger than or equal to 380 MPa, the yield strength is larger than or equal to 360 MPa, and the ductility is largerthan or equal to 6%.

Owner:太仓耀展金属制品有限公司

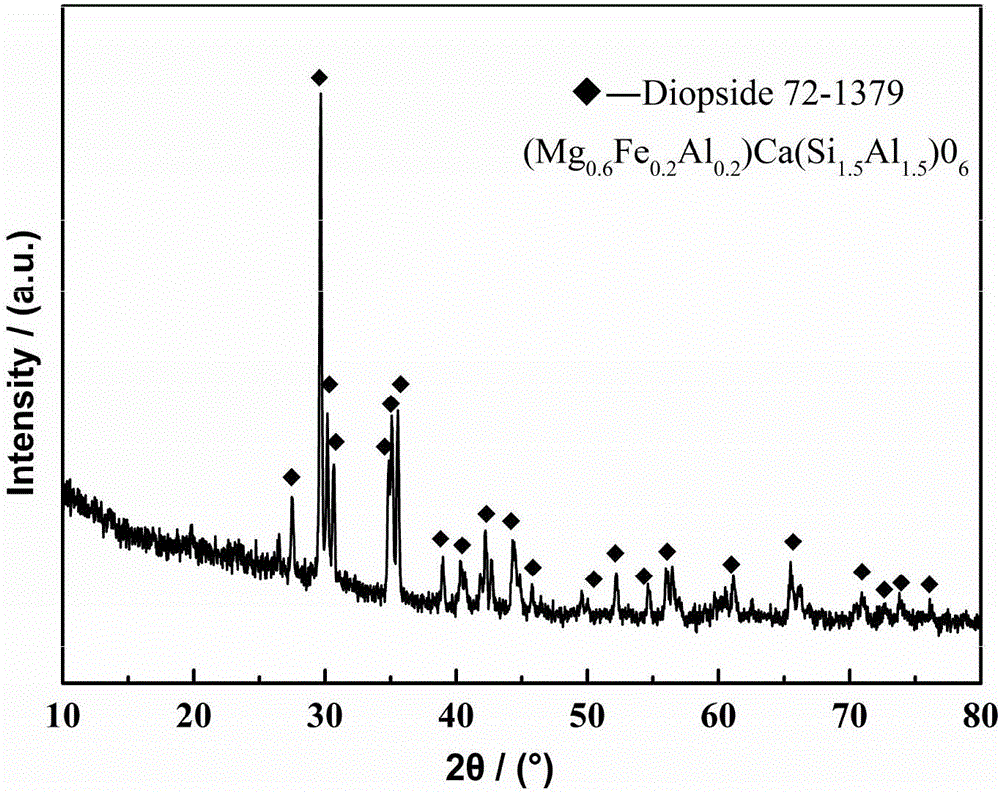

Recycling method of glass ceramic material

InactiveCN106430982ARealize comprehensive utilizationReduce pollutionGlass-ceramicEnergy consumption

The invention relates to a recycling method of a glass ceramic material. Waste generated in glass ceramic production is used as a main raw material, and recycling treatment is performed through the processes including smashing, screening, grading, binding agent adding, mixing and grinding, press-forming, drying, hot air hardening and the like to obtain a recycled glass ceramic product. Due to the fact that the waste produced in glass ceramic production is used as the main raw material, the energy consumption is reduced, stored waste glass ceramic materials can also be decreased, and environmental pollution is reduced. The production process is simple, the energy consumption is low, the production cost can be effectively reduced, different batches of products are good in reproducibility, and the recycling method is suitable for large-scale industrial production.

Owner:内蒙古科韵环保材料股份公司

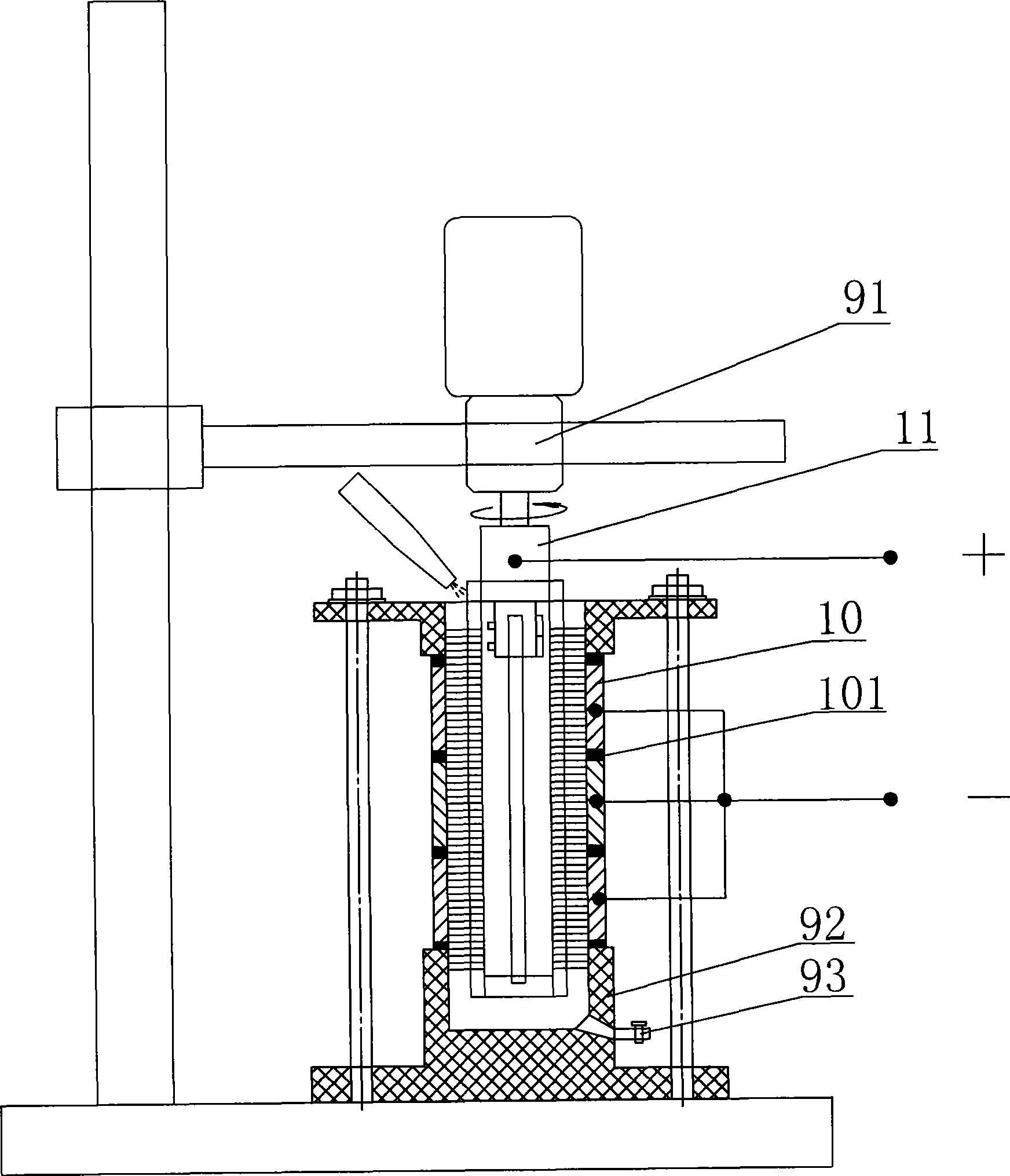

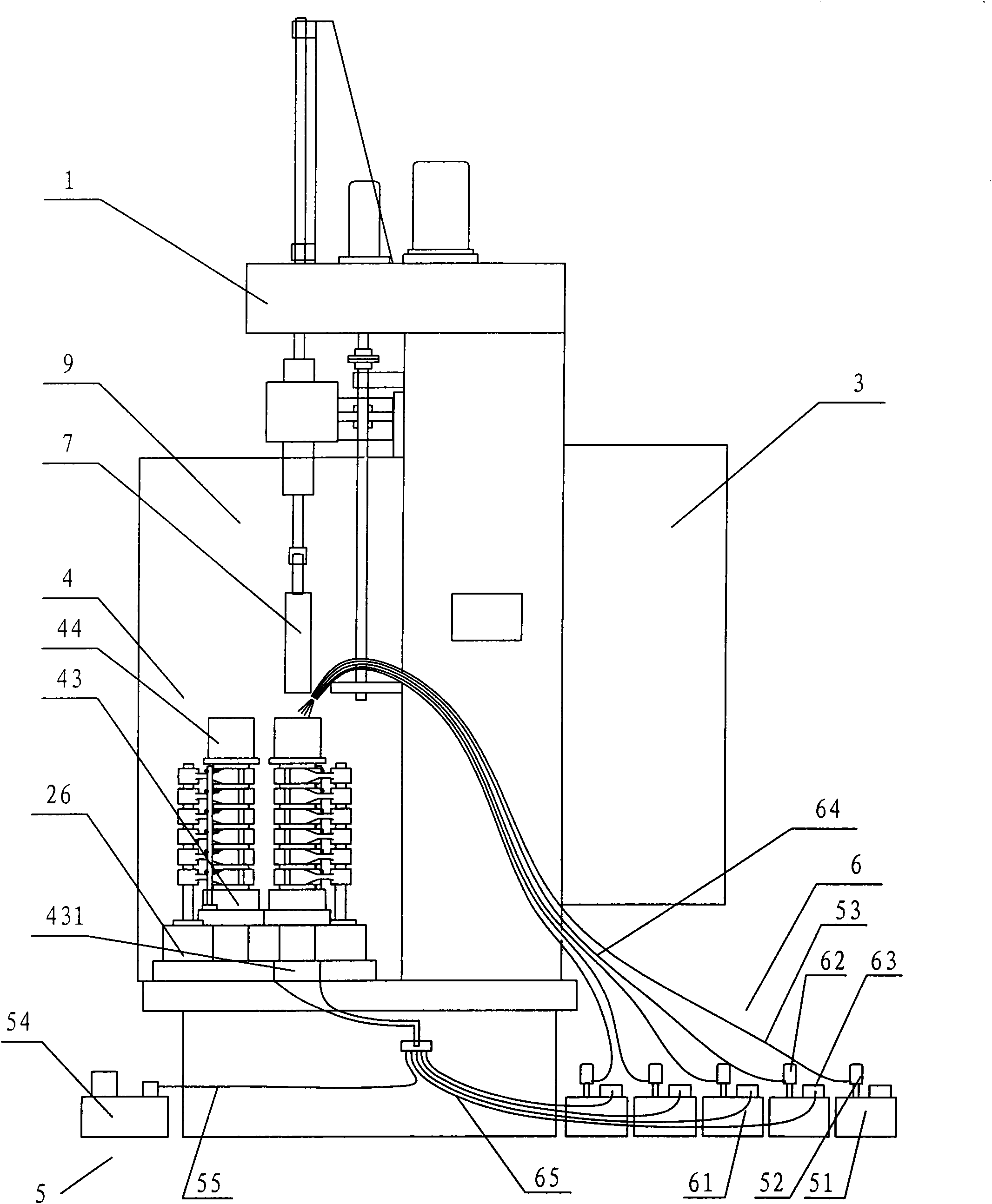

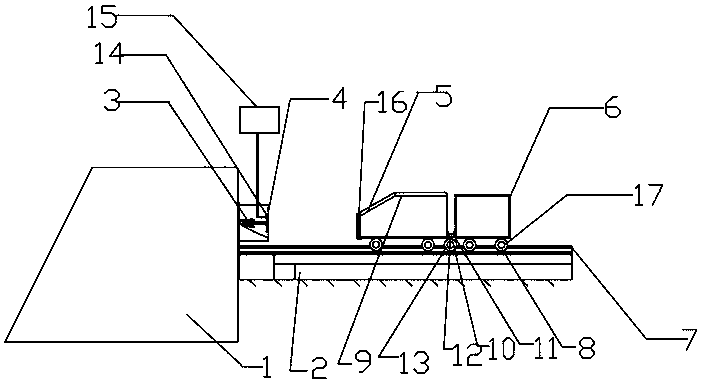

Connecting rod automation electro-brush plating machine tool

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Production method for surface strengthening layer of threaded element and threaded element for parallel twin-screw extruder

InactiveCN108580907AEasy to prepareIncrease productivityTransportation and packagingMetal-working apparatusAlloyHardness

The invention relates to a production method for a surface strengthening layer of a threaded element and the threaded element for a parallel twin-screw extruder and belongs to the technical field of screw extruders. The production method comprises the steps that tungsten carbide powder, nickel-based self-fluxing alloy powder and a binder are mixed and internally mixed, and feed is obtained; a substrate of the surface strengthening layer to be produced is arranged into a mold, and a filling space is reserved for the feed; and the feed is injected into the filling space and then dewaxed and sintered. The method is relatively simple, the production efficiency is high, the near-net forming can be realized, the subsequent processing is reduced, and the method is especially suitable for large-scale mass production. The surface of the threaded element for the parallel twin-screw extruder has the surface strengthening layer with the high metallurgical bonding strength and the excellent wear resistance, the metallurgical bonding of the surface strengthening layer and the substrate is good, the surface strengthening layer has the obvious transition zone, and the structure distribution is uniform. In addition, the surface strengthening layer is nearly fully compact, has high hardness larger than or equal to 64.5 HRC, has excellent corrosion resistance and wear resistance and has the service life more than 2 times longer than that of the prior art.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

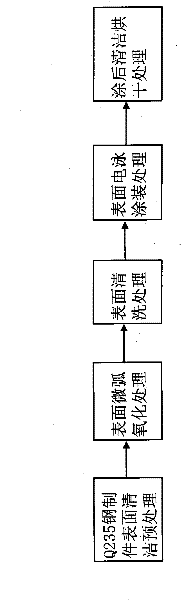

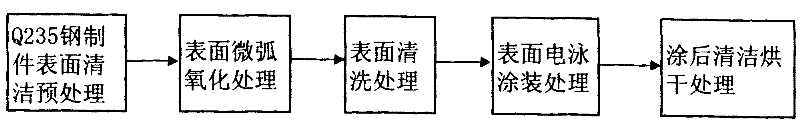

Microarc-oxidation electrophoretic-coating composite processing method of surface of Q 235 steel part

InactiveCN101831684BHigh practical valueThe method is simple and easy to controlAnodisationElectrophoretic coatingsPlasma electrolytic oxidationMicro arc oxidation

Owner:HOHAI UNIV CHANGZHOU

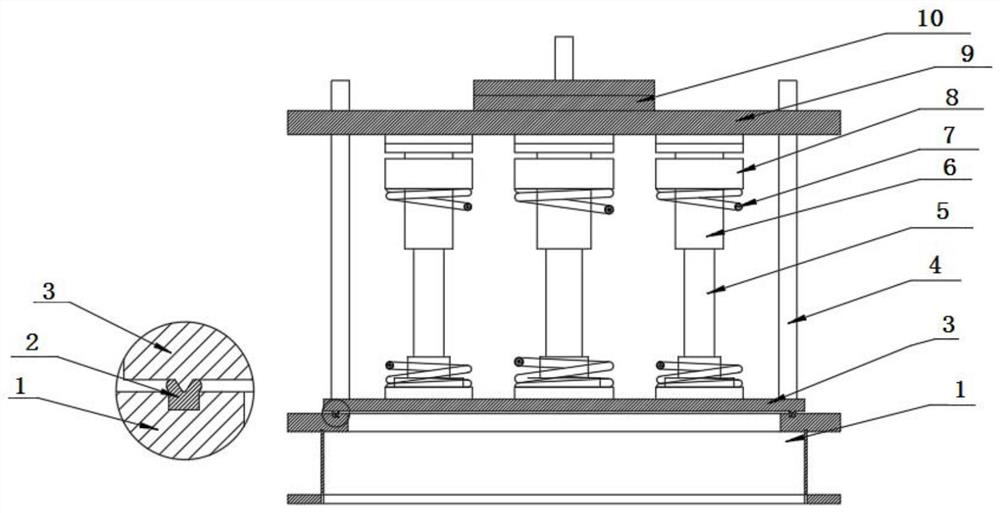

Automobile connecting rod fixing clamping device

InactiveCN110788637ASolve the problem of poor fixation and the need for multiple processingSimple structural designPositioning apparatusMetal-working holdersStructural engineeringMachining

The invention discloses an automobile connecting rod fixing clamping device. The device comprises a fixing base, a fixing clamping assembly, a clamping positioning assembly and a connecting rod workpiece, wherein the fixing clamping assembly and the clamping positioning assembly are fixedly arranged on the fixing base; and the connecting rod workpiece is arranged between the fixing clamping assembly and the clamping positioning assembly, one end of the connecting rod workpiece is connected in the fixing clamping assembly in a clamped mode and the connecting rod workpiece is axially fixed through a limiting clamping piece and a positioning clamping block of the fixing clamping assembly, and the other end of the connecting rod workpiece is connected in a clamping groove of the clamping positioning assembly in a clamped mode and the connecting rod big end of the connecting rod workpiece is radially positioned through the clamping positioning assembly. According to the device, the fixing effect is excellent, a product can be put into a general lathe for machining through the tool, the machining efficiency can be effectively improved, and the cost is greatly reduced; and a plurality ofmounting connecting hole grooves are uniformly distributed in the fixing base, and the fixing clamping assembly and the clamping positioning assembly are arranged in different mounting connecting holegrooves to be matched with the connecting rod workpieces of different models, so that the adaptability is excellent.

Owner:王爱民

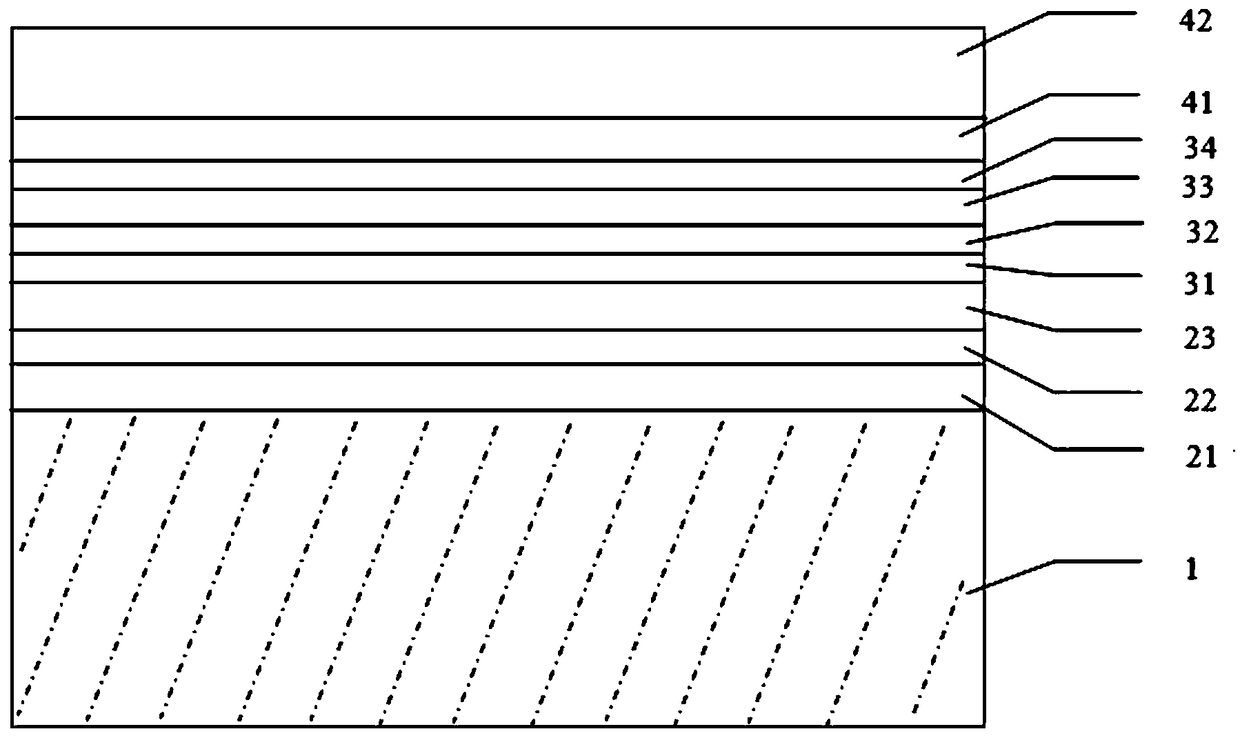

A kind of electric heating film for anti-icing and anti-fog of aircraft windshield glass and preparation method thereof

ActiveCN106082700BGood electric heating performanceReduce manufacturing costElectricityJet aeroplane

The invention discloses an electric heating film for airplane windshield glass ice and fog prevention and a preparation method thereof. The electric heating film for airplane windshield glass ice and fog prevention comprises a glass substrate, an inner structure layer, an electric heating function layer and an outer structure layer which are sequentially arranged from inside to outside. According to the electric heating film, electric heating performance is excellent, weather resistance and corrosion resistance are good, film layer visible light transmittance is high, the color is gentle, compact and uniform, light transmittance is uniform, electric heating ice and fog prevention performance can be improved, and the service life of the electric heating ice and fog prevention is prolonged.

Owner:GEMCH MATERIAL TECH SUZHOU

Automobile collision simulation experiment bench

InactiveCN107796587ASimple and reasonable structural designGuaranteed stabilityShock testingVehicle shock testingPlastic energyEnergy absorbers

The invention discloses an automobile collision simulation test bench, which comprises a guide rail fixing plate, a hydraulic buffer, a buffer fixing block, a traction block, a trailer, a guide rail, a reinforcing plate rib, a traction plate and a limit block, and the guide rail fixing plate is equipped with a The guide rail is equipped with a traction block and a trailer. The outer surface of the traction block and the trailer is provided with a stiffener plate. The trailer workshop is equipped with a traction plate and is connected through it. There are through holes at both ends of the traction plate. The rotation limit block is clamped in the traction plate. A support is installed under the traction plate, and a support is installed under the support. Rollers, the other side of the traction block is equipped with a plastic energy absorber, one side of the plastic energy absorber is provided with a buffer fixing block, and a hydraulic buffer is installed in the buffer fixing block. The structure design of the invention is simple and reasonable, and the connection between the traction block and the trailer is extremely firm.

Owner:靖江市中亿汽车配件制造有限公司

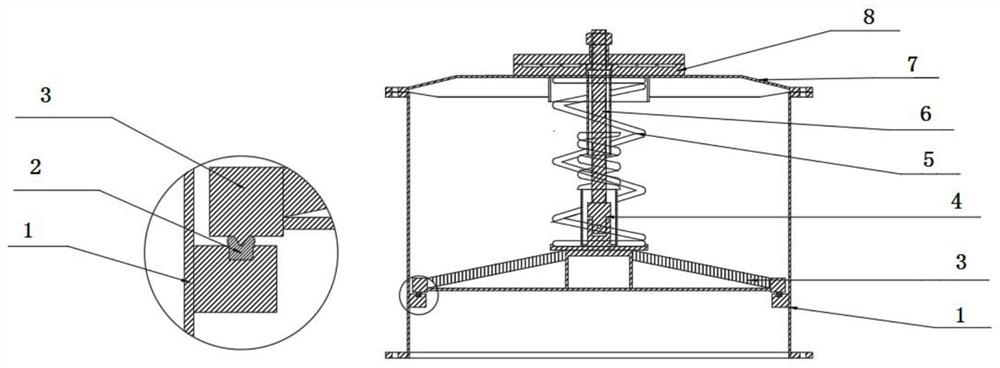

Explosion door structure

PendingCN114033873AGood corrosion resistance and wear resistanceImprove sealingEqualizing valvesSafety valvesUniversal jointGraphite

The invention provides a novel explosion door structure, the novel explosion door provided with a universal joint can automatically reset after the door cover is detonated under certain pressure, the door rod and the door cover cannot deform after continuous detonation, and the door rod and the door cover can be continuously pressed on the original sealing gasket, so that a better sealing effect is achieved. The sealing gasket adopts a structure that the lower part of the cross section is U-shaped and the upper part is triangular, a sealing structure is adopted among the valve body, the sealing gasket and the door cover, the sealing gasket is placed on a U-shaped groove of the valve body, the door cover is pressed into the sealing gasket, the door cover adopts a triangular structure, and the valve body, the sealing gasket and the door cover are tightly pressed and connected, so that the contact surface is larger, the sealing effect is better, and larger pressure can be borne; the sealing gasket is made of a graphite packing material, is low in cost, has a better sealing effect at a high temperature for a long time and is simple to replace. The novel explosion-proof door adopts a chromium plating process, and is better in corrosion resistance and wear resistance. By means of the technical scheme, the technical problems that in the prior art, when an explosion door returns, resetting is not accurate, and sealing is not tight are solved.

Owner:吉林省昱鑫机械制造有限公司

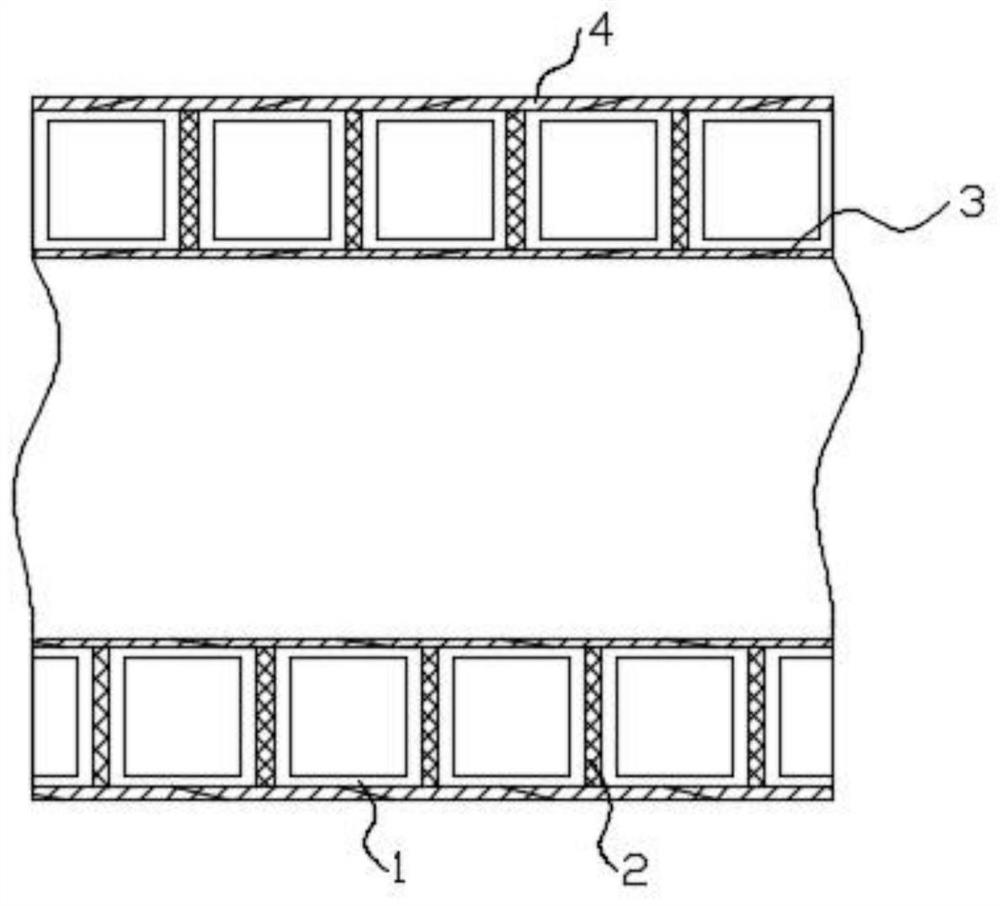

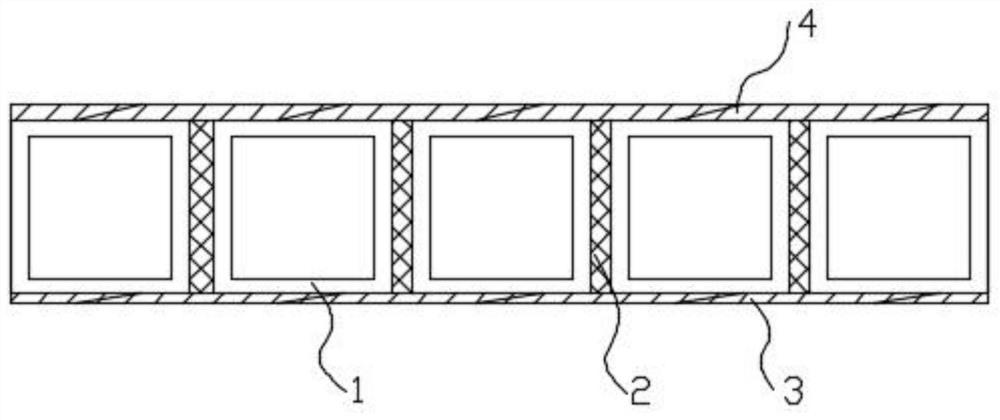

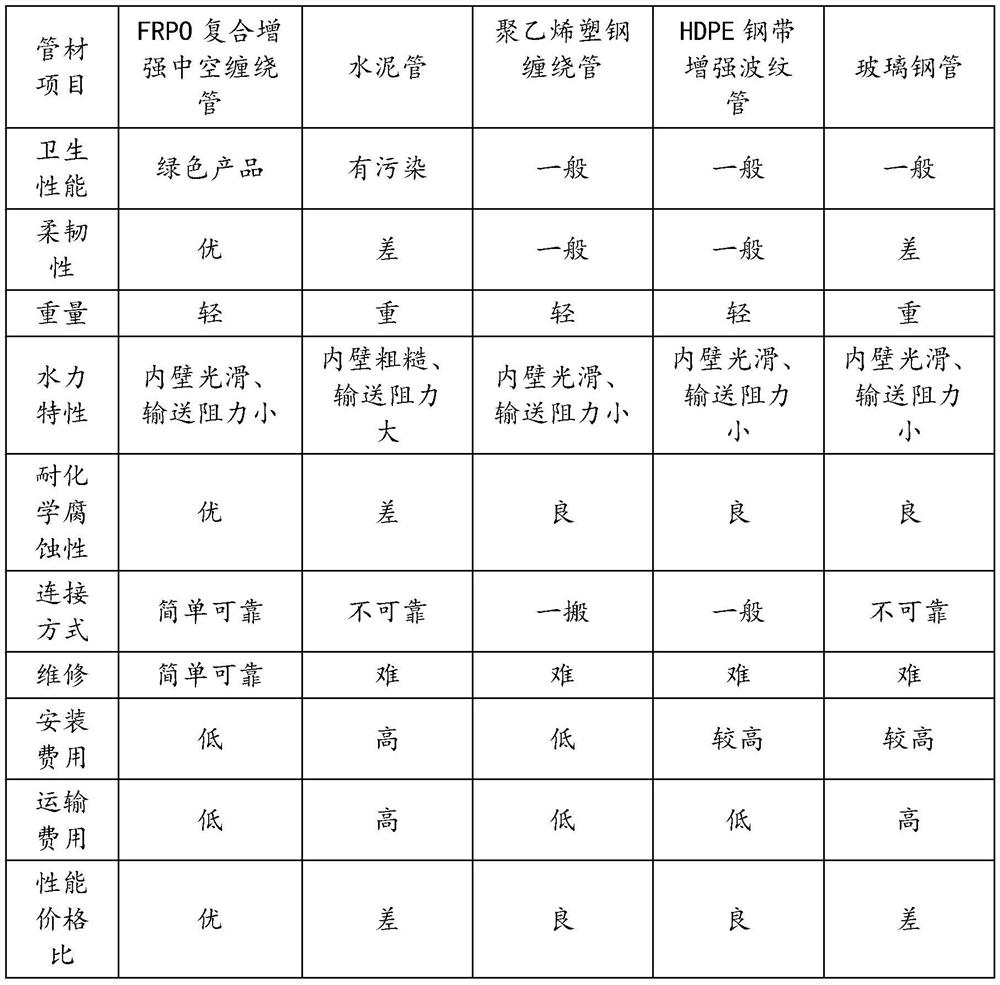

FRPO composite reinforced hollow winding pipe and preparation method thereof

PendingCN111946910AIncreased internal pressureLight in massRigid pipesPipe protection against damage/wearCorrosion resistantStructural engineering

The invention discloses an FRPO composite reinforced hollow winding pipe. The FRPO composite reinforced hollow winding pipe comprises a winding pipe body formed by winding rectangular pipes, the smoothness of the inner wall and the outer wall of the winding pipe body is Ra0.012-Ra0.009, the inner wall and the outer wall of the winding pipe body are provided with a wear-resisting layer and a compression-resisting and stretching-resisting layer respectively, and bonding reinforcing ribs are arranged at positions, located between every two adjacent rectangular pipes, inside the winding pipe body.The composite reinforced hollow winding pipe has the advantages of high impact resistance, high strength, high wear resistance, super corrosion resistance, light weight, simplicity and convenience ininstallation, large through-flow, long service life and the like.

Owner:成都市华迪塑胶有限公司

Plating pen for electro-brush plating inner bore parts

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Corrosion-resistant and wear-resistant tool steel

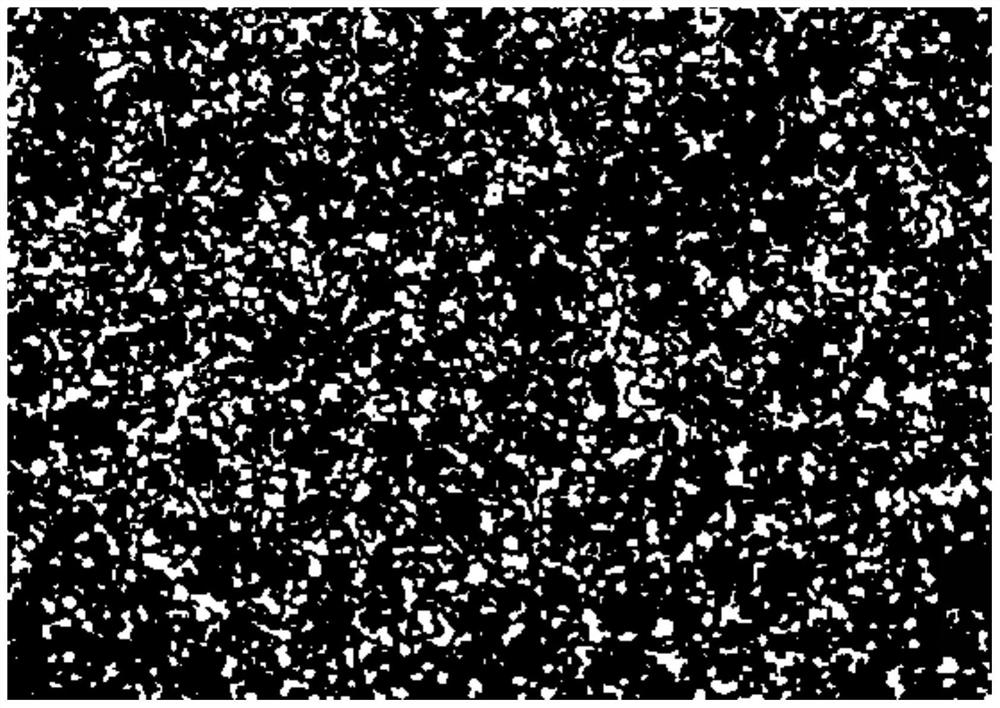

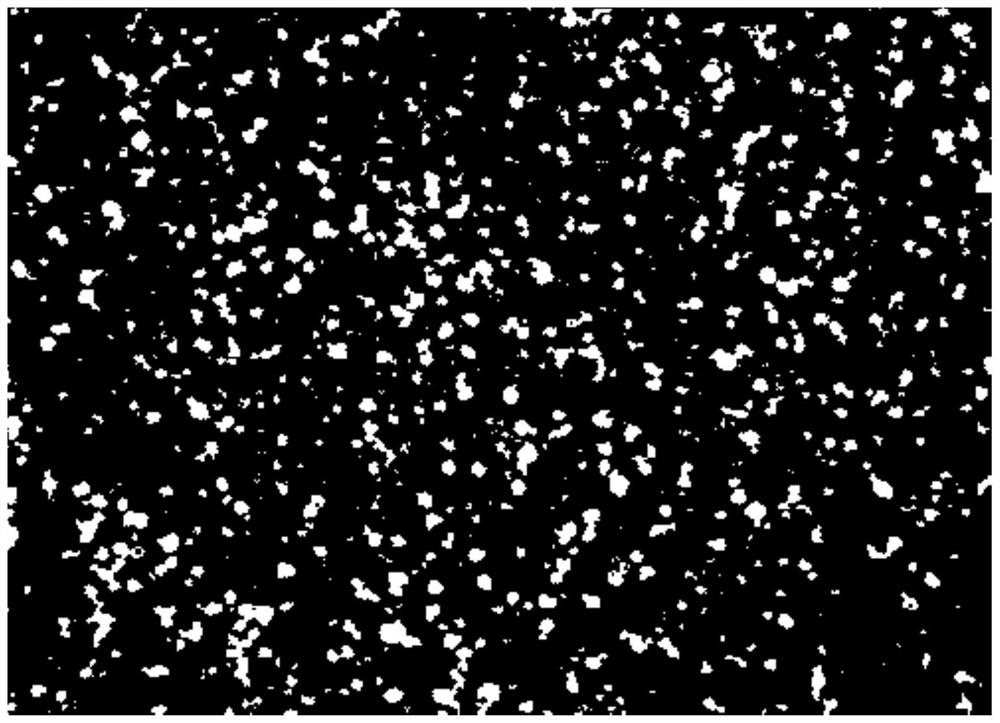

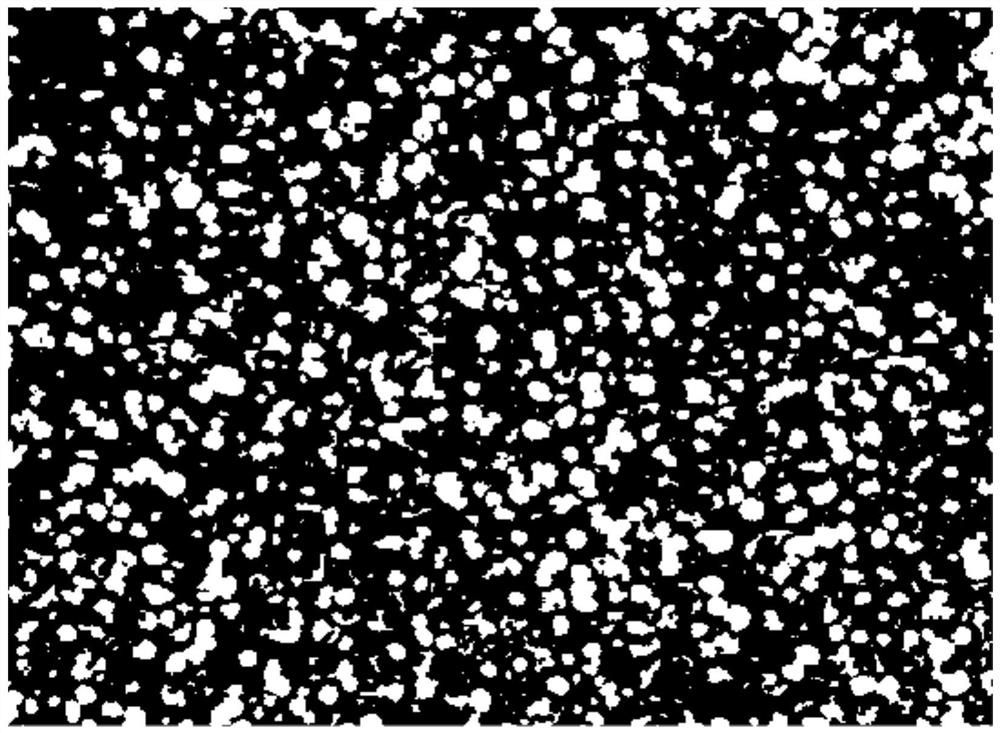

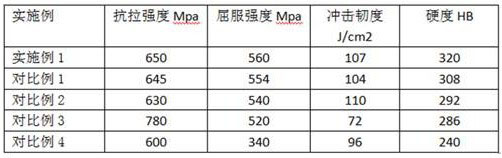

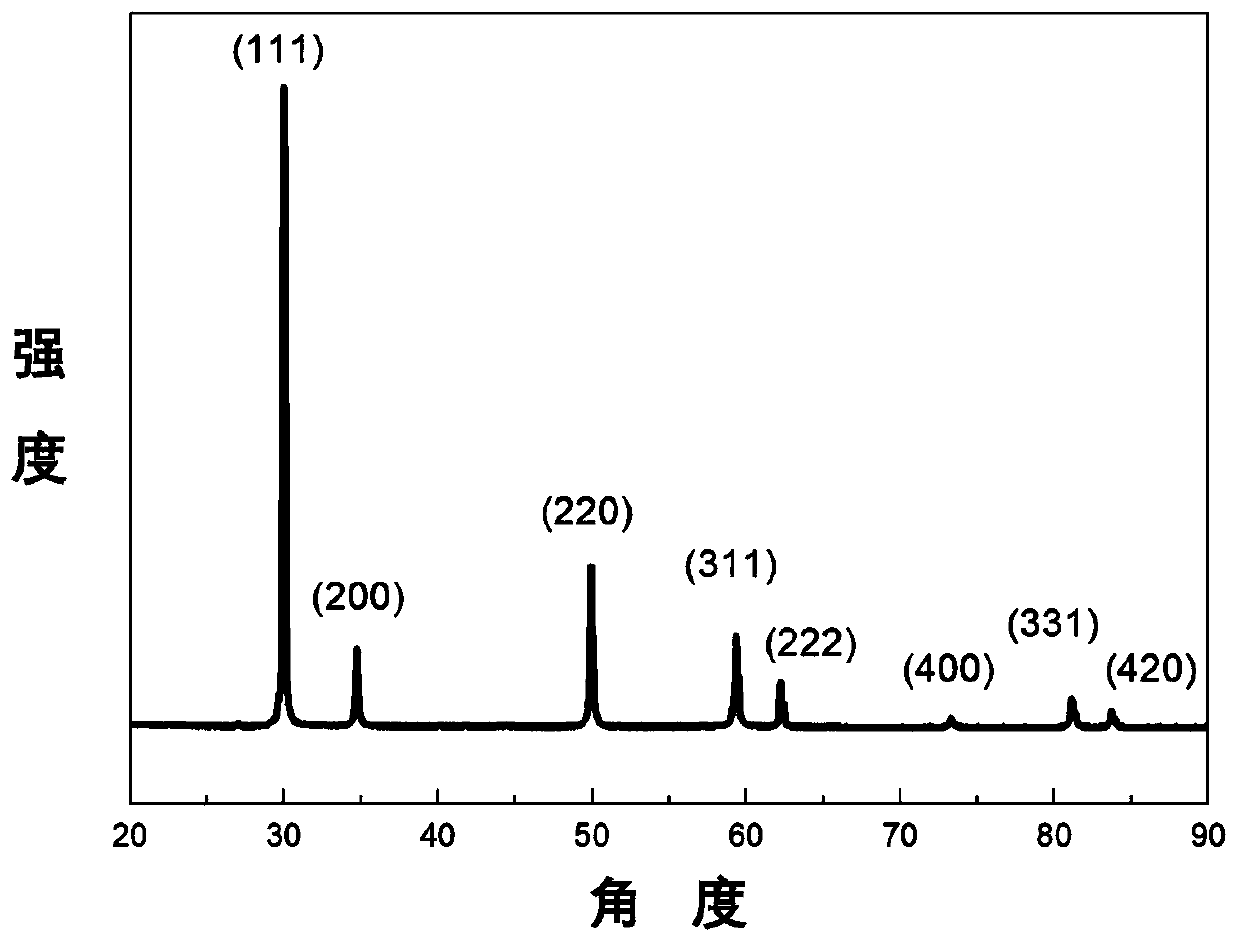

ActiveCN114318132AGood corrosion resistance and wear resistanceAccelerated corrosionProcess efficiency improvementWear resistanceMechanical property

The invention provides corrosion-resistant and wear-resistant tool steel which is prepared by adopting a rapid solidification process and comprises the following chemical components in percentage by mass: 1.2-3.5% of C, 0.4-1.0% of Si, 0.2-1.0% of Mn, 12-27% of Cr, 0.8-3.0% of Mo, less than or equal to 4% of Co, less than or equal to 10% of V, less than or equal to 4% of Nb, 0.5-6% of Ti and the balance of Fe and impurities. According to the corrosion-resistant and wear-resistant tool steel, the second phase is small in size and uniform in distribution, excellent comprehensive mechanical properties are achieved, and especially due to existence of the high-hardness second phase in the structure, the steel can have excellent wear resistance.

Owner:武汉钜能科技有限责任公司

All-day automatic tracking system

InactiveCN102109852BGood corrosion resistance and wear resistanceImprove protectionControl using feedbackHydraulic cylinderElectricity

Owner:JIANGSU WUJIN HYDRAULIC HOIST

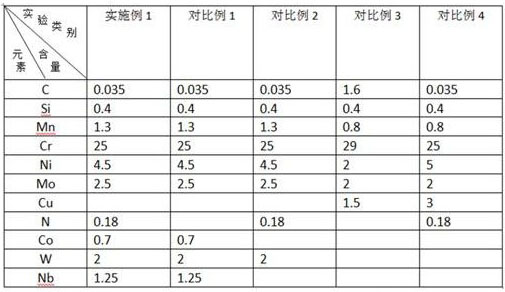

Wear-resistant and corrosion-resistant stainless steel material for pump and preparation method thereof

The invention provides a wear-resistant and corrosion-resistant stainless steel material for a pump. The wear-resistant and corrosion-resistant stainless steel material comprises the following chemical components including, by mass, less than or equal to 0.04% of C, 0.3%-0.5% of Si, 1.0%-1.5% of Mn, 24%-26% of Cr, 4.0%-5.0% of Ni, 2.0%-3.0% of Mo, 0.5%-1.0% of Co, 1.5%-2.5% of W, 1.0%-1.5% of Nb, less than or equal to 0.04% of P and S, 0.15%-0.25% of N and the balance Fe. A casting made of the stainless steel material is free of defects such as subsurface pores and cracks, good in casting performance, excellent in corrosion resistance and wear resistance and suitable for being used as a preparation material of a limestone (lime)-gypsum method desulfurization slurry pump which is large in operating condition change and has harsh wear resistance and corrosion resistance requirements, and the service life of a pump type product reaches two years or longer.

Owner:烟台恒邦合金材料有限公司

Processing method of improved 6061 aluminum alloy refrigerator foaming die cast

InactiveCN103014448BHigh strengthImprove wear resistanceFoundry moulding apparatusRare-earth elementIcebox

The invention discloses a processing method of an improved 6061 aluminum alloy refrigerator foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and carrying out thermal treatment. According to the invention, an appropriate amount of rare earth elements Nd, Ce and Sc are added to the improved 6061 aluminum alloy, so that the size of eutectic phase is significantly reduced, the as-cast structure of the alloy is uniformed and refined, and the strength as well as corrosion resistance and wear resistance of the alloy are improved. The processed aluminum alloy refrigerator foaming die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州佳诚模具制造有限公司

Self-opening-closing type explosion door structure

PendingCN114033881AImprove sealingGood orientationEqualizing valvesSafety valvesStructural engineeringIndustrial engineering

The invention provides a novel explosion door structure which plays a role in pressure relief and prevents a main ventilator from being damaged due to impact of explosion airflow. Three or more springs are evenly arranged between a door cover and an upper cover, a novel explosion door with guide columns and guide sleeves is installed, the valve cover can be automatically in situ after being detonated under certain pressure, the valve cover can return to the original position after being detonated continuously, the valve cover continues to be pressed on an original sealing gasket, and a better sealing effect is achieved. The guide columns and the guide sleeves are not installed on stand columns, the guide columns and the guide sleeves are separated from the stand columns to return, the better guiding effect is achieved, and the service life is longer. A sealing strip adopts a structure that the lower part of the cross section is U-shaped and the upper part is triangular, and the valve body, the sealing strip and the door cover are tightly pressed and connected, so that the contact surface is larger, the sealing effect is better, and larger pressure can be borne. By means of the technical scheme, the technical problems that in the prior art, when an explosion door returns, resetting is not accurate, and sealing is not tight are solved.

Owner:吉林省昱鑫机械制造有限公司

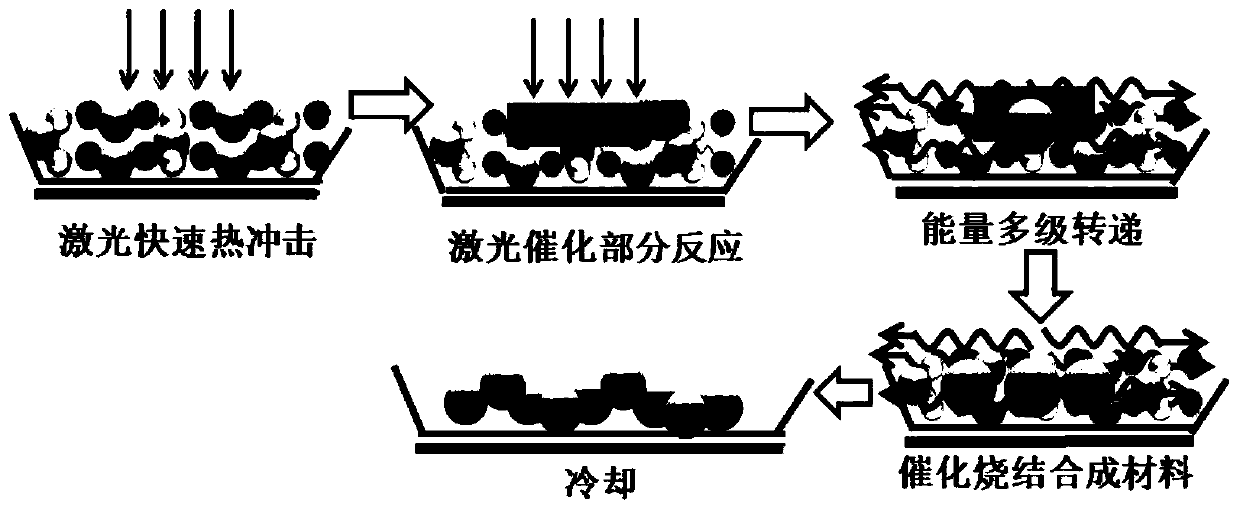

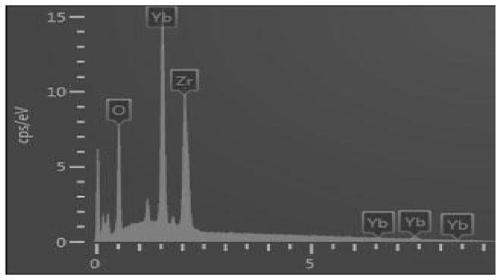

Preparation method of transparent camouflage material

The invention discloses a preparation method of a transparent camouflage material. The preparation method comprises the following steps: S1, adding lithium fluoride and metal oxides into zirconium dioxide, and carrying out ball milling until the average particle size does not exceed 1 mu m to obtain mixed powder; and S2, compacting the mixed powder, and carrying out reactive sintering under the irradiation of laser to obtain the transparent camouflage material. According to the preparation method, zirconia-based transparent ceramic is sintered under laser catalysis, the laser input energy is absorbed by utilizing the sintering activity of the material to catalyze a reaction process, and a sample is synthesized by sintering in a laser-catalyzed high-heat environment, not only is the sintered sample compact and high in transmittivity, but also the preparation method is simple, capable of saving time and materials, clean, pollution-free and suitable for large-scale industrial production.

Owner:CHONGQING INST OF EAST CHINA NORMAL UNIV +1

Automobile towing hook device

InactiveCN107856484APlay a protective effectExtended service lifeTowing devicesPetroleum engineering

Owner:江苏金卡汽车部件有限公司

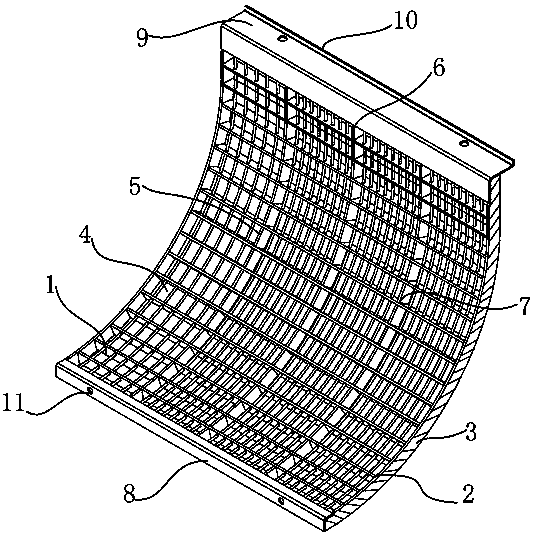

Harvester large drum rear plate screen

InactiveCN107615977AGood corrosion resistance and wear resistanceSolve poor anti-corrosion performanceMowersThreshersEngineeringRear quarter

The invention discloses a harvester large drum rear plate screen comprising a plate screen body (1), side plates (2), an anti-corrosion wear-resisting layer (3), a screen (4), a first reinforcing rib(5), a second reinforcing rib (6), a third reinforcing rib (7), a base plate (8) and an inserting plate (9); side plates (2) are installed at two sides of the plate screen body (1); the anti-corrosionwear-resisting layer (3) is installed on external surface of the side plates (2); the anti-corrosion wear-resisting layer (3) is applied with the side plates (2); the base plate (8) is installed at abottom of the plate screen body (1); the base plate (8) is welded to the plate screen body (1); the inserting plate (9) is installed at an upper end of the plate screen body (1); the inserting plate(9) is welded to the plate screen body (1); the screen (4) is installed on the plate screen body (1); the first reinforcing rib (5), the second reinforcing rib (6) and the third reinforcing rib (7) which are adapted to each other are installed in the screen (4). The harvester large drum rear plate screen of the invention has reasonable design and stable connection; the side plate has good anti-corrosion and wear-resisting performance.

Owner:朱怀东

Casting method for anti-corrosive and abrasion-resistant composite check valve body

InactiveCN105970081AGood surface protectionEasy to useFoundry mouldsFurnace typesChemical compositionCheck valve

The invention discloses a casting method for an anti-corrosive and abrasion-resistant composite check valve body. The casting method includes the following steps that (1) casting liquid is prepared, and chemical components of the casting liquid comprise, by weight, 0.22%-0.26% of C, 0.25%-0.45% of Si, 0.60%-0.80% of Mn, 0.15%-0.25% of V, 0.30%-0.50% of Ni, 0.10%-0.15% of Al, 0.03% or less of P, 0.02% or less of S, and the balance Fe; (2) casting-infiltration coating is prepared; (3) the valve body is cast; and (4) heat treatment and finishing are conducted. The check valve body obtained through the casting method disclosed by the invention is provided with a uniform and stable casting-infiltration composite layer on the surface, has excellent anti-corrosion and abrasion-resistant performance, and is high in yield, stable in quality, good in appearance quality and use performance and long in service life.

Owner:ANHUI XINHONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com