Wear-resistant and corrosion-resistant stainless steel material for pump and preparation method thereof

A corrosion-resistant pump and stainless steel technology, applied in the field of wear-resistant and corrosion-resistant stainless steel materials for pumps and its preparation, can solve the problem within 5, 6 months, or even 2-3 months, the material is difficult to meet the use requirements, and customers High use cost and other issues, to achieve excellent resistance to chloride ion corrosion, improve intergranular corrosion resistance, and good casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

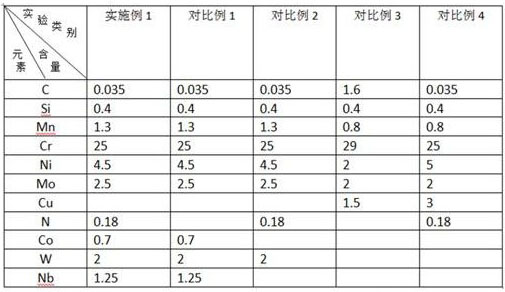

[0026] (1) A stainless steel material for wear-resistant and corrosion-resistant pumps, chemical composition settings: C: 0.035%, Si: 0.4%, Mn: 1.3%, Cr: 25%, Ni: 4.5%, Mo: 2.5%, Co: 0.7%, W: 2.0%, Nb: 1.25%, P, S: ≤0.04, N: 0.18%, and the rest is Fe.

[0027] Ingredients ratio, each chemical composition is provided by the following mass ratio of raw materials: 316L scrap 50%, metal ferrochrome 16%, electrolytic manganese 0.5%, metal cobalt 0.7%, metal tungsten 2%, ferroniobium 2.5%, ferrochromium nitride 5% %, industrial pure iron 23.3%;

[0028] For example, to make a TLC250-400 pump body, 980Kg of molten steel is required, and various raw materials are weighed according to the ratio: 316L scrap 490Kg, metal chromium 157Kg, electrolytic manganese 4.9Kg, metal cobalt 6.86Kg, metal tungsten 19.6Kg, ferroniobium 24.5Kg, Ferrochromium nitride 49Kg (block size controlled at 20-50mm), industrial pure iron 228.4Kg;

[0029] (2) Add 316L leftovers, metal chromium, metal cobalt, me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com